Patents

Literature

66results about How to "Corrosion free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass fiber reinforcement cement board and production method thereof

InactiveCN101386509AGuaranteed StrengthGuaranteed lifeSolid waste managementCeramicwareExpanded clay aggregateCement board

The invention relates to a building material and a method for preparing the same, in particular to a glass fiber reinforced cement board and a method for preparing the same. The glass fiber reinforced cement board comprises the following components in weight portion: 100 portions of Portland cement, 13.6 to 15 portions of high alumina cement, 3.1 to 3.4 portions of fly ash, 5.7 to 6.3 percent of plaster stone powder, 120 to 132 portions of ceramsite, 6.5 to 7.1 percent of foaming agent, 74.5 to 81.3 percent of dispersing agent, 53 to 58.7 portions of pure water and 3.6 to 4 portions of plastic-coated glass fiber grid cloth. The preparation method sequentially comprises the following steps: mixing weighed-up solid materials, adding weighed-up liquid materials in the previous step, cavity forming, roll extruding, vibration, cutting and curing. The invention has the advantages that: the glass fiber reinforced cement board has advantages of light volume weight, high strength, low dry shrinkage wet swelling coefficient, no after expansion and shrinkage, corrosion resistance, sound insulation, heat insulation, fire resistance and non-combustion; the preparation method has the characteristics of scientific and reasonable method, continuous production, high efficiency and low cost, flat board surface, convenient in-site mounting and the like; the glass fiber reinforced cement board is good in water resistance, and particularly applied to the finishing of internal and external walls and ceilings of various buildings in wet environments; moreover, the glass fiber reinforced cement board and a method for preparing the same have the advantages of ensuring the strength and service life of cement due to the adoption of the plastic-coated anti-alkali glass fiber grid cloth, along with reasonable blending ratio and reduced alkalinity.

Owner:YINGCHUANG BUILDING TECH SHANGHAI CO LTD

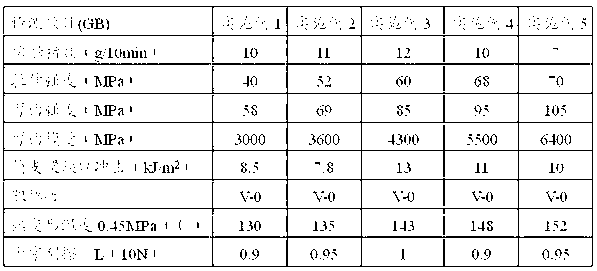

Kitchen flame-retardant and scrapping-resistant polypropylene materials and preparation method of the same

The invention discloses kitchen flame-retardant and scrapping-resistant polypropylene materials, and further discloses a preparation method of the kitchen flame-retardant and scrapping-resistant polypropylene materials. The kitchen flame-retardant and scrapping-resistant polypropylene materials are prepared from the following components: by weight, 29-55.5 parts of polypropylene, 5-20 parts of continuous glass fiber, 5-10 parts of compatilizer, 19-27 parts of compound flame retardant and 1.5-3 parts of scrapping-resistant agent. The kitchen flame-retardant and scrapping-resistant polypropylene materials have the advantages of being flame-retardant, scrapping-resistant, environment-friendly, non-poisonous, free of sucking water, mould-proof, anticorrosion, acid-alkali resistant, anti-aging, heat-resisting, recoverable, capable of conducting injection molding, convenient to process, capable of having different color custom-made according to requirements and being made into different styles and patterns in an injection molding mode according to requirements and the like, simple in production flow, continuous in production process, high in production efficiency and stable in production quality, and satisfies requirements for energy conservation, emission reduction, environmental-friendly residence, comfort and beauty, and are ideal kitchen materials.

Owner:HEFEI GENIUS NEW MATERIALS

Method for electroplating zinc-nickel coating on magnesium alloy electroplate surface

InactiveCN104233416AWeak corrosiveCorrosion freeMetallic material coating processesPotassium fluoridePhosphoric acid

The invention relates to a method for electroplating a zinc-nickel coating on a magnesium alloy electroplate surface. The method employs a novel pickling activation and zinc immersion pre-treatment technology, wherein an acid solution is the complex formulation solution, the acid solution comprises 10-14g / L oxalic acid, 40-60g / L sodium fluoride, 5-25ml / L phosphoric acid, 2-25g / L ammonium bifluoride and 0.005-5g / L sodium dodecanesulphonate. The activation temperature is 25-35 DEG C, the activation time is 1-5 minutes; wherein the sulfate zinc-immersion technology comprises the following steps: immersing in a zinc-immersion solution comprising 30g of 20-40g / L of zinc sulfate, 5g of 3-7g / L sodium carbonate or potash, 7g of 2-4g / L potassium fluoride and 150g of 100-120g / L potassium pyrophosphate for zinc immersion, wherein the pH of the zinc-immersion solution is between 10.2 and 10.4, the zinc immersion temperature is from 30 DEG C to 70-80 DEG C, wherein the zinc immersion time is 10-15 minutes, and then obtaining the compact and uniform zinc-immersion layer as a base coat for subsequent electroplating. The combination capacity of the coating and a matrix can be increased.

Owner:无锡市森信精密机械厂

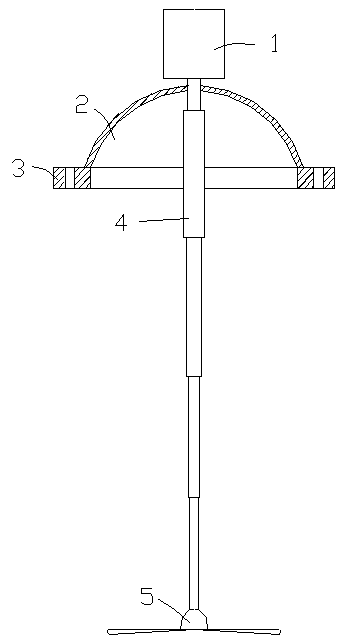

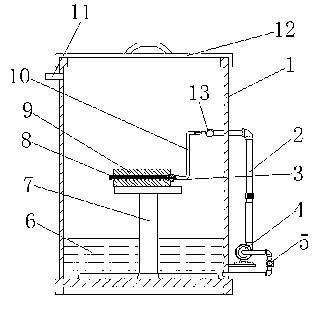

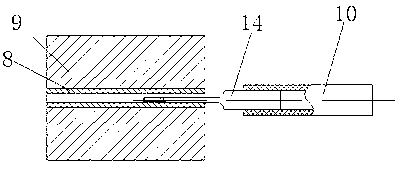

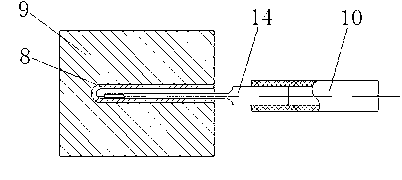

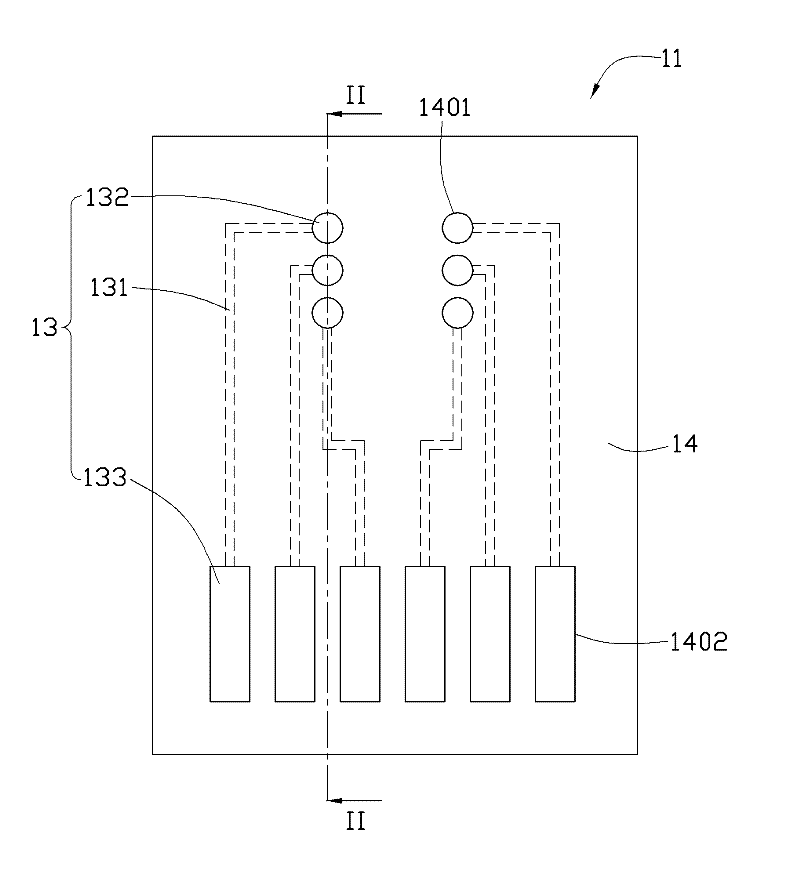

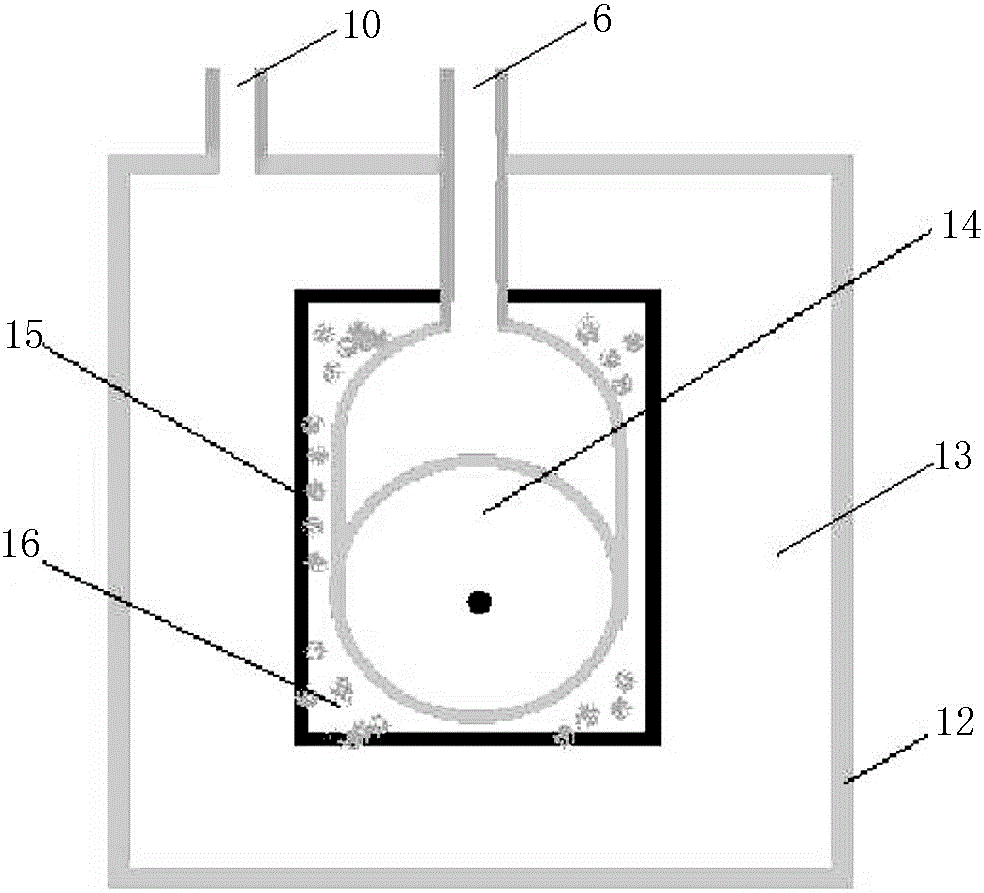

Extension type stirring device

The invention discloses an extension type stirring device, comprising a tank cover, wherein a flange plate is arranged at the bottom of the tank cover, a motor is arranged on the top of the tank cover, the bottom of the motor is connected with an extension rod, the bottom of the extension rod is connected with a stirrer, the center of the extension rod is hollow, the motor is connected with the stirrer after passing through the center of the extension rod, and ant-corrosion paint is coated on the surfaces of the extension rod and the stirrer. The tank cover is fixed on a pressure vessel tank by the flange plate, the length of the extension rod is adjusted according to the height of the pressure vessel tank, the motor drives the stirrer to stir, and the ant-corrosion paint on the surfaces of the extension rod and the stirrer can prevent the device from corrosion.

