Patents

Literature

41results about How to "Reduce production and construction costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

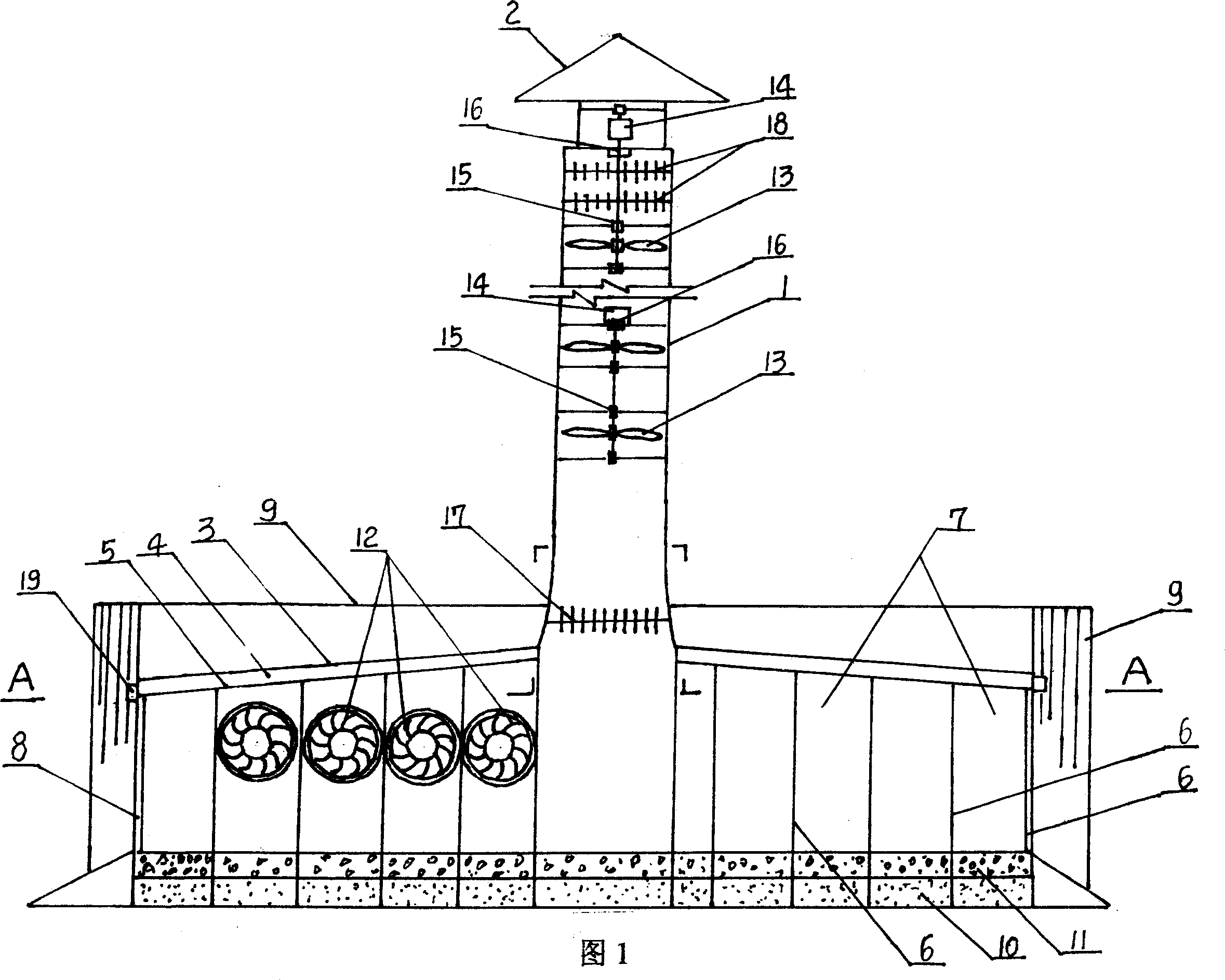

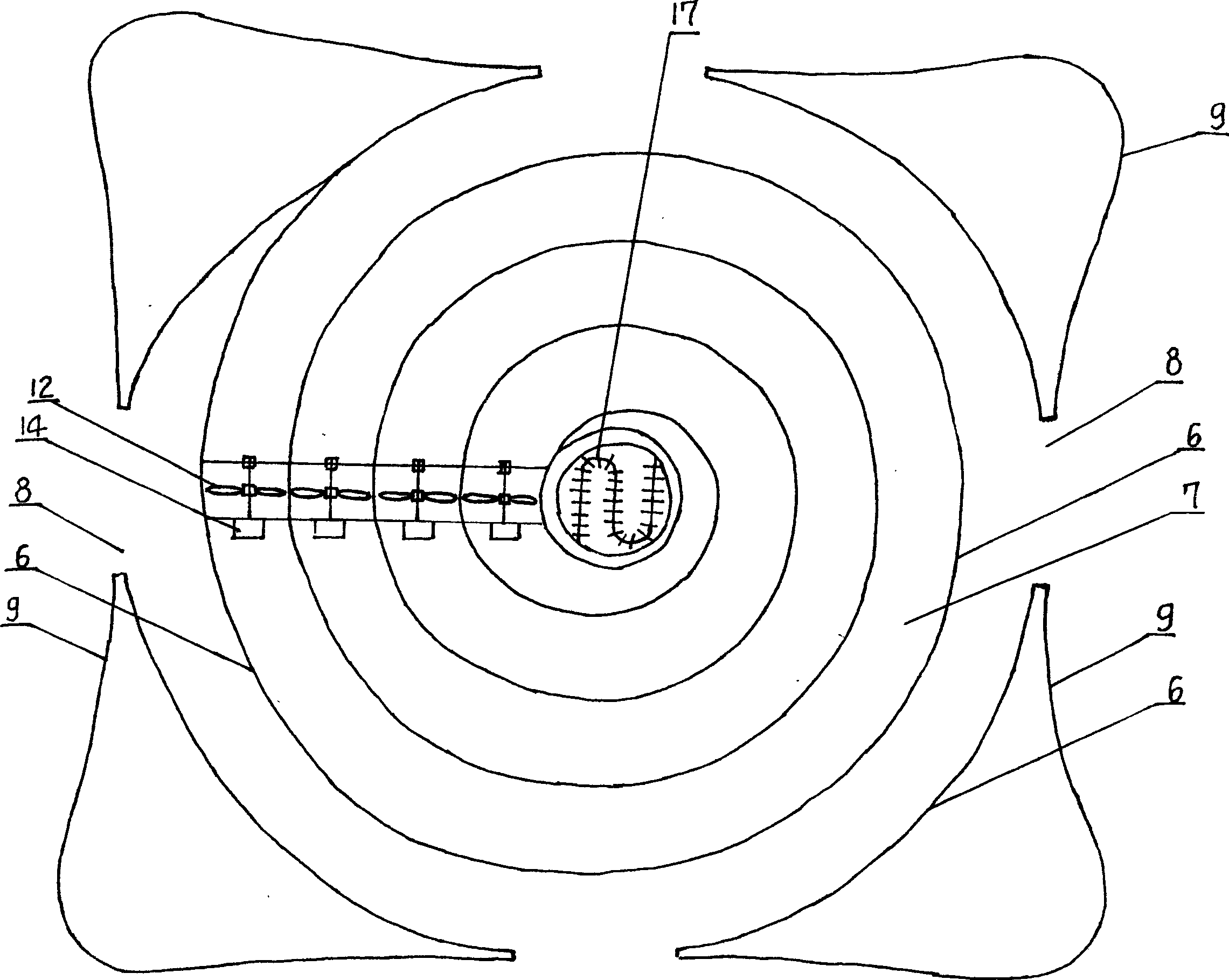

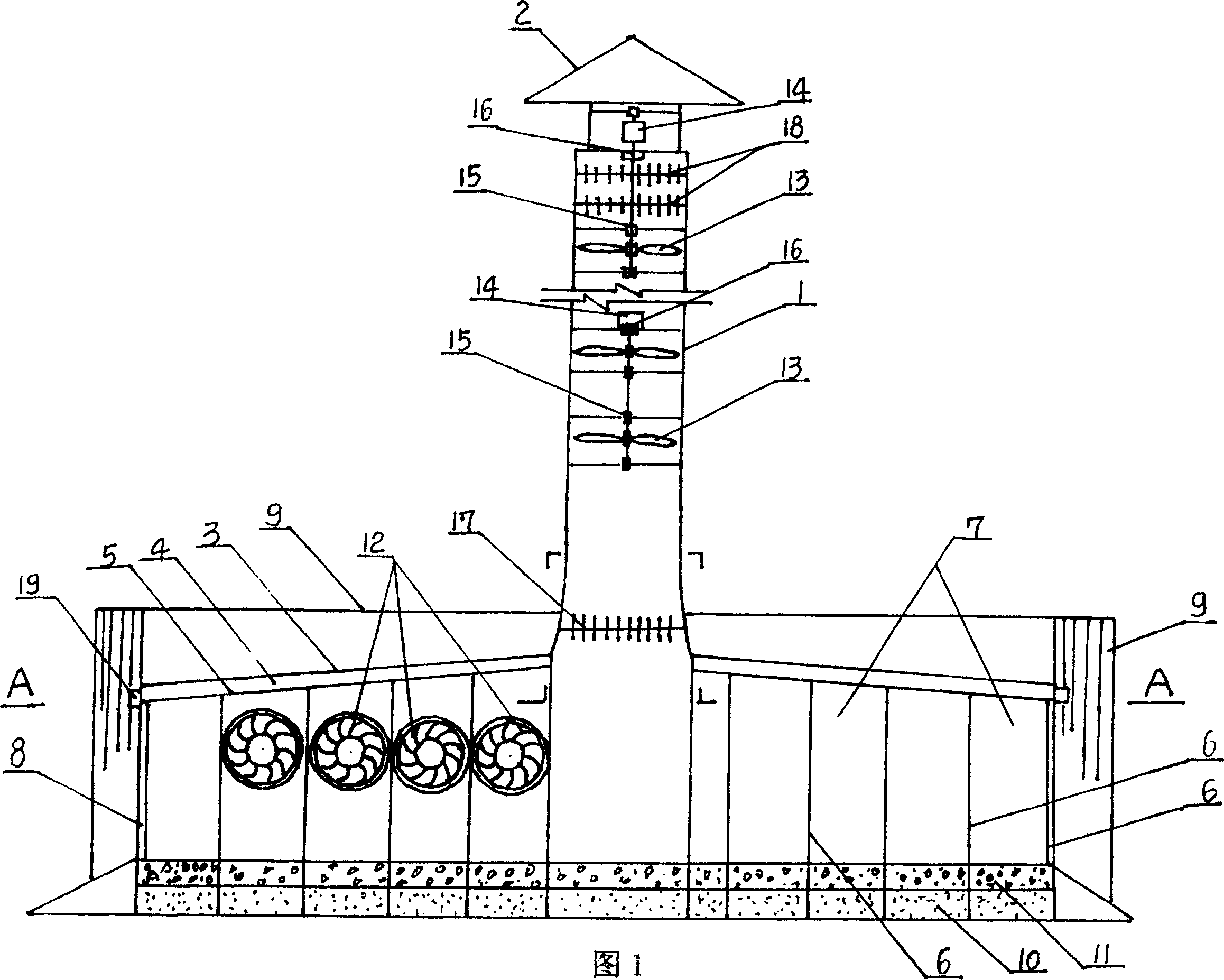

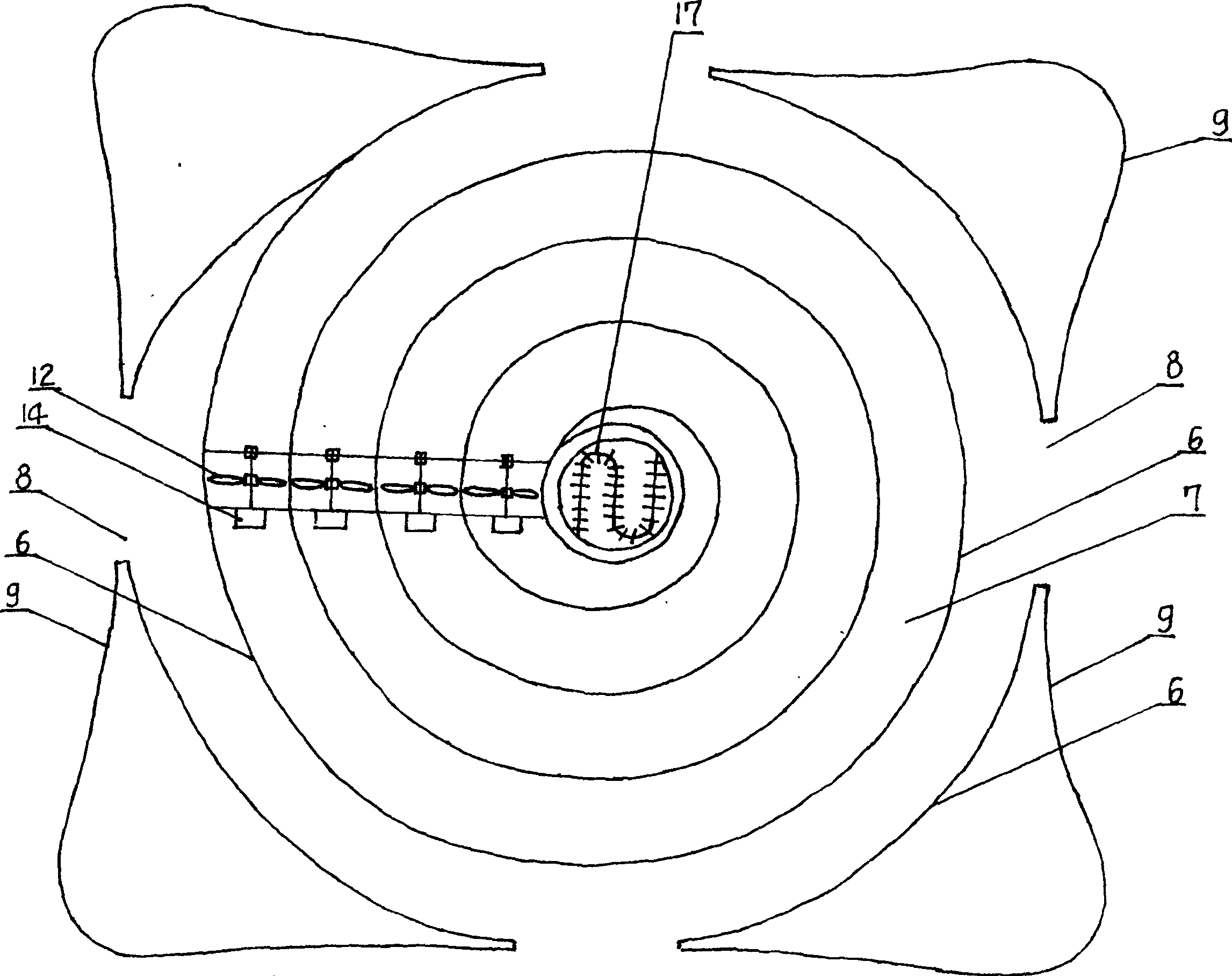

High efficiency solar electricity generator

InactiveCN1766309APracticalReduce construction and production costsSolar heating energyMachines/enginesEngineeringSolar power

The invention discloses a new type high effective solar generation device, which comprises the following parts: chimney-shape hollow wind tower, solar greenhouse, wind tunnel, wind collection inlet, heat pump condenser, heat pump expander and turbine generator set. The invention reduces the construction cost, which improves the generation efficiency greatly.

Owner:HEBEI AGRICULTURAL UNIV.

Technology for making sand from sandstone

ActiveCN101525218ASolve construction needsReduce production and construction costsPrimary screeningSewage

The invention discloses a technology for making sand from sandstone, comprising the steps of: coarse crushing and machining, storing the raw materials of semi-finished products, primary screening the raw materials of semi-finished products, rescreening, dehydrating, machining in a way of middle crushing, machining in a way of fine crushing, machining in a way of superfine crushing, making sand by a sand-making machine, treating and recovering sewage, etc. the invention is applicable for making the sand by taking the sandstone as raw material.

Owner:SINOHYDRO BUREAU 5

Full-sea-depth unmanned submersible

ActiveCN106828834ALow costReduce weightVessel partsUnderwater equipmentMaterial typeStructure of the Earth

The invention discloses a full-sea-depth unmanned submersible. The full-sea-depth unmanned submersible is characterized in that low-cost easily-available lightweight common materials resistant to seawater corrosion and collision and having a certain structural strength are used for making a dimensional shell of the submersible; the interior of the submersible and all interior gaps of all equipment, facilities and components carried by the submersible are filled with liquid, so that a closed space type pressure resisting mode that an exterior hard pressure-resistant dimensional shell of a previous submersible bears all pressure is converted into a material-type pressure resisting mode that materials for manufacturing the dimensional shell of the submersible as well as the equipment, the facilities and the components carried inside the submersible bear pressure jointly. The full-sea-depth unmanned submersible has the advantages that the characteristics that liquid is incompressible, liquid with a roughly consistent density bears no larger pressure and the pressure is conductible are used, so that manufacturing cost of the submersible is reduced significantly, and the submersible is not restricted by a submerged depth.

