Acid corrosion resistance thin-film solar battery component

A solar cell, acid corrosion-resistant technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of lack, insufficient anti-ultraviolet aging ability of epoxy resin, unable to meet long-term use, etc., and achieve the effect of high safety, reliability and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

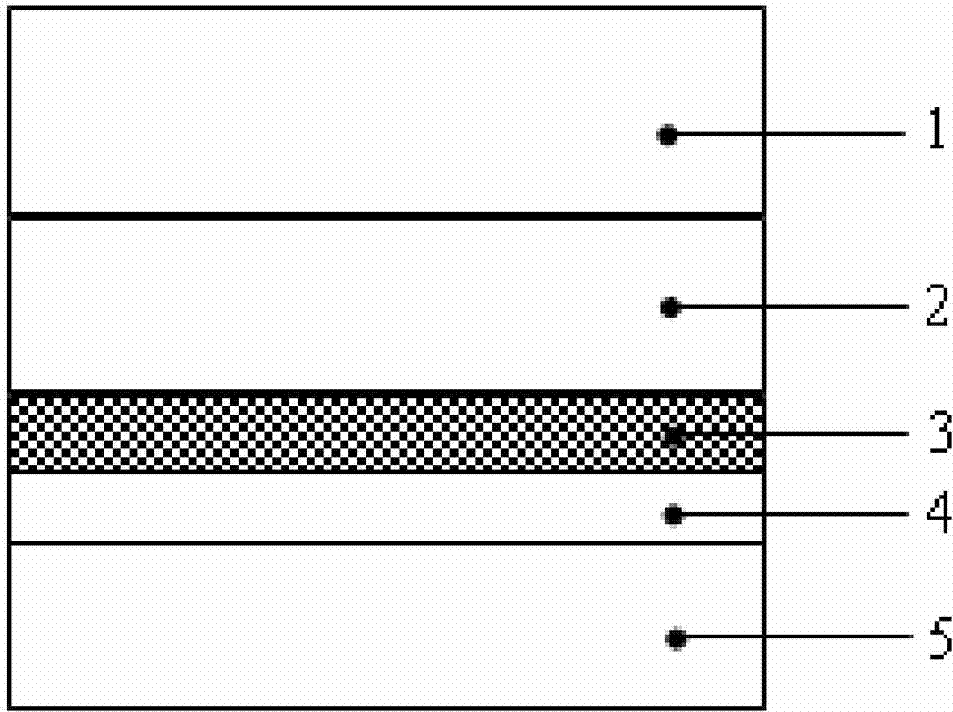

[0019] See attached figure 1 The thin-film solar cell is provided with a front plate 1, a battery layer 2, an acid-resistant corrosion layer 3, a transparent PVB film (ie, an encapsulation film 4) and a back plate 5 sequentially from the direction of sunlight incidence. On the battery layer 2, a layer of acid-resistant corrosion layer 3 is evenly printed by screen printing method. The thickness of the acid-resistant corrosion layer 3 after curing is 25 microns, and the material is phenolic resin. The packaging film 4 and the back plate are covered on the acid-resistant layer 3. 5. Encapsulate the batteries together by lamination process.

[0020] After the completion of the production, compared with the solar cell modules without the acid-resistant corrosion layer, it was found that the solar cell modules with the acid-resistant corrosion layer passed the 1000h damp heat accelerated aging test, and the bus bar of the battery was observed to be free from looseness and corrosion...

Embodiment 2

[0022] The acid corrosion resistant material phenolic resin of the acid corrosion resistant layer 3 in embodiment 1 is replaced with white or nearly white acid resistant ash or porcelain powder, quartz powder, kaolin, and its parts by weight are in the range of 10-50 parts, and the film-forming material is selected ring Oxygen resin, the parts by weight are 50-90 parts, the thickness of the acid corrosion-resistant layer is in the range of 10-500 microns, and the solar cell modules made according to the same method are subjected to 200 thermal cycle aging tests, and the power decay ratio is higher than that of the acid-resistant corrosion-resistant Layer components are 1.5% lower.

Embodiment 3

[0024] Mix acid-resistant ash and film-forming material silicone resin according to the ratio of 25 and 75 parts by weight respectively, and obtain an acid-resistant film with a thickness of 200 microns through a film-making process, and apply this acid-resistant film to copper indium selenium thin film solar cells In the encapsulation structure of the solar cell module, after 1000h of damp heat aging test, the power decline is 1.5% lower than that of the module without the acid corrosion-resistant film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com