Owner:CHONGQING HENGTAI CABLE GRP

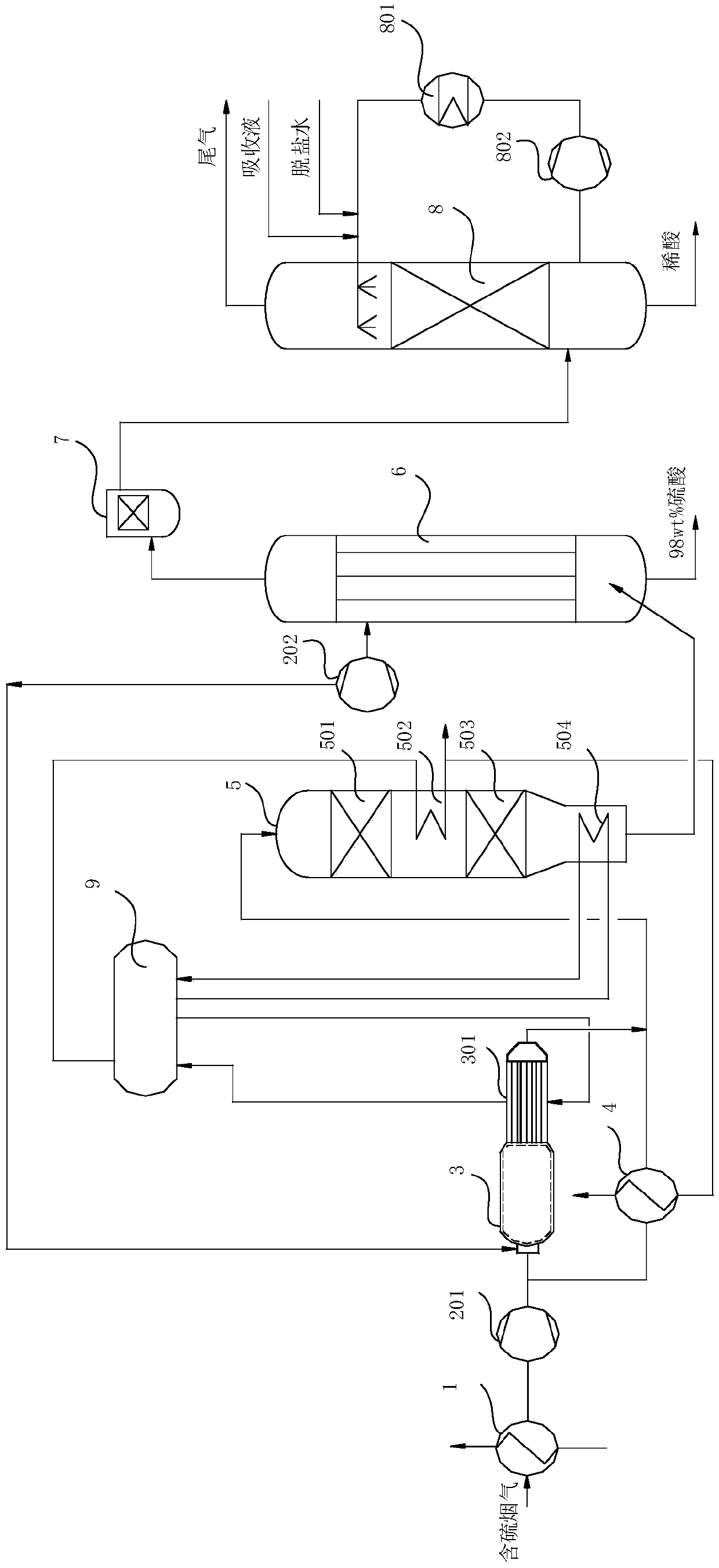

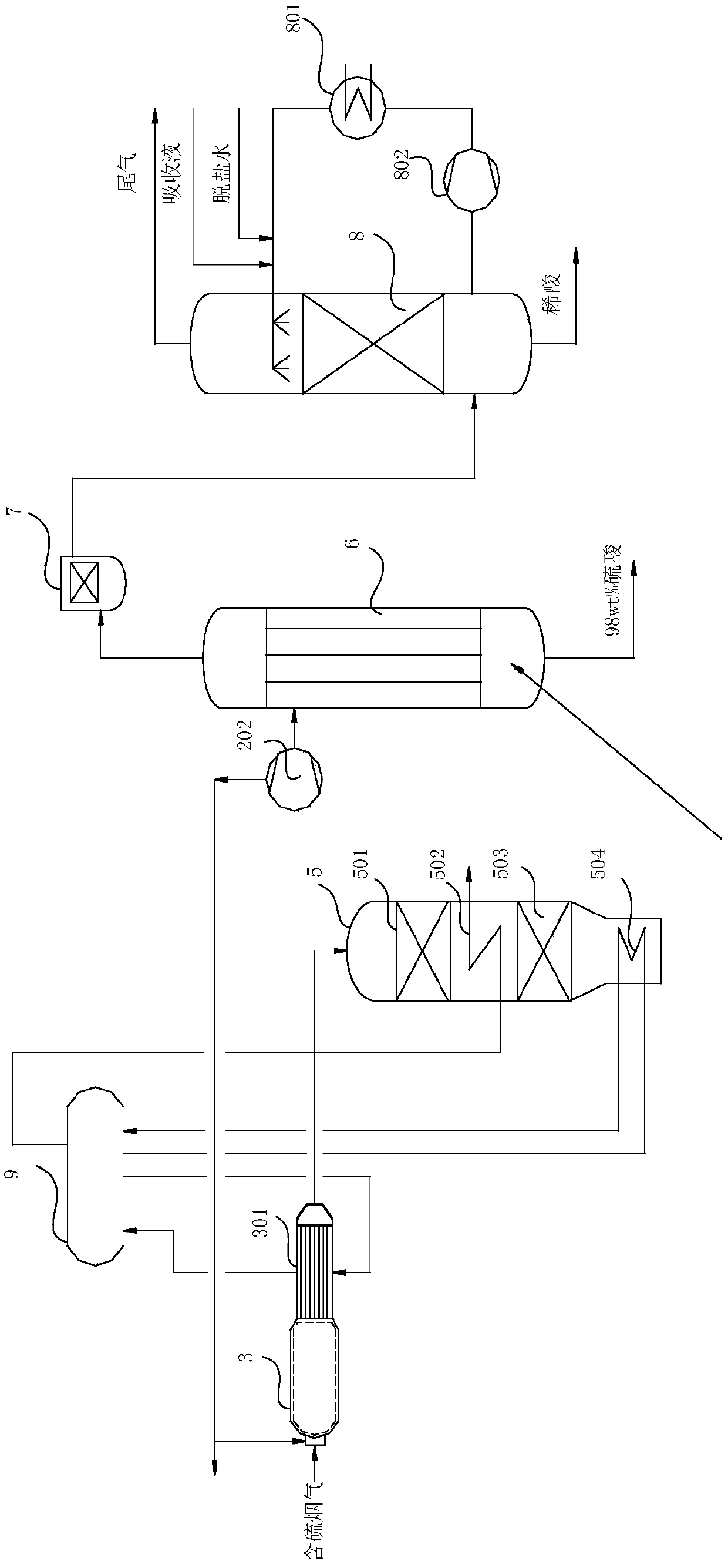

Technical system and technical method for converting sulfur-containing exhaust gas into sulfuric acid

The invention discloses a technical system and a technical method for converting a sulfur-containing exhaust gas into sulfuric acid. The technical system comprises an exhaust gas preheater, an exhaustgas fan and a sulfuric acid vapor condenser, wherein the exhaust gas preheater is used for preheating the sulfur-containing exhaust gas to above dew point temperature at 15-30 DEG C; a glass tube isserved as a heat exchange tube of the exhaust gas preheater; the exhaust gas fan is used for boosting the preheated acidic process gas, conveying one part into a combustion furnace and conveying the other part into a process gas steam heater; the combustion furnace and the process gas steam heater are connected with each other and then are connected with a combined reactor; the combined reactor isused for catalytically oxidizing SO2 in the acidic process gas into SO3; the sulfuric acid vapor condenser is used for condensing the SO3 generated by the combined reactor into sulfuric acid; a coldend of the sulfuric acid vapor condenser is connected with the exhaust gas preheater and is used for supplying hot air to the exhaust gas preheater. The device provided by the invention is capable ofresisting against the fluctuation of SO2 concentration in raw gas and is capable of achieving considerable economic benefit of the device and reasonable utilization of energy.

Owner:KEYON PROCESS +1

Method for flowingly corroding complicated slender copper tube cores made of aluminum alloy castings

The invention discloses a method for flowingly corroding complicated slender copper tube cores made of aluminum alloy castings. Slots are formed on embedded copper tube cores in the prior art, and the copper tube cores are corroded by a method for soaking the copper tube cores in corrosive liquid and has shortcomings that the corrosion efficiency is low; the copper tube cores cannot be thoroughly corroded, and the quality of castings which are processed in follow-up procedures such as thermal treatment for the castings is affected; and matrixes of the aluminum alloy castings are corroded. In order to overcome the shortcomings, the method is used for dynamically corroding the complicated slender copper tube cores made of the aluminum alloy castings by means of enabling corrosive liquid to flow. The method has the advantages that the corrosive liquid flows in copper tubes by the aid of corrosion-resistant magnetic valves, and the corrosion efficiency is improved; the flow rate of the corrosive liquid can be adjusted, so that the corrosion speed is controlled; the multiple copper tubes or a plurality of castings can be corroded simultaneously by the aid of a multi-tube joint; the requirement on corroding parts with different apertures can be met by means of replacing different sleeves; and the corrosive liquid is basically prevented from being in contact with matrixes of the castings, and accordingly the matrixes are protected against being corroded.

Owner:NANCHANG HANGKONG UNIVERSITY

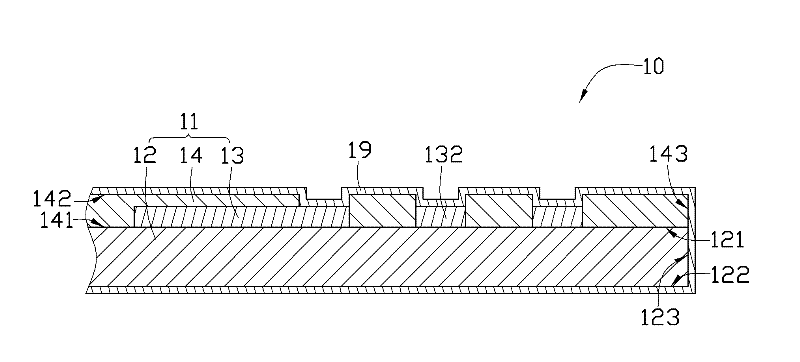

Circuit board and manufacturing method thereof

ActiveCN102480849ALower surface energyWith protectionPrinted circuit detailsMultilayer circuit manufactureFluorideFluorocarbon

The invention provides a circuit board which comprises: a substrate, a line layer, a protective layer and a fluorocarbon film. The substrate possesses a first surface. The line layer is formed on the first surface. The line layer comprises: a plurality of conductive lines and a plurality of conductive terminals. The protective layer covers the conductive lines and the first surface of the substrate which is exposed from the line layer. A first protective layer possesses a first protection surface which is close to the substrate and a second protection surface which is opposite to the first protection surface. The first protective layer is provided with a plurality of through holes which pass through the first protection surface and the second protection surface so as to expose the conductive terminals. The fluorocarbon film is deposited on the second protection surface and the surfaces of the conductive terminals. The fluorocarbon film is formed by carbon elements and fluoride elements and a ratio of a fluorine atom quantity to a quantity is 1.2 to 1.5. The circuit board of the invention has a long storage life. The technical scheme also provides a manufacturing method of the circuit board.

Owner:QING DING PRECISION ELECTRONICS HUAIAN CO LTD +1

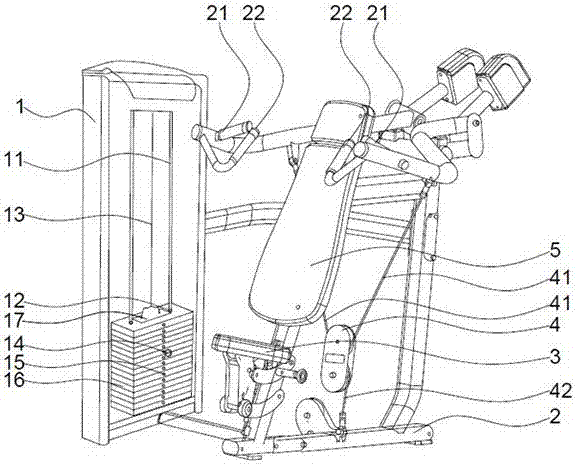

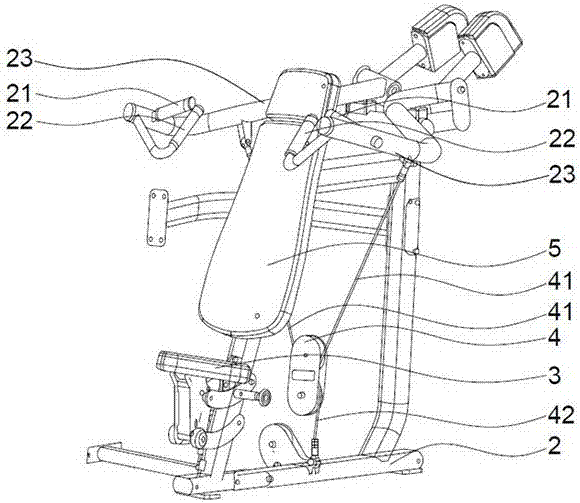

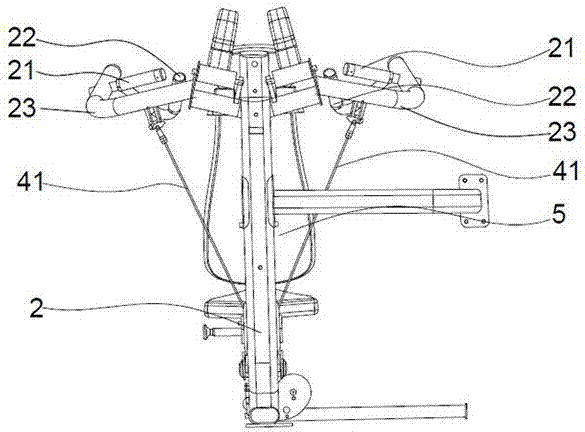

Lifting-pushing device used for shoulders

InactiveCN107376236AEasy to controlReduce falling speedMuscle exercising devicesEngineeringUser friendliness

The invention provides a lifting-pushing device used for shoulders, and belongs to the field of body building instruments. The device includes a weight adjusting box and a bracket; the inside of the weight adjusting box is vertically provided with two supporting columns, the supporting columns penetrate through a lifting device, the lifting device is provided with two column holes allowing the supporting columns to pass through, the weight adjusting box is internally provided with a lifting steel cable, one end of the lifting steel cable is connected with a lifting device, the bracket is provided with two movable support frames which are bilaterally symmetrical, each movable support frame is provided with a first lifting-pushing handle and a second lifting-pushing handle, each movable support frame is connected with one end of a lifting-pushing steel cable, the middle end of lifting-pushing steel cable is connected with a movable pulley, the movable pulley is connected with one end of a connecting steel cable, the other end of the connecting steel cable passes through the bracket and is connected with the weight adjusting box and the lifting steel cable, the surfaces of the supporting columns are coated with corrosion resistant coatings, and a buffering layer is affixed to the bottom surface of each balance weight. The lifting-pushing device used for shoulders can achieve the silent effect and meanwhile achieve the precision and user friendliness of training.

