Rapid permeable compressive concrete

A technology of permeable concrete and concrete, which is applied to cohesive pavement paved on site, climate change adaptation, pavement details, etc., and can solve problems such as loss of water permeability and damage to the internal structure of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

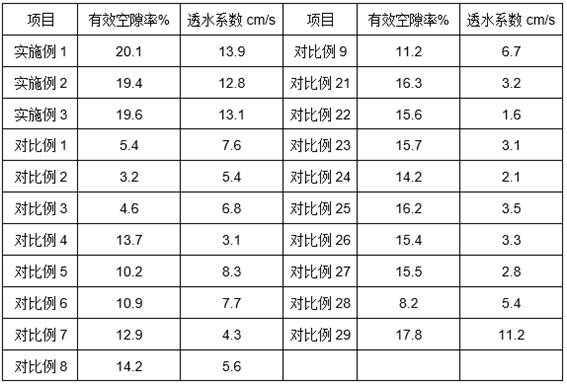

[0349] Water permeability coefficient and water permeability velocity of experimental example 1 concrete

[0350] The porosity and water permeability coefficient of the permeable concrete prepared in the examples and comparative examples are tested according to the standard of Shanghai Engineering Design Code DGJ08-"Technical Regulations for the Application of Permeable Concrete Pavement of Non-motor Vehicle Roads", and the final results are recorded in Table 1;

[0351] Table 1 Porosity and water permeability coefficient of concrete

[0352]

[0353] It can be obtained from Table 1 that the permeable concrete prepared in Examples 1-3 has good water permeability and an effective void ratio up to 20.1%, and the water permeability is excellent; Comparative Examples 1-3 did not layer or adopt permeable concrete The particle size of the stones in the raw materials is the same, so the effective porosity of the permeable concrete is reduced, and the water permeability coefficient...

experiment example 2

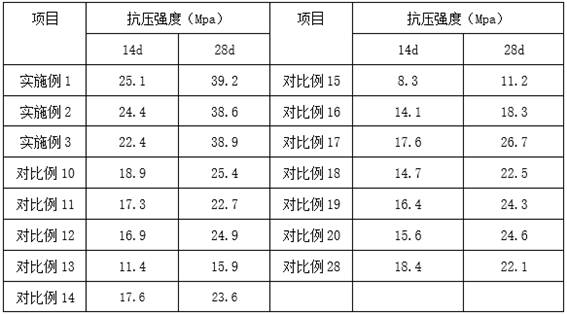

[0354] The compressive strength test of experimental example 2 concrete

[0355] The concretes prepared in Examples and Comparative Examples were tested according to the industry standard CJJT135-2009 "Technical Regulations for Permeable Cement Concrete Pavements", and the specific results are recorded in Table 2.

[0356] Table 2 Compressive strength of concrete over time

[0357]

[0358]It can be observed from Table 1 that the concrete of Examples 1-3 has excellent compressive strength after curing for 28 days, and the strength far exceeds the industry standard; Comparative Example 10 and Comparative Examples 12-14 change the formulation of the binder, so the permeable concrete The compressive strength of the concrete decreased significantly, and even did not meet the industry standard; Comparative Example 11 changed the process parameters of the binder preparation, so the structure of the binder changed, and the strength of the concrete decreased; Comparative Example 15...

experiment example 3

[0359] Experimental example 3 freeze-thaw cycle experiment of concrete

[0360] Through the industry standard CJJT135-2009 "Technical Regulations for Permeable Cement Concrete Pavement", the concrete prepared by the embodiment and the comparative example is tested for the loss rate of compressive strength and the rate of mass loss, and is tested by the embodiment and the comparative example. Each embodiment or A sample is selected for the comparative example, wherein the final data is recorded in Table 3;

[0361] Table 3 Freeze-thaw resistance test of permeable concrete

[0362]

[0363] As can be seen from Table 3, the compressive strength loss rate and mass loss rate of Examples 1-3 are in line with industry standards; Comparative Example 10 and Comparative Examples 12-13 change the formulation of the binder, so the strength and mass loss of permeable concrete The quality all has certain loss; Comparative Example 11 changes the preparation process of concrete, so the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com