Processing technology for aluminum plastic packaging bags

A processing technology and packaging bag technology, which is applied in the field of aluminum-plastic packaging bag processing technology, can solve the problems of large amount of scrapped aluminum-plastic packaging bags, unstable quality of aluminum-plastic packaging bags, and inaccurate lamination of two-layer films, etc., to achieve Easy to center, high strength, thick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

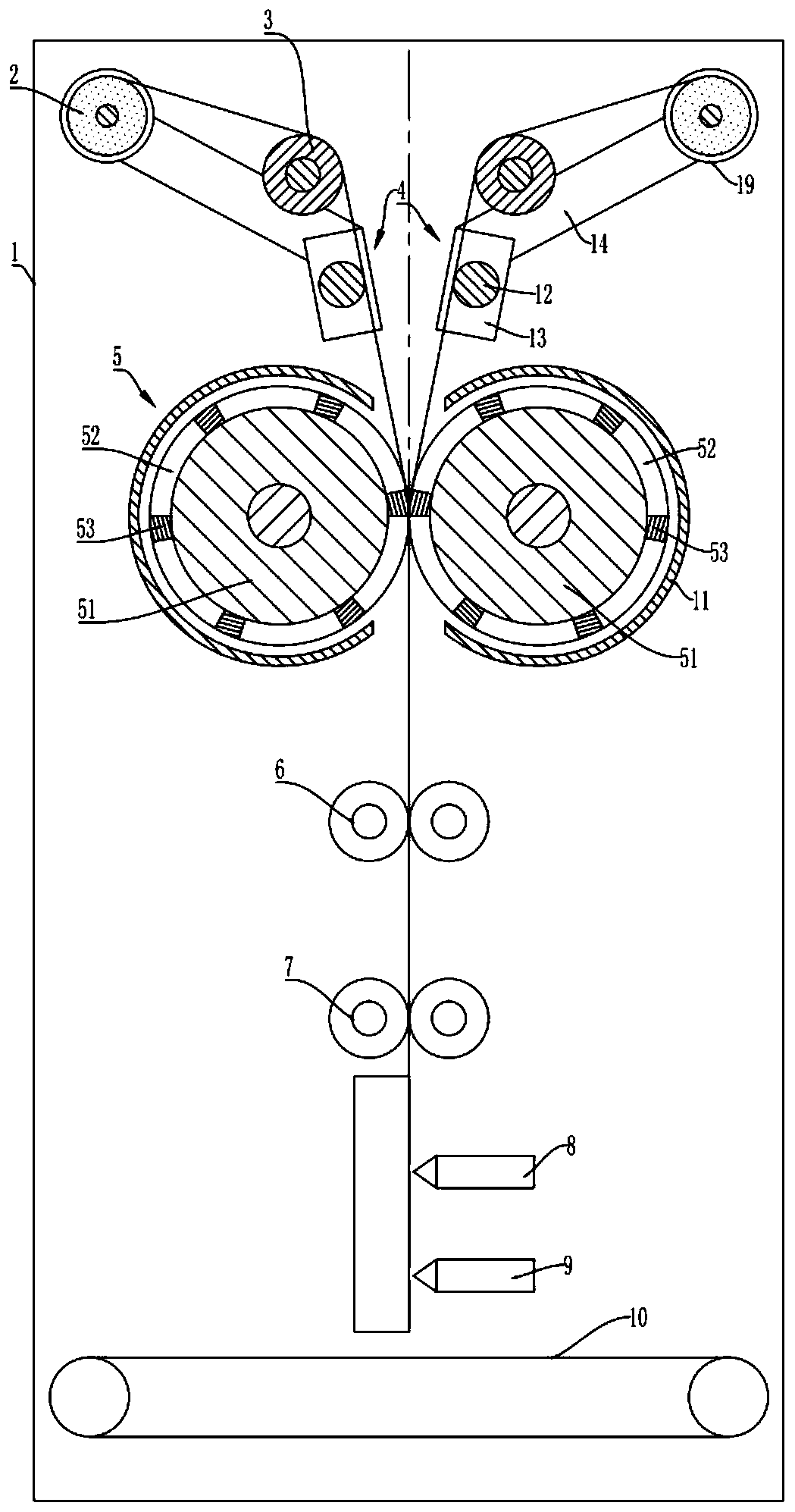

[0040] Embodiment one is basically as attached Figure 1 to Figure 5 Shown:

