Titanium-based surface antibacterial and bone tissue regeneration-inducing functional coating and its preparation method and application

A technology for bone tissue regeneration and surface antibacterial, applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc., can solve the problems of low bonding strength between coating and substrate, impure phase of coating, no nanofiber, etc. , to achieve the effect of being conducive to large-scale mass production, low price and simple ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

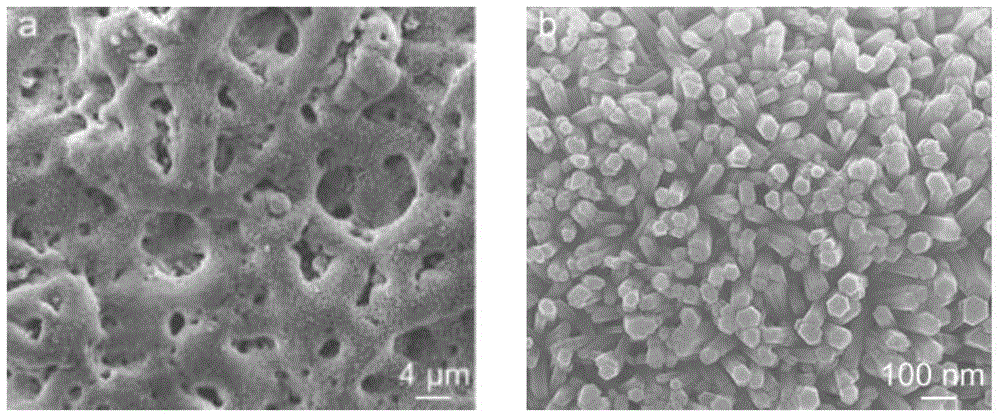

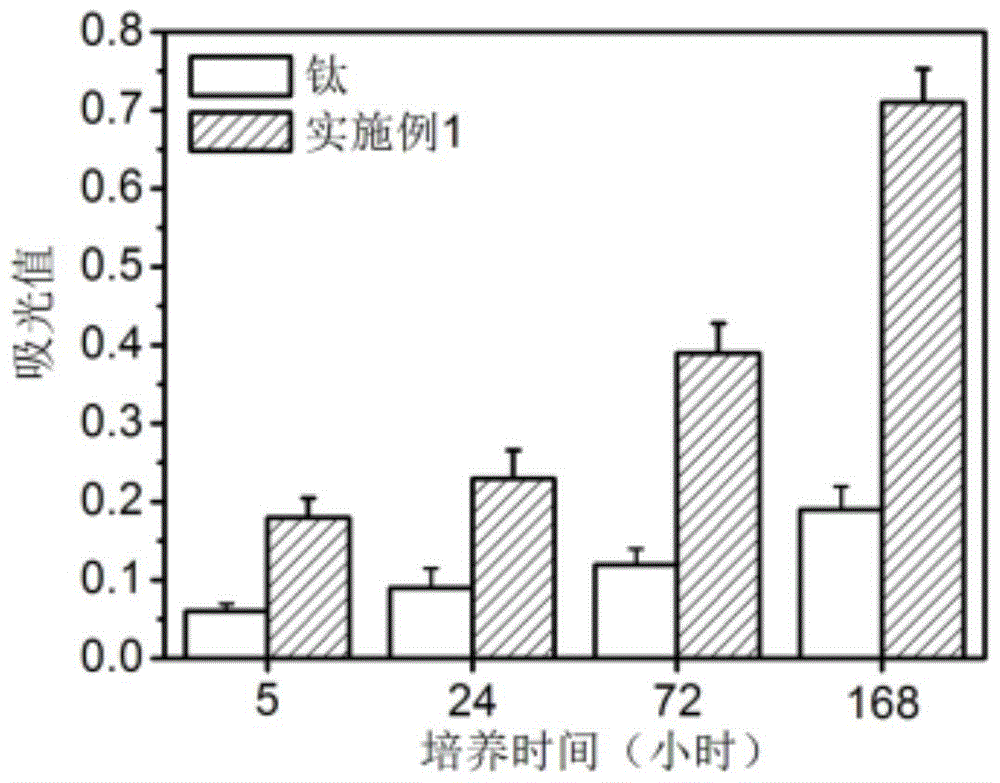

Embodiment 1

[0036] 1) Preprocessing:

[0037] Polish the titanium disc (size Ф14×2mm) with 180#, 360#, 800#, 1000#, 1500# sandpaper in sequence, and then use 99.5% acetone, 99.7% absolute ethanol, and deionized water to ultrasonically for 20 minutes each;

[0038] 2) Electrolyte preparation:

