Energy-saving leveling putty powder

A technology of powder and heavy calcium carbonate powder, which is applied in the field of building materials, can solve the problems of increasing production costs and construction costs, increasing packaging, transportation and construction processes, and increasing the proportion of putty powder, so as to reduce production costs and construction costs, reduce The effect of weight and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

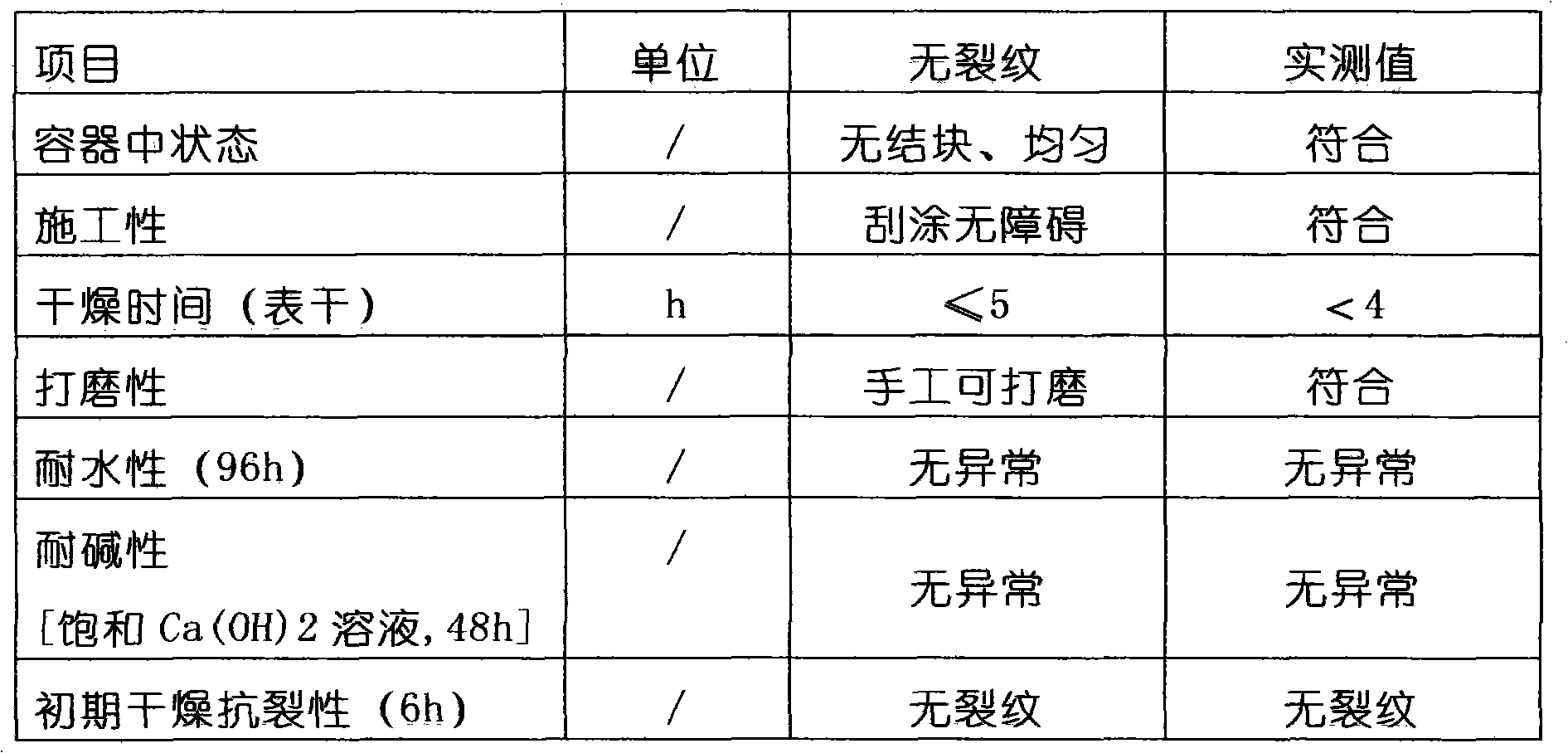

[0009] Take the production of 100 energy-saving leveling putty powders as an example. The processed raw materials are selected. The proportions by weight of the ingredients are: 425# white cement 28%, gray matter calcium powder 7%, heavy calcium carbonate powder 51%, 80 mesh polystyrene Granules 9%, 2mm polypropylene fiber 0.5%, polyvinyl alcohol 0.9%, carboxymethyl cellulose 1.1%, polymer powder 2.5%.

