Chemical treatment method for aluminum alloy surface

A technology of aluminum alloy surface and chemical treatment, applied in the direction of metal material coating process, etc., can solve the problems of toxic hexavalent chromium ions, environmental pollution, human health hazards, etc., and achieve excellent surface quality, stable process and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

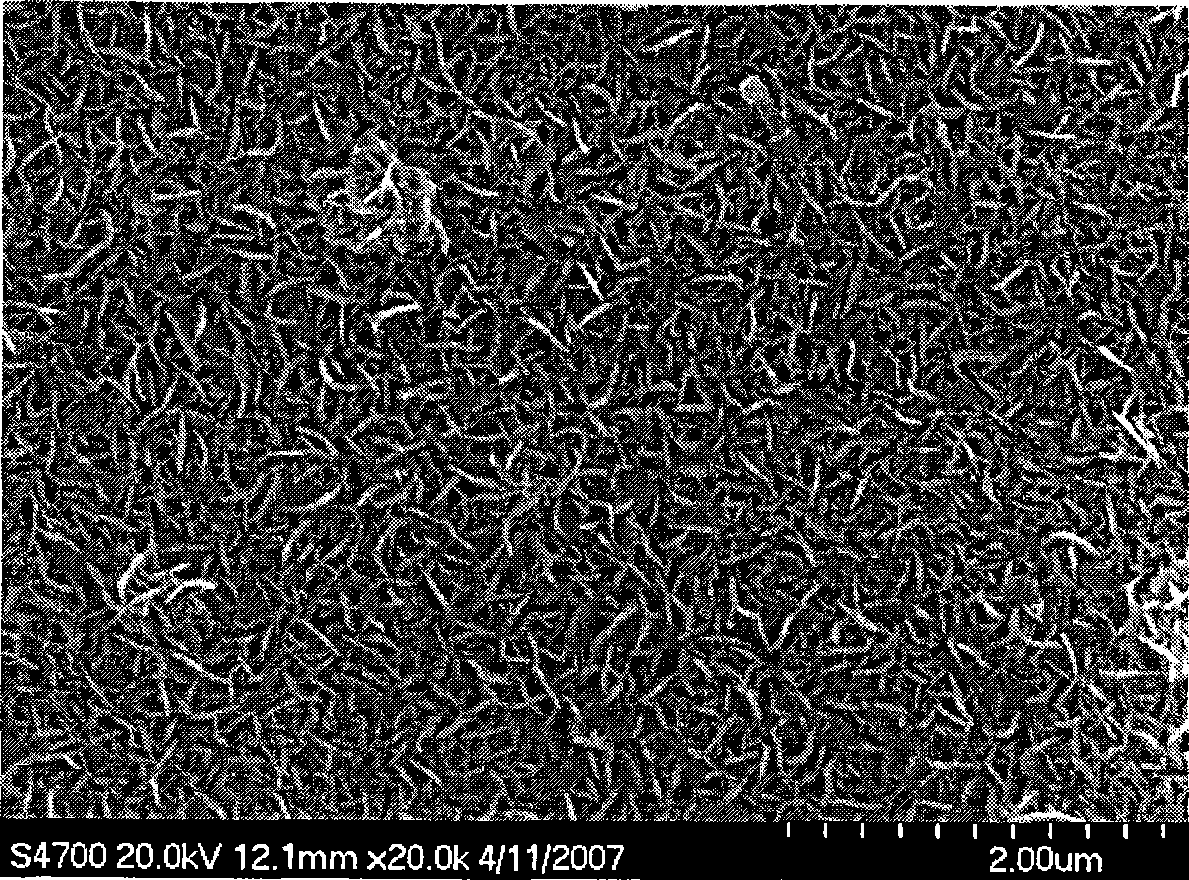

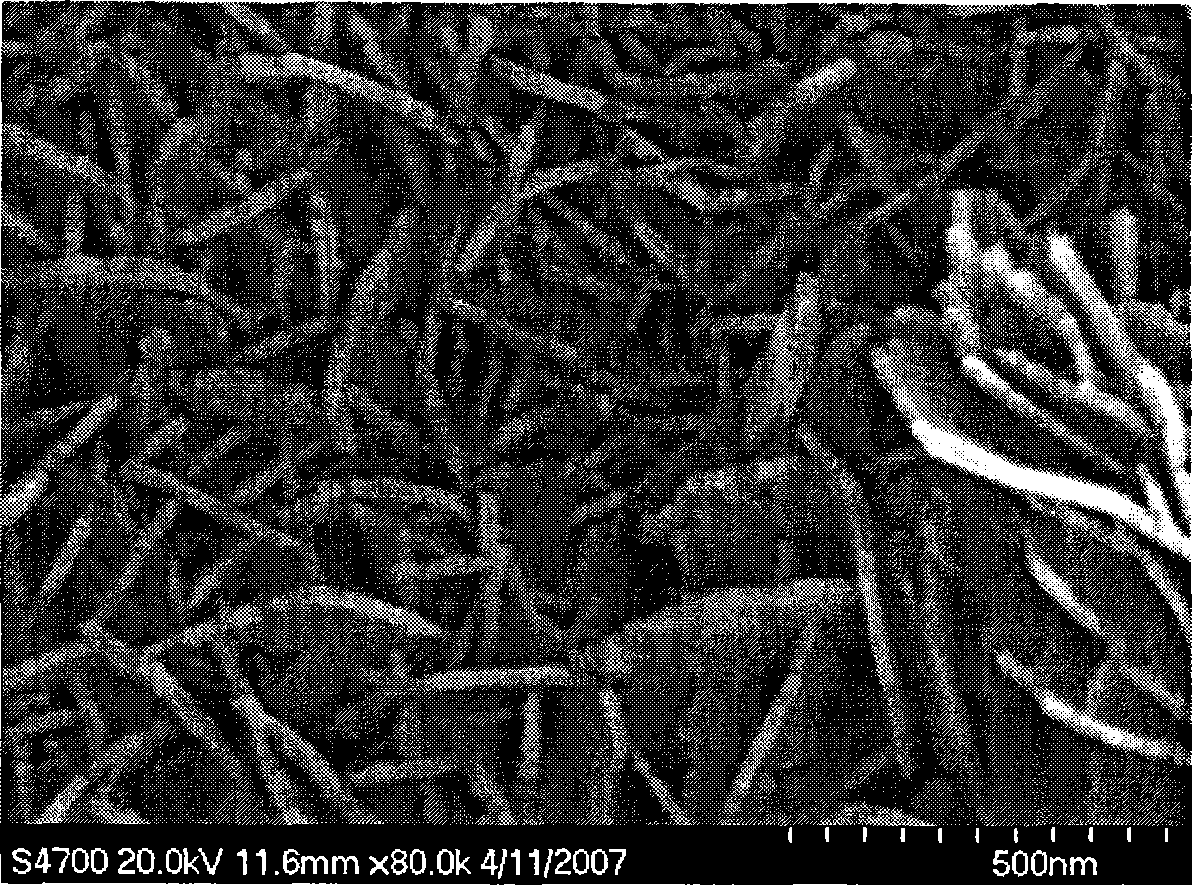

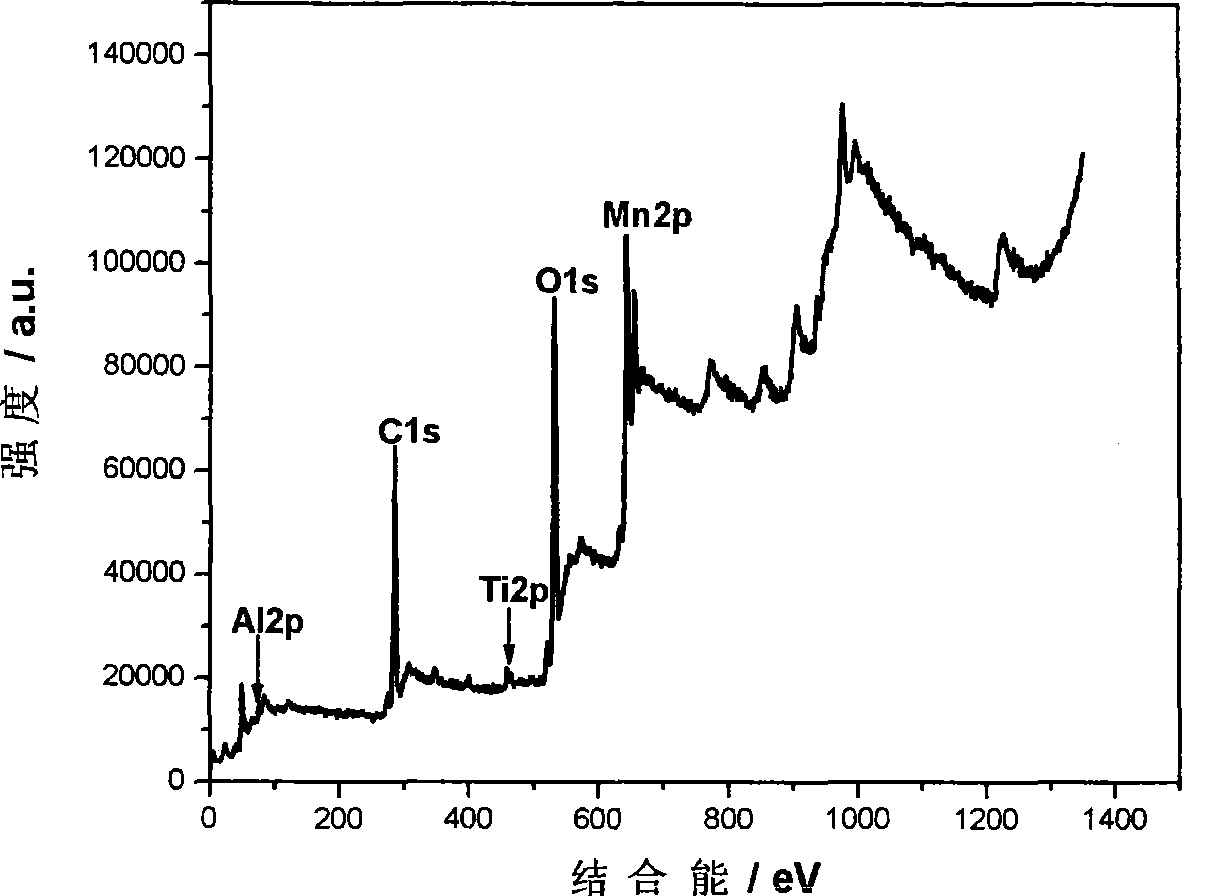

Image

Examples

Embodiment 1

[0035] Take a 20×70×2mm LY12 aluminum alloy sample for use.

[0036] (1) Grinding. Sand with water-resistant sandpaper to 800 # .

[0037] (2) Chemical degreasing. First prepare the chemical degreaser, the formula is as follows:

[0038]

[0039]

[0040] Dissolve the above-mentioned components other than the deionized water in deionized water according to the formula ratio, mix to obtain an aqueous solution, and put it into a container for later use. Soak the aluminum alloy sample to be treated in the above aqueous solution, keep the temperature of the solution at 55° C., and soak for 5 minutes.