Owner:舟山市领尚体育发展有限公司普陀分公司

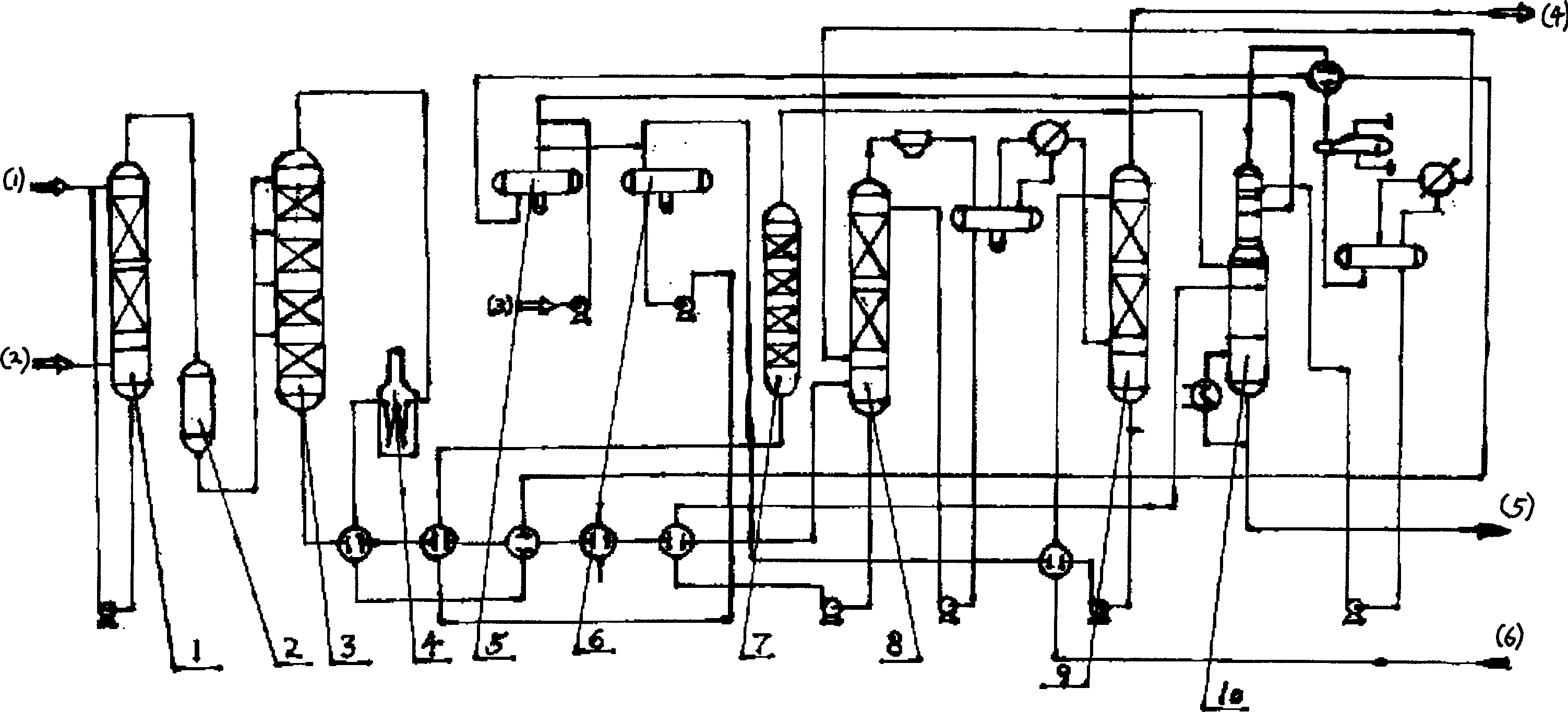

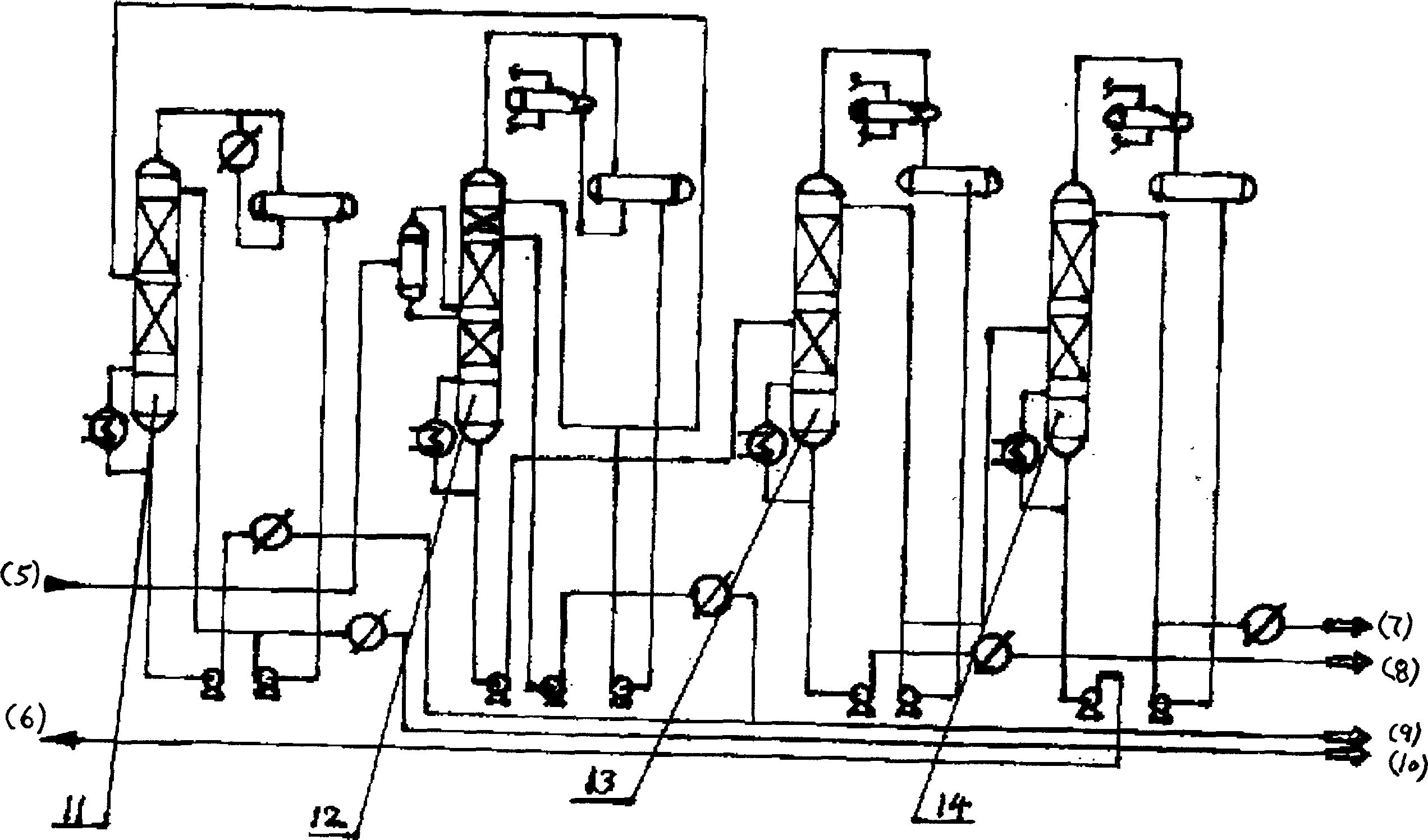

Technological process for catalyzing dry gas to prepare ethylbenzene

The ethyl benzene preparing process with catalytic dry gas has the advantages of no corrosion to pipeline, high benzene recovering rate and low power consumption. The apparatus includes water washing tower, alkylation tower, coarse separation tower, absorption tower, benzene tower, toluene eliminating tower, ethyl benzene tower, polyethyl benzene eliminating tower, diethyl benzene tower, heat exchanger, pump and tank. The catalytic dry gas is treated through water washing to eliminate MDEA, alkylation, heat exchange, coarse separation, cooling, serial separation in various towers and other steps to prepare ethyl benzene.

Owner:中国寰球工程有限公司辽宁分公司 +1

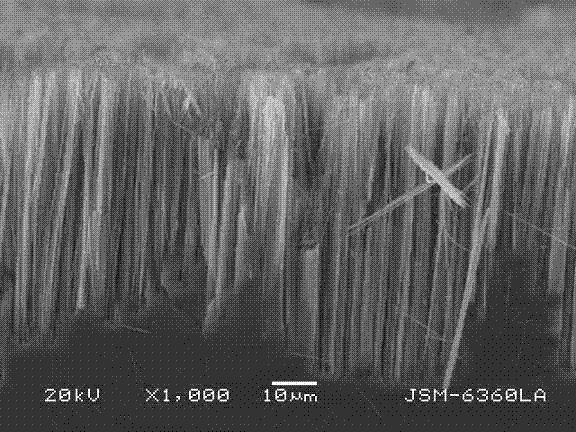

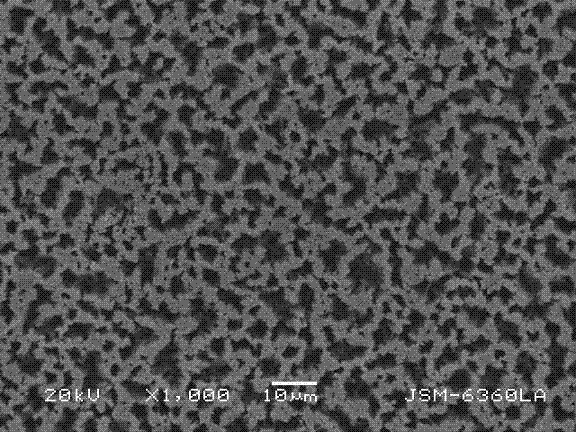

Pd-Ni/SiNWs array electrode glucose sensor and manufacturing method and application thereof

InactiveCN102539491AStable structureExtended service lifeMaterial electrochemical variablesEpoxyGlucose sensors

The invention discloses Pd-Ni / SiNWs array electrode glucose sensor which comprises silicon substrate material, a basal SiNWs array material layer, a metal Pd-Ni nanoparticle coated layer, a copper wire and an epoxy resin protection layer. The basal SiNWs array material layer is grown on the silicon substrate material; the metal Pd-Ni nanoparticle coated layer is arranged on the basal SiNWs array material layer; the copper wire is arranged on the metal Pd-Ni nanoparticle coated layer,; and the epoxy resin protection layer wraps the contact part of the copper wire and the metal Pd-Ni nanoparticle coated layer. The invention further discloses a manufacturing method and application of the Pd-Ni / SiNWs array electrode glucose sensor. The Pd-Ni / SiNWs array electrode glucose sensor has a small volume, a large surface area, high activity, high sensitivity and interference resistance and can be applied widely.

