Pd-Ni/SiNWs array electrode glucose sensor and manufacturing method and application thereof

A glucose sensor and array electrode technology, which is applied in the field of glucose detection, can solve the problems of sensor incompatibility, etc., and achieve the effects of increased detection sensitivity, mature technology, and simple operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the Pd-Ni / SiNWs array electrode glucose sensor in this embodiment, the specific steps include:

[0033] Step 1: using the silicon substrate material 1 as the silicon substrate material for growing the SiNWs array, and growing the base SiNWs array material layer 2 by chemical wet etching;

[0034] Step 2: On the substrate SiNWs array material layer 2, a metal Pd-Ni nanoparticle coating 3 is provided, and the metal Pd-Ni nanoparticle coating 3 is modified by electroless plating technology to obtain a Pd-Ni / SiNWs array material;

[0035] Step 3: performing rapid thermal annealing on the Pd-Ni / SiNWs array material prepared in step 2 under the protection of nitrogen atmosphere;

[0036] Step 4: Bond the copper wire 6 to the surface of the Pd-Ni / SiNWs array material with silver paste and connect it to the metal Pd-Ni nanoparticle coating 3 to form a Pd-Ni / SiNWs array electrode, and place it in a drying oven to dry;

[0037] Step 5: Wrap the silv...

Embodiment 1

[0039] 1. Preparation of silicon nanowires (SiNWs) materials by chemical wet etching

[0040] (1) Use P-type (100) crystal orientation (resistivity: 1~10 ) Double-sided polished silicon wafers, cut into 0.5×0.5cm samples, cleaned by standard RCA process, put into 35mM / L silver nitrate (AgNO 3 ) and a mixed etching solution composed of 20% hydrofluoric acid HF to grow SiNWs, and the etching time is about 40 minutes.

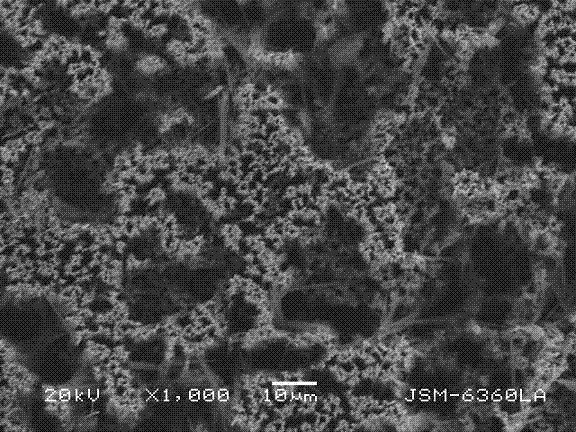

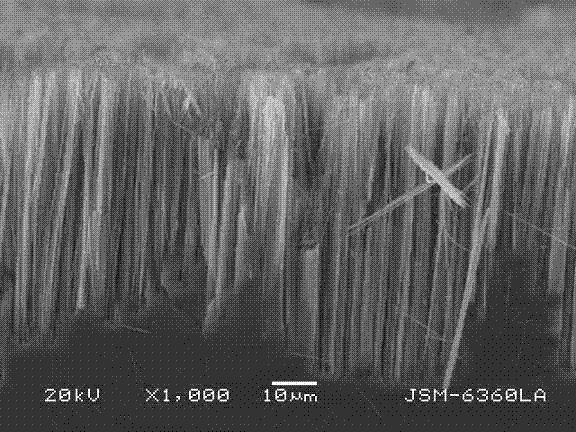

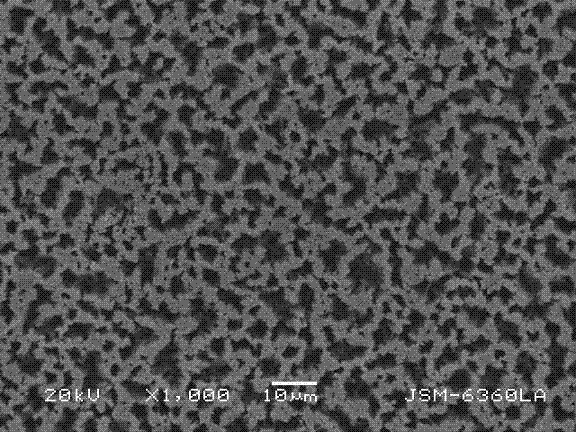

[0041] (2) Wash away the remaining silver particles on the etched SiNWs surface with 65% nitric acid solution by mass percentage, clean the SiNWs surface with a large amount of deionized water, and dry it in an oven at 80 °C. The surface morphology of the prepared SiNWs is as follows figure 1 and 2 as shown, figure 1 Shown is the SEM top view of SiNWs; figure 2 Shown is the SEM profile of SiNWs. The diameter of SiNWs is about 200nm, and the length is about 50-60μm.

[0042] 2. Electroless plating technology to modify metal Pd-Ni on the surface of silicon ...

Embodiment 2

[0052] The parts that are the same as those in Embodiment 1 will not be described again.

[0053] 1. Fabrication of Silicon Nanowires (SiNWs) by Chemical Wet Etching

[0054] (1) Use P-type (100) crystal orientation (resistivity: 1-10 ) Double-sided polished silicon wafers, cut into 0.5cm×0.5cm samples, cleaned by standard RCA process, put in 30mM / L silver nitrate AgNO 3 In a mixed etching solution composed of 20% by mass of hydrofluoric acid HF, silicon nanowires were grown, and the etching time was 50 minutes.

[0055] (2) Wash away the remaining silver particles on the etched SiNWs surface with a nitric acid solution with a mass percentage of 30%, and clean the SiNWs surface with a large amount of deionized water, and then dry it in an oven at 80 °C. The prepared SiNWs have a diameter of about 150 nm and a length of 70 μm to 90 μm.

[0056] 2. Electroless plating technology modified metal palladium nickel on the surface of silicon nanowires to make Pd-Ni / SiNWs arra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com