Owner:王晓航

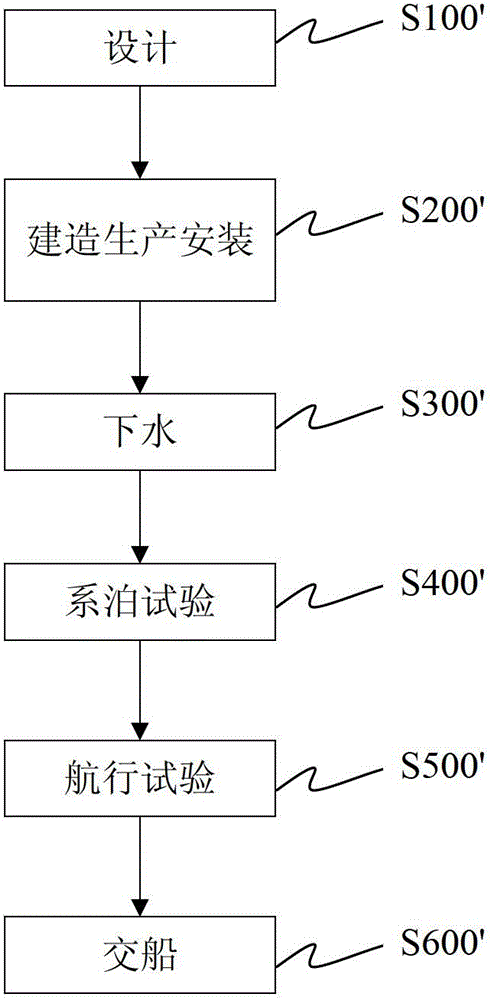

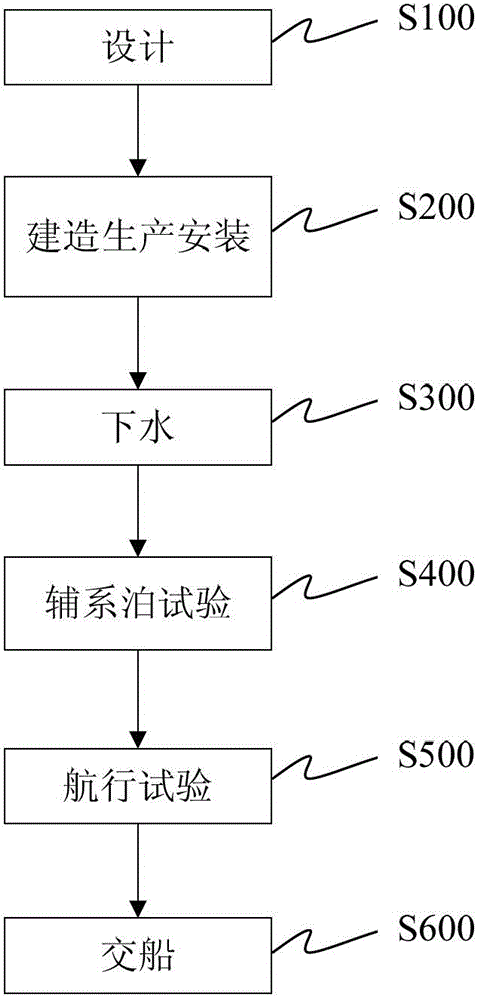

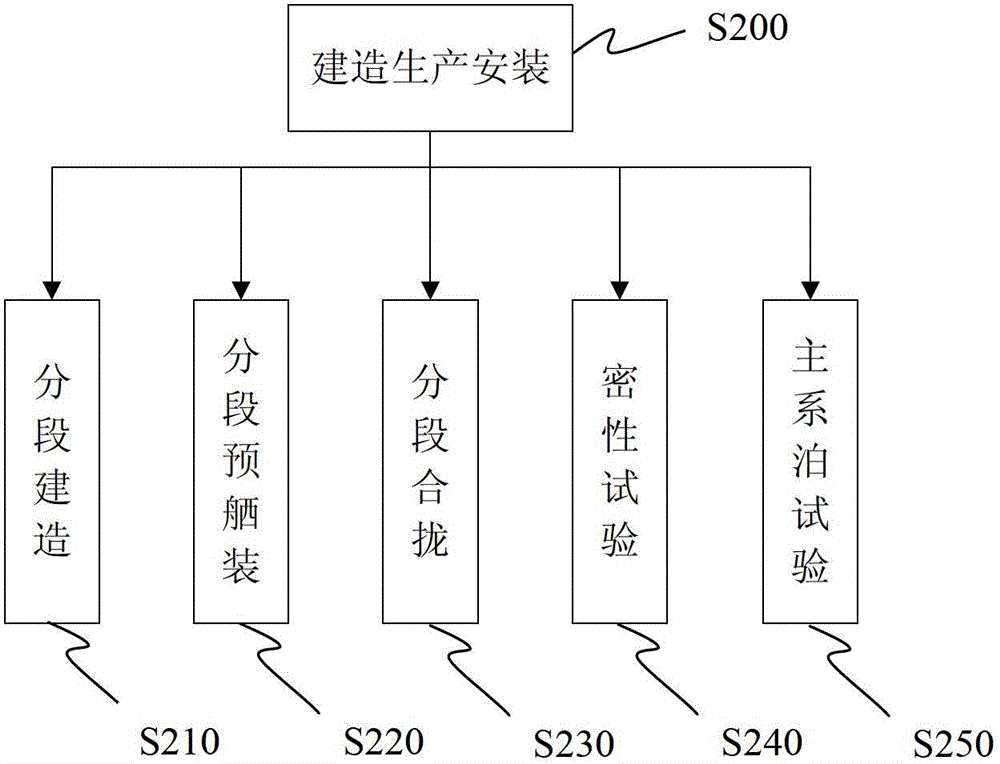

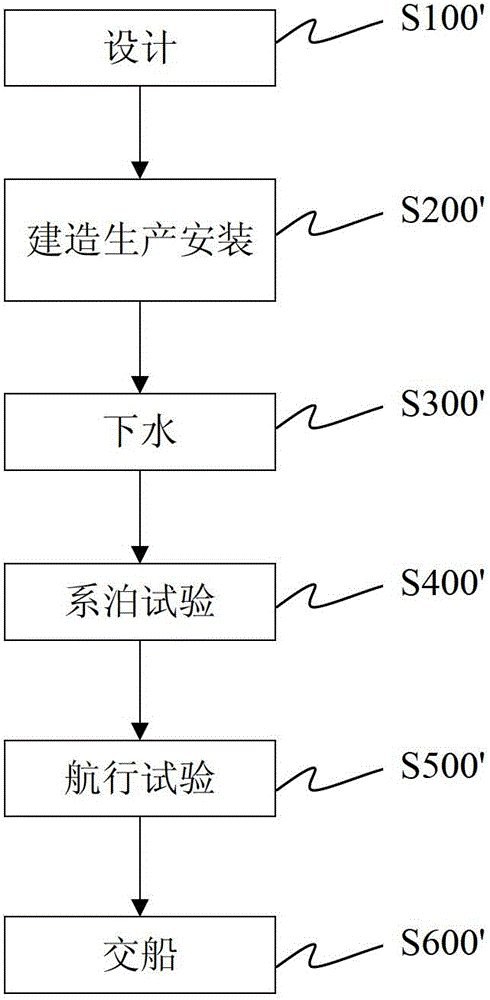

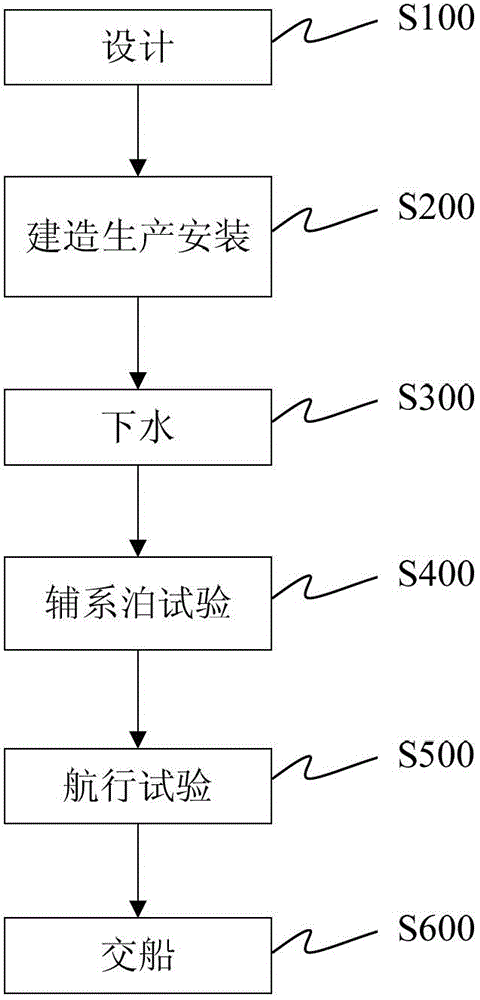

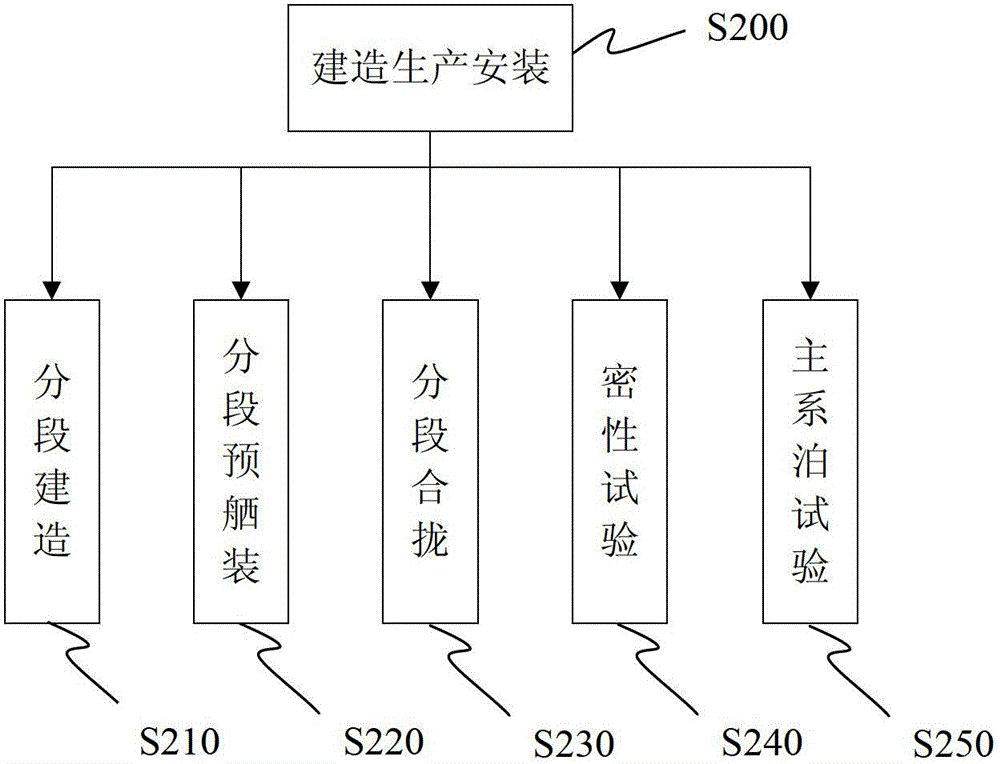

Offshore platform construction and implementation method

ActiveCN104029789AShorten the timeImprove production and construction efficiencyVessel partsBuilding constructionSystems engineering

The invention discloses an offshore platform construction and implementation method and relates to the field of marine engineering and ship construction. The offshore platform construction and implementation method includes steps of design; construction, production and installation; launching; mooring test; sailing test and ship delivery. The mooring test includes a main mooring test and an auxiliary mooring test, the main mooring test is simultaneously performed with the construction, production and installation, and the auxiliary mooring test is performed between the launching and the sailing test. The offshore platform construction and implementation method saves the time of an individually-performed main mooring test, thereby improving the production and construction efficiency, shortening construction periods and reducing production and construction costs.

Owner:CIMC OFFSHORE ENG INST +2

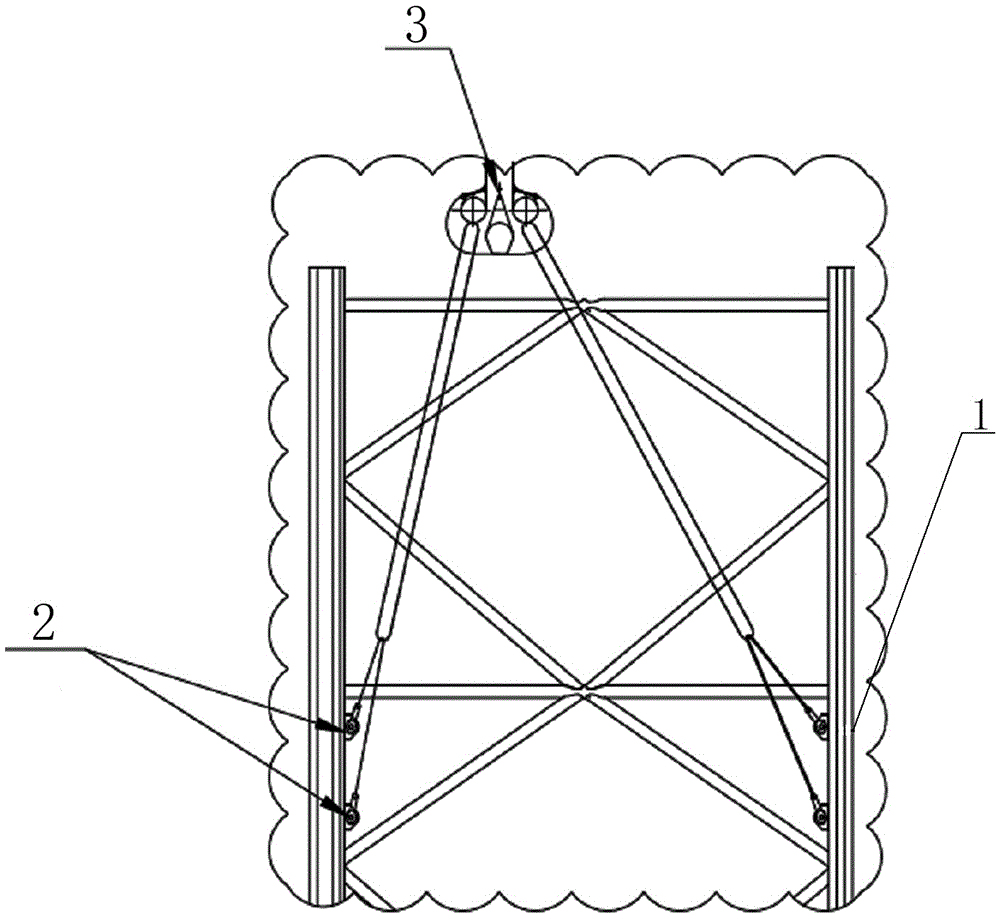

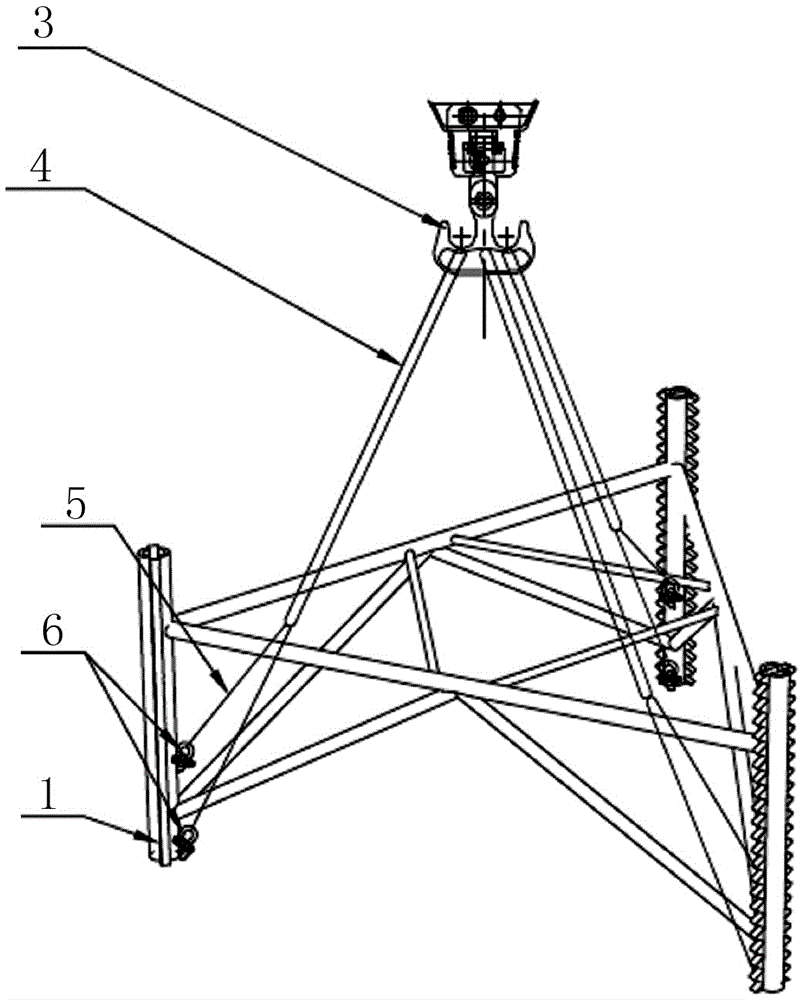

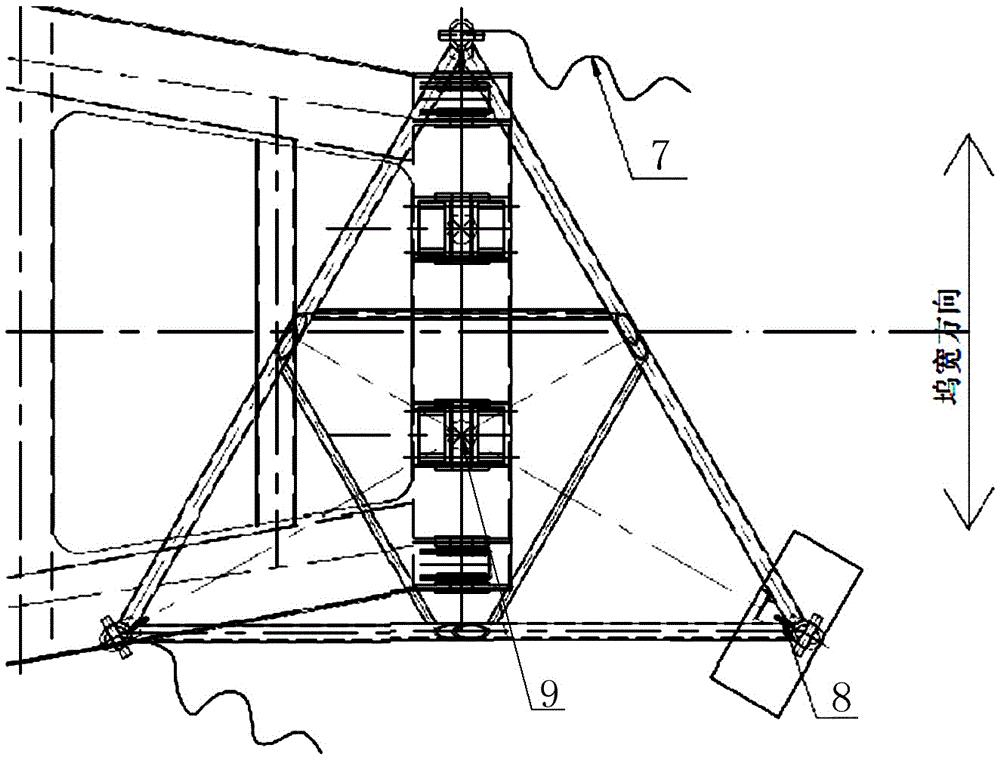

Method for carrying out pile leg connection by utilizing 3000t floating crane