Owner:EAST CHINA NORMAL UNIV

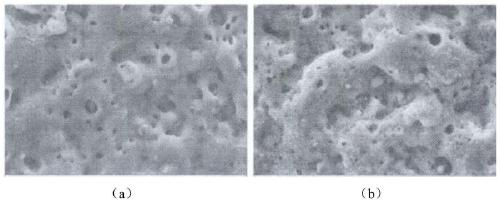

Wear resisting material and preparation method thereof

ActiveCN109868386AImprove wear resistanceImprove surface wear resistanceAnodisationOxide ceramicMicro arc oxidation

The invention discloses a wear resisting material. Aluminum nitride, aluminum oxide, molybdenum disilicide and graphite powder particles are uniformly distributed in an aluminum alloy basal body; a composite micro-arc oxidation layer is distributed on the surface of the aluminum alloy basal body; the aluminum nitride, the aluminum oxide and the molybdenum disilicide are high in hardness to prominently improve the hardness and the wear resistance of the material; and through graphite powder, the antifriction can be improved. Through the composite micro-arc oxidation layer on the surface, the alloy surface wear resistance and corrosion resistance can be effectively improved. Strengthening phases of such elements as Sn, Ru, Sr, Lu, Cu, Mn, Mg, Mo and Fe in an alloy are in dispersion strengthening to improve mechanical performances of the material. In a preparation method, through a mode of attaching mixed powder on a pure aluminum metal wire, the mixed powder is positioned in the center of mother alloy liquid during casting, so that the quick dispersion and the homogenization of micropowder particles are facilitated, and the production efficiency is improved; and micro-arc oxidation film forming parameters and conditions are optimized, so that the hardness and the smoothness degree of oxide ceramic films are improved, the film thickness is reduced, and the wear resistance of the material is effectively improved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Oral care solution and preparation method thereof

InactiveCN104622954ASterilization and anti-inflammationAromatic and sweetDigestive systemPlant ingredientsWater vaporTherapeutic effect

The invention discloses an oral care solution and a preparation method thereof. The oral care solution comprises the following components by weight percent: 0.002-2.0% of traditional Chinese medicine volatile oil, 0.4-8.0% of alcohol soluble traditional Chinese medicine, 0.1-5.0% of solubilizer, 1.0-10.0% of cosolvent, 0.1-15.0% of corrigent and 60.0-98.0% of water, and the pH value range is 6.0-8.5; the traditional Chinese medicine volatile oil and the alcohol soluble traditional Chinese medicine are prepared from eupatorium and elsholtzia according to a mass ratio of 1: 1 to 10:1, by using a steam distillation method. The oral care solution disclosed by the invention is applied to oral care and has curative effects of sterilizing, diminishing inflammation and removing bad breath on such oral diseases as oral odor, periodontitis, gingivitis, and the like. The oral care solution disclosed by the invention is simple in raw materials, extract in principle and strong in pertinence, a modern mature process is adopted to well control the product quality, and the oral care solution is suitable for the demand of modern production technology, is conductive to market promotion and truly brings gospel to patients.

Owner:GUANGXI NORMAL UNIV

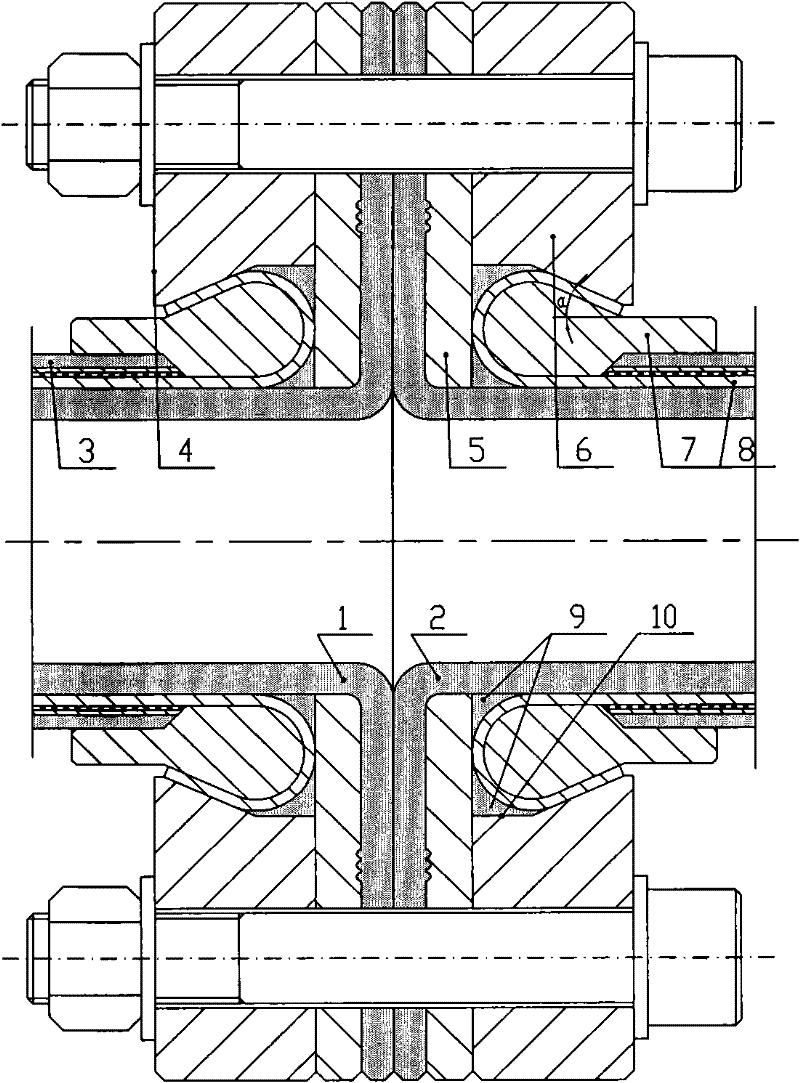

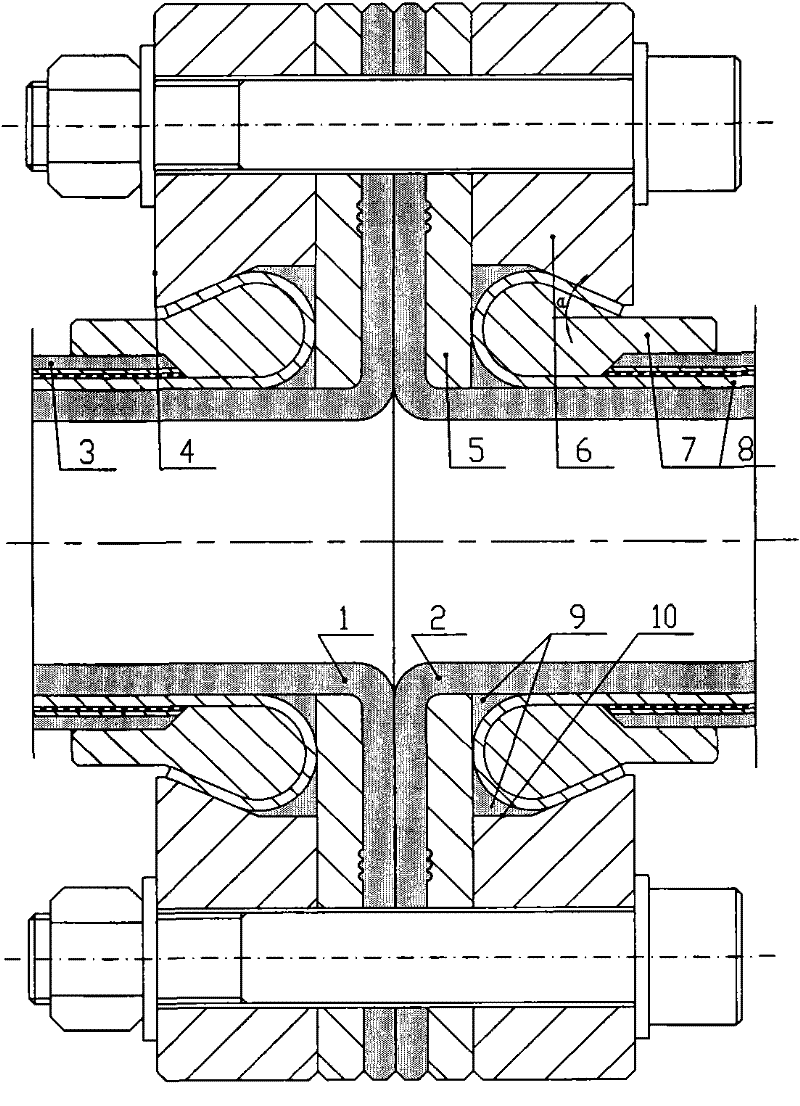

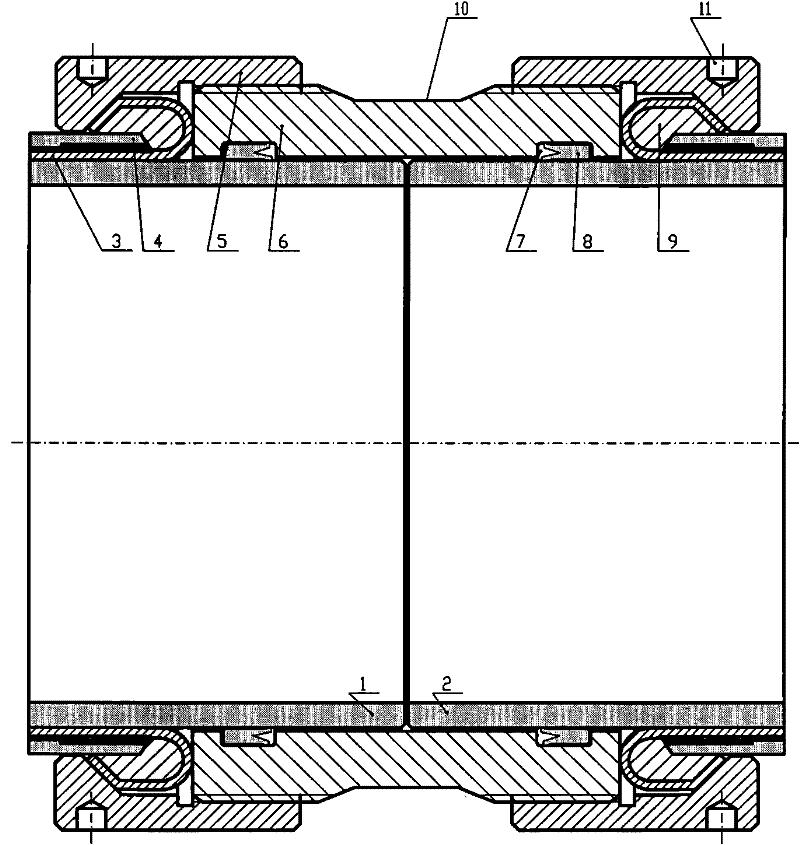

Steel belt self-locking type flange pipe connector used for connecting compound pipes

InactiveCN102242846AReasonable structural designSimple preparation processPipe connection arrangementsSelf lockingEngineering

The invention discloses a steel belt self-locking type flange pipe connector used for connecting compound pipes and belongs to the technical field of the pipe connector. The steel belt self-locking type flange pipe connector comprises a shrinking sleeve, a flange 4, a sleeve liner, a steel belt and a filling layer, wherein the flange 4 is composed of an upper flange 5 and a lower flange 6; the shrinking sleeve is arranged between the steel belt and the sleeve liner; a ladder-shaped inner hole is formed on one side, which is close to a pipe body, of the lower flange 6; the sleeve liner is positioned in a hollow cavity; the steel belt is tangent with the outer side of the upper flange 5 and an end of the steel belt is matched with the inner wall of the inner hole, thereby forming the hollow cavity; the filling layer is positioned in the hollow cavity which is encircled by the steel belt, the upper flange 5 and the inner wall of the inner hole; the steel belt is positioned between the sleeve liner and the inner hole; an inclined angle of 30 degrees is formed between the slope of the ladder-shaped inner hole and the axial line of the pipe body. The steel belt self-locking type flange pipe connector can be used for reducing 10% of cost. The loading capacity is above dozens of MPa and the tensile yield strength is above 10MPa. The steel belt self-locking type flange pipe connector used for connecting compound pipes is capable of being used for efficiently promoting the tensile yield strength of the pipes and is reliable in connection and long in service life.

Owner:JIANGSU SHENSHI NEW MATERIAL TECH

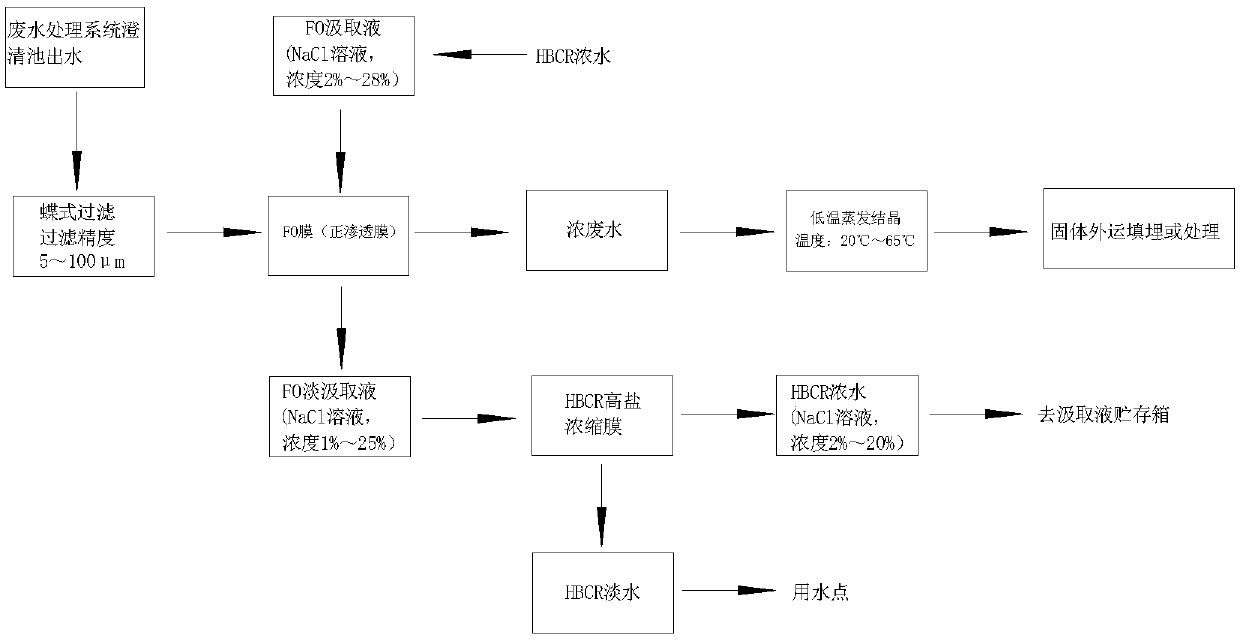

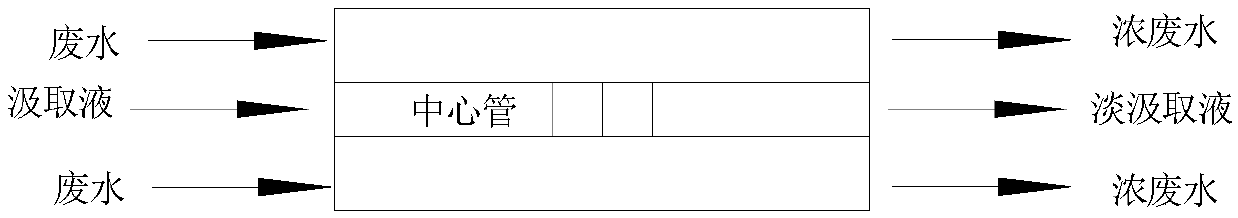

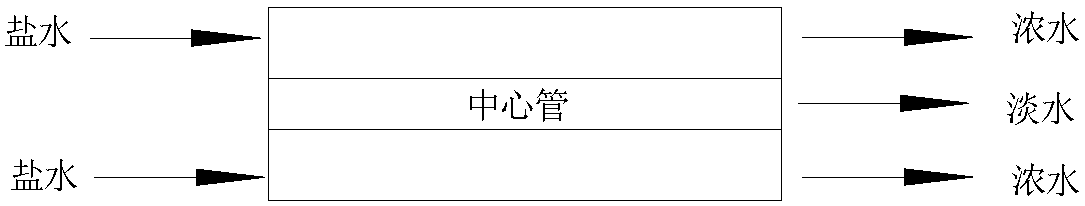

Zero emission technology for wastewater

InactiveCN107585937AThe pre-processing process is simpleEasy to recycleWater contaminantsMultistage water/sewage treatmentParticulatesEvaporation