[0041] (3) Alkali corrosion. The above chemically degreased aluminum alloy sample was immersed in 50g / L sodium hydroxide, the temperature was maintained at 55°C, and the treatment time was 6 minutes.

[0042] (4) Light out. Immerse the above chemically degreased aluminum alloy sample in 200g / L nitric acid, and treat it at room temperature for 3 minutes.

[0043] (5) Ch...

Embodiment 2

[0050] Take a 20×70×2mm LY12 aluminum alloy sample for use.

[0051] (1) Grinding. Sand with water-resistant sandpaper to 800 # .

[0052] (2) Chemical degreasing. First prepare the chemical degreaser, the formula is as follows:

[0053]

[0054] Dissolve the above-mentioned components other than the deionized water in deionized water according to the formula ratio, mix to obtain an aqueous solution, and put it into a container for later use. Soak the aluminum alloy sample to be treated in the above aqueous solution, keep the temperature of the solution at 55° C., and soak for 5 minutes.

[0055] (3) Alkali corrosion. The above chemically degreased aluminum alloy sample was immersed in 50g / L sodium hydroxide, the temperature was maintained at 55°C, and the treatment time was 6 minutes.

[0056] (4) Light out. Immerse the above chemically degreased aluminum alloy sample in 200g / L nitric acid, and treat it at room temperature for 3 minutes.

[0057] (5) Chemical treat...

Embodiment 3

[0064] Take a 20×70×2mm LY12 aluminum alloy sample for use.

[0065] (1) Grinding. Sand with water-resistant sandpaper to 800 # .

[0066] (2) Chemical degreasing. First prepare a chemical degreaser, the formula is as follows:

[0067]

[0068] Dissolve the above-mentioned components other than the deionized water in deionized water according to the formula ratio, mix to obtain an aqueous solution, and put it into a container for later use. Soak the aluminum alloy sample to be treated in the above aqueous solution, keep the temperature of the solution at 55° C., and soak for 5 minutes.

[0069] (3) Alkali corrosion. The above chemically degreased aluminum alloy sample was immersed in 50g / L sodium hydroxide, the temperature was maintained at 55°C, and the treatment time was 6 minutes.

[0070] (4) Light out. Immerse the above chemically degreased aluminum alloy sample in 200g / L nitric acid, and treat it at room temperature for 3 minutes.

[0071] (5) Chemical treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com