ActiveCN105523477AReduce the cycle of segment collapseReduce production and construction costsLoad-engaging elementsButt weldingSafe operation

The invention discloses a method for carrying out pile leg connection by utilizing a 3000t floating crane. The method comprises the following steps: carrying out water drilling on a pile below an offshore self-elevating type drilling platform, and pre-joining two truss type pile leg sections on a slipway to form a total section (with height being about 70 cm, triangle edge length being 13 m, and total height being about 550 t); then, assembling a rope and a rig for hoisting; and finally, utilizing a secondary hook (with safety load being 750t) of the 3000t floating crane to hoist the pile leg total section to a trunk of the drilling platform from the slipway, positioning the floating crane by utilizing a tug and a rope, carrying out butt-welding on the lower end of the pile leg total section and the top end of the front pile leg section, and dismounting a hoisting tool until the total section is firmly welded. The method for carrying out pile leg connection disclosed by the invention can effectively reduce operations such as high-altitude put-up, welding, transporting and the like of pile leg connection, and is carried out at a height of about 100m from the ground; meanwhile, the hoisting times of the floating crane are halved; hoisting points are reasonably arranged, so that the pile leg total section is uniform in stress; and the method not only can guarantee the safe operation, but also can greatly reduce the production cost and can guarantee the construction quality of a pile leg.