The invention discloses a zero emission technology for wastewater. The technology comprises steps as follows: (1), pretreatment: the wastewater passes through a segmented filter, and particulate matter with grain size larger than 100 mu m is removed; (2), FO (forward osmosis): the pretreated wastewater passes through an FO membrane; (3), concentrated wastewater obtained after the pretreated wastewater passes through the FO membrane is subjected to low-temperature evaporative crystallization by a low-temperature evaporative crystallizer; an FO light draw solution obtained after the wastewater passes through the FO membrane is pumped into a high-salt concentration membrane by a high-pressure pump; produced concentrated water is taken as a draw solution to be recovered, and produced fresh water is taken as industrial water. The technical scheme has beneficial effects as follows: 1, pretreatment is simple; 2, the draw solution is recovered with the high-salt concentration membrane technology, the recovery is simple, and no chemical is required to be added; 3, the low-temperature evaporative crystallizer is driven by air in the evaporation process, and required temperature is about 30 DEG C and is the lowest temperature for evaporation in current water treatment industry.

Owner:上海缘脉环境科技有限公司

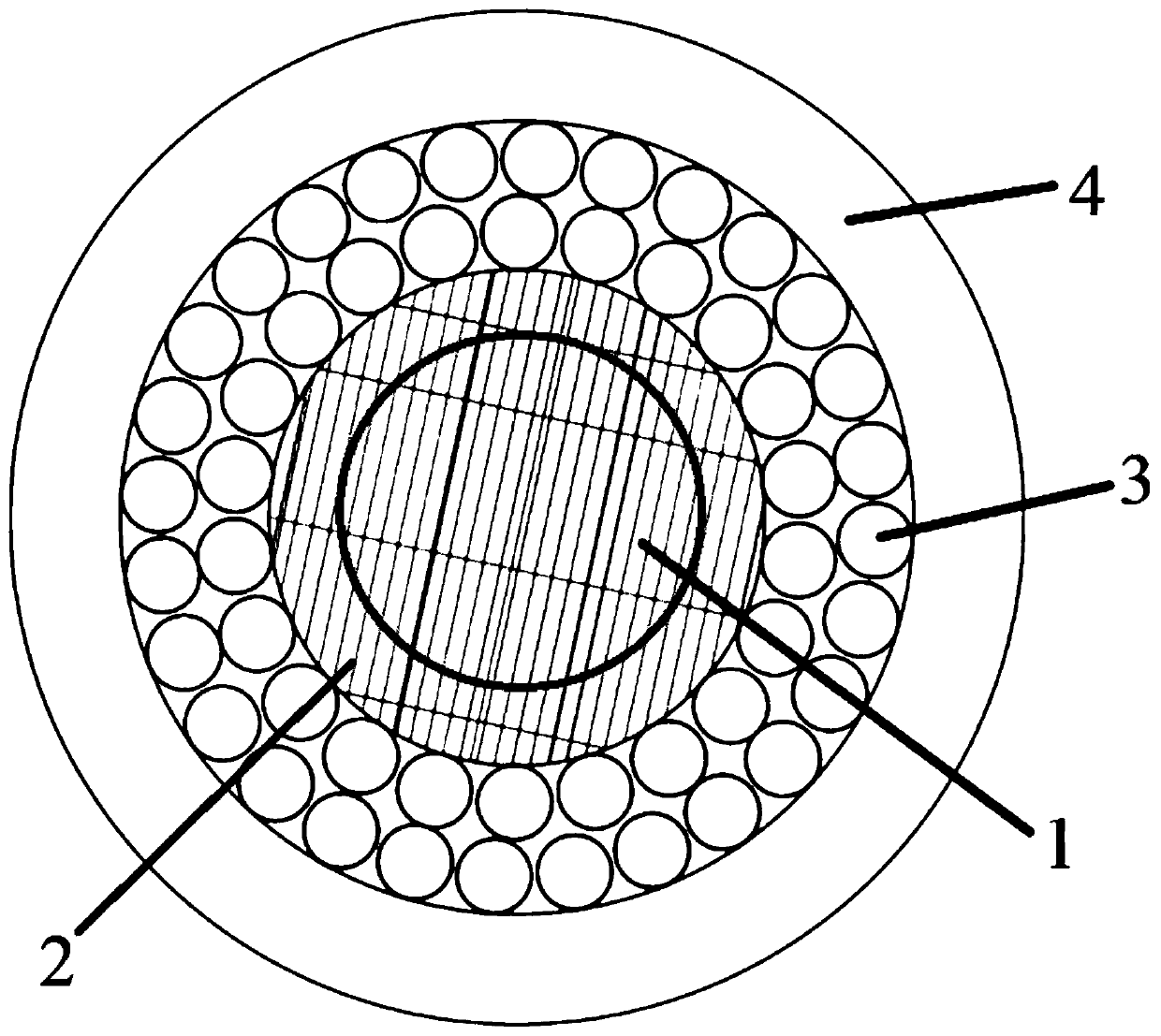

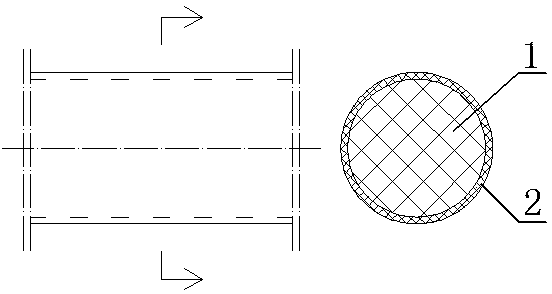

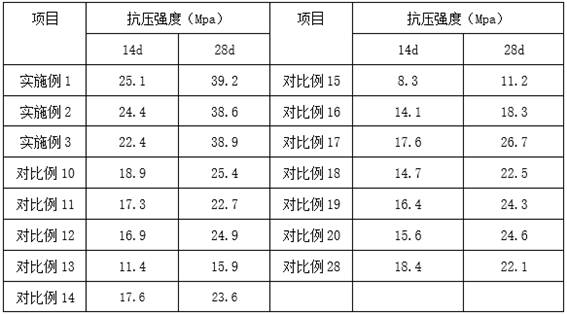

Fiber composite core stranded metal wire sucker rod and preparation method and application thereof

ActiveCN110566134AStrong impact resistanceIncrease the counterweightDrilling rodsCoatingsThermoplasticFibrous composites

The invention relates to the technical field of composite sucker rods, in particular to a fiber composite core stranded metal wire sucker rod and a preparation method and application thereof. The sucker rod structure comprises a rod body, a metal wire structural layer and an impact-resistant anti-corrosion thermoplastic layer, wherein the rod body is divided into a rigid layer and a protective layer wound on the surface of the rigid layer; the rigid layer is formed by composite thermosetting resin of fiber filaments, and the protective layer is made of high-strength fibers; the metal wire structural layer is formed by stranding metal wire on the surface of the protective layer; and the impact-resistant anti-corrosion thermoplastic layer is coated on the surface of the metal wire structurelayer. The sucker rod has good impact resistance and bending performance, one or more layers of high-strength metal wires are stranded outside, the sucker rod is endowed with excellent impact resistance, meanwhile, the weight of the sucker rod is increased to a certain extent, the sucker rod can be guaranteed to be in a stretched state all the time in the running process, the operation can be completed without using a counterweight rod, and the cost is reduced.

Owner:SHANDONG UNIV

High-nutrition dietary fiber brown rice roll and preparation method thereof

InactiveCN105029217AImprove a single shortcomingNourishing qi and bloodFood ingredient functionsFood preparationGLYCYRRHIZA EXTRACTSpleen

The invention discloses a high-nutrition dietary fiber brown rice roll and a preparation method thereof, and belongs to the technical field of health food. The high-nutrition dietary fiber brown rice roll is prepared from the following raw materials in parts by weight: 70-75 parts of brown rice powder, 57-65 parts of walnut kernels, 55-59 parts of whole wheat flour, 115-122 parts of butter, 19-23 parts of hazelnut kernels, 14-17 parts of peanut kernels, 49-53 parts of dried cranberry, 22-26 parts of black and white sesames, 19-24 parts of dried grapes, 34-37 parts of red sugar, 28-32 parts of syrup, 42-45 parts of eggs, 4-8 parts of apricot kernels, 10-12 parts of corns, 4-6 parts of liquorice, 25-28 parts of mung beans, 11-14 parts of cashew nuts, 4-8 parts of olive oil and 2-7 parts of edible salt. The high-nutrition dietary fiber brown rice roll and the preparation method thereof have the beneficial effects that the material use is accurate, and the high-nutrition dietary fiber brown rice roll tastes delicious, does not contain an additive or a preservative and is enriched by trace elements such as proteins, vitamins and amino acid; the defect that a high-nutrition dietary fiber product in the market is single is overcome, and the high-nutrition dietary fiber brown rice roll has the effects of tonirying the kidney, warming the lung, strengthening the spleen and stomach, nourishing qi-blood and relaxing the bowl.

Owner:李慧

Seawater-resistant ultra-high-molecular-weight polyethylene fiber yarn

The invention provides a seawater-resistant ultra-high-molecular-weight polyethylene fiber yarn. According to the technical scheme, the surface of the ultra-high-molecular-weight polyethylene fiber yarn is coated with an acid and alkali-resistant protective material. The yarn can be used for making marine ship cables and can be effectively protected from seawater corrosion, corrosion of seawater and sea frog to ropes is avoided, and the purpose of effectively improving the product quality and service life of ultra-high-molecular-weight polyethylene ropes is achieved. The seawater-resistant ultra-high-molecular-weight polyethylene fiber yarn has the following beneficial effects: every ultra-high-molecular-weight polyethylene fiber yarn has the function of seawater corrosion prevention; ropes can be better protected from seawater corrosion; and the seawater resistance and service life of ultra-high-molecular-weight polyethylene ropes are strongly guaranteed.

