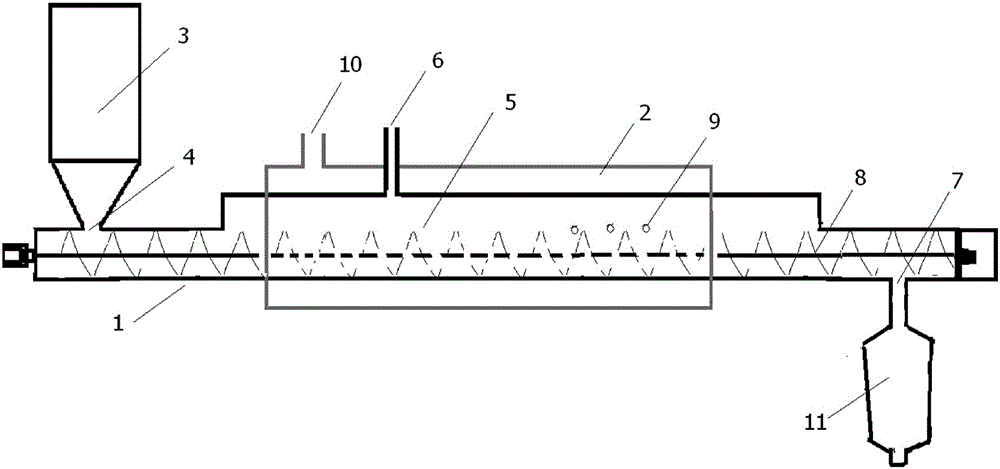

Equipment and method for evaporation recovery of yellow phosphorus from phosphorus mud

A phosphorus mud and yellow phosphorus technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of harsh operating environment and inconvenient operation, and achieve good sealing effect, low corrosion, and low corrosion of mud and phosphorus. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

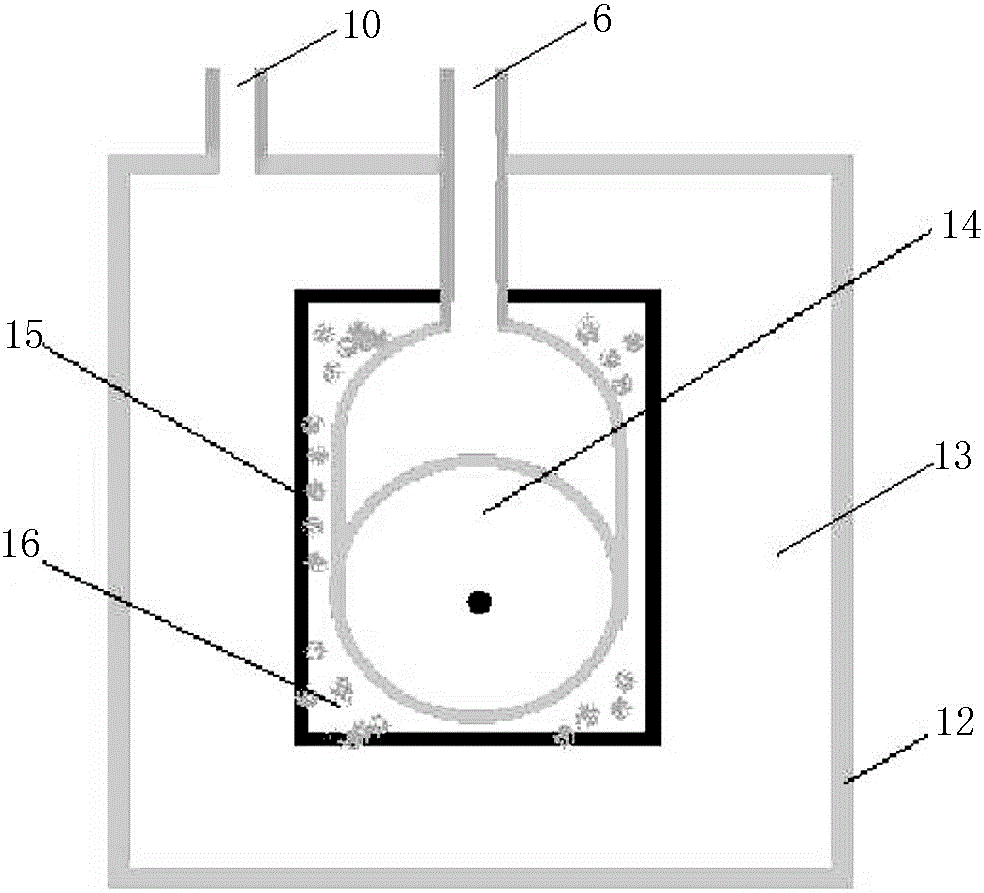

Method used

Image

Examples

Embodiment 1

[0031] About 2000 kg of phosphorus mud with a yellow phosphorus content of 45.1% was driven into 5m? ? In the reaction kettle (the reaction kettle has 1m of water in advance), open the jacket steam heating to maintain the temperature at about 75 degrees Celsius, continuously and slowly put 60 kg of calcium carbonate powder into it while stirring, keep stirring for 8 hours and then inject phosphorus in the mud storage tank.

[0032] Turn on the gas heating, adjust the temperature of the combustion chamber to 450-500°C, slowly enter the phosphorus sludge in the phosphorus sludge storage tank into the evaporator through the feed port, and after 96 hours of continuous evaporation, finally obtain about 900 kg of yellow phosphorus and 470 kg of residue kg, the purity of the yellow phosphorus obtained is 99.95%, and the total phosphorus content (in terms of phosphorus pentoxide) in the residue is 15.6%, and the residue does not emit smoke when placed in the air.

Embodiment 2

[0034] About 2000 kg of phosphorus mud with a yellow phosphorus content of 27.1% was driven into the 5m? ? In the reaction kettle (the reaction kettle has 1m of water in advance), open the jacket steam heating to maintain the temperature at about 75 degrees Celsius, continuously and slowly put 50 kg of calcium carbonate powder into it while stirring, keep stirring for 8 hours and then inject phosphorus in the mud storage tank.

[0035] Turn on the gas heating, adjust the temperature of the combustion chamber to 450-550°C, slowly enter the phosphorus sludge in the phosphorus sludge storage tank into the evaporator through the feed port, and after continuous evaporation for 96 hours, finally obtain about 500 kg of yellow phosphorus and 420 kg of residue kg, the purity of yellow phosphorus obtained is 99.95%, and the total phosphorus content (in terms of phosphorus pentoxide) in the residue is 19.6%, and the residue does not emit smoke when placed in the air.

Embodiment 3

[0037] About 2000 kg of phosphorus mud with a yellow phosphorus content of 17.6% was driven into 5m? ? In the reaction kettle (the reaction kettle has 1m of water in advance), open the jacket steam heating to maintain the temperature at about 75 degrees Celsius, continuously and slowly put 60 kg of calcium carbonate powder into it while stirring, keep stirring for 8 hours and then inject phosphorus in the mud storage tank.

[0038] Turn on the gas heating, adjust the temperature of the combustion chamber to 500-600°C, slowly enter the phosphorus sludge in the phosphorus sludge storage tank into the evaporator through the feed port, and after continuous evaporation for 96 hours, finally obtain about 300 kg of yellow phosphorus and a residue of 510 kg, the purity of yellow phosphorus obtained is 99.95%, and the total phosphorus content (in terms of phosphorus pentoxide) in the residue is 14.6%, and the residue does not emit smoke when placed in the air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com