Thinning-free one-time brush-molded latex paint finishing coat and preparation method thereof

A latex paint, non-dilution technology, applied in the direction of coating, etc., can solve the problems of time-consuming, inconsistent water mixing ratio, high labor cost, etc., achieve good anti-splash performance, ensure the thickness of the wet film, and reduce the workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 (best embodiment):

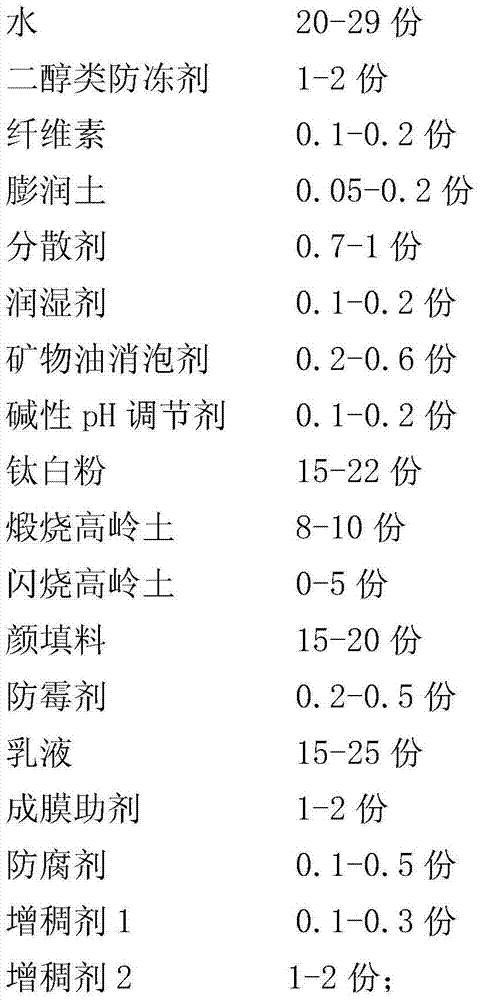

[0032] A non-diluting one-time brushing forming latex paint finish, which is prepared by the following raw materials according to the following weight ratio:

[0033]

[0034]

[0035] The preparation method of this no-diluted one-time painting latex paint topcoat comprises the following steps carried out in sequence:

[0036] (1) Mix 0.05 parts of bentonite and 1.5 parts of glycol antifreeze for later use;

[0037] (2) Start the disperser and adjust the speed to 300 rpm. At this speed, first add 22 parts of water, 1 part of dispersant, 0.1 part of wetting agent and 0.15 part of mineral oil defoamer, and then add bentonite and glycol Antifreeze-like mixture, then dispersed for 3 minutes;

[0038] (3) At a speed of 200 rpm, add 0.15 parts of cellulose and 0.15 parts of alkaline pH regulator in turn, and then add 20 parts of titanium dioxide, 10 parts of calcined kaolin, and pigments and fillers in sequence after the cellulose is ...

