Process for preparing compact magnesium oxide/hydroxyapatite nano fiber double-layer coating on surface of magnesium base

A hydroxyapatite and nanofiber technology is applied in the field of preparation of biomedical materials, which can solve the problems of difficulty in blocking body fluid infiltration, low matrix bonding strength and low capacity, and achieves high bonding strength, low price, and early fixation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

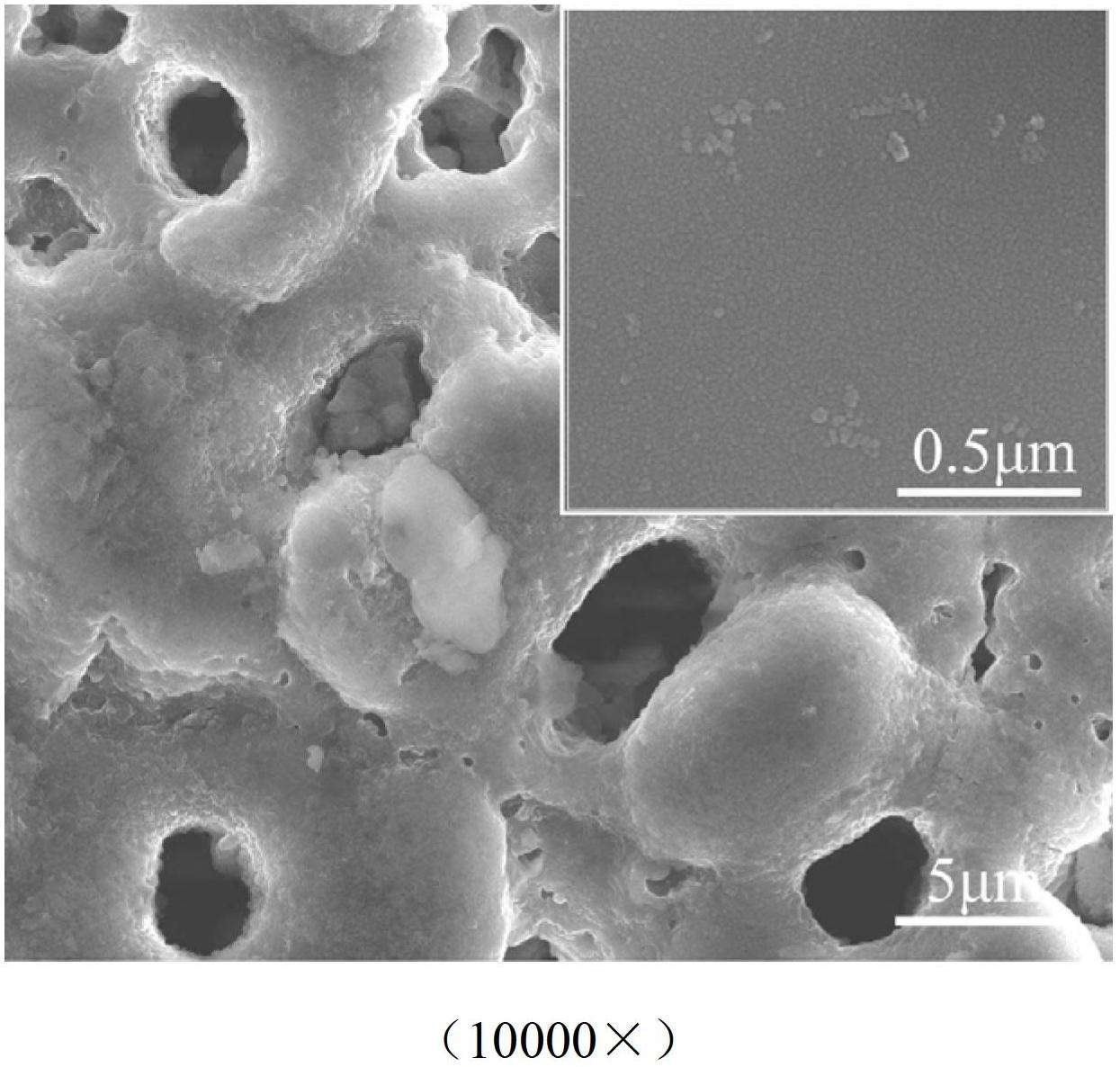

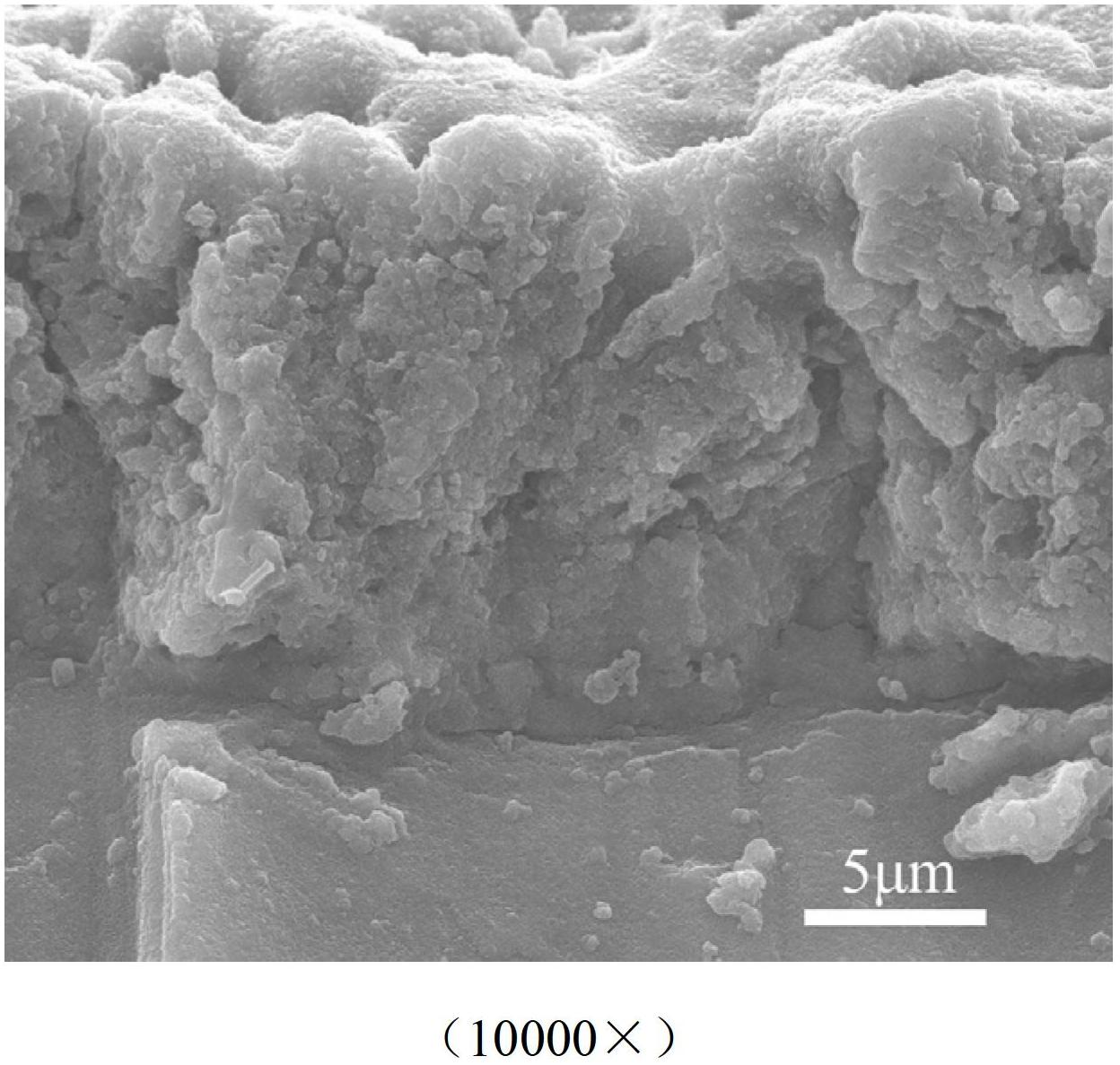

[0025] Configured with 0.0137M Ca(OH) 2 , 0.02M β-GP and 0.125M NaOH aqueous solution as electrolyte, magnesium or magnesium alloy as anode, stainless steel as cathode, pulse power supply, constant voltage of 450 volts, initial current density of 2.6 mA / mm2, Micro-arc oxidation treatment was performed for 10 minutes under the condition of frequency of 100 Hz, duty ratio of 26%, and distance between cathode and anode plates of 8 cm to obtain a phosphorus- and calcium-containing porous magnesium oxide coating with a thickness of 15 microns. The SEM photos of its surface and cross-sectional microscopic morphology refer to figure 1 and figure 2 .

Embodiment 2

[0027] The porous magnesium oxide coating containing phosphorus and calcium was prepared by the method in Example 1.

[0028] Add a mixed aqueous solution of 0.05M Ca-EDTA and 0.5M NaOH into the autoclave, and place the phosphorus- and calcium-containing porous magnesium oxide coating formed by micro-arc oxidation in it, and hydrothermally treat it at 90°C for 24 hours . A nanofibrous hydroxyapatite layer grows on the surface of the porous magnesium oxide, and the nanofibers are in the shape of a hexagonal column with a length of about 330.4 nanometers and a diameter of about 193 nanometers. After the combined process of micro-arc oxidation and hydrothermal treatment, the phase composition of the double-layer structure coating is magnesium oxide, magnesium hydroxide and hydroxyapatite.