[0010] Put about half of the amount of white cement, gray calcium powder, heavy calcium carbonate powder and polystyrene particles into the container, and stir for 10 minutes; then add polypropylene fiber, polyvinyl alcohol, carboxymethyl cellulose and polymer powder, after stirring for 10 minutes; then add the remaining white cement, gray calcium powder, heavy calcium carbonate powder and polyphenylene particles, continue stirring for 30 minutes to discharge the material, pack it into a bag after exhaust, and weigh it according to the bagging standard seal. The putty powder ...

Embodiment 2

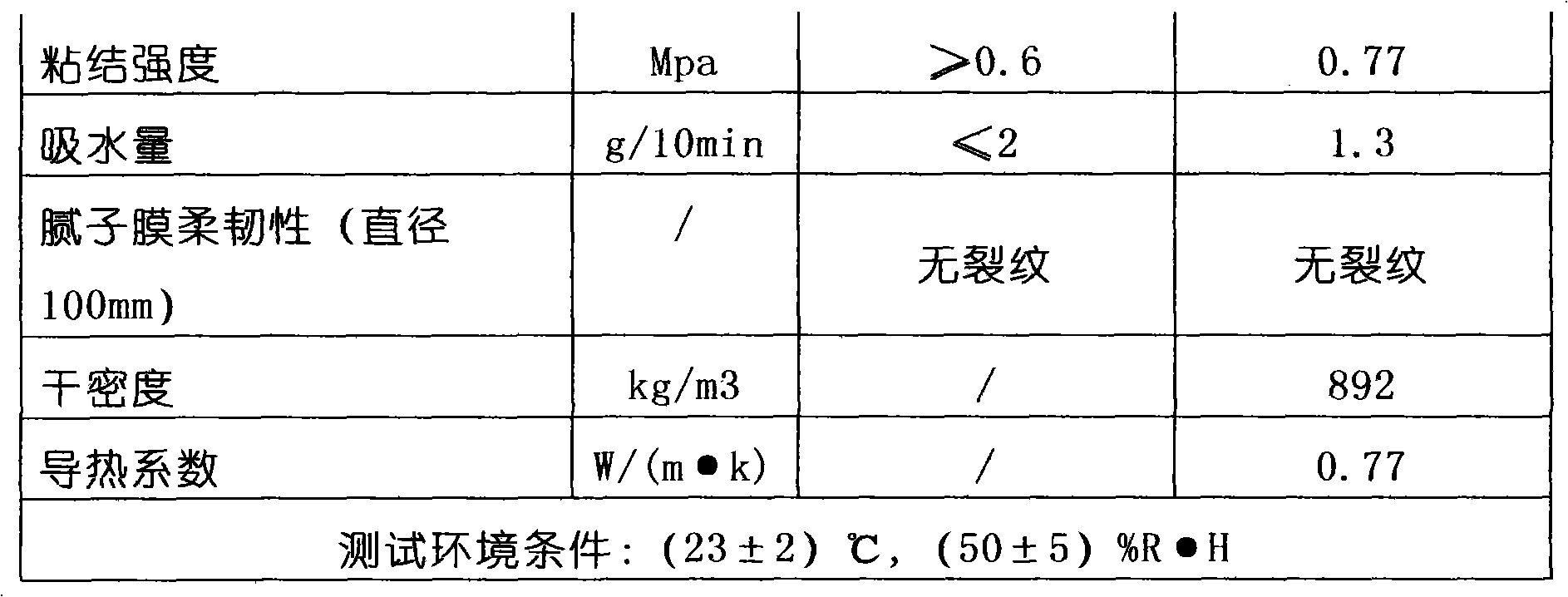

[0015] According to the same process of the previous example, and according to the ratio range of the following preferred raw materials, the raw materials are mixed and stirred, wherein 28% of 425# white cement, 8% of gray matter calcium powder, 55% of heavy calcium carbonate powder, 55% of 70 mesh vitrified microspheres %, 0.6% of 2mm polypropylene fiber, 0.7% of polyvinyl alcohol, 0.8% of carboxymethyl cellulose, and 1.9% of polymer powder.