Owner:盐城神力制绳有限公司

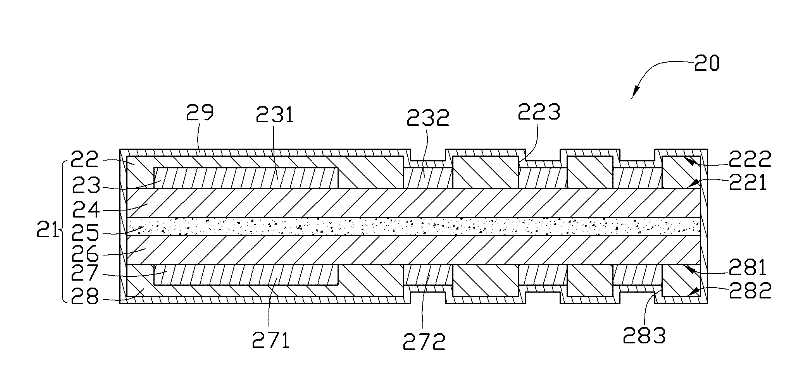

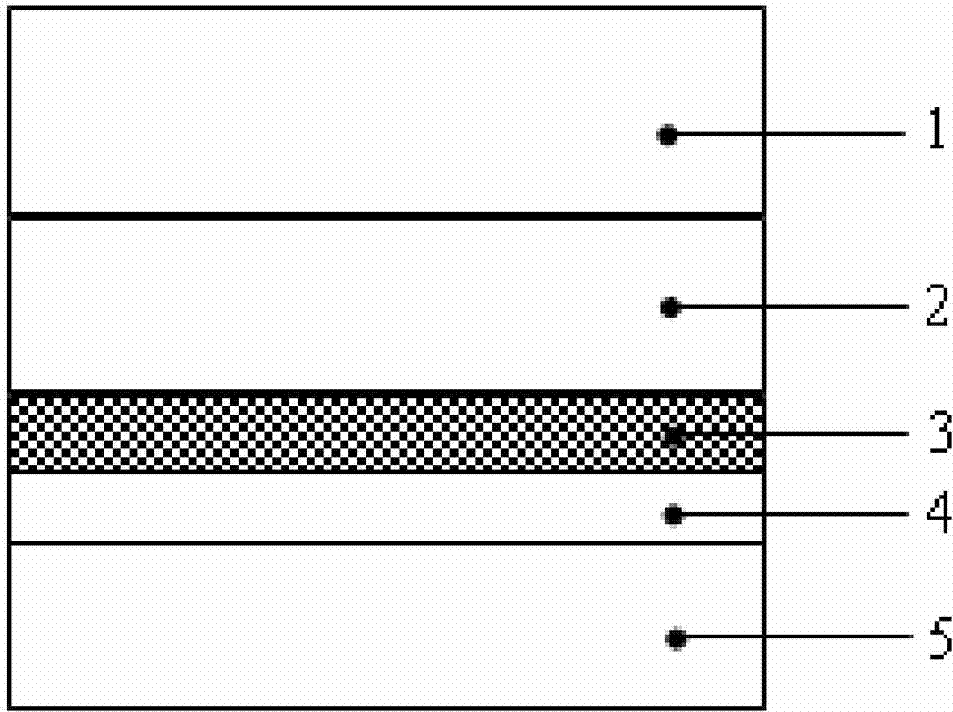

Acid corrosion resistance thin-film solar battery component

InactiveCN103035766ACorrosion freeProtected from external erosionPhotovoltaic energy generationSemiconductor devicesElectrical batteryPhysical chemistry

The invention discloses an acid corrosion resistance thin-film solar battery component which comprises a front panel, a battery layer, an encapsulation film and a back panel, wherein the front panel, the battery layer, the encapsulation film and the back panel are arranged in sequence along the incidence direction of sunlight, and at least one acid corrosion resistance layer is arranged between a back side of the battery layer and the encapsulation film. The at least one acid corrosion resistance is made of colorless, white and / or close-to-white acid corrosion resistance materials which are good in acid resistance and insulation. According to the acid corrosion resistance thin-film solar battery component, the acid corrosion resistance layer is manufactured between the back side of the battery layer and the encapsulation film, can prevent acidic material produced by aging of the encapsulation film from being directly contacted with the battery layer, and protects a battery from corrosion. In addition, the acid corrosion resistance layer is a good insulation protective layer and a first protective layer to protect the battery from corrosion of the outer side, the battery is protected by two layers including the acid corrosion resistance layer and the encapsulation film, and safe and reliable performance is high.

Owner:河北京碳能源有限公司

Steel plate coated with titanium

InactiveCN101078127AImprove protectionNot easy to corrodeWind energy with garvitational potential energyVacuum evaporation coatingSheet steelTitanium ion

The invention provides a protecting film for the aero-generator air tank including the steel plate, metal titanium. The steel plate is put into the vacuum furnace and connected the cathode. The titanium ion is produced by the titanium voltaic arc and bomb the steel plate, so a layer of metal titanium is filtered into the steel plate surface. Compared to the present technology, the titanium is the protecting layer of the steel plate to prevent the steel from corrosion.

Owner:FANGXIA ENTERPRISE INFORMATION CONSULTING WUJIANG

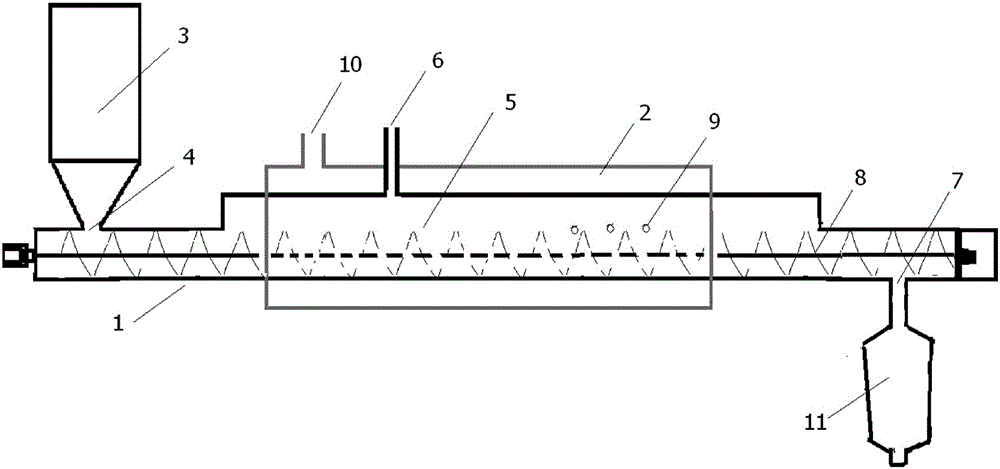

Equipment and method for evaporation recovery of yellow phosphorus from phosphorus mud

The invention provides equipment for evaporation recovery of yellow phosphorus from phosphorus mud. The equipment comprises a spiral conveying evaporator. The inner side of the spiral conveying evaporator is provided with a conveying chamber, which is internally equipped with a conveying blade running through the conveying chamber from head to tail. An upper wall of the spiral conveying evaporator is provided with a projecting chamber, which is an evaporation chamber, and an upper wall of the evaporation chamber is provided an exhaust port. Phosphorus mud with a neutralizer added is conveyed to a phosphorus mud storage container through rotation; the phosphorus mud enters the phosphorus mud evaporation equipment from an inlet of the phosphorus mud storage container and is conveyed to the evaporation chamber through the conveying blade inside the spiral conveying evaporator; yellow phosphorus is recovered in the evaporator through high-temperature evaporation; and evaporation waste residue can be treated through direct burial. Through the equipment, elementary phosphorus can be totally recovered from phosphorus mud. The equipment is well sealed during the whole process and produces no obvious smoke. The phosphorus recovery rate is high, and the residue after yellow phosphorus recovery is harmless.

Owner:瓮安县龙马磷业有限公司

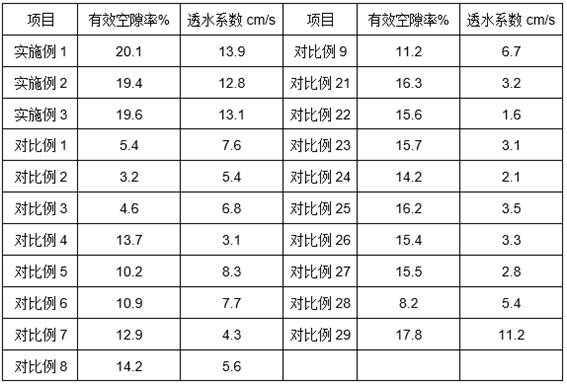

Rapid permeable compressive concrete

PendingCN113501693AHigh compressive strengthFast water permeabilityIn situ pavingsPaving gutters/kerbsAmmonium nitriteCompressive strength

The invention provides rapid permeable compressive concrete and a preparation method thereof. The permeable concrete is prepared into two layers, more stones with small particle sizes are contained in the permeable concrete on the surface layer, more stones with large particle sizes are contained in the permeable concrete on the bottom layer, and rainwater can be filtered and permeated through the special structure. A binder is added to increase the cohesiveness between the framework to improve the compressive strength, meanwhile, the concrete has the effect of a water reducing agent, and sodium nitrate, ammonium nitrite, ethylene glycol and other components have the effect of reducing the freezing point, so that the anti-freezing capacity of the concrete is improved. Modified steel fibers are added to support the concrete, so that the compressive strength of the concrete is improved. A water repellent agent is added into the permeable concrete, so that the contact time and area with water are reduced, water is quickly drained, water in the concrete is reduced, and the compressive strength and water permeability of the concrete are protected.

Owner:抚州市正兴混凝土有限公司

A kind of environment-friendly steel surface antirust agent and preparation method thereof

Owner:珠海大利刀具有限公司

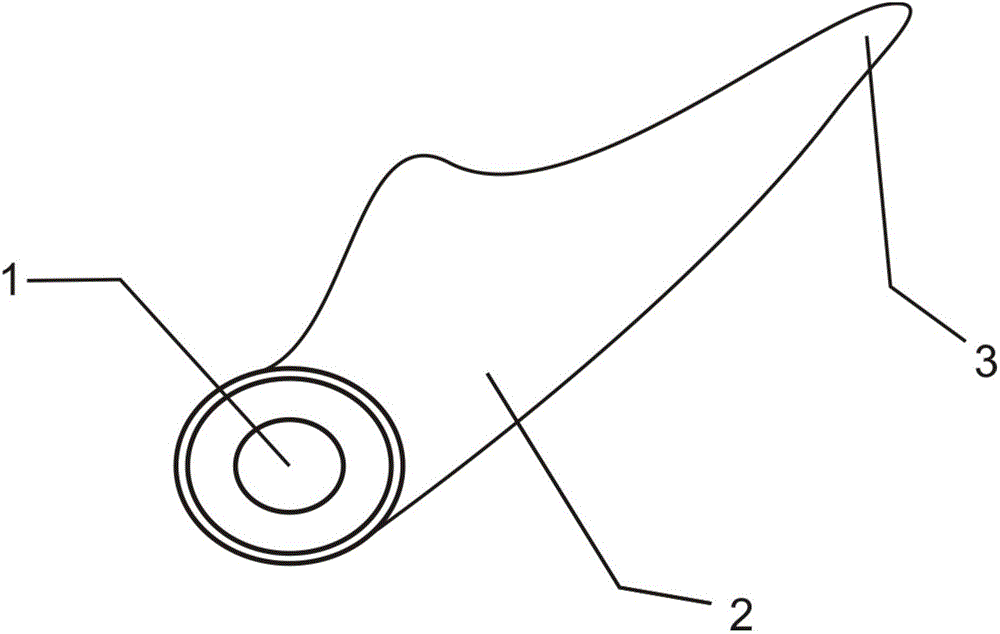

Anti-corrosion wind power generation blade

The invention relates to an anti-corrosion wind power generation blade. The anti-corrosion wind power generation blade comprises a blade body. The blade body comprises a blade inner surface, a blade outer surface and a blade tip part. Each of the blade inner surface, the blade outer surface and the blade tip part is provided with an inflaming retarding coating. Each of the blade outer surface and the blade tip part is provided with an anti-corrosion coating.

Owner:泰州神威新材料科技有限公司

Comprehensive ferment health care nutriment capable of delaying aging and improving human immunity and preparation method thereof

InactiveCN106566759ASolve difficult problems that cannot be maintained in the long runEffectiveOrganic active ingredientsDigestive systemRheumatismPollen

The invention relates to a comprehensive ferment health care nutriment capable of delaying aging and improving human immunity and a preparation method thereof. The nutriment is prepared from the following raw materials in parts by weight: 0.2 to 0.5 part of poria cocos, 0.2 to 0.5 part of Chinese angelica, 0.5 to 1.5 parts of Chinese yam, 1 to 5 parts of wolfberry, 1 to 4 parts of fleece flower root, 0.5 to 2 parts of licorice, 10 to 30 parts of cherokee rose fruit, 10 to 20 parts of pollen, 0.5 to 2 parts of cortex moutan, 1 to 3 parts of dried radix rehmanniae, 0.5 to 1 part of tea, 0.1 to 0.2 part of black fungus, 1 to 3 parts of pig blood, 2 to 8 parts of dorado, 1 to 3 parts of turtle, 5 to 15 parts of orange, 2 to 6 parts of peach, 30 to 50 parts of honey, 5 to 10 parts of brown sugar, and 5 to 20 parts of yeast. The nutriment has the functions of invigorating the spleen, boosting the stomach, dissipating dampness, eliminating rheumatism, enhancing immunity and endurance, preventing virus, relieving fatigue, and strengthening muscles, can effectively improve the micro-circulations of human body, and improves the human immunity.

