Gunning mix and preparation method thereof

A technology of gunning material and binder, applied in the field of refractory materials, can solve the problems of high labor intensity, long construction time, large amount of dust, etc., and achieve the effect of low labor intensity and short construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a preparation method of gunning material, comprising the following steps:

[0037] (1) Brown corundum and binder are mixed to obtain the first mixture;

[0038] (2) Mix the first mixture, silicon carbide, antioxidant, fiber and water reducer to get the gunning material.

[0039] In the present invention, in the step (1), it is preferable to first pour the brown corundum into the sand mixer and mix for 20-40 seconds, and then mix the brown corundum and the binder for 20-40 seconds, and the mixing time is further preferably 25-35 seconds, more preferably More preferably, it is 30s.

[0040] In the present invention, the mixing time in the step (2) is preferably 1-3 minutes, more preferably 1.5-2.5 minutes, even more preferably 2 minutes.

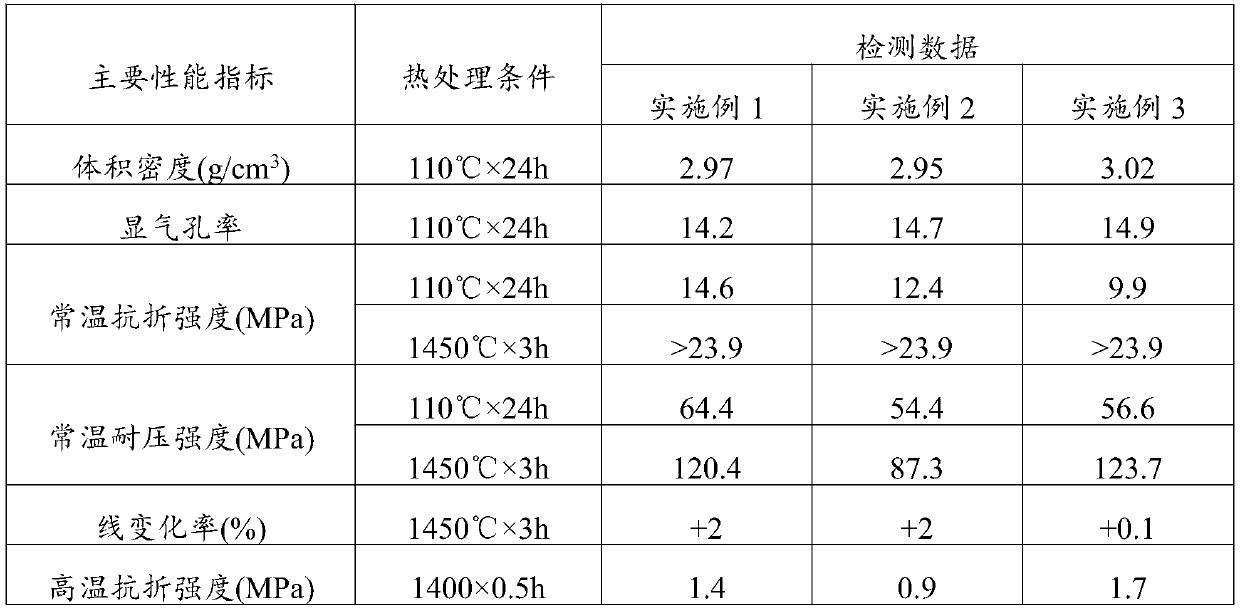

Embodiment 1

[0043] Take 30 parts of brown corundum with a particle size of 0-1mm, 35 parts of brown corundum with a particle size of 1-3mm, 17 parts of silicon carbide, 6 parts of alumina powder with a particle size of 2-4μm, 3 parts of spherical pitch, 5 parts Cement, 0.1 part of metal silicon powder, 4.5 parts of zirconium silica fume, 0.05 part of polypropylene fiber, 0.1 part of polycarboxylate superplasticizer. Pour brown corundum into the sand mixer in proportion and mix for 30 seconds, then add alumina powder, spherical asphalt and cement and mix for 30 seconds, and finally put silicon carbide, metal silicon powder, zirconium silica fume, polypropylene fiber and water reducer into the mixer Mix in medium for 2 minutes, stir evenly and pack into bags.

Embodiment 2

[0045] Take 27 parts of brown corundum with a particle size of 0-1mm, 38 parts of brown corundum with a particle size of 1-3mm, 18 parts of silicon carbide, 5 parts of alumina powder with a particle size of 2-4μm, 3 parts of spherical pitch, and 5 parts Cement, 0.1 part of metal silica fume, 4 parts of zirconium silica fume, 0.05 part of polypropylene fiber, 0.1 part of polycarboxylate superplasticizer. Pour brown corundum into the sand mixer in proportion and mix for 30 seconds, then add alumina powder, spherical asphalt and cement and mix for 30 seconds, and finally put silicon carbide, metal silicon powder, zirconium silica fume, polypropylene fiber and water reducer into the mixer Mix in medium for 2 minutes, stir evenly and pack into bags.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com