[0016] A kind of energy-saving leveling putty powder of the present invention is prepared according to the preparation method, and its performance indicators are as follows:

[0017]

[0018]

Embodiment 3

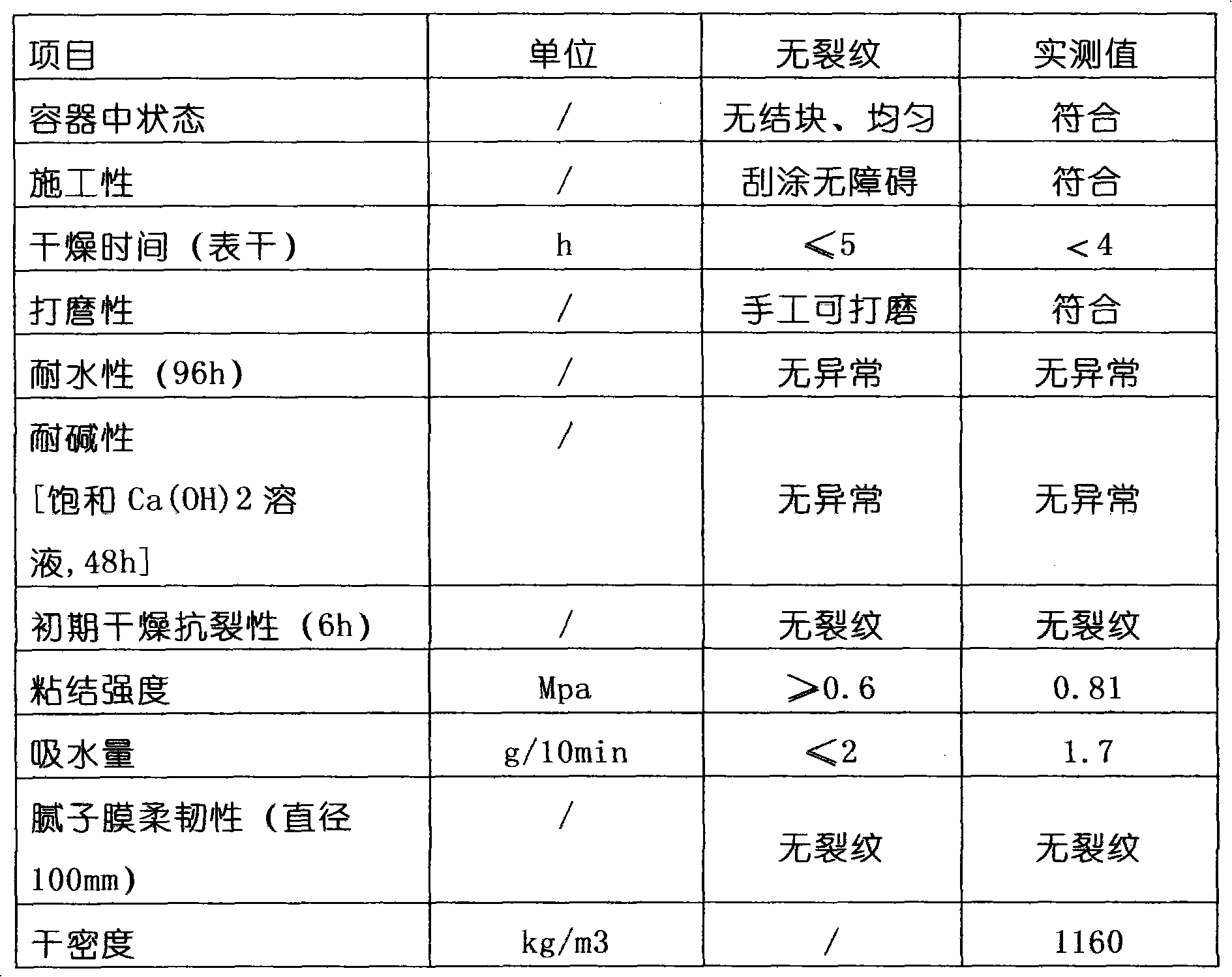

[0020] Prepare the raw materials according to the same process as the previous example, and mix and stir the raw materials according to the following preferred raw material ratio ranges, wherein 425# white cement 29%, gray matter calcium powder 7%, heavy calcium carbonate powder 44%, 100 mesh expansion Perlite 15%, 2mm polypropylene fiber 0.7%, polyvinyl alcohol 0.7%, carboxymethyl cellulose 1.3%, polymer powder 2.3%.

[0021] A kind of energy-saving leveling putty powder of the present invention is prepared according to the preparation method, and its performance indicators are as follows:

[0022]

[0023] The putty samples of the present invention are tested, and it is found that the putty powder of the present invention has outstanding heat insulation function, low thermal conductivity, good grinding performance, excellent adhesion, and water and seepage resistance. Moreover, the dry density is low, which greatly reduces the load of transportation and construction, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com