Embodiment 3

[0030] The porous magnesium oxide coating containing phosphorus and calcium was prepared by the method in Example 1.

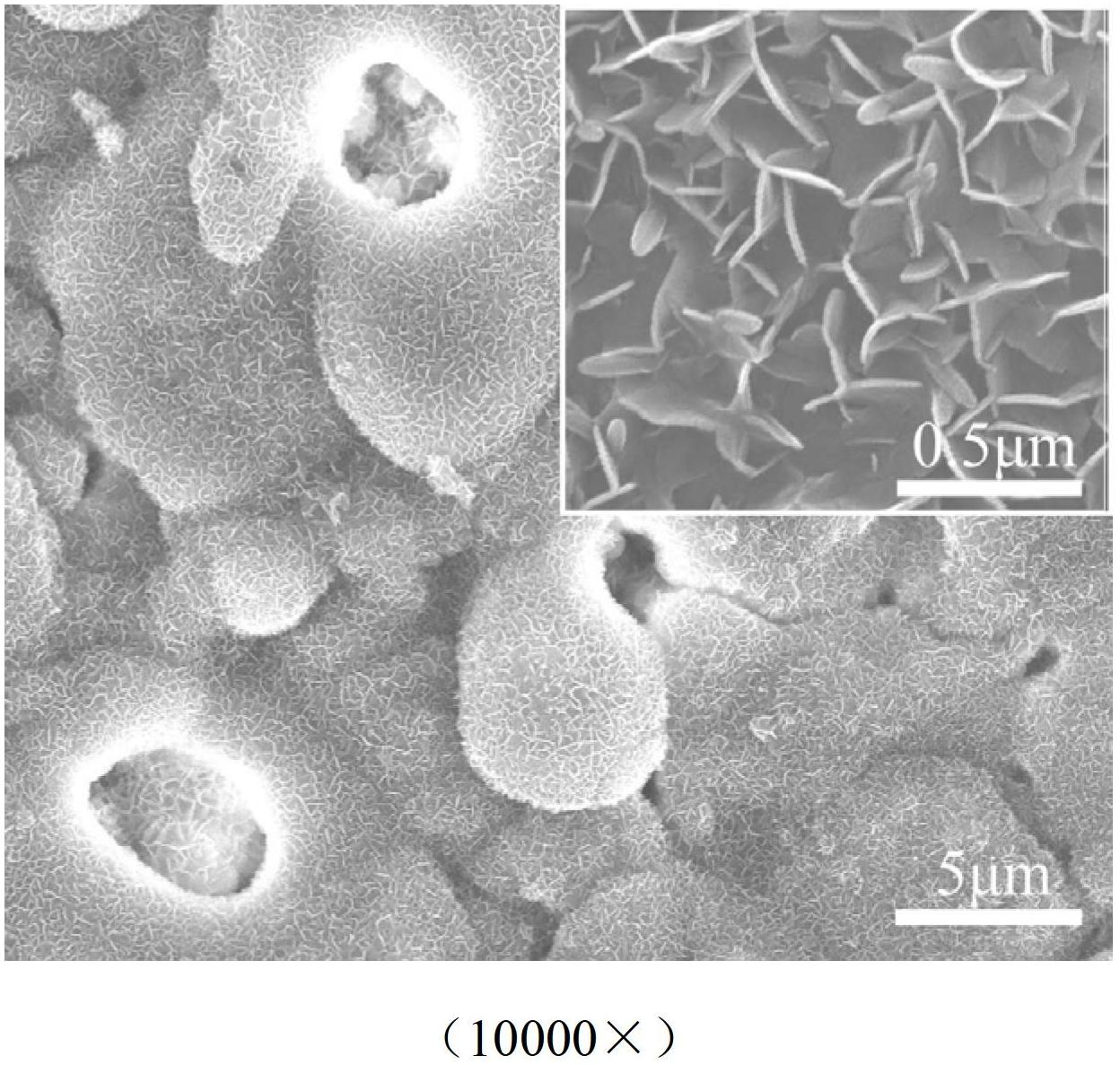

[0031] Add a mixed aqueous solution of 0.1M Ca-EDTA and 0.5M NaOH into the autoclave, and place the phosphorus- and calcium-containing porous magnesium oxide coating formed by micro-arc oxidation in it, and hydrothermally treat it at 90°C for 2 hours . The surface layer of the porous magnesium oxide forms a layer of flaky magnesium hydroxide, and the magnesium hydroxide has a sealing effect on the conductive through-holes formed by the micro-arc oxidation treatment. After the combined process of micro-arc oxidation and hydrothermal treatment, the phase composition of the double-layer structure coating is magnesium oxide and magnesium hydroxide. Its surface microscopic morphology and phase composition refer to image 3 and Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com