Technological process for catalyzing dry gas to prepare ethylbenzene

A process flow and dry gas technology, applied in the fields of organic chemistry, hydrocarbons, hydrocarbons, etc., can solve the problem that the catalyst can never be in contact with the gas phase, the density of the packing spray cannot be too high, and the energy utilization of the device is not reasonable. and other problems, so as to achieve the effect of preventing pipeline corrosion, reducing load and saving energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The characteristics and positive effects of the present invention can be manifested from the following application examples.

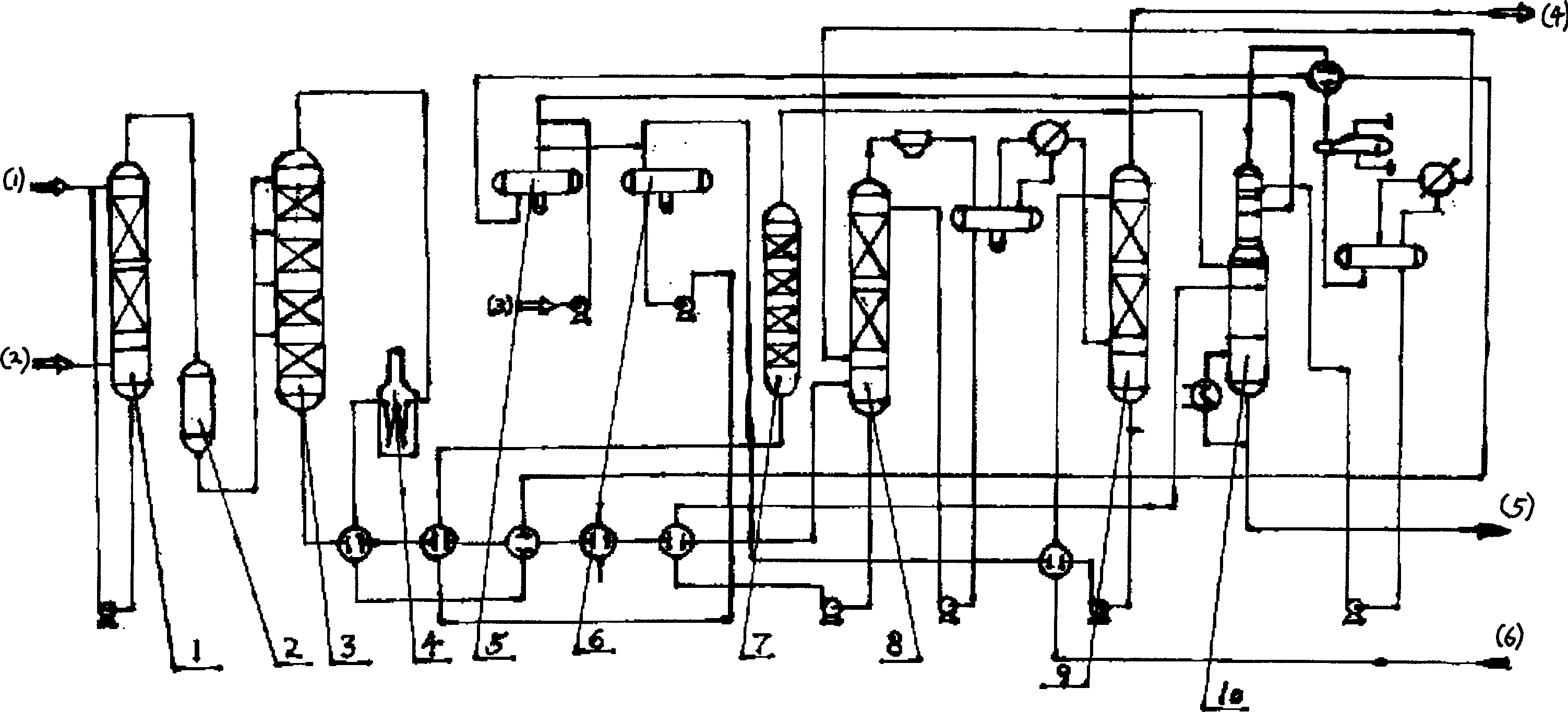

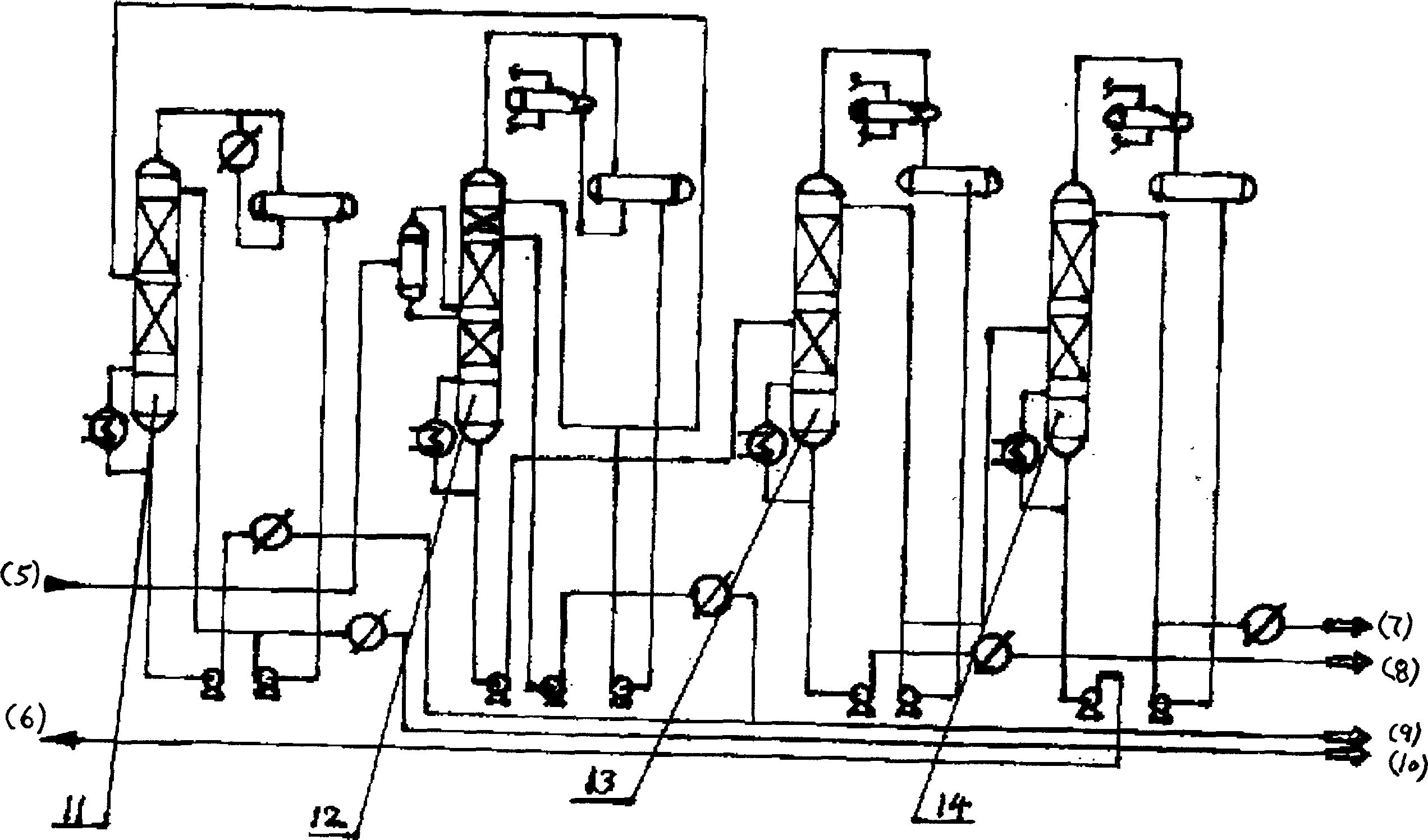

[0065] The invention includes a reaction part, an absorption part and a product separation part, and is characterized in that: the catalytic dry gas is eluted out of MDEA through a water washing tower (1) and then enters into a dry gas separator tank (2) and enters an alkylation reactor (3) in four ways The reactant enters the crude separation tower (8) after heat exchange, and the anti-alkylation material comes from the absorption tower (9), mixes with benzene and enters the anti-alkylation reactor (7) for reaction, and the reaction product is mixed with the crude The material at the bottom of the sub-tower (8) enters the benzene tower (10) respectively. The hydrocarbonation reaction product is cooled to 100-150°C through a series of heat exchanges and then enters the crude fractionation tower (8). The oil and gas at the top of the tower is par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com