Preparation technology of porous calcium gluconate tantalite/nono-funicular hydroxylapatite bioactive coating

A hydroxyapatite and nanofiber technology, applied in metal material coating process, coating, superimposed layer plating and other directions, can solve the problems of far apart crystalline morphology and low ability of new bone formation, and achieve the promotion of Adhesion and growth, simple composition, stable process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

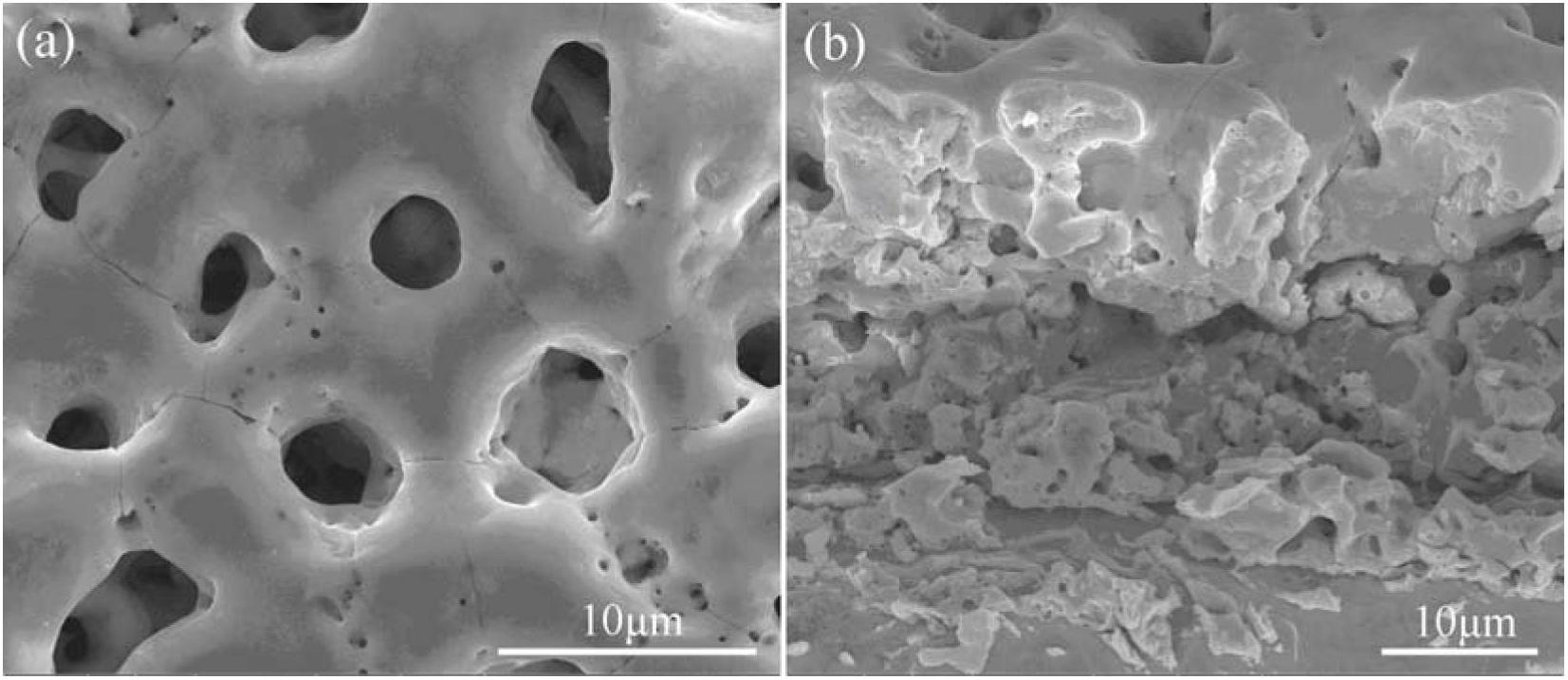

[0022] Will contain 0.2M (CH 3 COO) 2 Ca with 0.02M β-C 3 h 7 Na 2 o 6 An aqueous solution of P serves as the electrolyte. Using metal tantalum sheet as anode and stainless steel as cathode, using DC pulse power supply, under the conditions of positive voltage 470 volts, negative voltage 100 volts, frequency 100 Hz, and duty cycle 26%, the tantalum sheet was subjected to micro-arc oxidation treatment for 5 minutes. , the calcium tantalate-based multiphase layer containing calcium and phosphorus was obtained, and the SEM photos of the surface and cross-section microscopic morphology were respectively referred to figure 1 (a) and (b). Then the calcium tantalate-based multiphase layer / tantalum sheet sample obtained after micro-arc oxidation treatment was suspended in a hydrothermal reaction kettle with a concentration of 0.01M β-C 3 h 7 Na 2 o 6 Above the P aqueous solution, the filling degree of the solution is 15%, and it is hydrothermally treated at 140°C for 3 hours...