Owner:CHINA MERCHANTS HEAVY IND JIANGSU

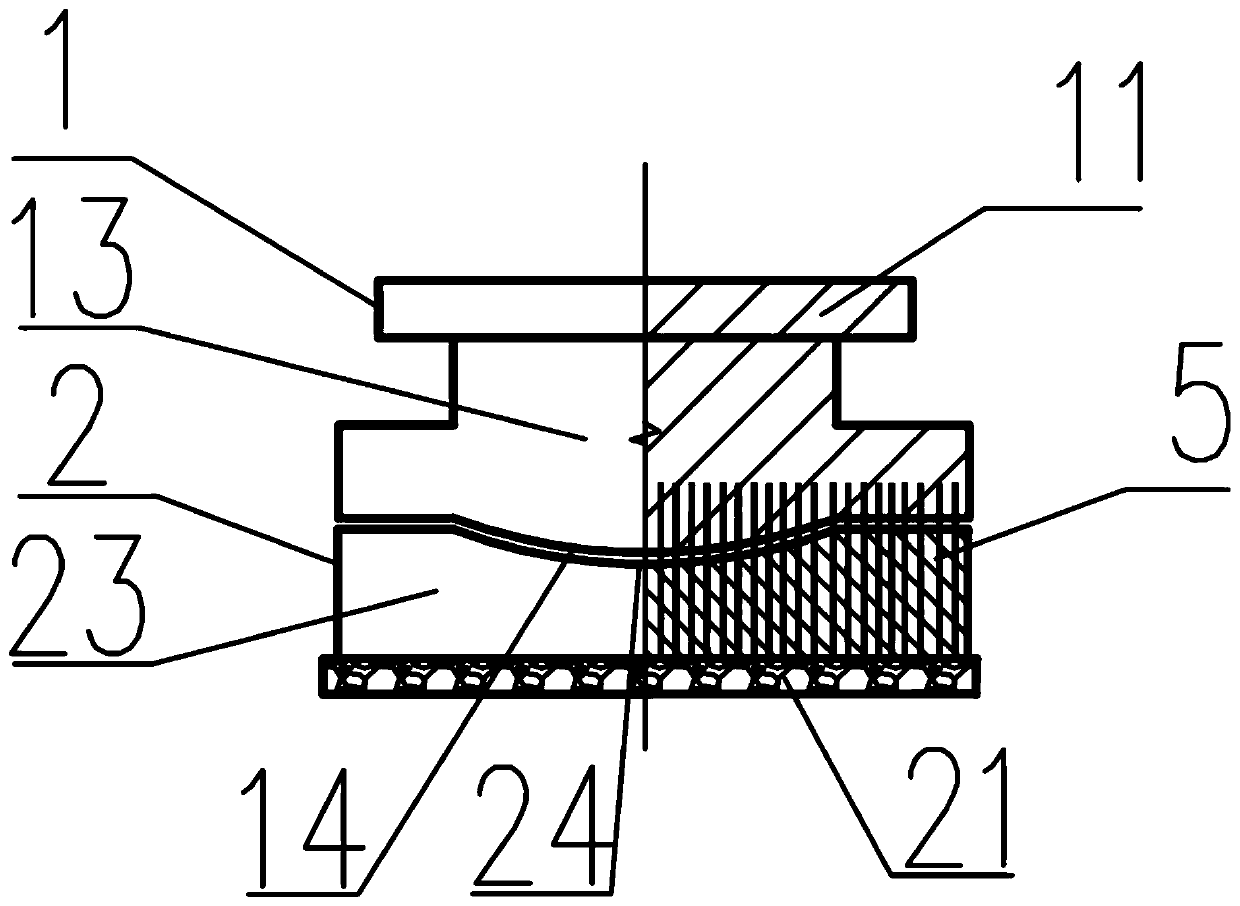

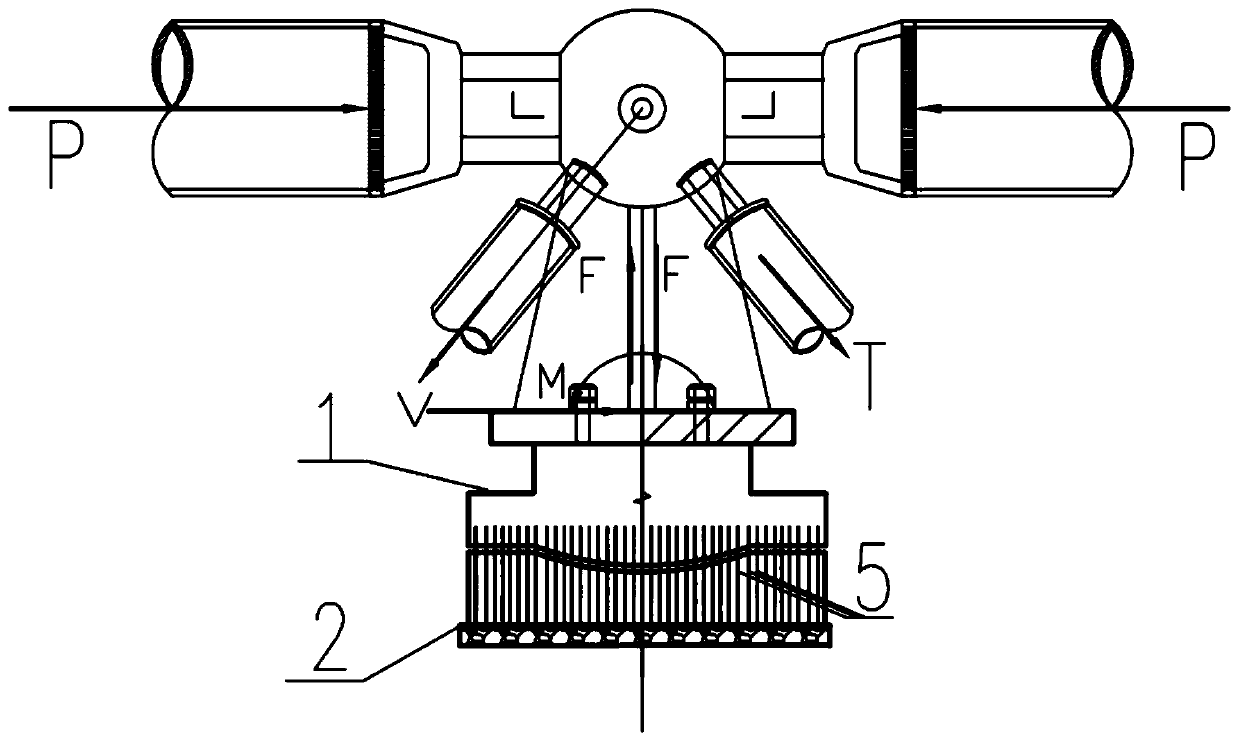

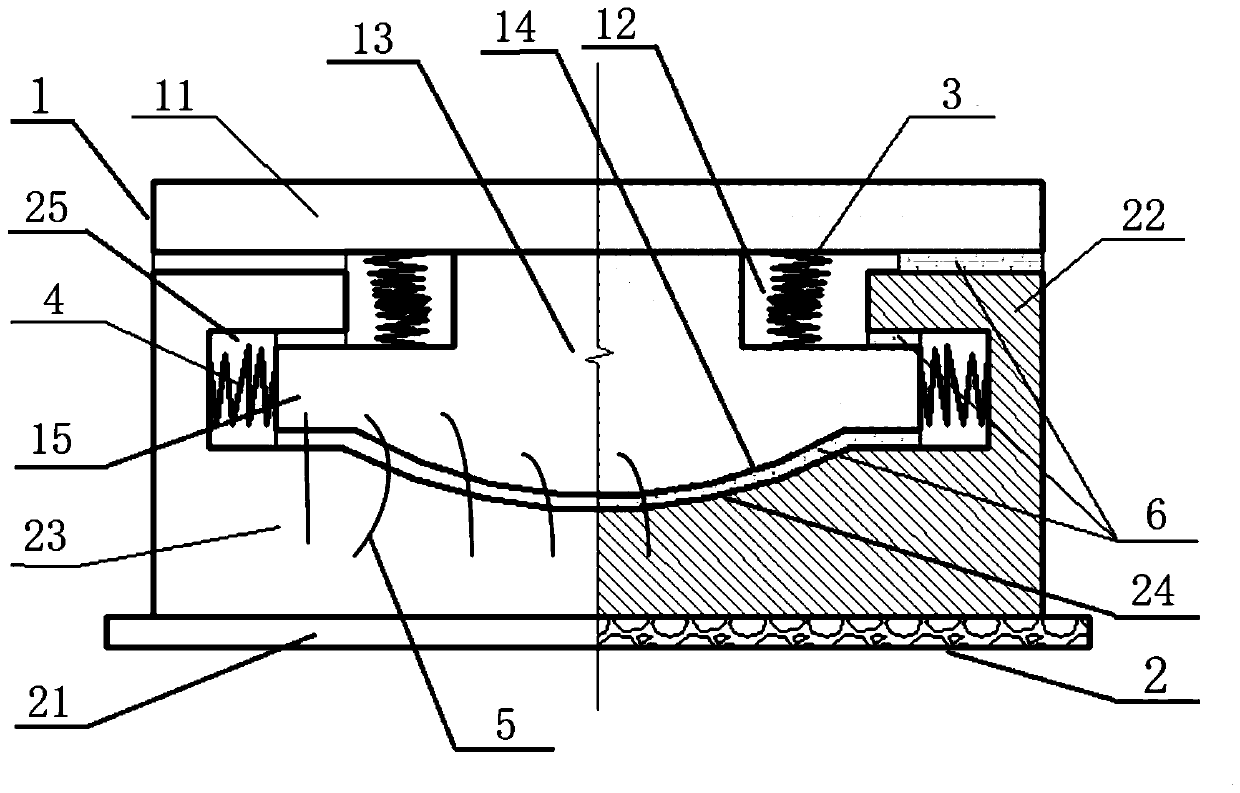

Large-span grid structure multidirectional bearing and anti-seismic spherical hinge support joint

PendingCN109750889AGood vertical bearing capacityGood reset functionProtective buildings/sheltersShock proofingHorizontal forceTemperature stress

The invention provides a large-span grid structure multidirectional bearing and anti-seismic spherical hinge support joint, comprising an upper support, a lower support and a flexible steel bar group.An upper support base is located at the lower end of the upper support, and a lower support supporting seat is located at the upper end of the lower support. The spherical convex face of the upper support base and the spherical concave face of the lower support supporting seat are connected in an embedded fit mode. The upper support and the lower support are connected through the flexible steel bar group. Micro vertical, horizontal and rotary displacements can be allowed, the stability of the structure out of the plane is limited, and the load effects of bearing vertical pressure, stirring force, horizontal force, bending moment, earthquake force, temperature stress and the like are achieved. The structure is used for absorbing and consuming loads caused by earthquakes, the form of support nodes is simplified, good anti-seismic and damping effects on the upper grid structure are achieved, the influence of complex loads on deformation of the lower structure is reduced, and the overallanti-seismic performance of the structure is improved. The manufacturing is simple, the development of an assembly type space structure is promoted, and engineering popularization and application arefacilitated.

