Seawater-resistant ultra-high-molecular-weight polyethylene fiber yarn

An ultra-high molecular weight, polyethylene fiber technology, applied in fiber treatment, artificial filament physical therapy, artificial filament cleaning/drying, etc., can solve the corrosion of rope quality, breakage, and ropes that cannot be coated with seawater corrosion-resistant materials Fiber and other problems, to ensure the seawater resistance and service life, improve the effect of safety

Inactive Publication Date: 2016-03-02

盐城神力制绳有限公司

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the seawater corrosion-resistant method of the known cable fiber filaments for marine ships is to coat the seawater corrosion-resistant material on the surface of the braided fiber rope. The defect is that the surface of the rope will inevitably be damaged during use. When the surface of the rope is damaged, seawater will It will easily immerse into the inside of the rope along the damaged opening, so that it will be soaked and corroded until the inside of the rope has no fiber filaments that can be coated with seawater corrosion-resistant materials, and even seawater will not come out after long-term immersion in the rope because of the surface coating of the rope. , because seawater contains about 3.5% salt, it will seriously corrode the quality of the rope, so as to reduce the product quality and service life of the rope

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

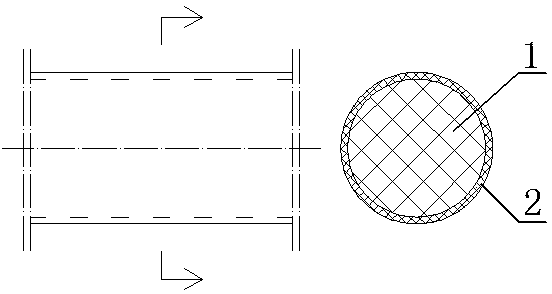

[0009] exist figure 1 Middle: The outer surface of the ultra-high molecular weight polyethylene fiber (1) is coated with a seawater corrosion-resistant protective material (2), which is a seawater-resistant ultra-high molecular weight polyethylene fiber of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a seawater-resistant ultra-high-molecular-weight polyethylene fiber yarn. According to the technical scheme, the surface of the ultra-high-molecular-weight polyethylene fiber yarn is coated with an acid and alkali-resistant protective material. The yarn can be used for making marine ship cables and can be effectively protected from seawater corrosion, corrosion of seawater and sea frog to ropes is avoided, and the purpose of effectively improving the product quality and service life of ultra-high-molecular-weight polyethylene ropes is achieved. The seawater-resistant ultra-high-molecular-weight polyethylene fiber yarn has the following beneficial effects: every ultra-high-molecular-weight polyethylene fiber yarn has the function of seawater corrosion prevention; ropes can be better protected from seawater corrosion; and the seawater resistance and service life of ultra-high-molecular-weight polyethylene ropes are strongly guaranteed.

Description

Technical field [0001] The invention relates to a cable fiber filament for marine ships, in particular to a seawater-resistant ultra-high molecular weight polyethylene fiber filament coated with a seawater corrosion-resistant material. Background technique [0002] At present, the seawater corrosion-resistant method of the known cable fiber filaments for marine ships is to coat the surface of the braided fiber rope with seawater corrosion-resistant materials. The defect is that the surface of the rope will inevitably be damaged during use. When the surface of the rope is damaged, seawater will It will easily immerse into the inside of the rope along the damaged opening, so that it will be soaked and corroded until the inside of the rope has no fiber filaments that can be coated with seawater corrosion-resistant materials, and even seawater will not come out after long-term immersion in the rope because of the surface coating of the rope. , because seawater contains about 3.5...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D01D10/00D01D10/06

Inventor 王世东梁星洪戴礼华钱文华祁学勤苗国华

Owner 盐城神力制绳有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com