Embodiment 2

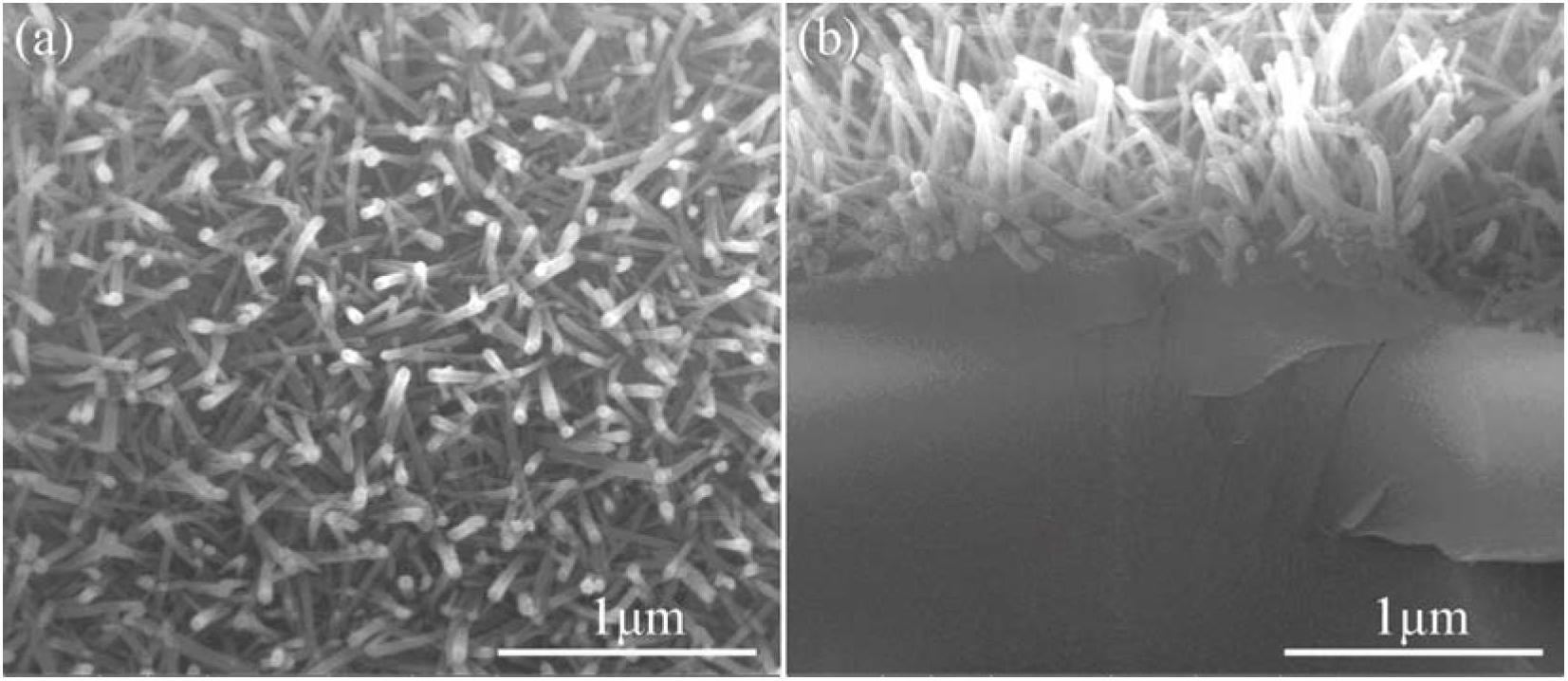

[0024] Will contain 0.2M (CH 3 COO) 2 Ca with 0.02M β-C 3 h 7 Na 2 o 6 An aqueous solution of P serves as the electrolyte. Using metal tantalum sheet as anode and stainless steel as cathode, using DC pulse power supply, under the conditions of positive voltage 470 volts, negative voltage 100 volts, frequency 100 Hz, and duty cycle 26%, the tantalum sheet was subjected to micro-arc oxidation treatment for 5 minutes. , to obtain a calcium tantalate-based multiphase layer containing calcium and phosphorus. Then the calcium tantalate-based multiphase layer / tantalum sheet sample obtained after micro-arc oxidation treatment was suspended in a hydrothermal reaction kettle with a concentration of 0.01M β-C 3 h 7 Na 2 o 6 Above the P aqueous solution, the filling degree of the solution is 15%, and it is hydrothermally treated at 140°C for 24 hours, and the fibers that are closely arranged and parallel to the calcium tantalate-based multiphase layer can be obtained, and the fib...

