Method for manufacturing glue-less fiber board by leak-free type hot pressing technology

A hot-pressing process and fiberboard technology, applied in the direction of manufacturing tools, flat products, wood processing appliances, etc., can solve the problems that have not been applied in actual production, and achieve the effect of small process reform, good effect and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: In this example, the method for manufacturing glue-free high-density fiberboard with a closed hot pressing process is:

[0017] Using wood as raw material, glue-free high-density fiberboard is produced on the existing medium-density fiberboard production line.

[0018] 1) Fiber separation and water repellent: Chip the wood on a chipper, separate the fibers according to the MDF production process and apply paraffin water repellent, the amount of which is 0.8% of the dry fiber mass.

[0019] 2) Drying and paving: the hot-milled fibers are dried by pipeline air-flow drying method, and the moisture content is controlled at 18%;

[0020] 3) Pre-pressing: the process is the same as that in the existing medium density fiberboard production.

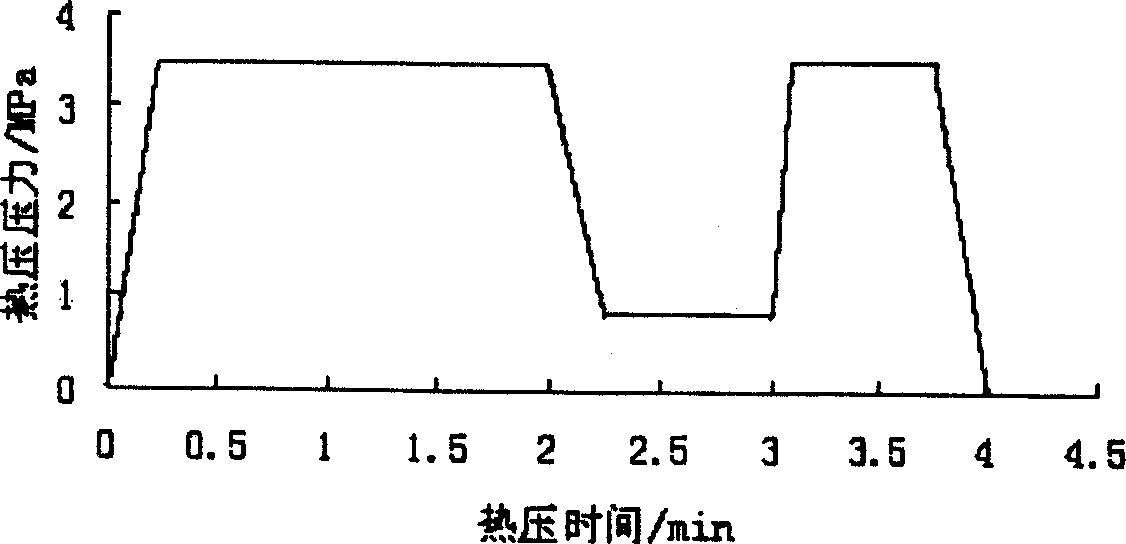

[0021] 4) Airtight hot pressing: send the pre-pressed slab into the airtight frame (rectangular shape made of steel with a thickness of 6.0mm and a rectangular cross-sectional shape, the airtight frame is fixed on the upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com