Owner:JIYANG COLLEGE OF ZHEJIANG A & F UNIV

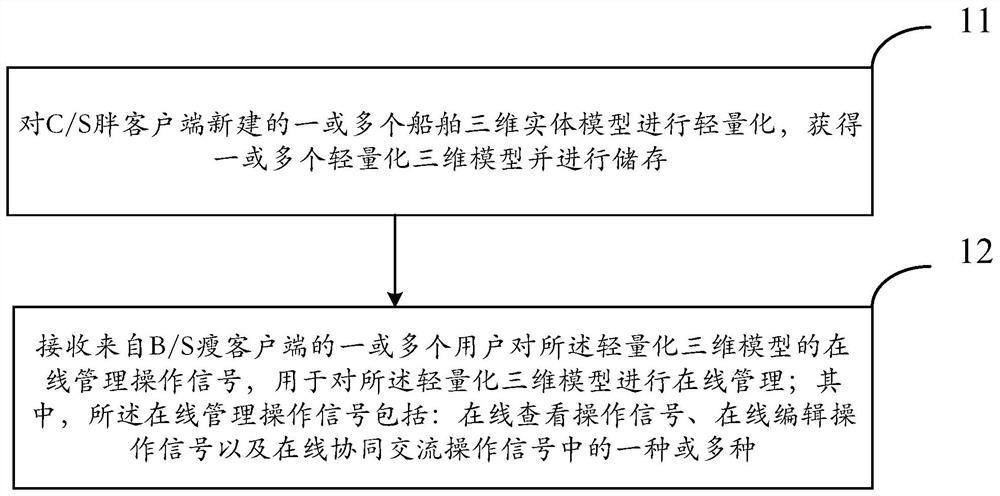

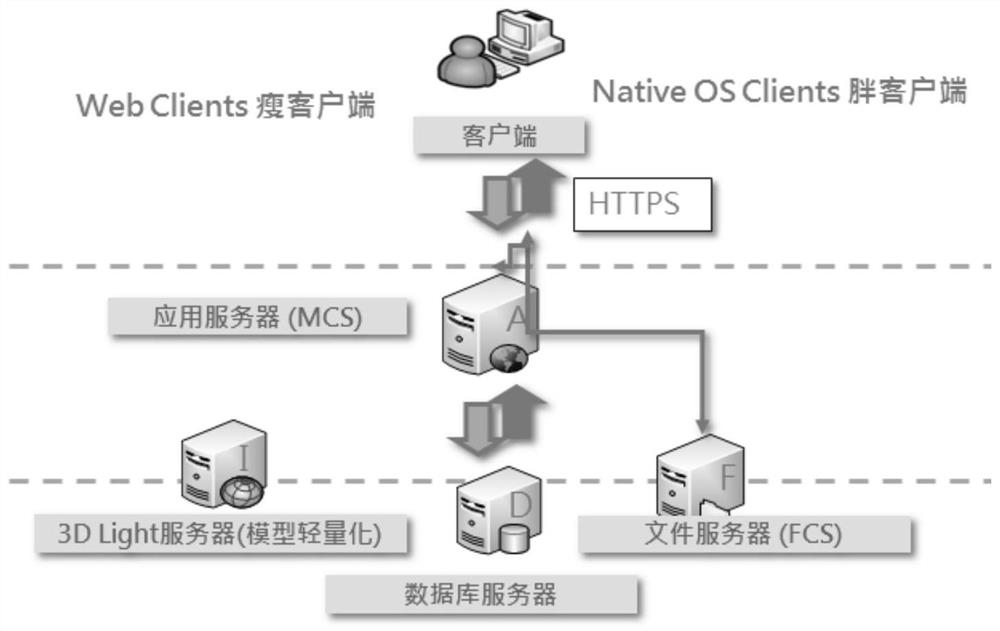

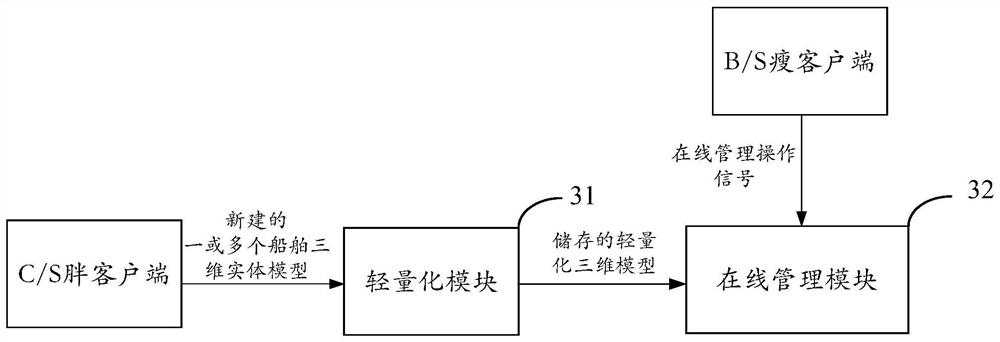

Online operation management method and system based on ship three-dimensional model and terminal

PendingCN111915276AAchieve fast and lightweightLower requirementGeometric CADOffice automationReworkIndustrial engineering

The invention provides an online operation management method and system based on a ship three-dimensional model and a terminal. The method comprises the steps: lightening a ship three-dimensional entity model newly built at a C / S fat client to acquire a light-weight three-dimensional model, and storing the light-weight three-dimensional model; receiving online management operation signals of one or more users from a B / S thin client, wherein the online management operation signals are used for carrying out online management on the lightweight three-dimensional model; wherein the online management operation signal comprises one or more of an online viewing operation signal, an online editing operation signal and an online cooperative communication operation signal. The problems that in the prior art, the requirement for field terminal application equipment is high, the application cost is high, and online cooperation between design and manufacturing cannot be achieved for a three-dimensional model are solved. Online cooperation between ship design and manufacturing is achieved, online communication between field manufacturing personnel and designers is supported, the design problem existing in the manufacturing field is rapidly solved, design change and manufacturing rework are reduced, and the production and construction cost is saved.

Owner:JIANGNAN SHIPYARD GRP CO LTD

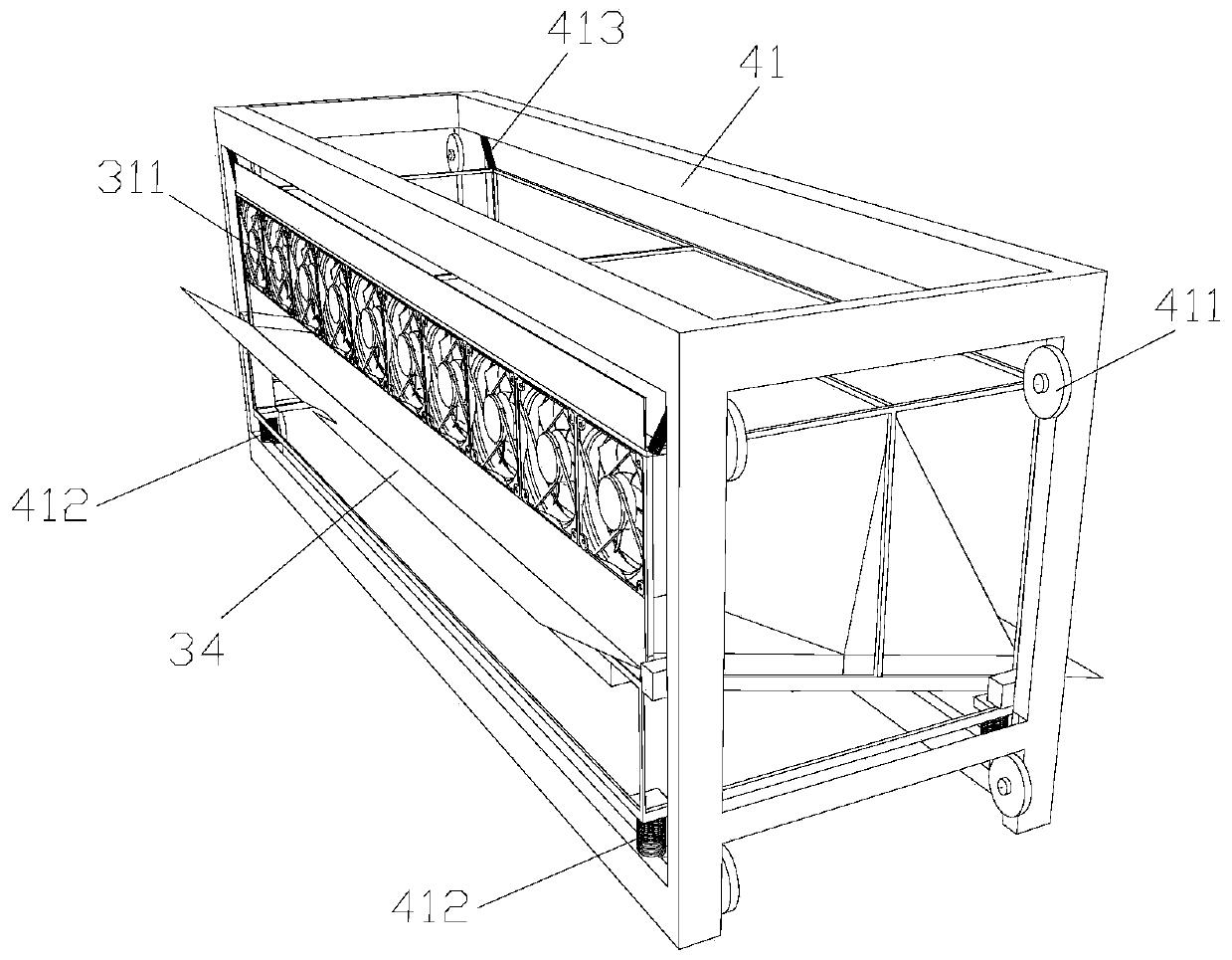

Screening and conveying device for yellow mealworm breeding and yellow mealworm breeding system

PendingCN111151444AImprove work efficiencyAchieve separationSievingGas current separationAnimal scienceZoology

The invention discloses a screening and conveying device for yellow mealworm breeding. The screening and conveying device for yellow mealworm breeding comprises a screening and conveying box connectedbetween an upper yellow mealworm breeding conveying device and a lower yellow mealworm breeding conveying device, wherein a worm skin collection chamber, a worm body conveying chamber and a worm dungcollection chamber are sequentially arranged in the screening and conveying box from top to bottom; the left opening part of the screening and conveying box communicates with the inlet ends of the worm skin collection chamber and the worm body conveying chamber; an inlet guide plate is arranged on the outer side of the inlet end of the worm body conveying chamber; and suction negative pressure isformed in the worm skin collection chamber. The outer side of the outlet end of the worm body conveying chamber is provided with an outlet guide plate for conveying the yellow mealworms in the worm body conveying chamber to the lower yellow mealworm breeding conveying device through the outlet guide plate. The invention also discloses a yellow mealworm breeding system. The screening and conveyingdevice for yellow mealworm breeding and the yellow mealworm breeding system have the advantages that operation is convenient and quick, the intelligence degree and the screening efficiency are high,no damage is caused to the yellow mealworms, the labor intensity of workers can be greatly reduced, and the screening and conveying device for yellow mealworm breeding and the yellow mealworm breedingsystem can adapt to an automatic breeding system well.