Embodiment 3

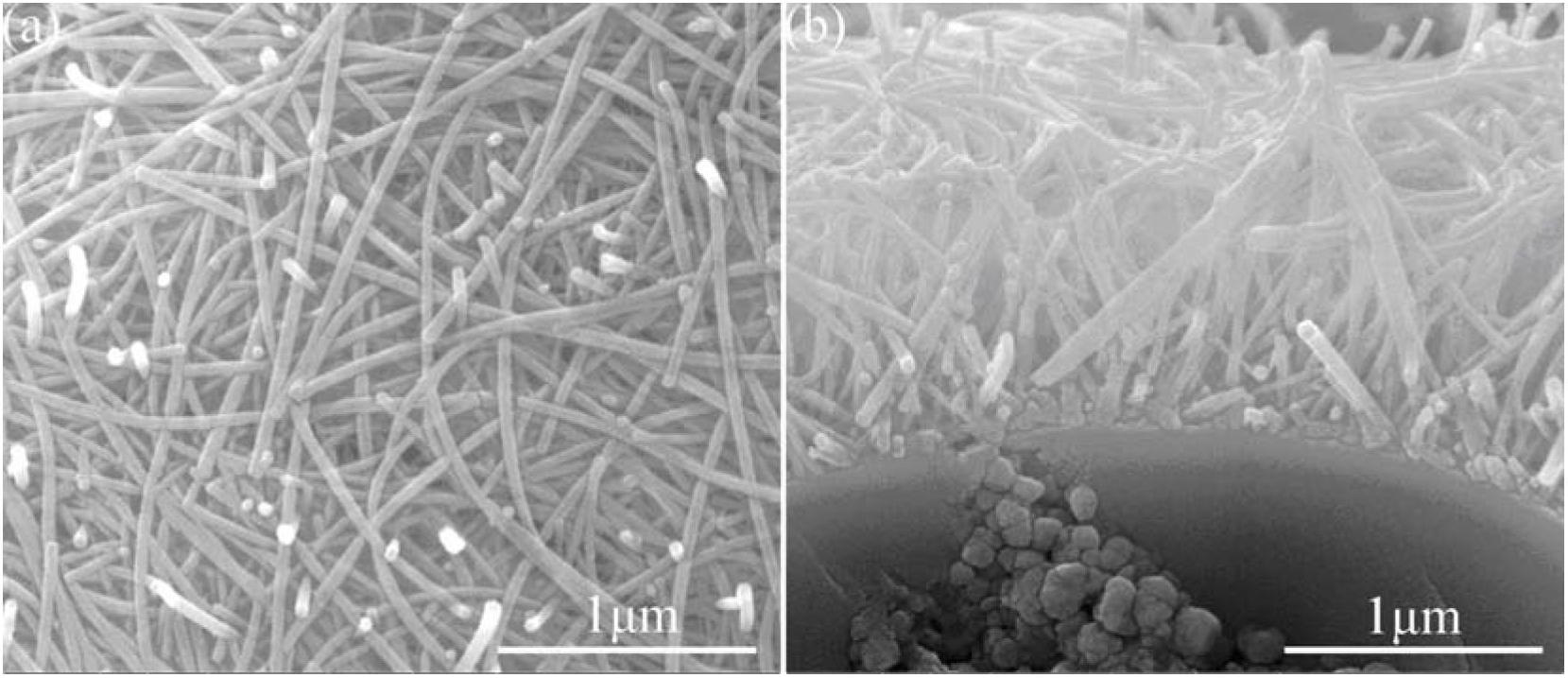

[0026] Will contain 0.2M (CH 3 COO) 2 Ca with 0.02M β-C 3 h 7 Na 2 o 6 An aqueous solution of P serves as the electrolyte. Using metal tantalum sheet as anode and stainless steel as cathode, using DC pulse power supply, under the conditions of positive voltage 470 volts, negative voltage 100 volts, frequency 100 Hz, and duty cycle 26%, the tantalum sheet was subjected to micro-arc oxidation treatment for 5 minutes. , to obtain a calcium tantalate-based multiphase layer containing calcium and phosphorus, and then soak the calcium tantalate-based multiphase layer / tantalum sheet sample obtained after micro-arc oxidation treatment into a hydrothermal reaction kettle with a concentration of 0.01M β-C 3 h 7 Na 2 o 6 In the P aqueous solution, the filling degree of the solution is 15%, and it is hydrothermally treated at 140°C for 3 hours, and the fibers that are closely arranged and parallel to the calcium tantalate-based multiphase layer can be obtained, and the fiber diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com