[0039] Will (CH 3 COO) 2 Ca, (CH 3 COO) 2 Sr and β-C 3 h 7 Na 2 o 6 Dissolve P(β-GP) in water, mix well, and prepare electrolyte solution; in the electrolyte solution (CH 3 COO) 2 The concentration of Ca is 0.2mol / L, (CH 3 COO) 2 The concentration of Sr is 0.1mol / L, the concentration of β-GP is 0.02mol / L;

[0040] 3) Micro-arc oxidation:

[0041] With titanium sheet as the anode and stainless steel as the cathode, a DC pulse power supply is used under the conditions of positive voltage 380 volts, negative voltage 50 volts, frequency 150 Hz, duty cycle 25%, distance between cathode and anode plates 9 cm, and electrolyte temperature 10 °C The micro-arc oxidation treatment was performed o...

Embodiment 2

[0052] 1) Preprocessing:

[0053] Polish the titanium disc (size Ф14×2mm) with 180#, 360#, 800#, 1000#, 1500# sandpaper in sequence, and then use 99.5% acetone, 99.7% absolute ethanol, and deionized water to ultrasonically for 20 minutes each;

[0054] 2) Electrolyte preparation:

[0055] Will (CH 3 COO) 2 Ca, (CH 3 COO) 2 Sr and β-C 3 h 7 Na 2 o 6 Dissolve P(β-GP) in water, mix well, and prepare electrolyte solution; in the electrolyte solution (CH 3 COO) 2 The concentration of Ca is 0.3mol / L, (CH 3 COO) 2 The concentration of Sr is 0.15mol / L, the concentration of β-GP is 0.03mol / L;

[0056] 3) Micro-arc oxidation:

[0057] With titanium sheet as the anode and stainless steel as the cathode, a DC pulse power supply is used under the conditions of positive voltage 380 volts, negative voltage 50 volts, frequency 150 Hz, duty cycle 25%, distance between cathode and anode plates 9 cm, and electrolyte temperature 10 °C The micro-arc oxidation treatment was performed ...

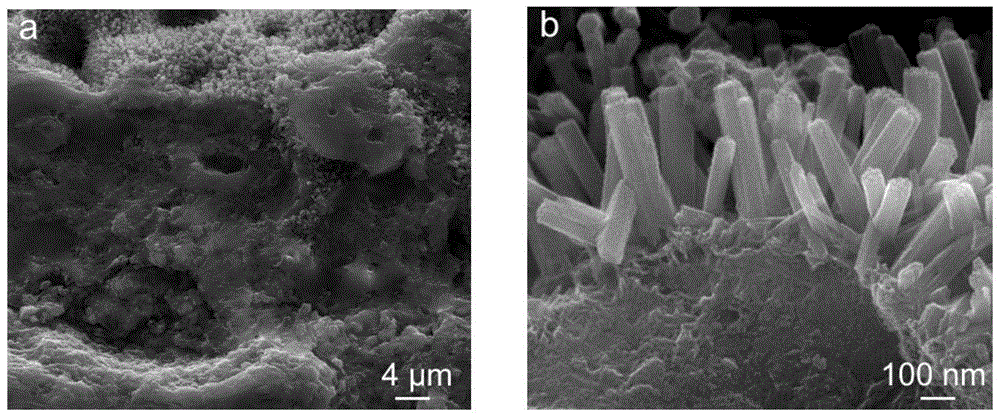

Embodiment 3

[0064] 1) Preprocessing:

[0065] Polish the titanium disc (size Ф14×2mm) with 180#, 360#, 800#, 1000#, 1500# sandpaper in sequence, and then use 99.5% acetone, 99.7% absolute ethanol, and deionized water to ultrasonically for 20 minutes each;

[0066] 2) Electrolyte preparation:

[0067] Will (CH 3 COO) 2 Ca, (CH 3 COO) 2 Sr and β-C 3 h 7 Na 2 o 6 Dissolve P(β-GP) in water, mix well, and prepare electrolyte solution; in the electrolyte solution (CH 3 COO) 2 The concentration of Ca is 0.2mol / L, (CH 3 COO) 2 The concentration of Sr is 0.1mol / L, the concentration of β-GP is 0.02mol / L;

[0068] 3) Micro-arc oxidation:

[0069] With titanium sheet as the anode and stainless steel as the cathode, a DC pulse power supply is used under the conditions of positive voltage 400 volts, negative voltage 80 volts, frequency 150 Hz, duty cycle 25%, distance between cathode and anode plates 9 cm, and electrolyte temperature 10 °C The micro-arc oxidation treatment was performed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com