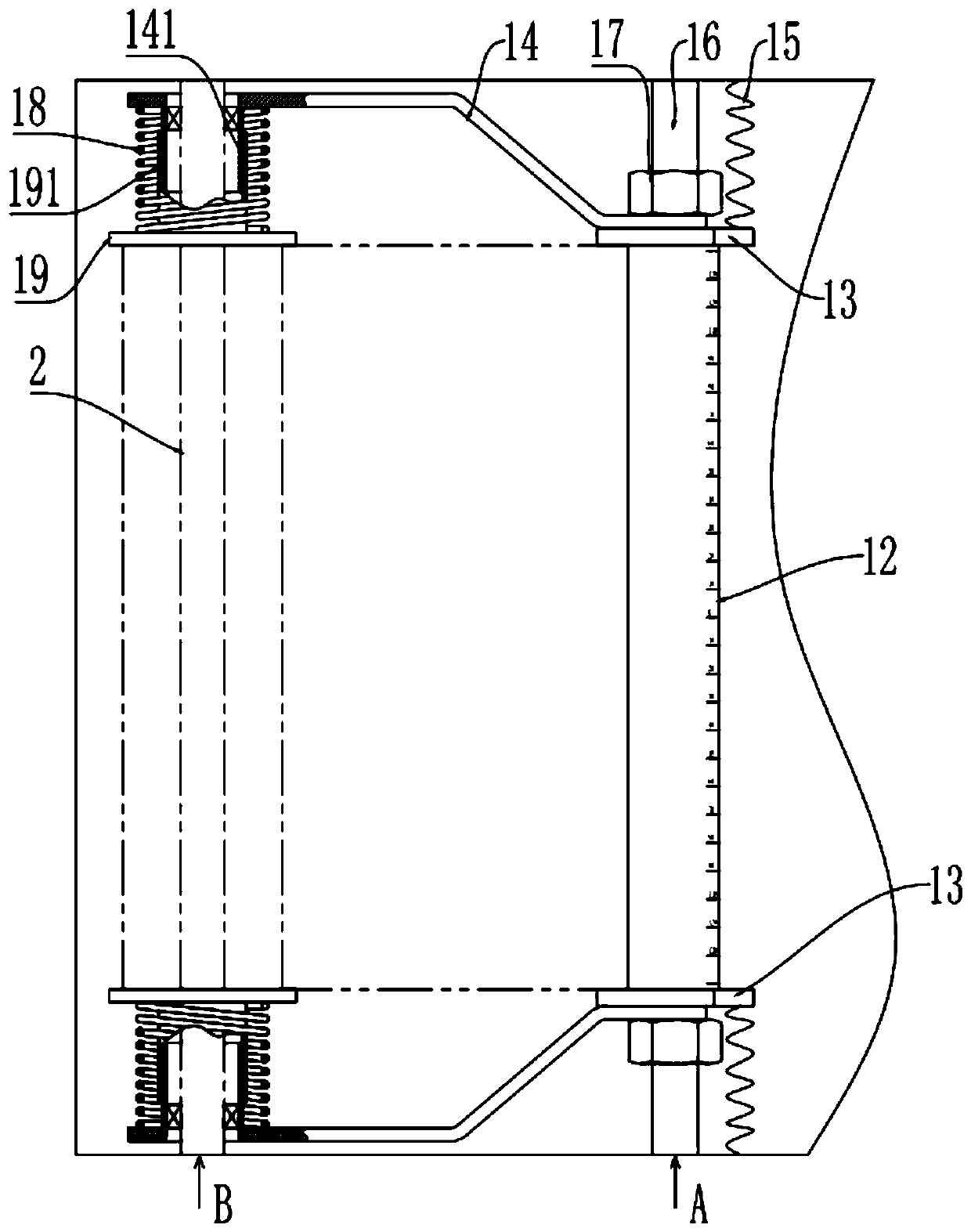

[0041] combine figure 1, the processing technology of aluminum-plastic packaging bags requires the use of aluminum-plastic packaging bag processing devices, and the aluminum foil packaging bag processing devices include two guide rollers 3, two guide units 4, and a thermal Sealing machine 5, two cooling rollers 6, a pair of traction rollers 7, a cutting knife 8, a cutting knife 9 and an assembly line 10, the guide roller 3, cooling roller 6 and traction roller 7 are all connected in rotation by bearings On the frame 1, the traction roller 7 and the cooling roller 6 are driven by the motor to rotate, and the cutting knife 8 and the cutting knife 9 can cut the aluminum-plastic packaging bag from right to left.

