Fiber composite core stranded metal wire sucker rod and preparation method and application thereof

A technology of fiber composite material and metal wire, which is applied in the direction of drill pipe, earthwork drilling, drilling equipment, etc., can solve the problems of poor corrosion resistance and impact resistance of sucker rods, large damage of sucker rods, and influence on use and promotion, etc., to achieve Excellent impact resistance, improve service life, and improve the effect of impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] As mentioned above, although the carbon fiber sucker rod has better flexibility, the composite sucker rod with a single structure also has the problems of poor corrosion resistance and poor impact resistance; moreover, it has a large impact on the well wall during operation. The damage to the sucker rod is relatively large. Therefore, the invention provides a fiber composite material core stranded metal wire sucker rod and a preparation method thereof.

[0027] In some typical embodiments, in the rigid layer, the fiber filaments are high modulus carbon fibers, or high modulus carbon fibers mixed with glass fibers and / or inorganic ceramic fibers.

[0028] Further, the inorganic ceramic fiber includes: any one of alumina fiber, silicon carbide fiber, boron carbide fiber, basalt fiber, quartz fiber and the like.

[0029] In some typical embodiments, in the rigid layer, the thermosetting resin includes: any one of epoxy resin, phenolic resin, unsaturated polyester resin, u...

Embodiment 1

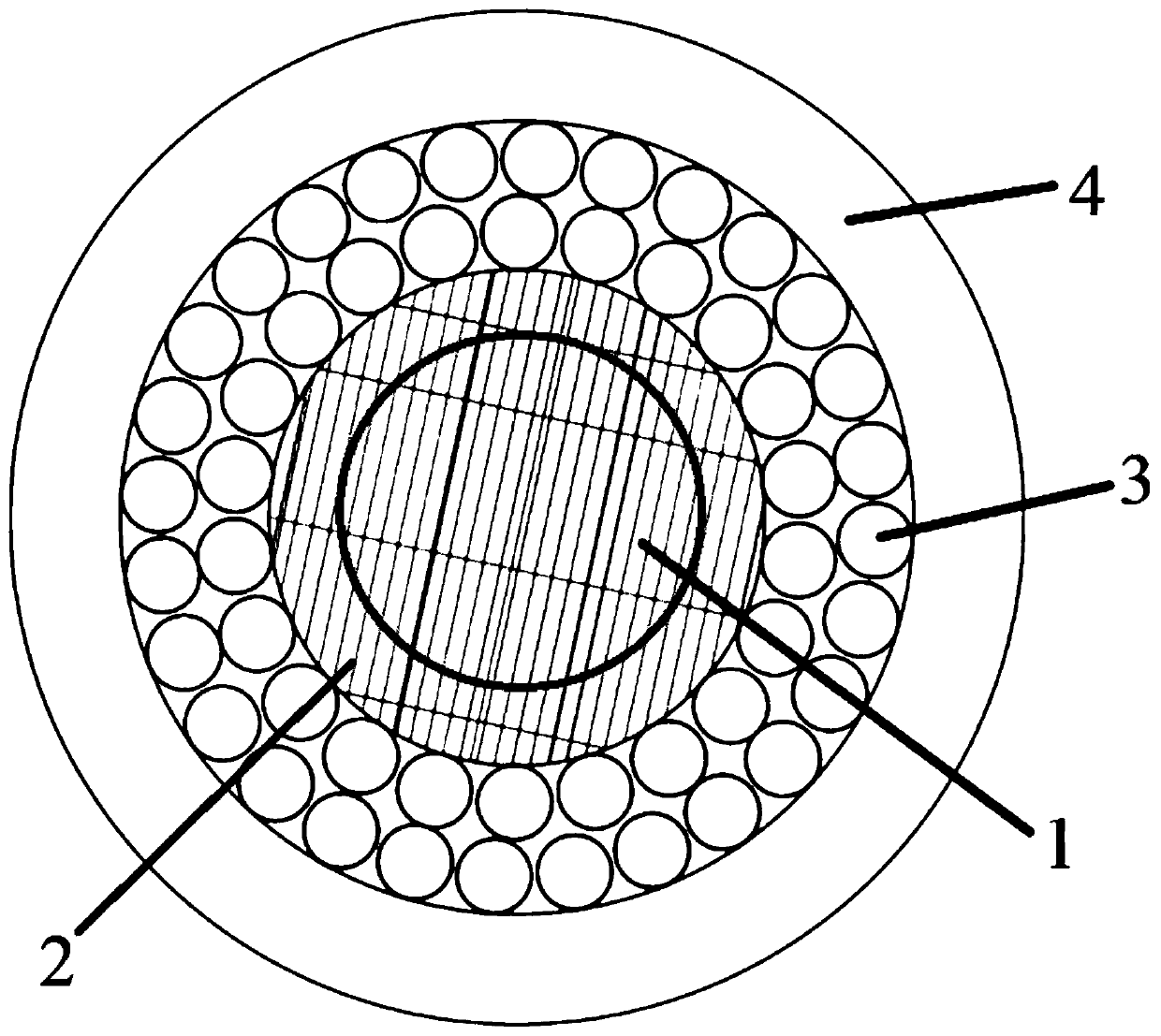

[0050] refer to figure 1 , an example of a fiber composite material core stranded metal wire sucker rod, its structure includes: a rod body, a wire structure layer and an impact-resistant and anti-corrosion thermoplastic layer; wherein:

[0051] The rod body is divided into a rigid layer 1 and a protective layer 2 wound on the surface of the rigid layer; the rigid layer 1 has a diameter of 7.0mm and is made of T700 carbon fiber filaments compounded with epoxy resin, and the thickness of the protective layer 2 is 0.5 mm. mm, its material is glass fiber reinforced yarn; the resin content in the rod body is 20%.

[0052] The metal wire structure layer 3 is formed by twisting metal wires on the surface of the protective layer, and three layers of circular high-strength stainless steel wires are twisted, wherein the inner layer of metal wires is twisted clockwise, the second outer layer is twisted counterclockwise, and the outermost The layers are twisted clockwise and the wires a...

Embodiment 2

[0062] A fiber composite material core stranded metal wire sucker rod, the same as embodiment 1, the difference is:

[0063] The diameter of the rigid layer 1 is 8mm, which is made of M40 carbon fiber mixed with high-strength basalt fiber and then compounded with epoxy resin. The thickness of the protective layer 2 is 1.5mm, which is formed by mixing glass fibers and basalt fibers; the resin content in the rod body is 21%.

[0064] The metal wire structure layer 3 is formed by twisting metal wires on the surface of the protective layer, and three layers of Z-shaped high-strength aluminum alloy wires are twisted, wherein the metal wires of the inner layer are twisted clockwise, and the second outer layer is twisted counterclockwise. The outer layer is twisted clockwise, and the cross-section of the high-strength aluminum alloy wire is equivalent to a round wire with a diameter of 1.5 mm. The strength of the high-strength aluminum alloy wire is greater than 1000 MPa, the fillin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com