Zero emission technology for wastewater

A zero-discharge, waste water technology, applied in the direction of water pollutants, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high material requirements, complex pretreatment, and equipment prone to fouling, etc. Achieve the effect of simple recycling and simple pretreatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical features of the present invention will be further described below in conjunction with the drawings and specific embodiments.

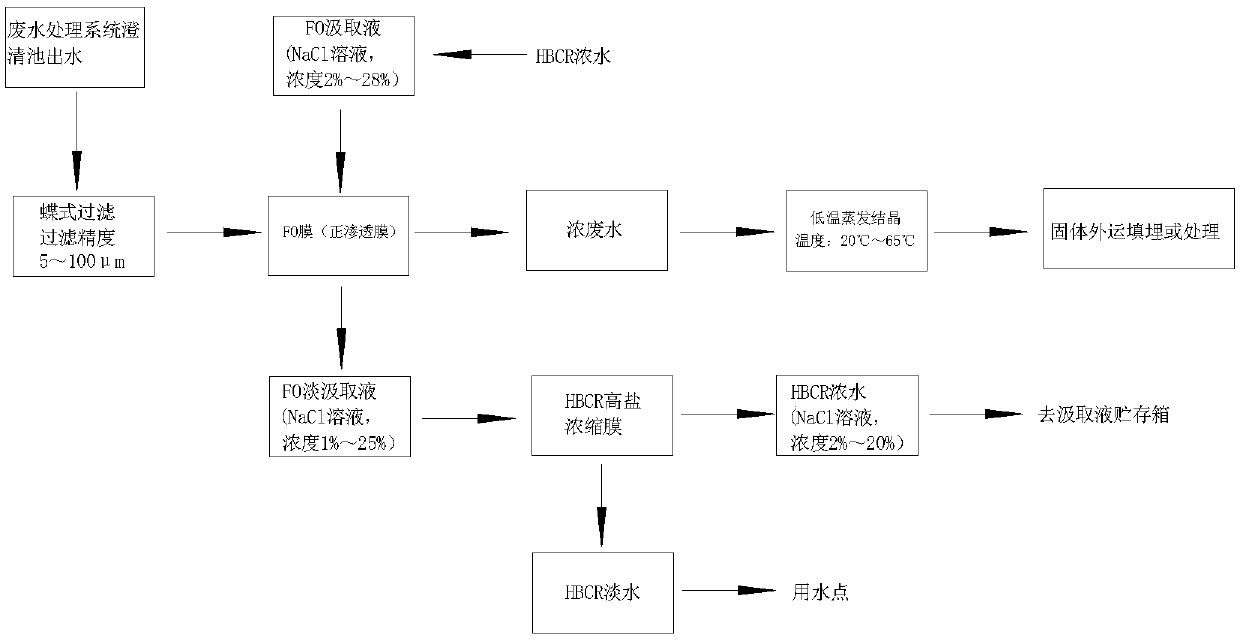

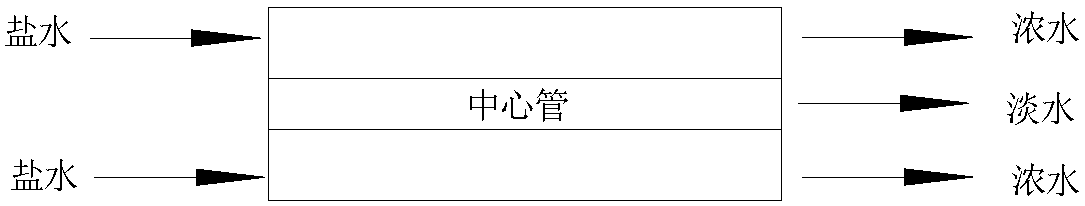

[0025] Such as figure 1 As shown in the zero-discharge wastewater process, high-salt water and high-COD water are pretreated by E1 and then enter E2. The concentrated water treated by E2 enters E4 for evaporation and crystallization. The fresh water flowing out of E2 enters E3 for concentration and recovery, and E3 flows out. The fresh water is sent to a suitable water point.

[0026] Specific steps are as follows:

[0027] (1) Pretreatment: Pass waste water (high brine and high COD water) through a laminated filter; remove particles with a particle size greater than 100 microns;

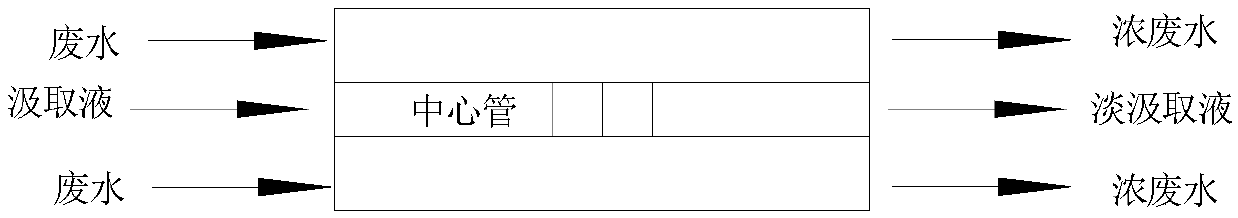

[0028] (2) Forward osmosis: The pretreated wastewater is passed through a forward osmosis membrane; the FO draw solution used is a sodium chloride solution with a mass percentage concentration of 2%-28%;

[0029] (3) After passing through the FO membrane, the obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com