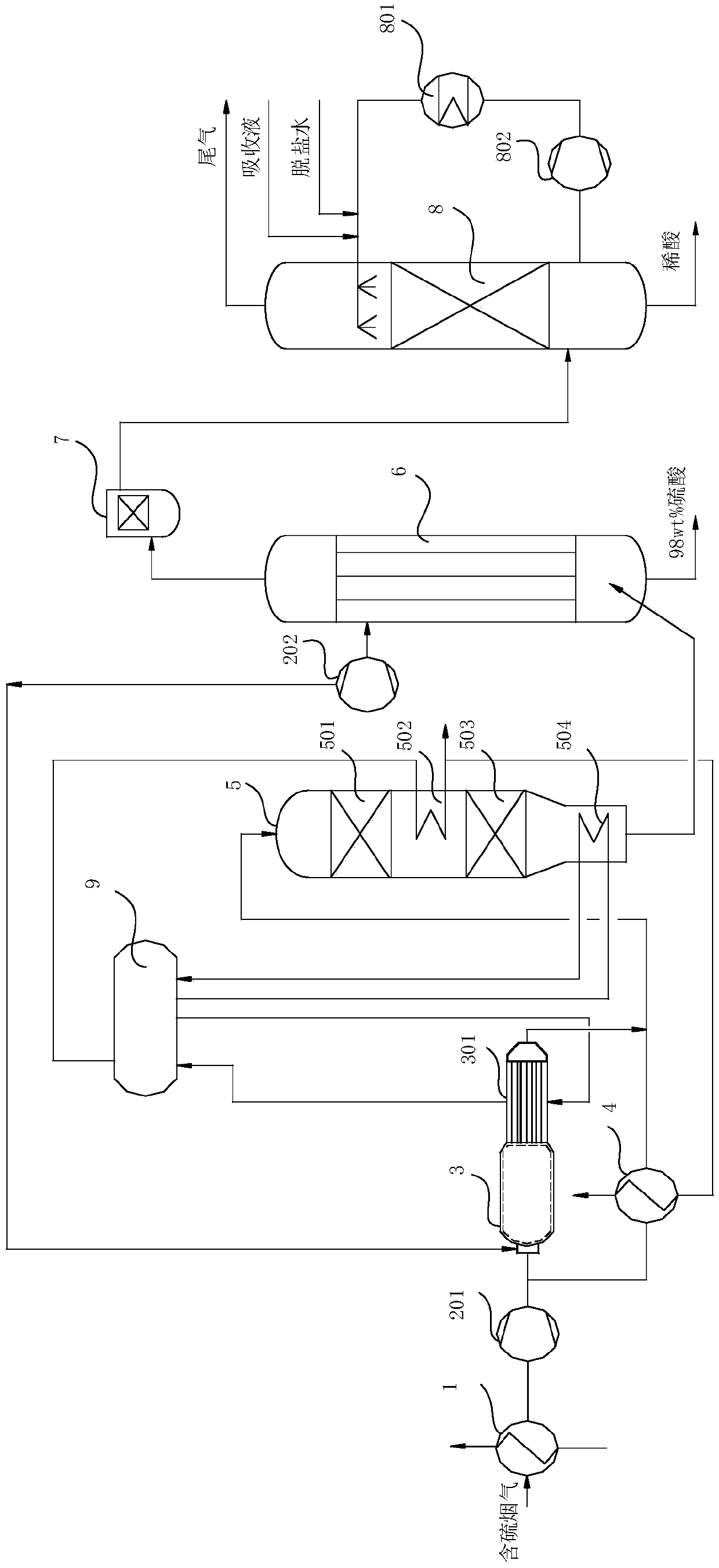

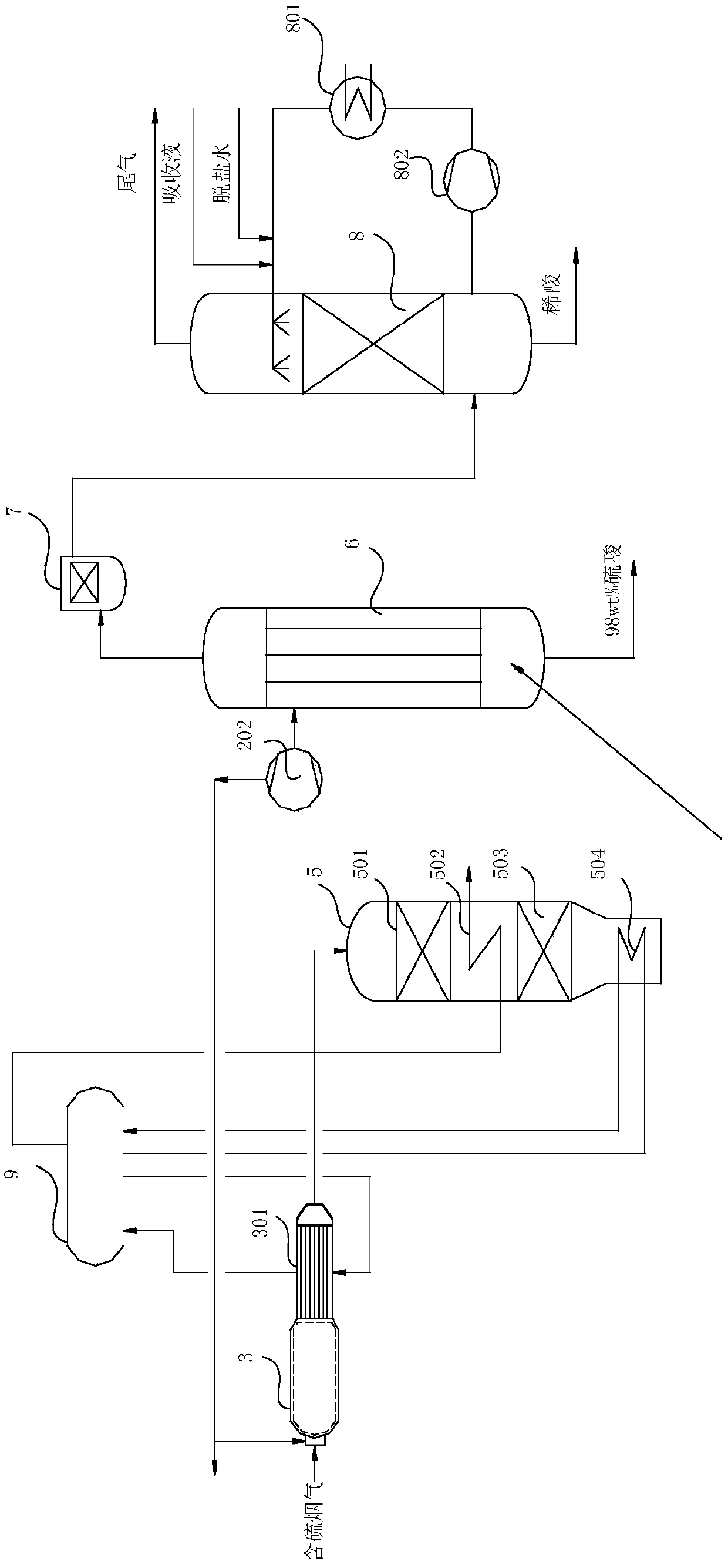

Technical system and technical method for converting sulfur-containing exhaust gas into sulfuric acid

A technology of process system and process method, which is applied in the field of smelting sulfur-containing flue gas treatment, can solve the problems of high energy consumption and large corrosion of equipment, and achieve the effects of reducing energy consumption, avoiding corrosion, and ensuring long-term operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Flue gas composition: 2% SO 2 , 15.5% O 2 , 3.6% CO 2 , 77.5%N 2 , 1.4%H 2 O, said percentage is mole percentage.

[0061] Such as figure 1 Shown, SO 2 Convert SO 3 The active ingredient of the catalyst is mostly V 2 o 5 . Because the sulfur-containing flue gas needs to reach a certain reaction temperature before entering the catalyst. The flue gas preheating in the front stage, the heat of flue gas preheating comes from the heat generated by the condensation of sulfuric acid first, and the heat generated by the waste pot and the heat released by each reaction bed can also be used later. The specific process is shown in the attached drawing.

[0062] After the front-end chilling and dust removal, cooling and purification, the low-concentration smelting sulfur-containing flue gas (hereinafter collectively referred to as acid process gas) enters the cold end inlet of flue gas preheater 1 to preheat the acid process gas to 165°C. The hot end of the flue gas pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com