Owner:长沙博约生物科技有限公司

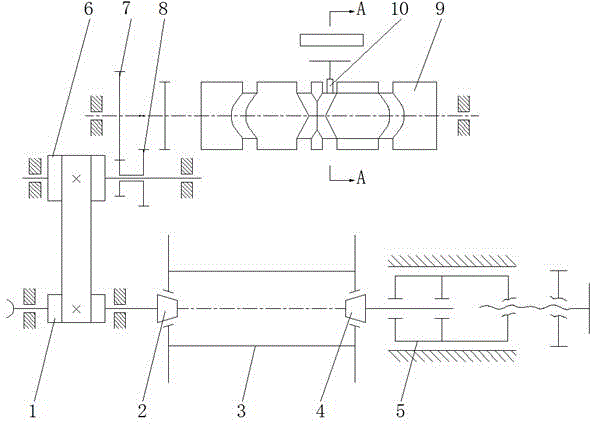

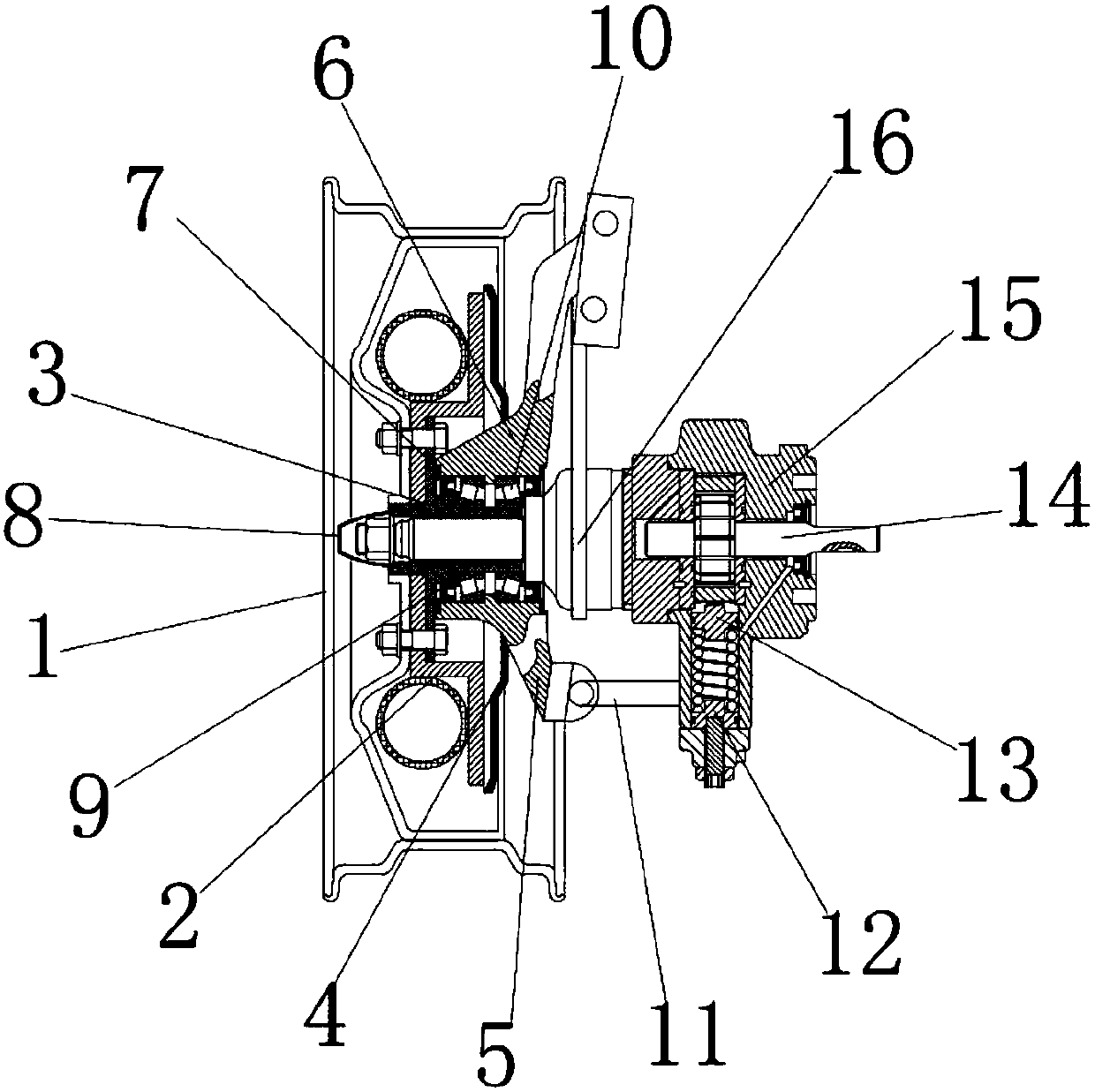

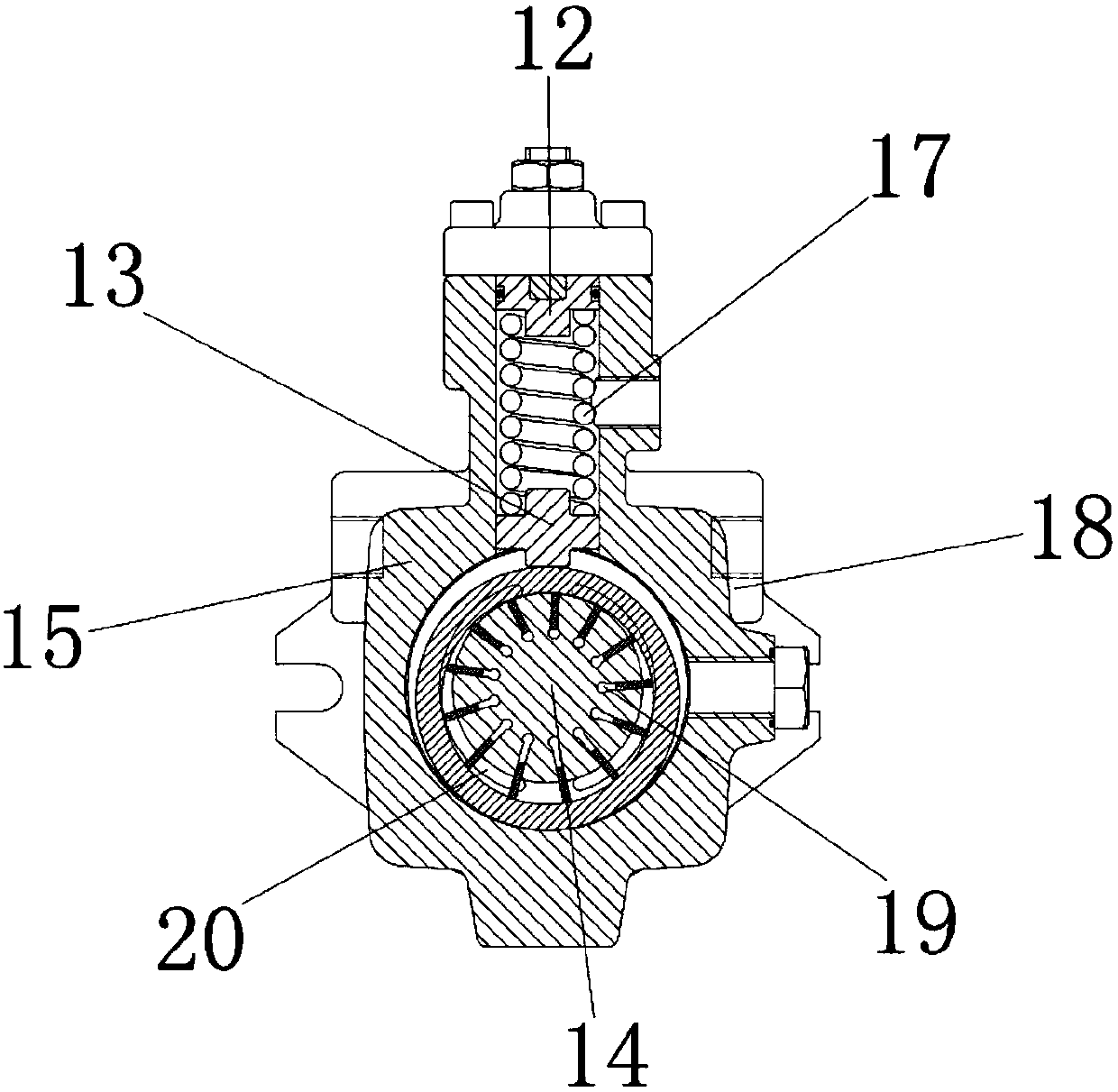

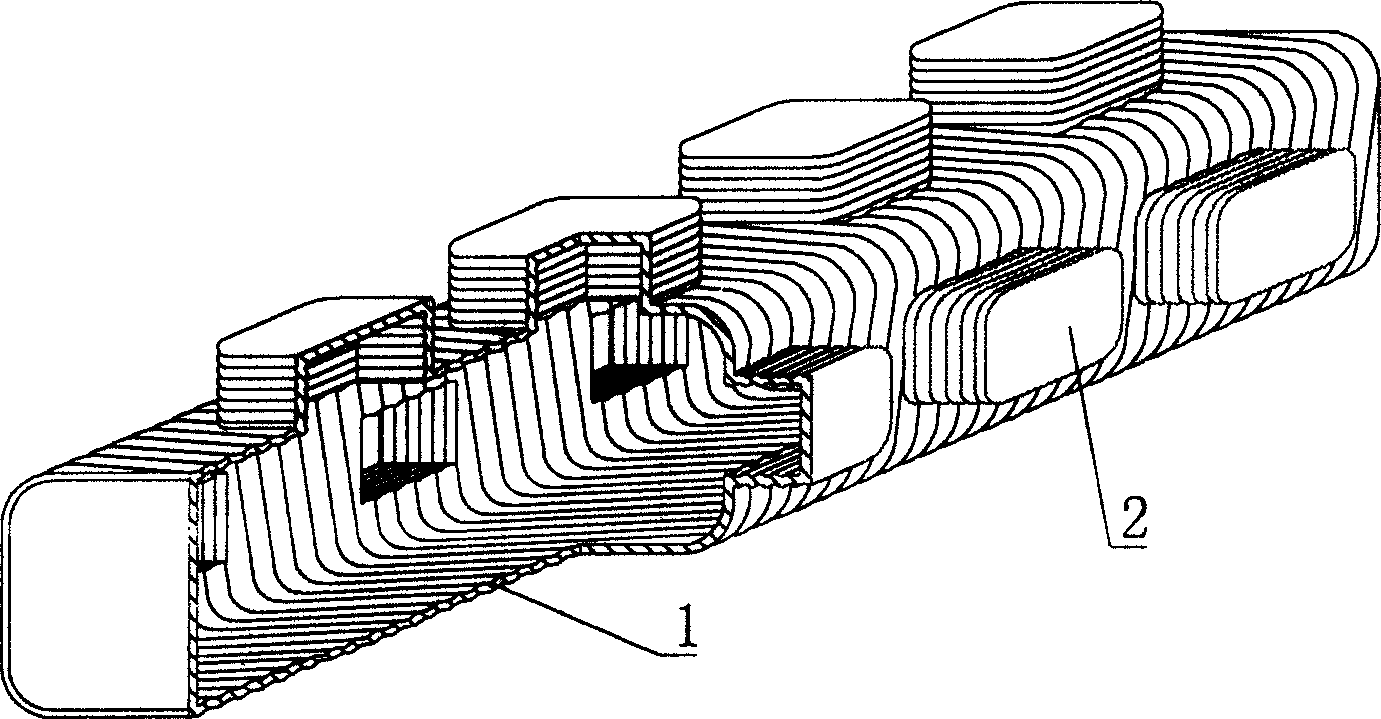

Transmission mechanism of small-section strip steel coiling machine

The invention discloses a transmission mechanism of a small-section strip steel coiling machine. The transmission mechanism comprises an adjustable-speed motor and a reducer, wherein the adjustable-speed motor is divided into two ways for output through a driving synchronous pulley and a driven synchronous pulley after reduced by the reducer; for one way, the driving synchronous pulley directly drives a rotary bevel pulley to drive a coiling disc to rotate, the coiling disc is sleeved with small-section strip steel capable of performing circumferential coiling motion around the axis of the coiling disc, a movable bevel pulley capable of performing linear motion in the axial direction of the coiling disc is arranged at the other end of the coiling disc, and the movable bevel pulley is fixedly mounted in an inner hole of a sliding drum in the axial direction; for the other way, the driven synchronous pulley drives a both-way cylindrical cam fixed in the axial direction to rotate, and a shuttle slider cooperating with the both-way cylindrical cam drives a movable frame to move leftwards and rightwards in the axial direction of the cam. The strip steel is uniformly coiled layer by layer in a helix manner, the storage quantity of the strip steel in single coiling disc is increased, matching and adjusting of a strip steel slitting machine and a flux-cored wire drawing unit can be met, and the production construction cost for an enterprise can be reduced.

