Method for manufacturing long-life anticorrosion structure for root of principal material of transmission tower

A technology for transmission towers and manufacturing methods, which is applied in the field of metal material anticorrosion, can solve problems such as interface cracking, main material tower foot metal corrosion, and main material corrosion, and achieve good water conduction, excellent crack resistance, and long anti-corrosion life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

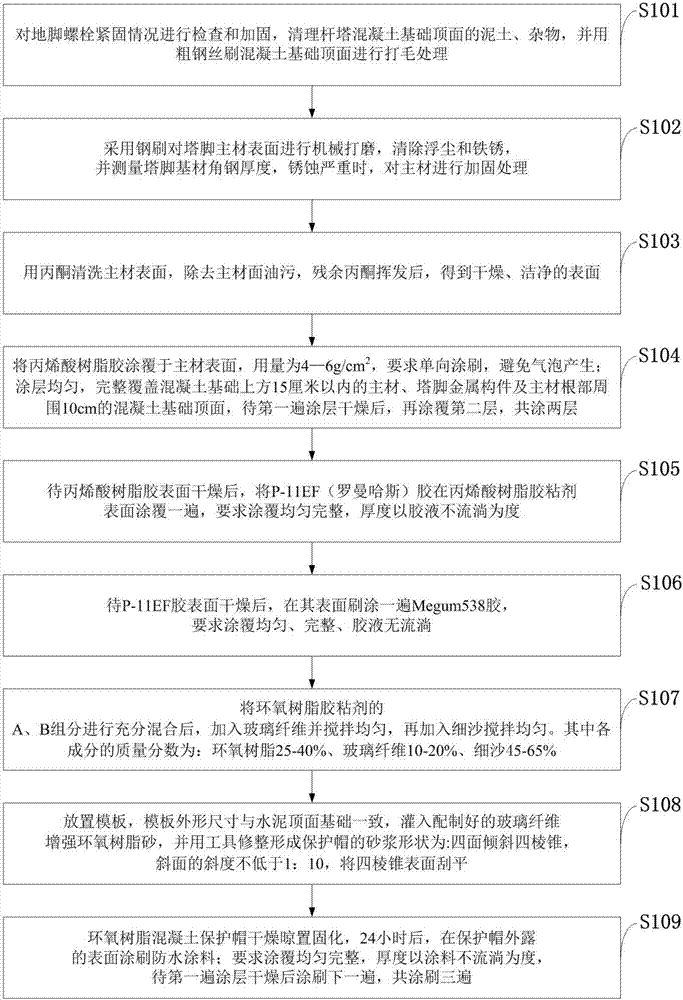

[0061] Transition layer production process

[0062] (1) Before the production of the transitional layer, the construction unit must take photos and video materials for the handover of production acceptance and inspection of excellence work.

[0063] (2) Before the transition layer is made, the fastening of the anchor bolts must be checked. If they are not fastened, they must be fastened in time. The main material bolts at the foot plate of the tower must be installed with anti-theft nuts and fastened according to the design requirements. At the same time, clean up the soil and debris on the top surface of the foundation.

[0064] (3) Remove the rusted part on the surface of the base material of the tower foot, and measure the thickness of the angle steel of the base material of the tower foot. If the corrosion is serious, the base material of the tower foot needs to be reinforced.

[0065] (4) Clean the rusted parts with acetone to remove the oil on the surface.

[0066] (5)...

