Circuit board and manufacturing method thereof

A technology of circuit boards and circuit substrates, applied in multilayer circuit manufacturing, printed circuit components, secondary treatment of printed circuits, etc., can solve the problems of copper surface oxidation, not longer, moisture absorption of insulating material layer, etc., and achieve weather resistance Good, low surface energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The circuit board provided by the technical solution and its manufacturing method will be further described in detail below in conjunction with the accompanying drawings and multiple embodiments.

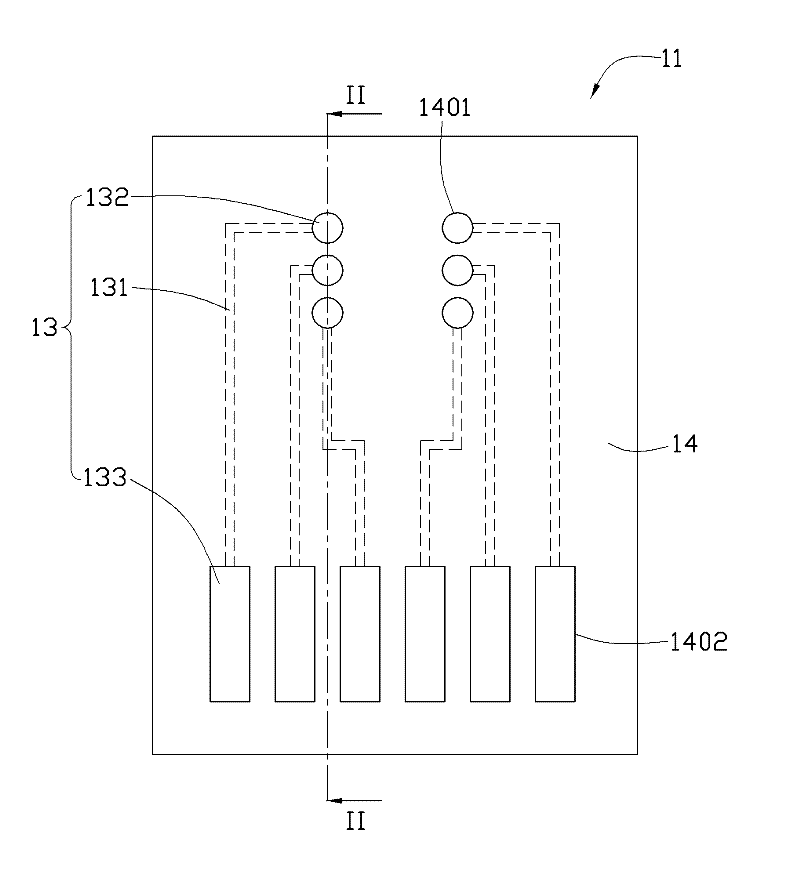

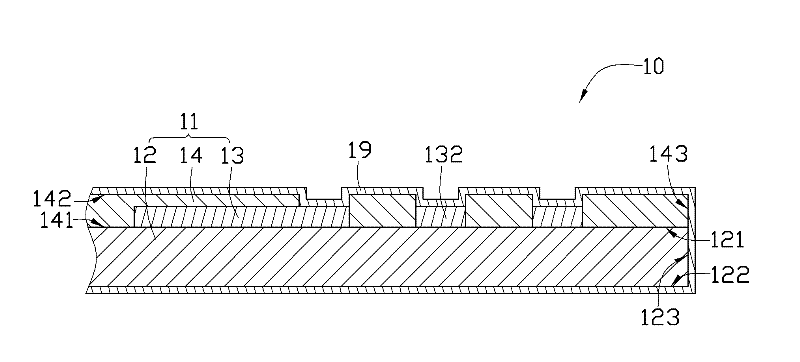

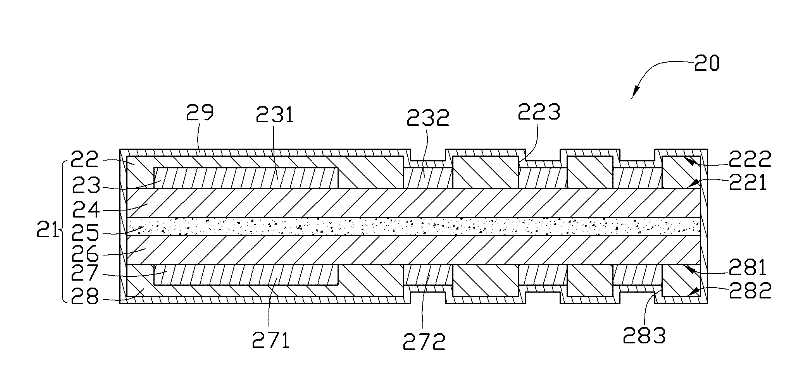

[0067] Please also refer to figure 1 and figure 2 , The circuit board 10 provided by the first embodiment of the technical solution includes a circuit substrate 11 and a fluorocarbon film 19 . The circuit substrate 11 includes a substrate 12 , a circuit layer 13 and a protection layer 14 stacked in sequence.

[0068] The base 12 can be a single-layer structure or a multi-layer structure. The single-layer structure refers to a structure including only one insulating layer. The multi-layer structure refers to a structure including at least one insulating layer and at least one conductive layer. The insulating layer can be a hard resin layer, such as epoxy resin, glass fiber cloth, etc., or a flexible resin layer, such as polyimide (Polyimide, PI), polyethylene terephthalat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com