Owner:姚小兵

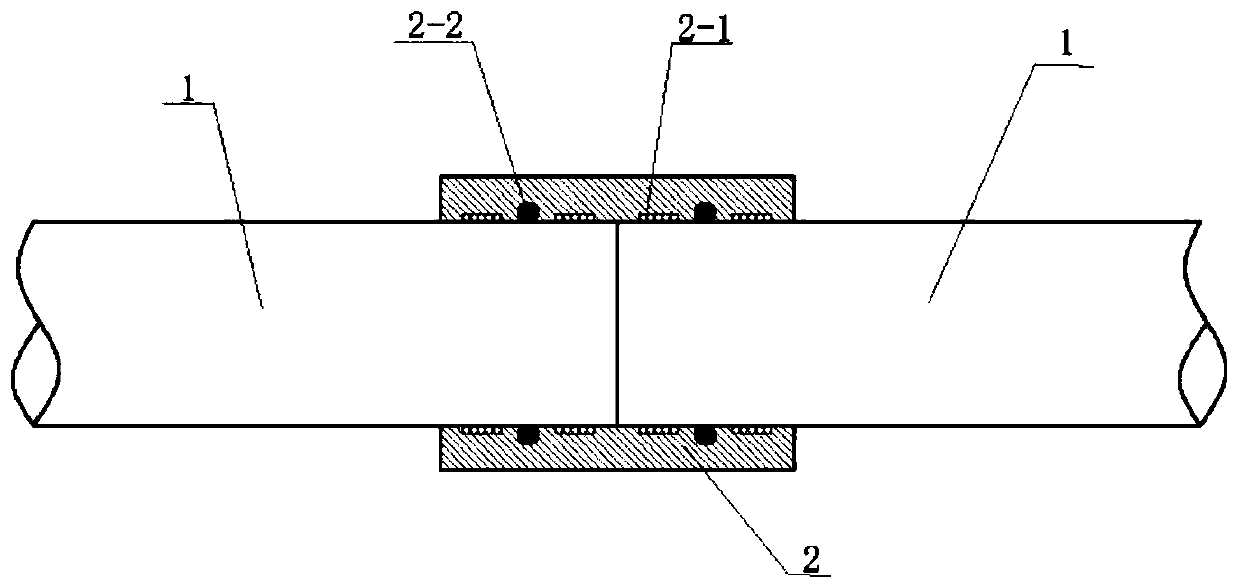

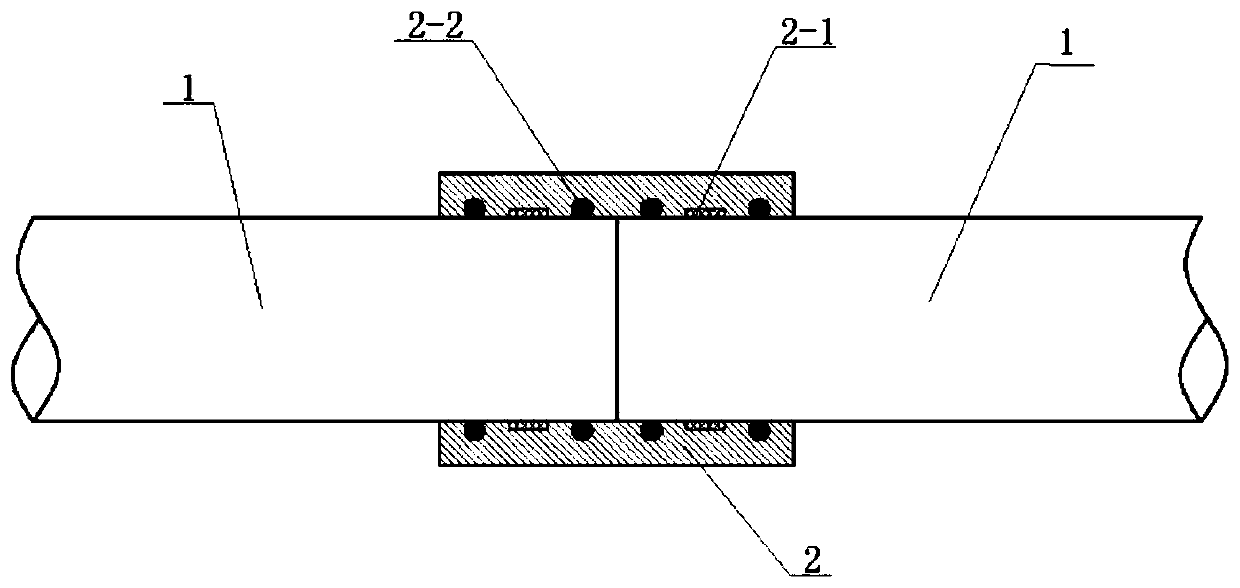

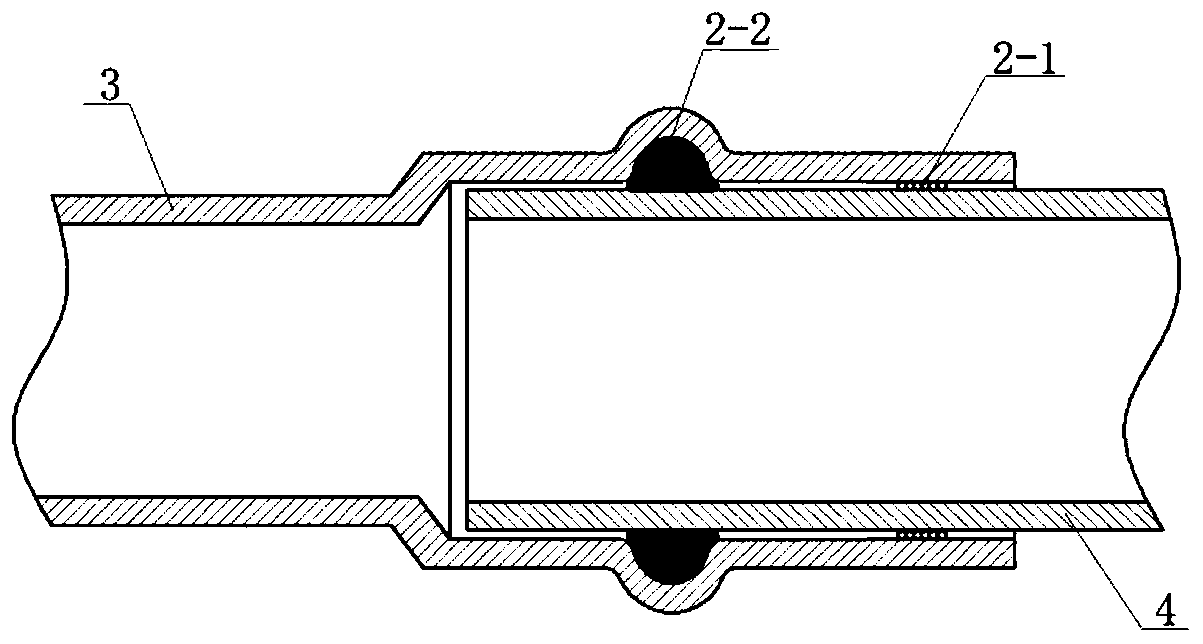

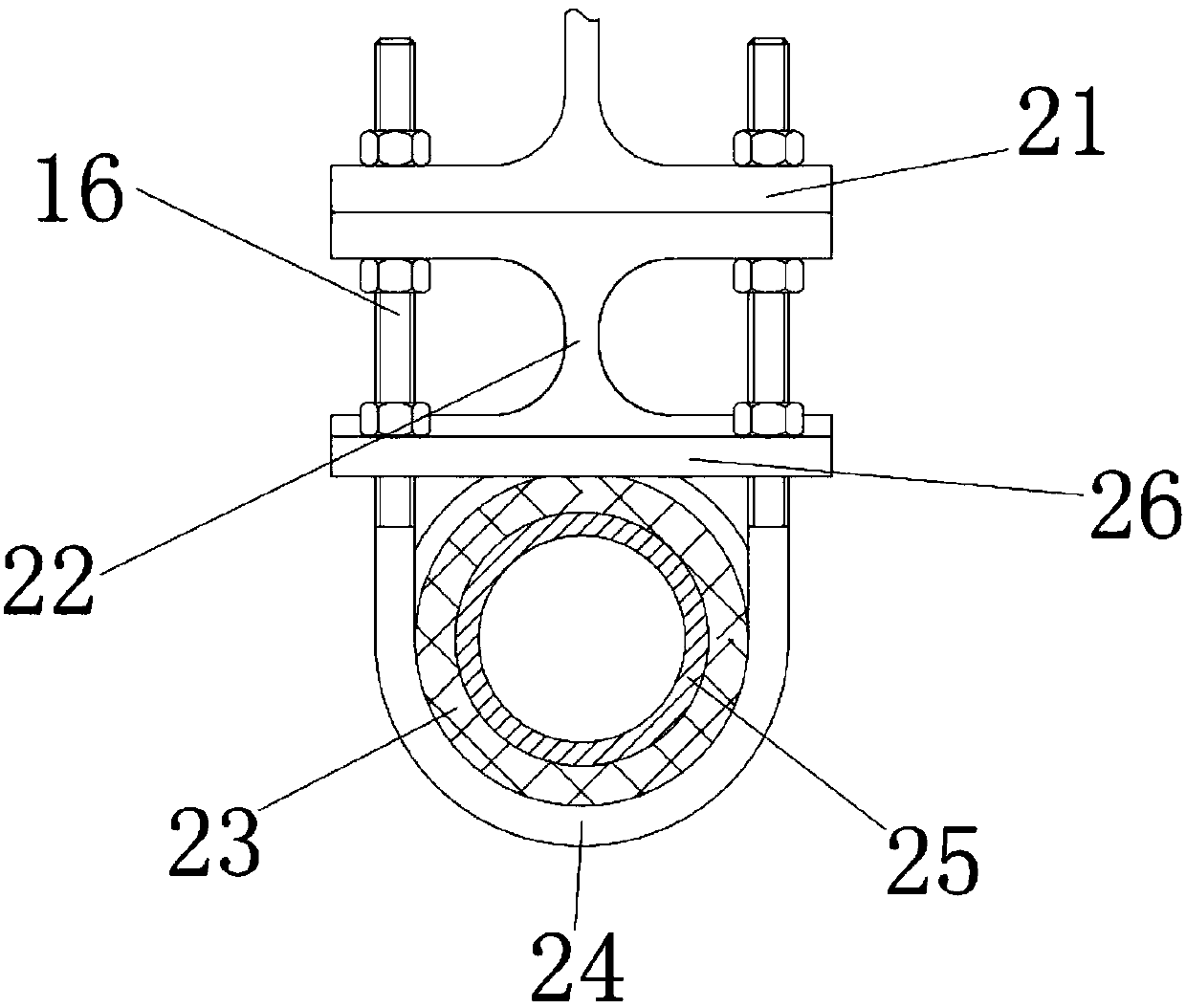

Combined sealing connecting method for plastic pipes

InactiveCN110657305AImprove sealingImprove stress resistancePipe connection arrangementsStructural engineeringMaterials science

The invention discloses a combined sealing connecting method for plastic pipes and belongs to the technical field of plastic pipes. Two plastic pipes, needing to be connected, with the same pipe diameter are horizontally placed; then the inner wall of a connecting casing pipe is provided with a sealing ring and a heating element; then the connecting casing pipe is firstly sleeved with the left plastic pipe, and then the right plastic pipe is in butt joint with the left plastic pipe; and then the heating element is electrified and melts the inner wall of the connecting casing pipe and the outerwalls of the plastic pipes in a heating manner. A rubber sealing ring and heating element melting and welding double-sealing technological means is adopted, pipeline connection is firmer, sealing isensured, and leakage is avoided; and the combined sealing and connecting method is widely applied to the fields of civic building water supply and drainage, gas and industrial pipelines and the like.

Owner:谭连平

House building rebar connecting structure

InactiveCN107829528AOvercome connection instabilityImprove work efficiencyBuilding reinforcementsRebarHouse building

The invention discloses a steel bar connection structure for building construction. A pressing plate is installed on the inner wall of the bottom frame, and the outer wall of the pressing plate is connected with the inner wall of the bottom frame. A rubber pad is sleeved, the outer wall of the rubber pad is connected with the inner wall of the pole, the outer wall of the sleeve is connected with the inner wall of the pressing plate, and the inner wall of the pressing rod is connected with the outer wall of the sleeve. The steel bar connection structure of the house construction, through the cooperation between the bottom frame and the pressure plate, under the action of the pressure plate and the end cover, in addition, the use function of the telescopic boss is single, only one steel bar can be fixed, and the disadvantage of low efficiency is solved. The cooperation between the end cover, the spacer and the rubber pad improves the work efficiency, reduces the operation strength, has good oxidation resistance and corrosion resistance, prolongs the service life of the steel bar connection structure of the building construction, is easy to recycle, and avoids waste at the same time The construction and production costs are saved, and the invention is suitable for popularization and application.