Owner:WUHAN YUNLAIJI BIO ENG CO LTD

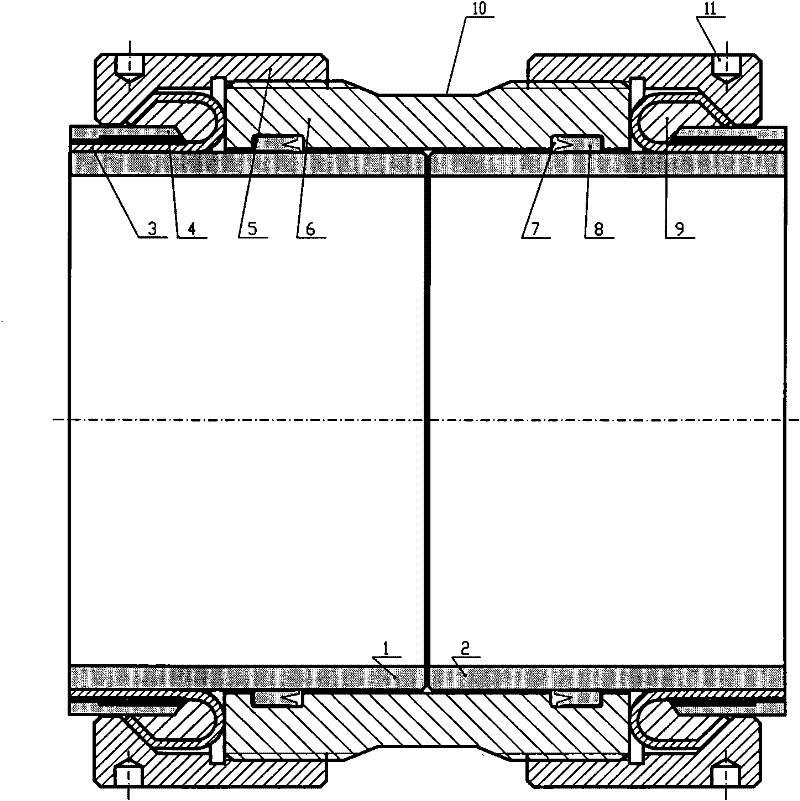

Ultrahigh molecular weight polyethylene composite pipe connector

InactiveCN102242844AGuaranteed uptimeExtended service lifePipe connection arrangementsMechanical engineeringUltrahigh molecular weight polyethylene

The invention discloses an ultrahigh molecular weight polyethylene composite pipe connector, and belongs to the technical field of pipeline connectors. The connector comprises a shrinkage sleeve, a locking nut, a positioning steel sleeve, a sealing ring groove, a sealing ring and a bush; the positioning steel sleeve is placed at the central position of butted faces of two pipe bodies; the annular shrinkage sleeve is arranged at one end of the positioning steel sleeve; the locking nut is arranged outside the positioning steel sleeve, the bush and the shrinkage sleeve; the bush is arranged in an annular cavity formed by the fitting surface of a steel strip and the positioning steel sleeve and the fitting surface of the shrinkage sleeve and the locking nut; and the steel strip wraps the outer end faces of the bush and the positioning steel sleeve and is fitted with the inside surface of the locking nut. The inside surface of the positioning steel sleeve is provided with an anticorrosive layer. The inside surface of the locking nut is step-shaped. The bearing capacity of the connector can reach 16MPa, bearing of pressure of 8MPa is kept, the cost can be reduced by 10 percent, and the work efficiency can be improved by 3 to 5 times; and the ultrahigh molecular weight polyethylene composite pipe connector ensures the safety and the reliability of pipeline operation and has long service life.

Owner:JIANGSU SHENSHI NEW MATERIAL TECH

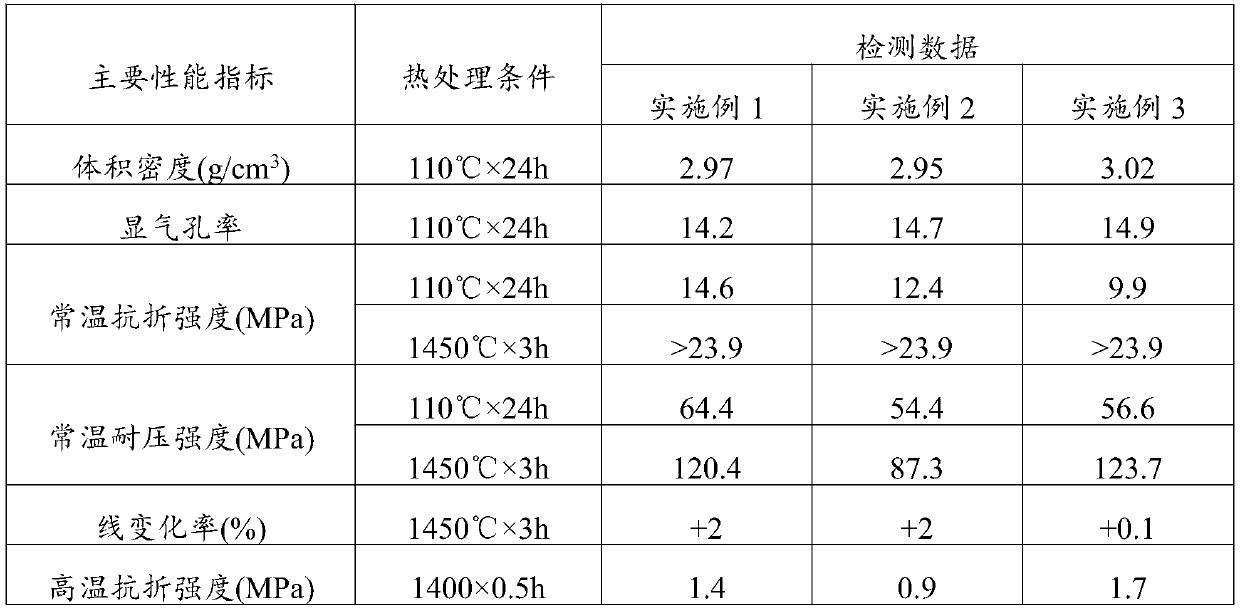

Gunning mix and preparation method thereof

The invention relates to the technical field of refractory materials, in particular to a gunning mix and a preparation method thereof. The gunning mix comprises the following components in parts by mass: 60-65 parts of brown fused alumina, 13-16 parts of silicon carbide, 13-15 parts of a binding agent, 5-6 parts of an antioxidant, 0.05-0.1 parts of fibers and 0.05-0.15 parts of a water reducing agent. The gunning mix developed by the invention is used under the condition of an iron runner and a hot runner, is free of baking, cracking and stripping, and is resistant to erosion of molten iron and iron slag. The gunning mix is short in construction time, low in labor intensity of workers, free of dust and peculiar smell during construction and significant to environmental protection, synergyand the like in the steel industry.

Owner:北京利尔高温材料股份有限公司

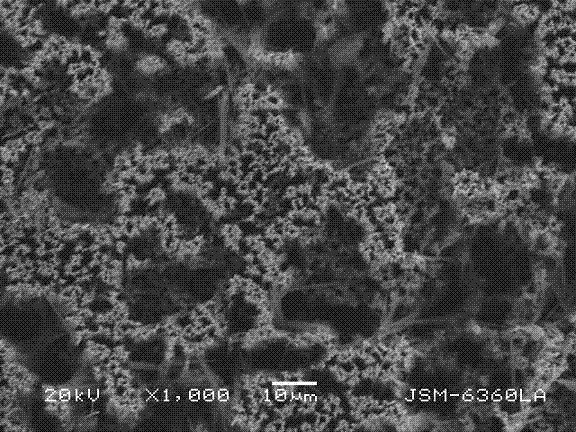

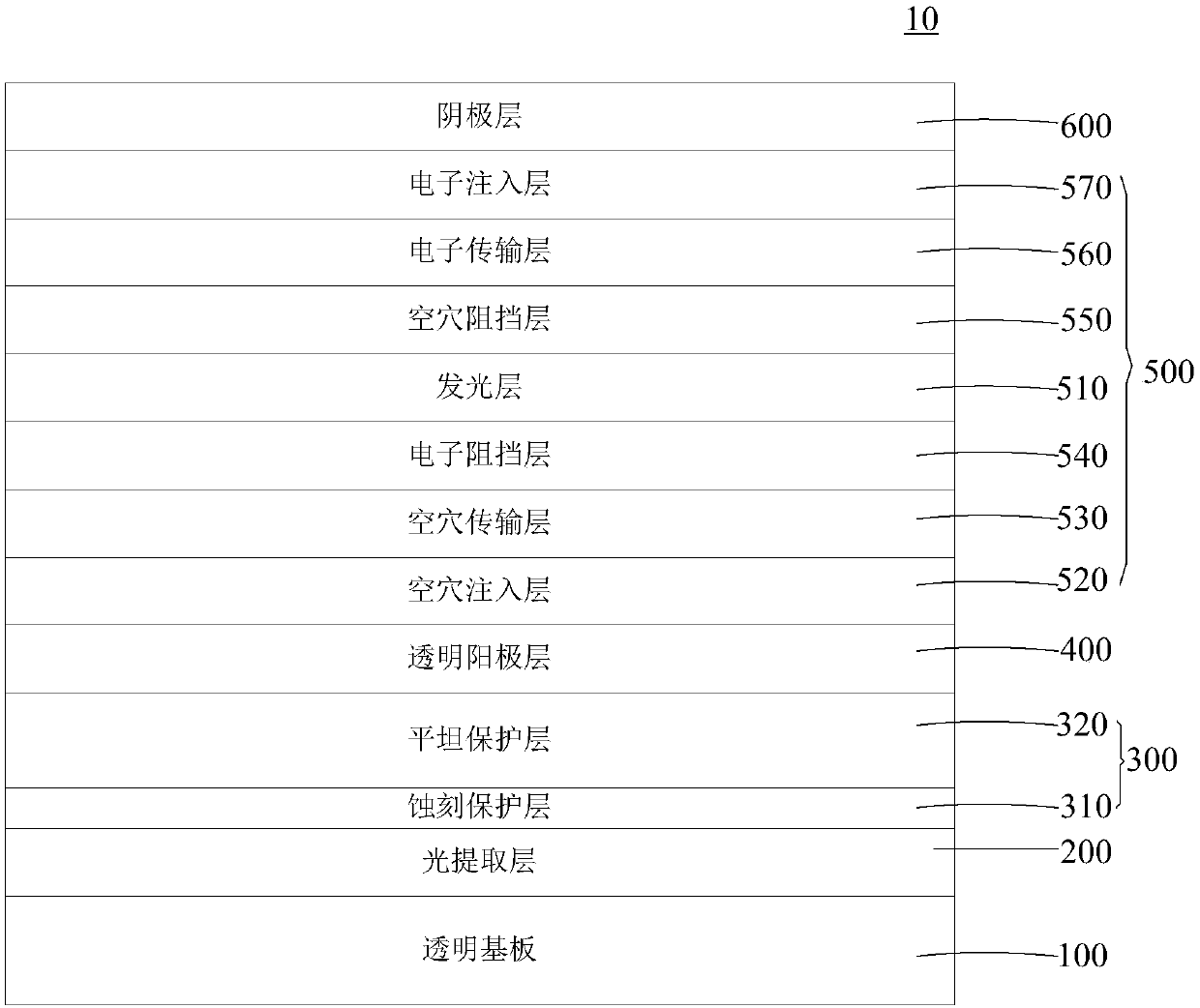

Optical antireflection structure, bottom emission electroluminescent device and preparation method

The invention relates to an optical antireflection structure, an electroluminescent device and a preparation method. The light extraction layer of the optical antireflection structure is prepared by aBi2O3 material which has a forbidden bandwidth of 2.8eV to 3eV, little absorption and high transmittance in a visible light region, and a high refractive index. For different preparation processes, the refractive index is generally from 1.8 to 2.2. When formed into a film, the Bi2O3 material is likely to form a rough surface where small particles protrude such that the surface of the light extraction layer has certain roughness. The particle protrusions of the rough surface can be used as a scattering unit to enhance the diffusion of light, reduce total reflection, and increase a light extraction rate. Therefore, the light extraction efficiency can be improved by inserting the Bi2O3 light extraction layer between a transparent anode layer and a transparent substrate. The Bi2O3 light extraction layer can be prepared by spin coating, magnetron sputtering or deposition, and is simple in process, low in cost is low, and good in film forming property.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

