Ultrahigh molecular weight polyethylene composite pipe connector

A polyethylene composite pipe, ultra-high molecular weight technology, applied in the direction of pipes/pipe joints/fittings, pipe connection layout, mechanical equipment, etc., can solve the difficulties of flange screw hole alignment adjustment, inconvenient operation, difficult construction, etc. problem, to achieve the effect of excellent sealing effect, convenient installation and operation, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

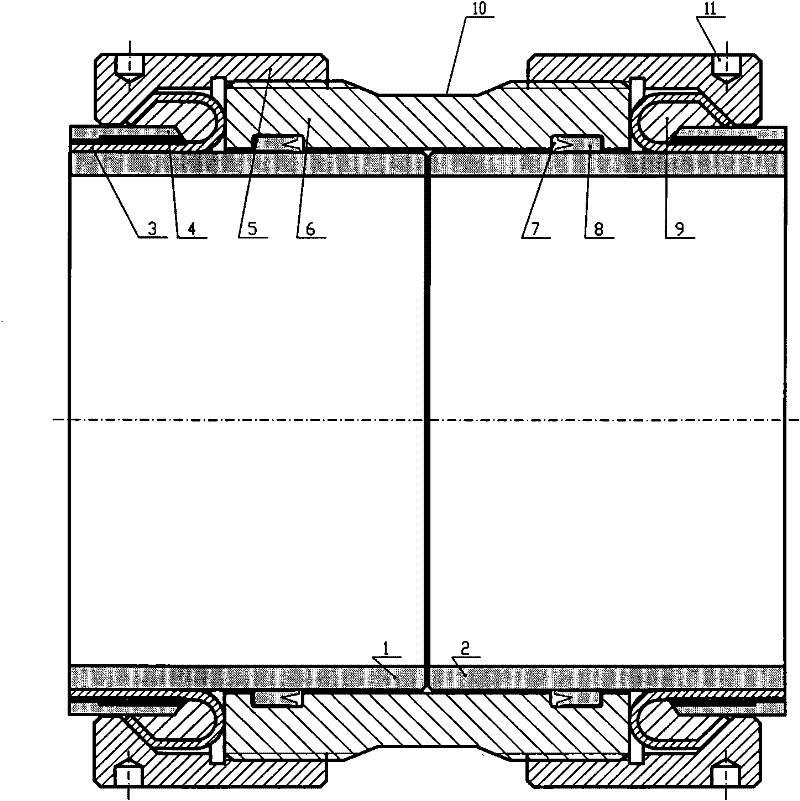

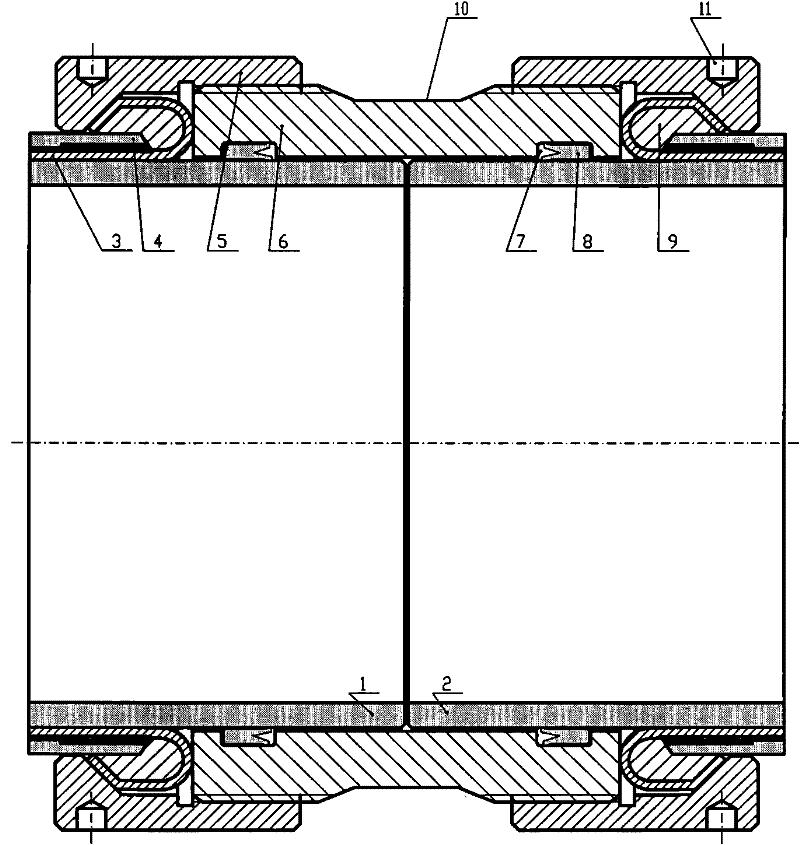

[0021] As shown in Figure 1 of the present invention, the ultra-high molecular weight polyethylene composite pipe connector includes a shrink sleeve, a lock nut, a positioning steel sleeve, a sealing ring groove, a sealing ring, and a bushing, and the positioning steel sleeve is placed on two sides. The center position of the butt surface of the pipe body coincides with the pipe body 1 and the pipe body 2 at the same time. The annular shrink sleeve is placed at one end of the positioning steel sleeve, and is placed on the outside of the steel belt until it coincides with the bushing. The lock nut is placed The outer side of the positioning steel sleeve, the bushing and the shrinking sleeve, the bushing is placed in the ring cavity formed by the matching surface of the steel belt and the positioning steel sleeve, the shrinking sleeve and the lock nut, and the steel belt wraps the bushing and the positioning steel sleeve. The outer end surface matches the inner surface of the loc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bearing capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com