A kind of refractory material and preparation method thereof

A technology of refractory materials and inorganic composite materials, which is applied in the field of refractory materials containing silica and its preparation, can solve the problems of complex process and high energy consumption, and achieve the effects of wide source of raw materials, good formability and excellent application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

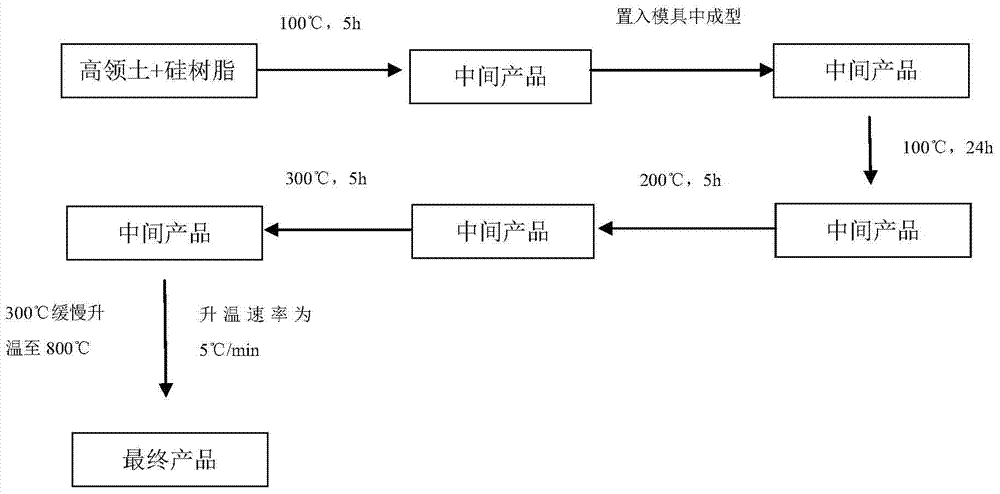

Method used

Image

Examples

Embodiment 1

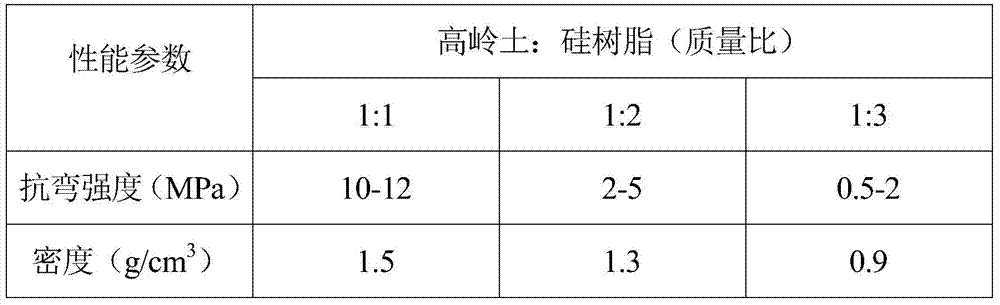

[0043] Pour the silicone resin and kaolin into the beaker according to the mixture, wherein the silicone resin content is 50%-75%, and the kaolin content is 25%-50%. Stir with a glass rod for 10 minutes to mix evenly. After mixing, a viscous and fluid mixture is obtained. The mixture was precured at 100° C. for 5 h, and stirred with a glass rod every 20 minutes during the precuring process. The purpose of pre-curing is to initially evaporate the solvent in the silicone resin, and the purpose of regular stirring is because the kaolin will condense and form a precipitate during the process, making the two mixed unevenly. Then put the mixture into a specific mold for curing and molding. The curing process is 100°C for 24 hours, and then apply pressure for molding. For kaolin content of 25%, 33% and 50%, the pressure is 5MPa, 7MPa and 10MPa respectively. Then keep it at 200°C for 5 hours, and at 300°C for 5 hours. At this stage, the solvent component xylene in the silicone resin w...

Embodiment 2

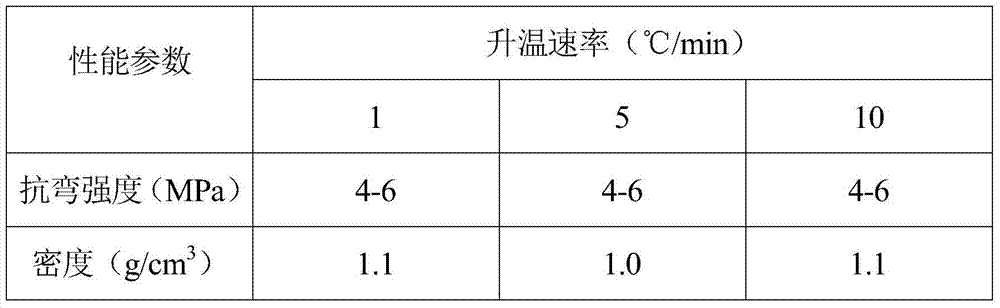

[0048] The difference between this example and Example 1 is that the mass ratio of kaolin and silicone resin is 1:3, and the temperature during the heating and oxidation process is 1°C / min, 5°C / min and 10°C / min, after 100°C heat preservation The molding pressure is 5MPa. Other steps are identical with embodiment 1. The performance parameters of the prepared refractories are listed in Table 2.

[0049] Table 2 Strength (MPa) and density (g / cm3) of refractories prepared at different heating rates 3 )

[0050]

Embodiment 3

[0052] The difference between this example and Example 1 is that the mass ratio of kaolin and silicone resin is 1:2, and the maximum heat treatment temperature is 800°C, 1300°C and 1500°C. Other steps are identical with embodiment 1. The performance parameters of the prepared refractories are shown in Table 3.

[0053] Table 3 Strength (MPa) and density (g / cm3) of refractories prepared at different maximum processing temperatures 3 )

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com