Embodiment 2

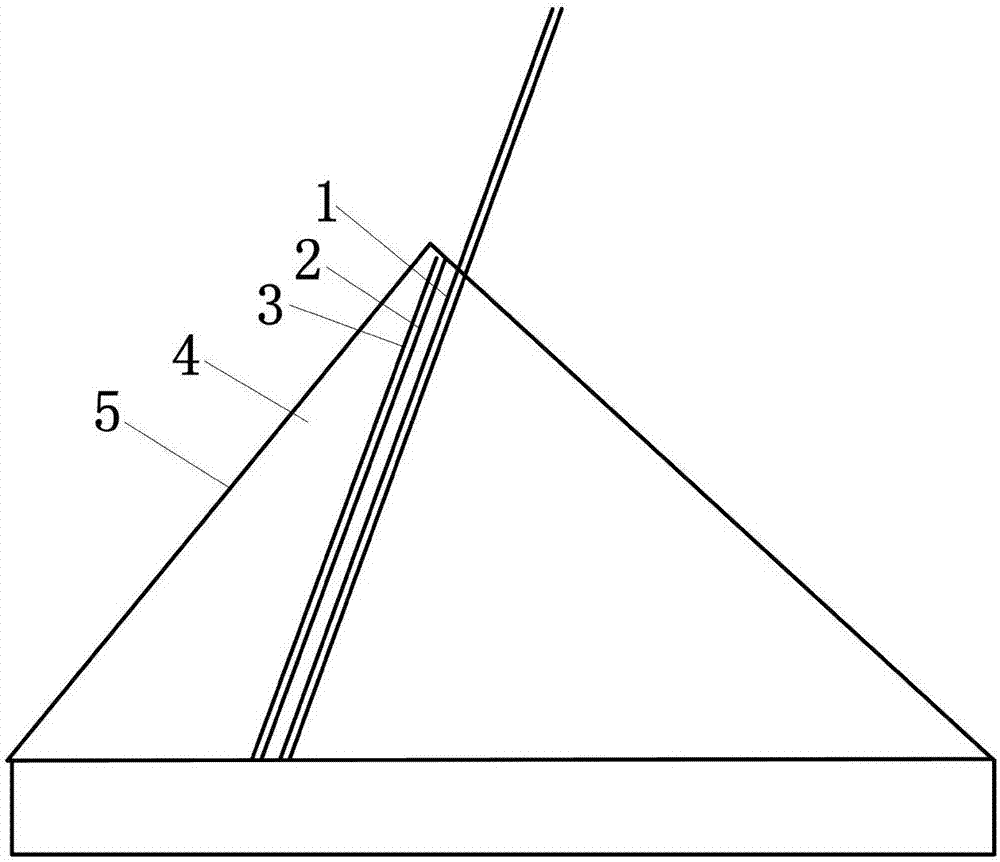

[0070] Protective cap production process

[0071] (1) On a clean glass plate, fully stir and mix the epoxy resin A and B component adhesives according to the volume ratio of 1:1, let it air for 1 minute, add glass fiber and stir evenly, and then add fine powder The sand is stirred evenly (fine sand cannot contain moisture and cannot contain soil), wherein the volume fraction of each component is: the volume fraction of the epoxy resin concrete component is: epoxy resin 25%-40%, glass fiber 10%-20 %, fine sand 45%-65%;

[0072] (2) The template for making the protective cap should be a clean steel template or wooden mold with suitable specifications.

[0073] (3) The bottom plate of the tower leg and the anchor bolts are completely covered by the protective cap and must not be exposed. The width of the protective cap is consistent with the concrete foundation, and the height shall not be less than 250mm.

[0074] (4) The top surface of the protective cap cannot be a plane, an...

Embodiment 3

[0080] Anti-seepage coating production process

[0081] Use a brush to apply commercial anti-seepage paint on the outer surface of the protective cap. The coating is required to be uniform and complete. The thickness of the coating is appropriate so that the anti-seepage paint does not flow downward. After the paint is dry, carry out the next pass, a total of three times.

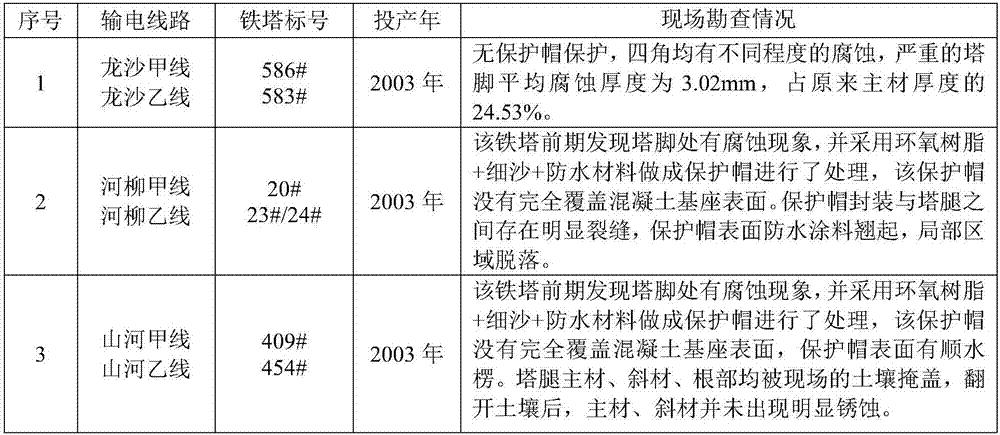

[0082] Table 2 Materials used for protective coatings and protective caps

[0083] material name

model

Manufacturer

Remark

Acrylic

Yicai DIY series

Wenzhou Yicai Car Accessories Co., Ltd.

Roman Haas glue

P-11EF

Shanghai Chuming Chemical Technology Co., Ltd.

Megum538 glue

Megum538

Shanghai Chuming Chemical Technology Co., Ltd.

Epoxy glue (Part A)

HZ8801

Nanjing Haozhuo Material Technology Co., Ltd.

Curing agent (Part B)

HZ8801

Nanjing Haozhuo Material Technology Co., Ltd.

Waterproof and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com