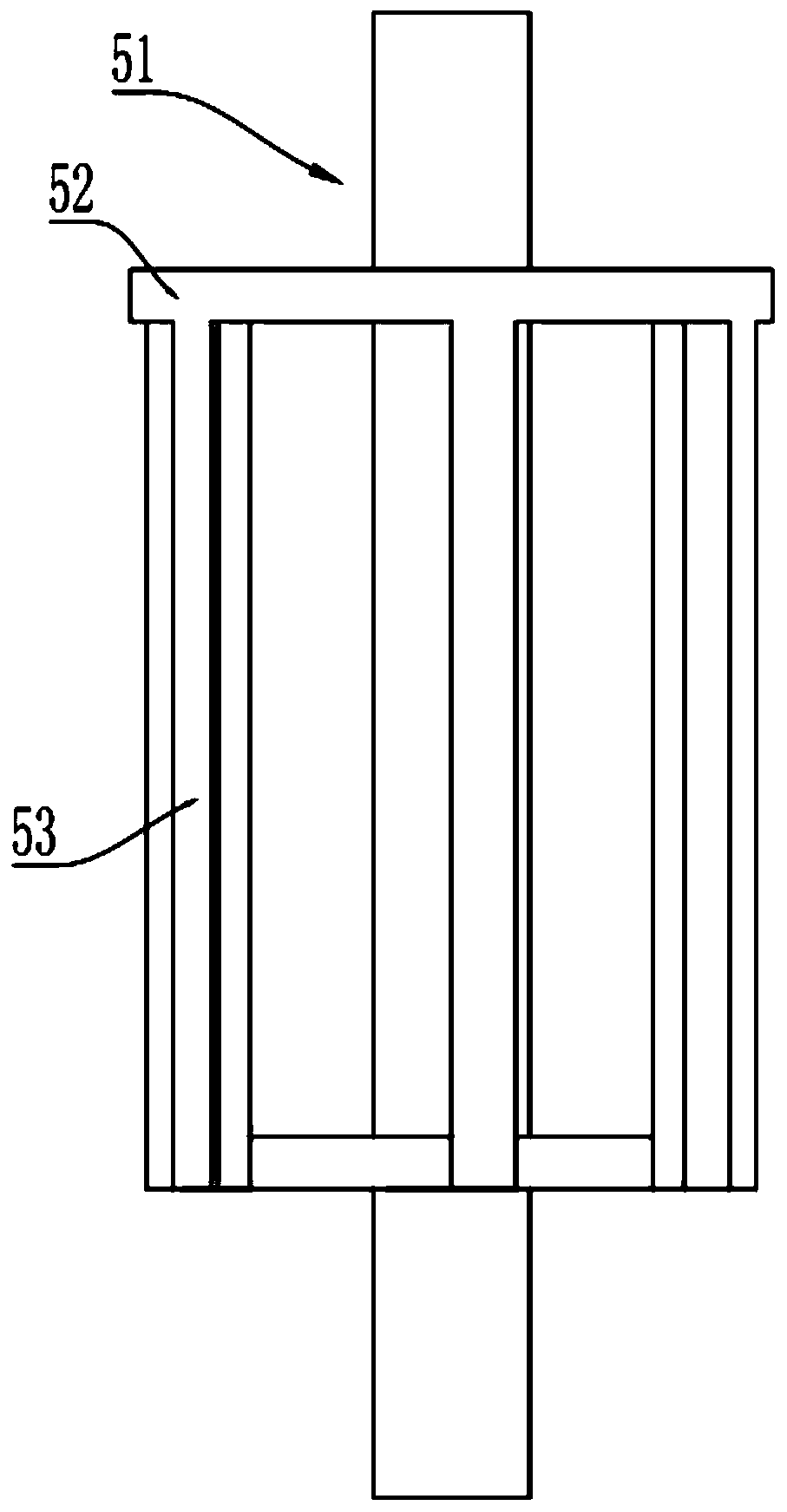

[0042] to combine figure 1 and figure 2 The heat-sealing machine 5 includes a driver and a heat-sealing roller, the driver adopts a motor, and the motor is fixedly installed on the frame 1...

Embodiment 2

[0058] Embodiment two is basically as attached Figure 6 As shown: Embodiment 2 has the following improvements on the basis of Embodiment 1. Step C is also included between Step 1 and Step 2. Step C is deviation correction: a sensor 20 and a controller are installed on the frame 1, The sensor 20 is electrically connected to the controller. The number of the sensor 20 is four. The sensor 20 adopts a proximity switch. The sensor 20 is located on both sides of the film after unwinding. When any sensor 20 senses the film, the controller controls the traction Roller 7 stops pulling, and heat sealer 5 shuts down.

[0059] Because the film of the aluminum-plastic packaging bag is opaque, the sensor 20 can sense the existence of the film. When the sensor 20 senses the film, it means that the film has been deflected. If the production continues, it will make the produced aluminum-plastic packaging The bag has the problem of low strength or unqualified, but in the second embodiment, af...

Embodiment 3

[0061] Embodiment 3 is improved on the basis of Embodiment 1, and exhaust hoods are installed on the front and rear sides of the heat-sealed rollers, and the exhaust hoods are connected to an external negative pressure machine; therefore, step D is also included in this embodiment 3. , Step D is exhaust gas absorption, and the gas generated by heat sealing is sucked away through the exhaust hood.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com