Calcium-mingled tantalum oxide nanometer bar structure biological activity coating and preparation method thereof

A bioactive, nanorod technology, applied in the field of bioactivation modification of medical metal surfaces, can solve the problems of difficult porous material coating preparation, poor adhesion between the coating and the substrate, etc., to promote adhesion and proliferation, and good binding ability. , the effect of simple ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing a calcium-doped tantalum oxide nanorod structure bioactive coating, comprising the following steps:

[0027] 1) Primary hydrothermal treatment of tantalum:

[0028] With 0.2~0.4mol / L HF and 1~2mol / L H 2 o 2 Prepare a hydrothermal solution with a certain molar concentration, pour it into a hydrothermal reaction kettle, the filling degree of the solution is 40%-60%, soak the tantalum sample in the solution, and treat it under the condition of 220-240°C for 12-24 hours. , the tantalum oxide nanorod structure coating can be obtained on the surface of the tantalum base, that is, the processed tantalum sample can be obtained;

[0029] 2) Secondary hydrothermal treatment of tantalum oxide nanorod structure coating:

[0030] Inject the calcium acetate solution with a concentration of 0.001-0.1mol / L into the hydrothermal reaction kettle, the filling degree of the solution is 40%-60%, and soak the treated tantalum sample into the calcium-containing solut...

Embodiment 1

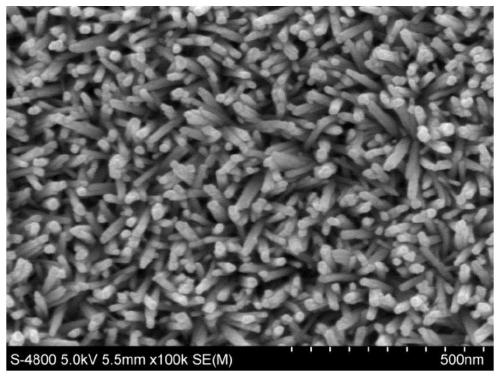

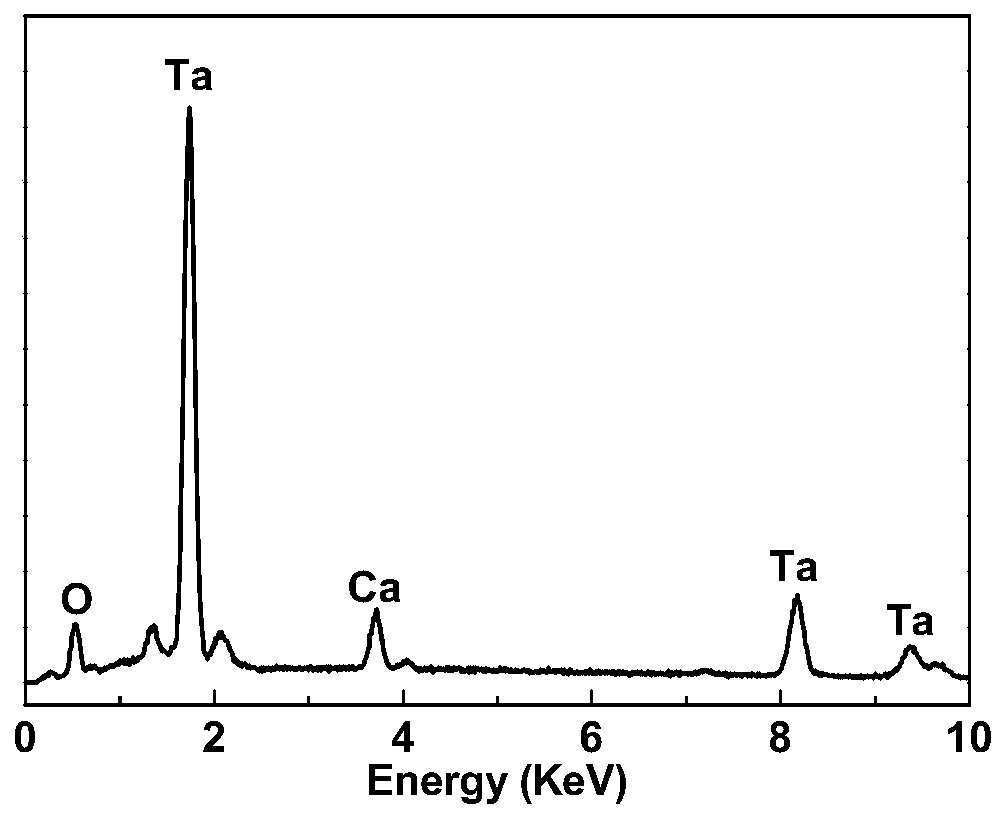

[0034] With 0.2mol / L HF and 1mol / L H 2 o 2 Prepare a hydrothermal solution with a molar concentration of 220°C for 24 hours, inject it into a hydrothermal reaction kettle, and the filling degree of the solution is 60%. A tantalum oxide nanorod structure coating is obtained, the microstructure of the coating is in the shape of upright nanorods, the average diameter of the nanorods is 28 nanometers, the length of the nanorods is about 100-200 nanometers, and the roughness Ra is about 96.3±9.5 nanometers.

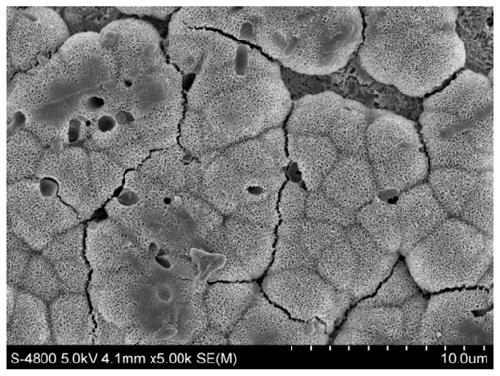

[0035] Inject the calcium acetate solution with a concentration of 0.001mol / L into the hydrothermal reaction kettle, and the filling degree of the solution is 60%, and soak the tantalum-based sample covered with the coating of tantalum oxide nanorods into the calcium acetate solution at 200°C The calcium-doped tantalum oxide nanorod structure coating can be obtained on the tantalum surface by hydrothermally treating it for 2 hours under certain conditions. The microstructure...

Embodiment 2

[0037] With 0.2mol / L HF and 1mol / L H 2 o 2 Prepare a hydrothermal solution with a molar concentration of 220°C for 24 hours, inject it into a hydrothermal reaction kettle, and the filling degree of the solution is 60%. A tantalum oxide nanorod structure coating is obtained, the microstructure of the coating is in the shape of upright nanorods, the average diameter of the nanorods is 28 nanometers, the length of the nanorods is about 100-200 nanometers, and the roughness Ra is about 96.3±9.5 nanometers.

[0038]Inject the calcium acetate solution with a concentration of 0.01mol / L into the hydrothermal reaction kettle, the filling degree of the solution is 60%, and soak the tantalum-based sample covered with the coating of tantalum oxide nanorods into the calcium acetate solution, at 200°C The calcium-doped tantalum oxide nanorod structure coating can be obtained on the tantalum surface by hydrothermally treating it for 2 hours under certain conditions. The microstructure of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com