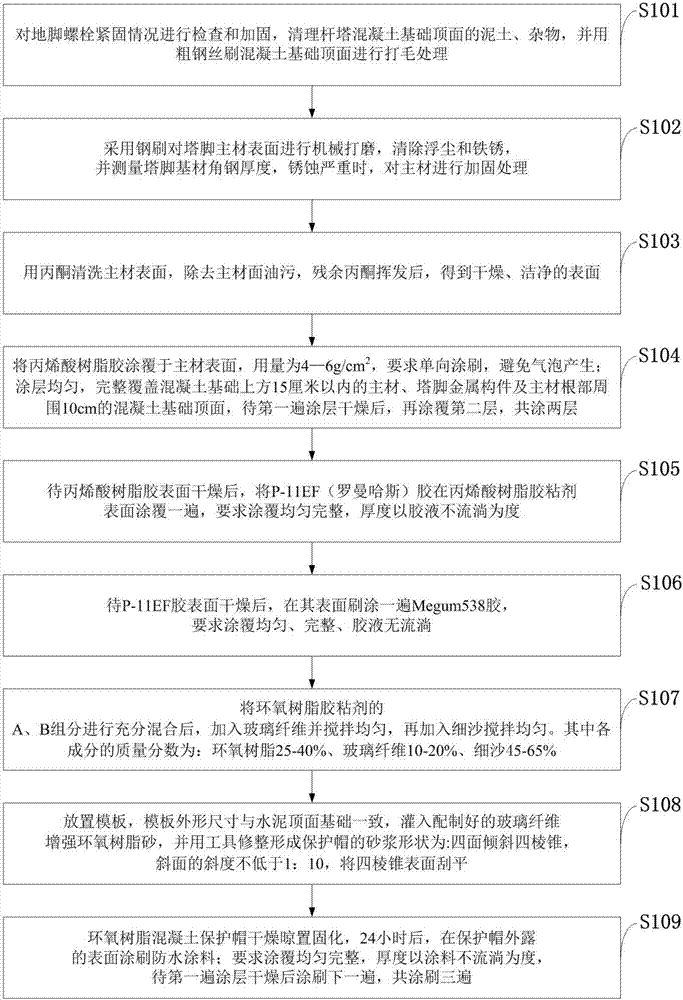

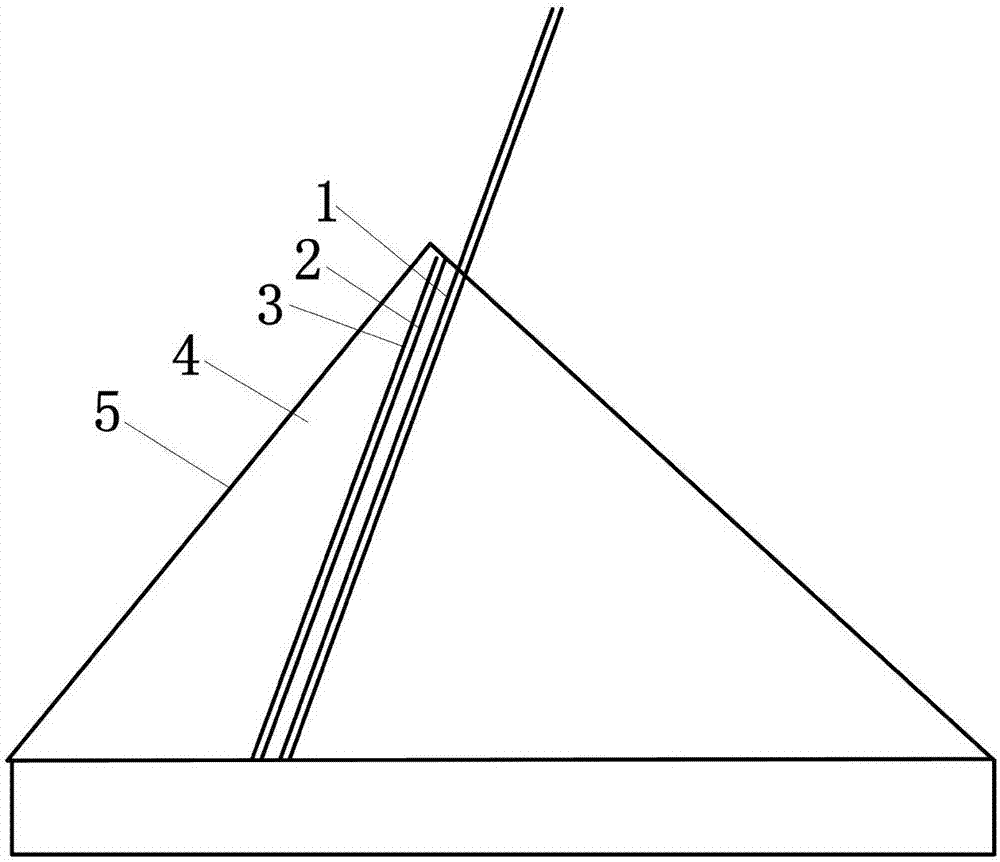

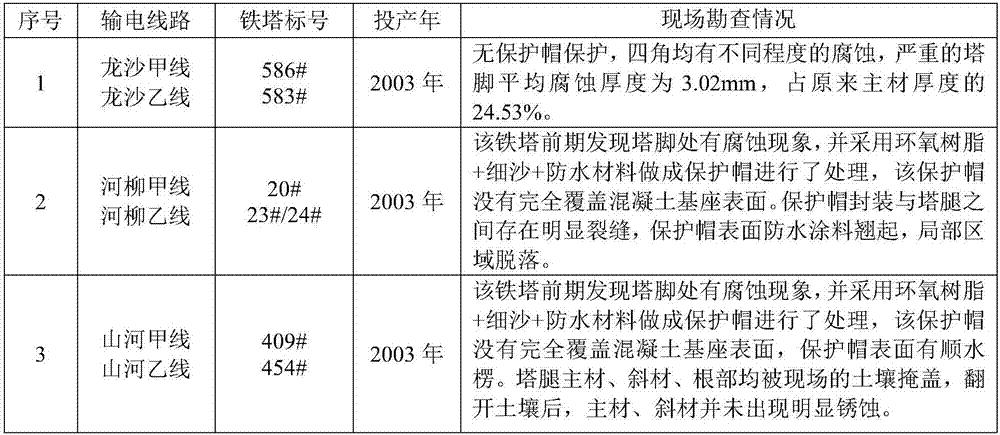

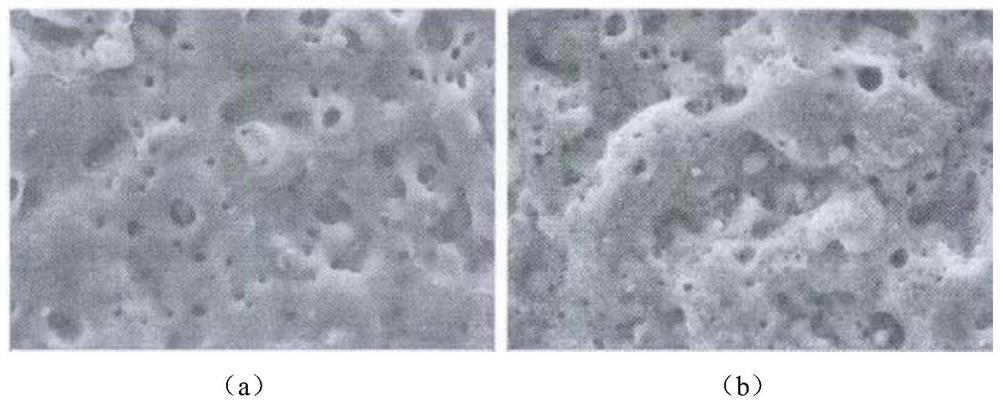

Method for manufacturing long-life anticorrosion structure for root of principal material of transmission tower

The invention belongs to the technical field of metallic material anticorrosion and discloses a method for manufacturing a long-life anticorrosion structure for the root of a principal material of a transmission tower. The position between a protection cap and a tower foot base material is coated with transition coatings; the surface of the tower foot base material is sequentially provided with acrylic resin, Rohm and Haas glue, Megum538 glue, epoxy resin concrete and waterproof anti-seepage coating from inside to outside; and the outer surface of the protection cap is coated with anti-seepage coating. The protection scheme of the acrylic resin, the Rohm and Haas glue, the Megum538 glue, the modified epoxy resin concrete and the waterproof anti-seepage coating is adopted, and thus the tower foot base material can be well protected; through a transition layer of the acrylic resin, the Rohm and Haas glue and the Megum538 glue, the bonding strength between the protection cap and the tower foot base material is improved; and through the design of the inverted-water-edge contour of the protection cap, deposition of rainwater on the protection cap can be effectively avoided, and the phenomenon that due to long-time rainwater erosion, bubbling of the waterproof anti-seepage coating on the outer layer of the protection cap is avoided.

Owner:中国南方电网有限责任公司超高压输电公司柳州局

A kind of wear-resistant material and preparation method thereof

The invention discloses a wear-resistant material, in which aluminum nitride, aluminum oxide, molybdenum disilicide, and graphite powder particles are evenly distributed in an aluminum alloy matrix, and a composite micro-arc oxidation layer is distributed on the surface of the aluminum alloy matrix, aluminum nitride, oxide Aluminum and molybdenum disilicide have high hardness, which can significantly improve the hardness and wear resistance of the material, and graphite powder can improve friction reduction. The composite micro-arc oxidation layer on the surface can effectively improve the wear resistance and corrosion resistance of the alloy surface. Sn, Ru, Sr, Lu, Cu, Mn, Mg, Mo, Fe and other elements in the alloy strengthen phase dispersion strengthening to improve the mechanical properties of the material. In the preparation method, the mixed powder is adhered to the pure aluminum wire, so that the mixed powder is located in the center of the master alloy liquid during casting, which is conducive to the rapid diffusion and homogeneity of the micro-powder particles, improves production efficiency, and optimizes the parameters of micro-arc oxidation film formation And conditions, improve the hardness and smoothness of the oxide ceramic film, reduce the film thickness, and effectively improve the wear resistance of the material.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

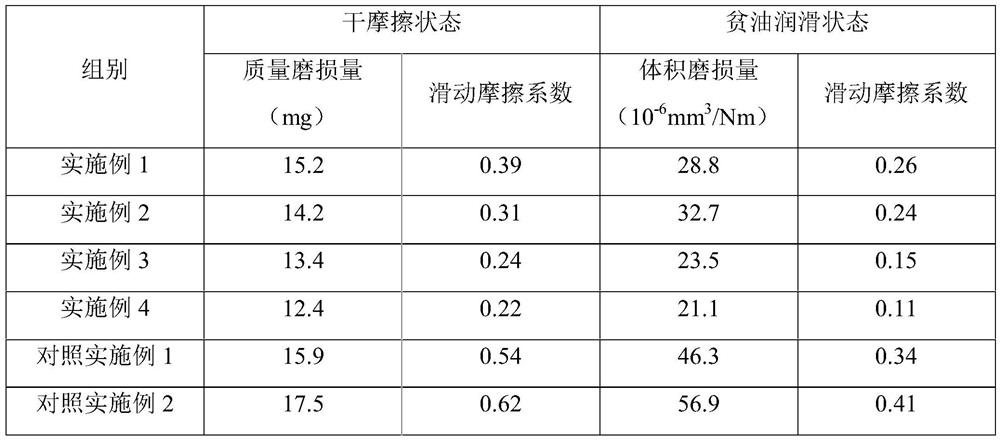

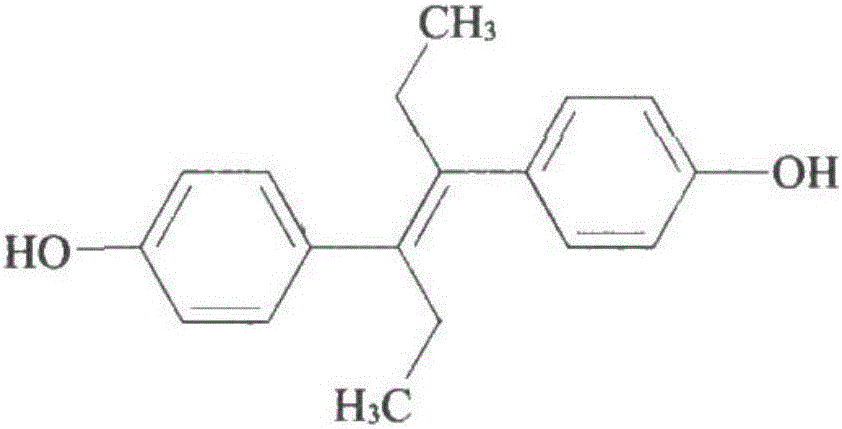

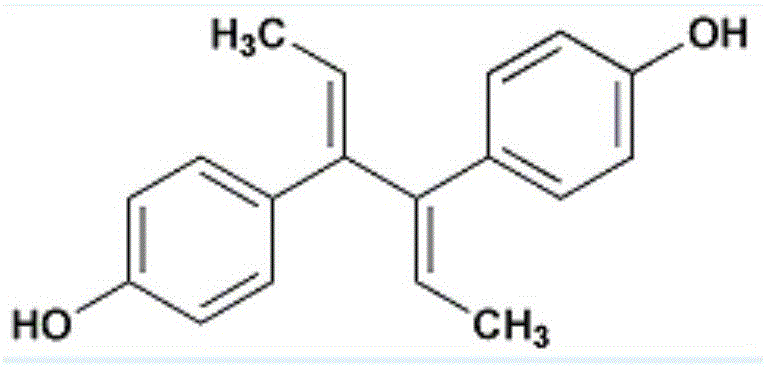

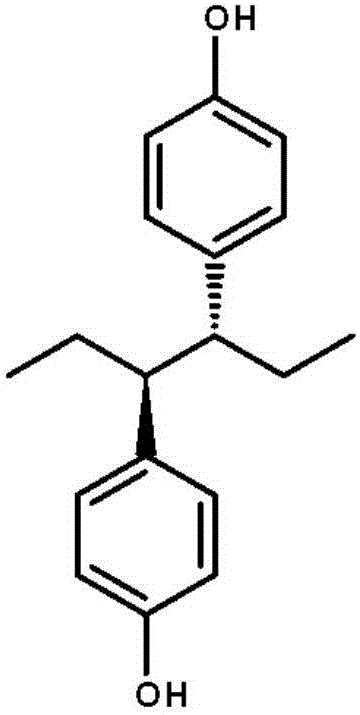

Diethylstilbestrol, diethylstilbestrol and hexestrol standard sample in rabbit meat, preparation method and application

InactiveCN106404492AExtended shelf lifeCorrosion freePreparing sample for investigationFreeze-dryingAntioxidant

The invention provides a diethylstilbestrol, diethylstilbestrol and hexestrol standard sample in rabbit meat, a preparation method and application, and belongs to the technical field of analytical chemistry. A rabbit is fed with feedstuff containing diethylstilbestrol, diethylstilbestrol and hexestrol, so that tissues in the body of the rabbit contains the diethylstilbestrol, the diethylstilbestrol and the hexestrol, after administration is finished, the rabbit is killed, and muscles of the rabbit are taken, are homogenized and homogenized, are processed into meat paste, are freeze-dried under vacuum, and are sieved, bottled and packed to obtain a rabbit meat standard sample containing the diethylstilbestrol, the diethylstilbestrol and the hexestrol. By the method, the problems that a target object and matrix combination situation is not completely consistent to a real detecting sample, so that treatment results of extracting, purifying and the like are quite different from daily analysis samples are solved. The standard sample is a material standard sample, is uniform and stable, does not contain a preservative or an antioxidant, is easy to store, and is used for proficiency testing of a non-steroidal anabolic hormones drug residue testing item, verification of a detecting method, calibration of a testing instrument, and quality control and assessment of a testing result.

Owner:辽宁省检验检疫科学技术研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com