Embodiment 2

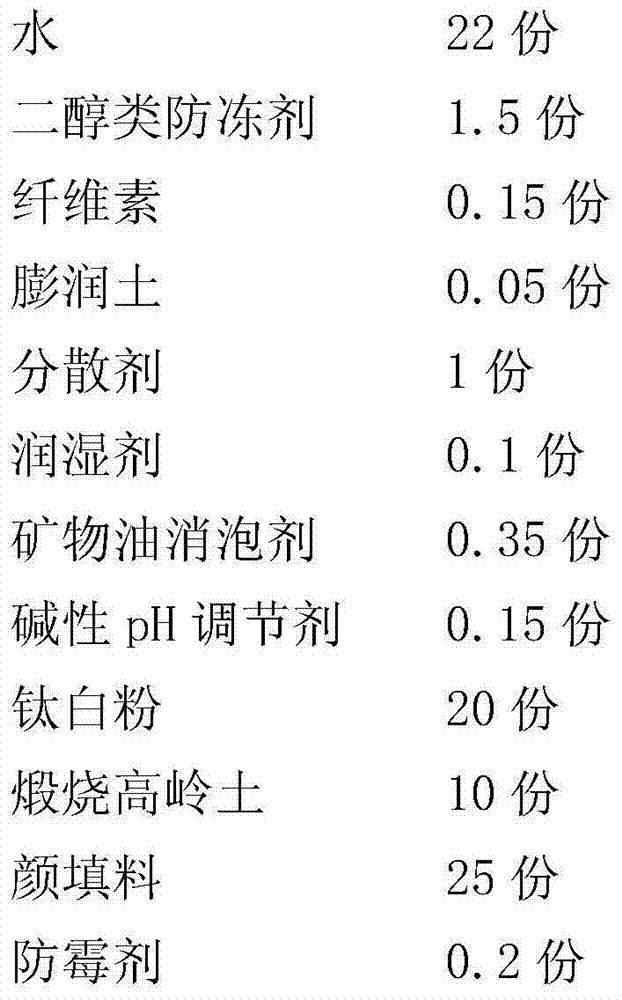

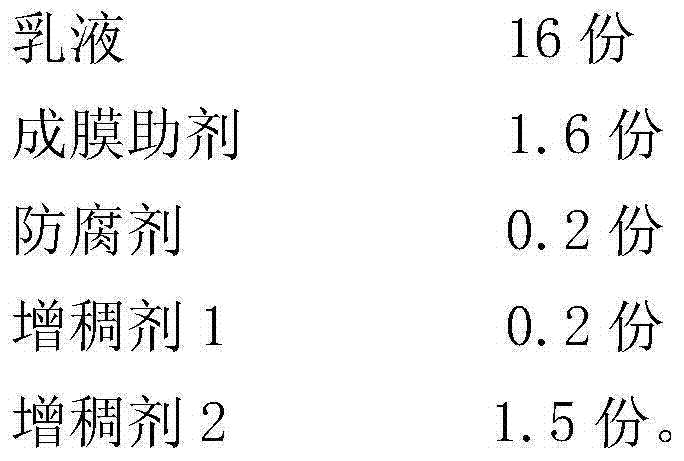

[0041] A non-diluting one-time brushing forming latex paint finish, which is prepared by the following raw materials according to the following weight ratio:

[0042]

[0043]

[0044] The preparation method of this no-diluted one-time painting latex paint topcoat comprises the following steps carried out in sequence:

[0045] (1) Mix 0.1 part of bentonite and 1 part of glycol antifreeze for later use;

[0046] (2) Start the disperser and adjust the speed to 400 rpm. At this speed, first add 29 parts of water, 0.7 parts of dispersant, 0.12 parts of wetting agent and 0.1 part of mineral oil defoamer, and then add bentonite and glycol Antifreeze-like mixture, then disperse for 2 minutes;

[0047] (3) At a speed of 400 rpm, add 0.13 parts of cellulose and 0.1 part of alkaline pH regulator in sequence. After the cellulose is completely dissolved, add 15 parts of titanium dioxide, 10 parts of calcined kaolin, and flash 5 parts of kaolin, 3 parts of pigment and filler celite49...

Embodiment 3

[0050] A non-diluting one-time brushing forming latex paint finish, which is prepared by the following raw materials according to the following weight ratio:

[0051]

[0052]

[0053] The preparation method of this no-diluted one-time painting latex paint topcoat comprises the following steps carried out in sequence:

[0054] (1) Mix 0.1 parts of bentonite and 1.2 parts of glycol antifreeze for later use;

[0055] (2) Start the disperser and adjust the speed to 200 rpm. At this speed, first add 23.8 parts of water, 0.8 parts of dispersant, 0.15 parts of wetting agent and 0.2 parts of mineral oil defoamer, and then add bentonite and glycol Antifreeze-like mixture, then dispersed for 4 minutes;

[0056] (3) At a speed of 200 rpm, add 0.2 parts of cellulose and 0.15 parts of alkaline pH regulator in sequence. After the cellulose is completely dissolved, add 19 parts of titanium dioxide, 9 parts of calcined kaolin, and flash 4 parts of kaolin, 3 parts of pigment and fille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com