Owner:CHENGDU LEYE TECH CO LTD

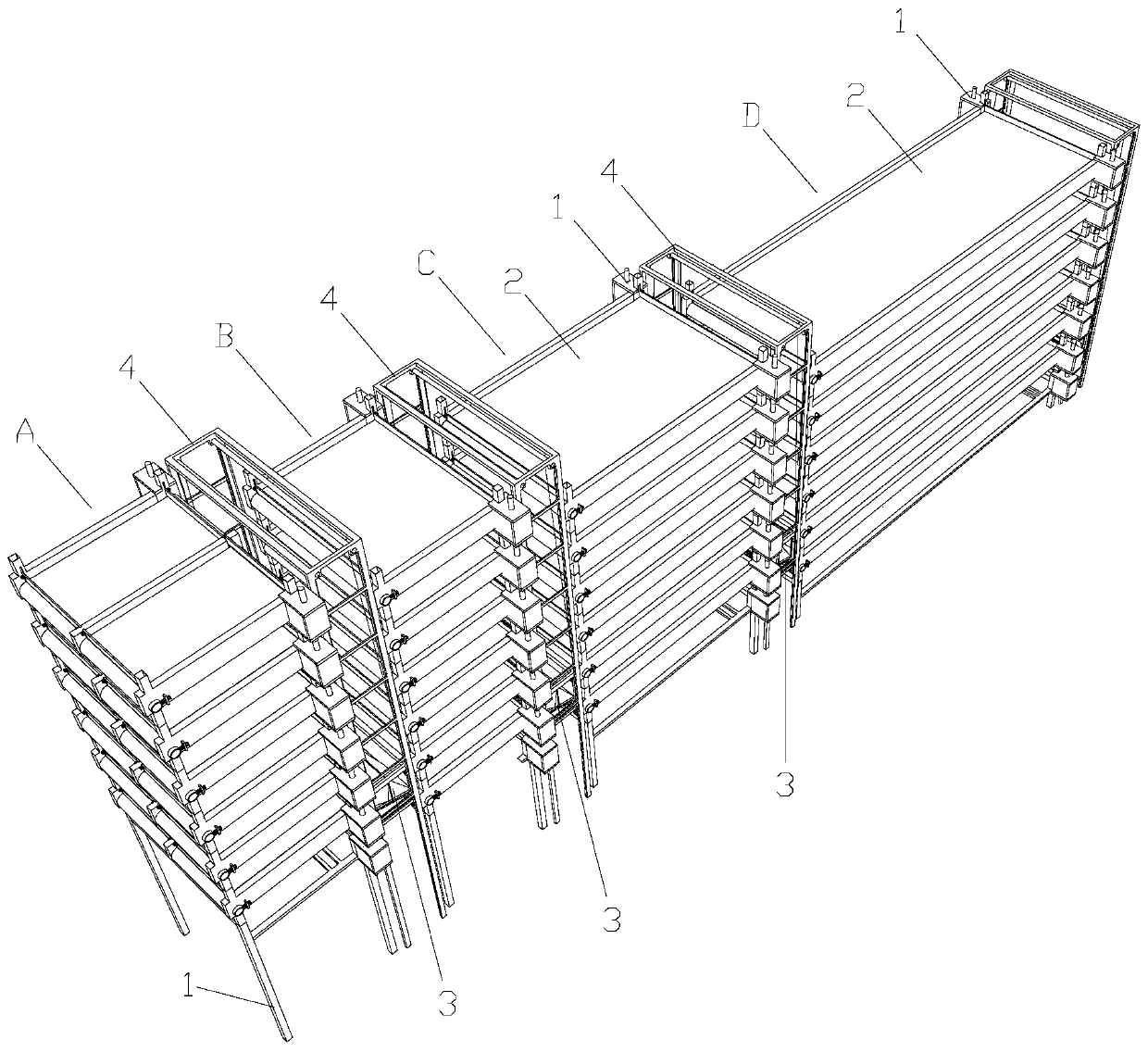

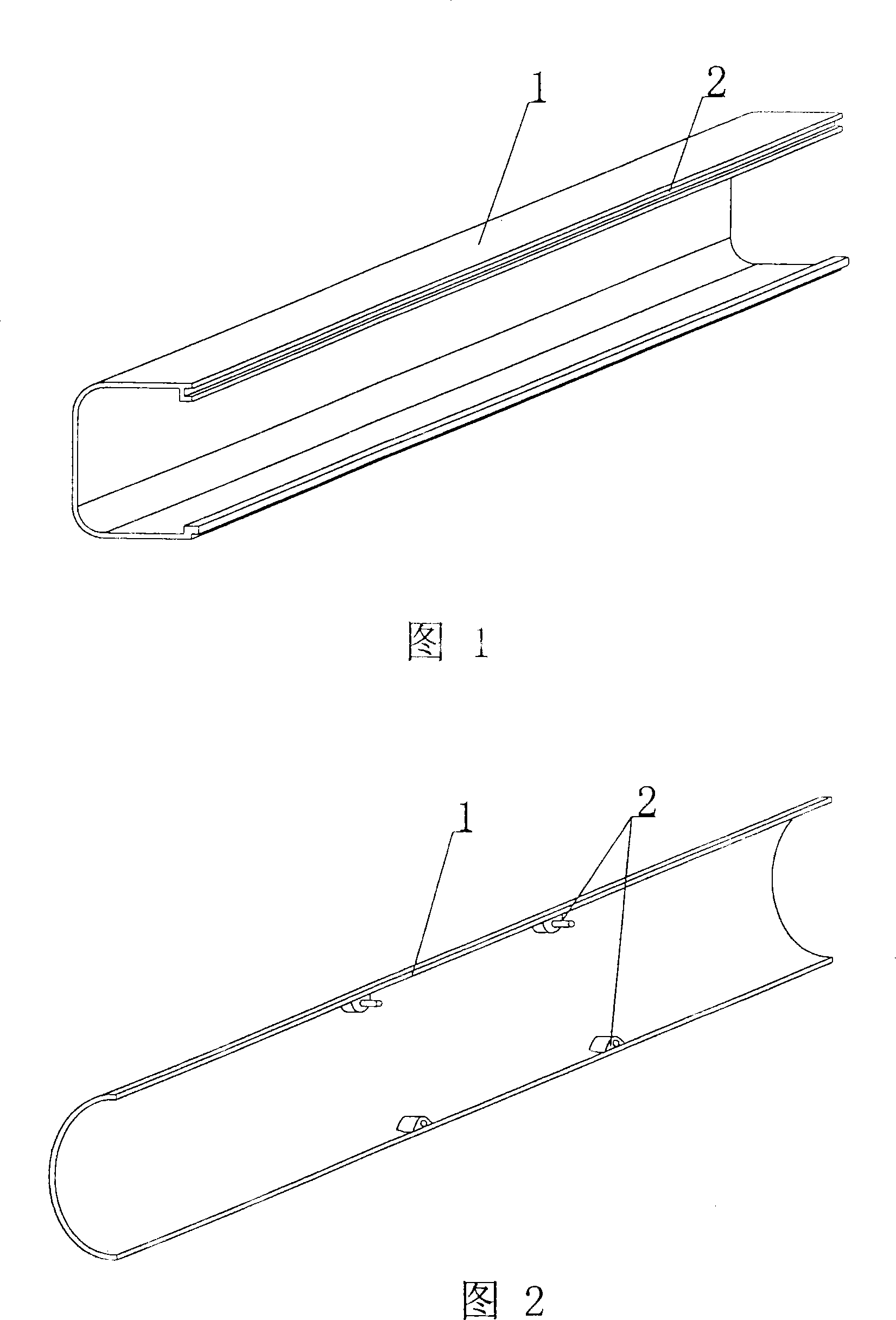

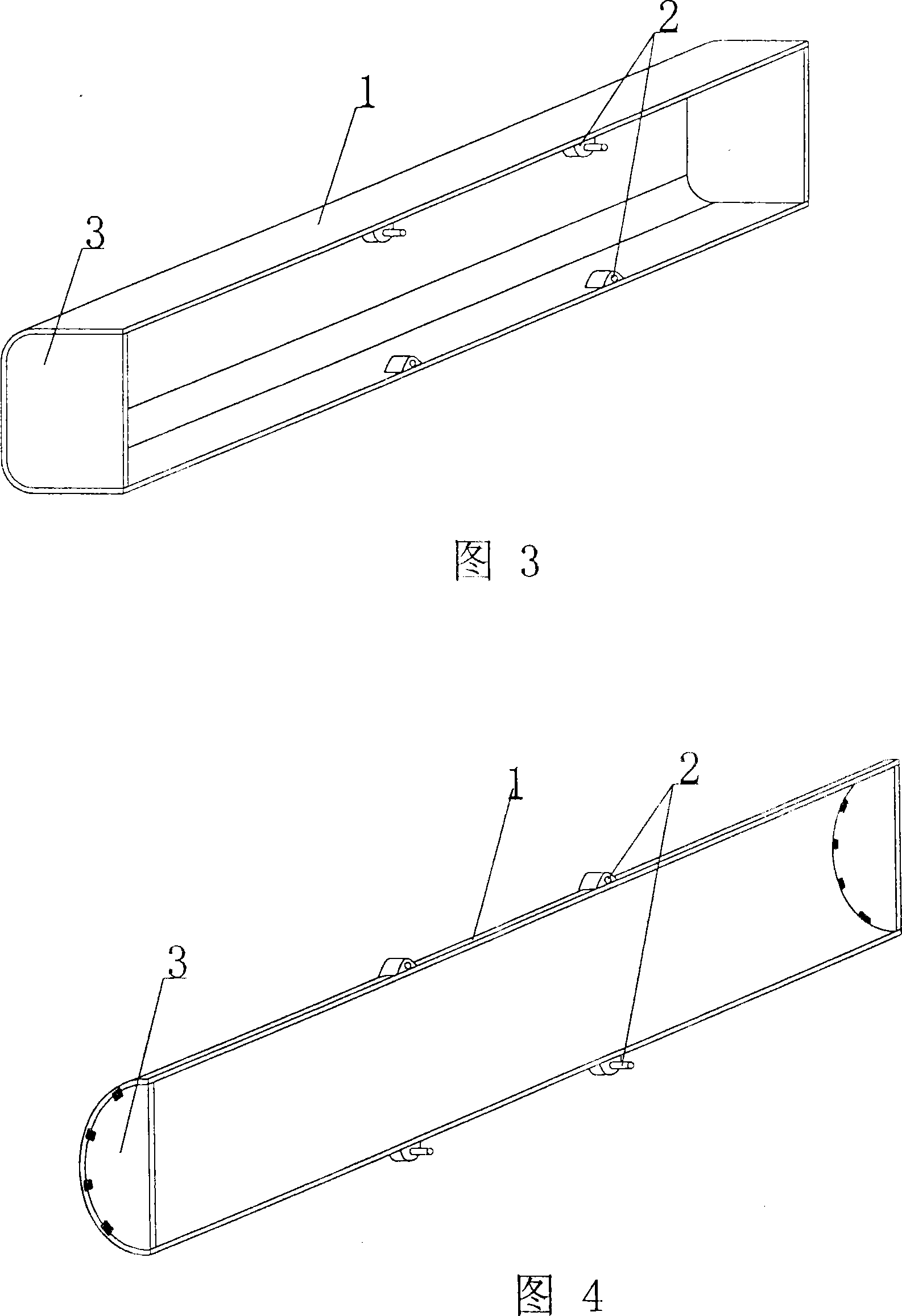

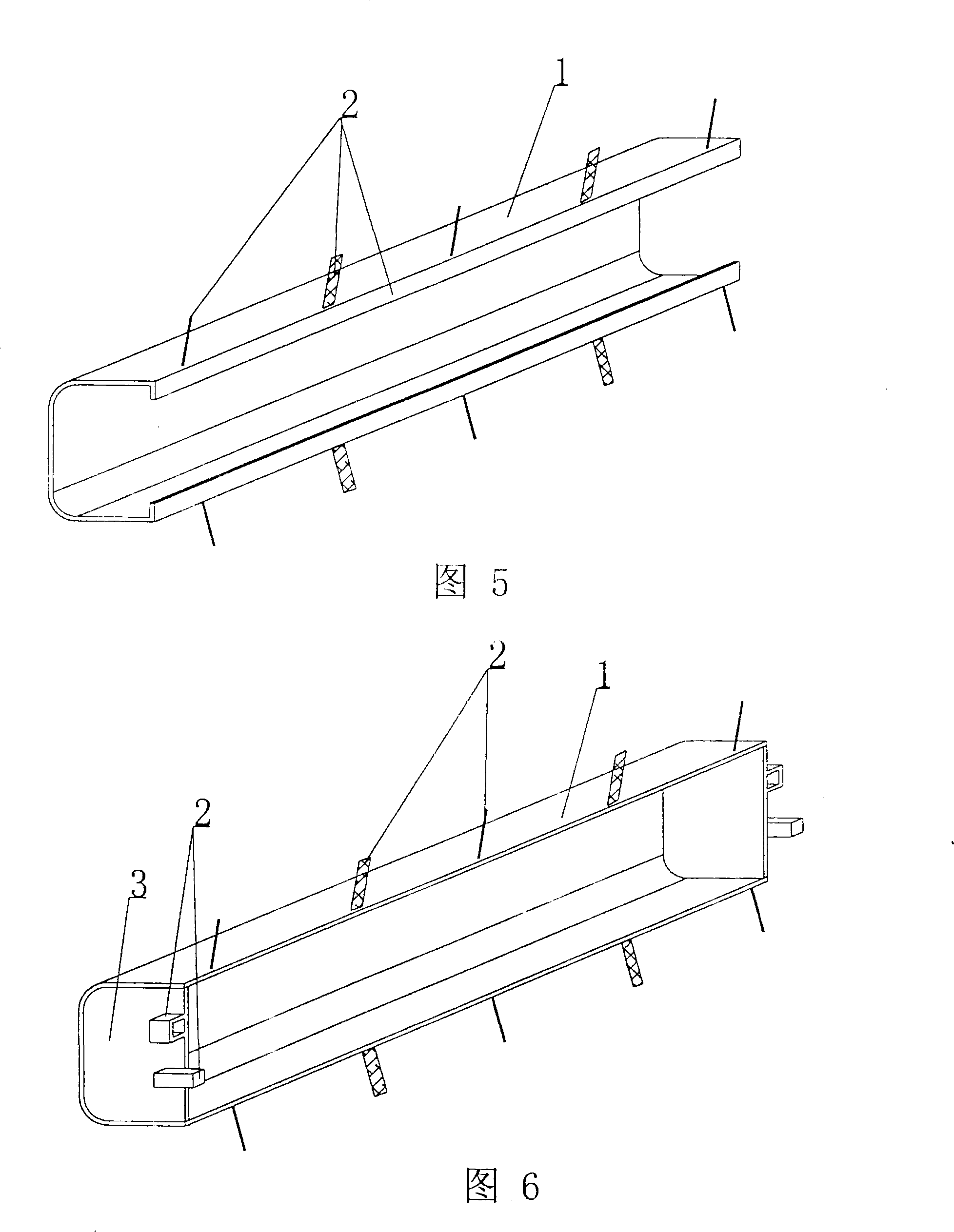

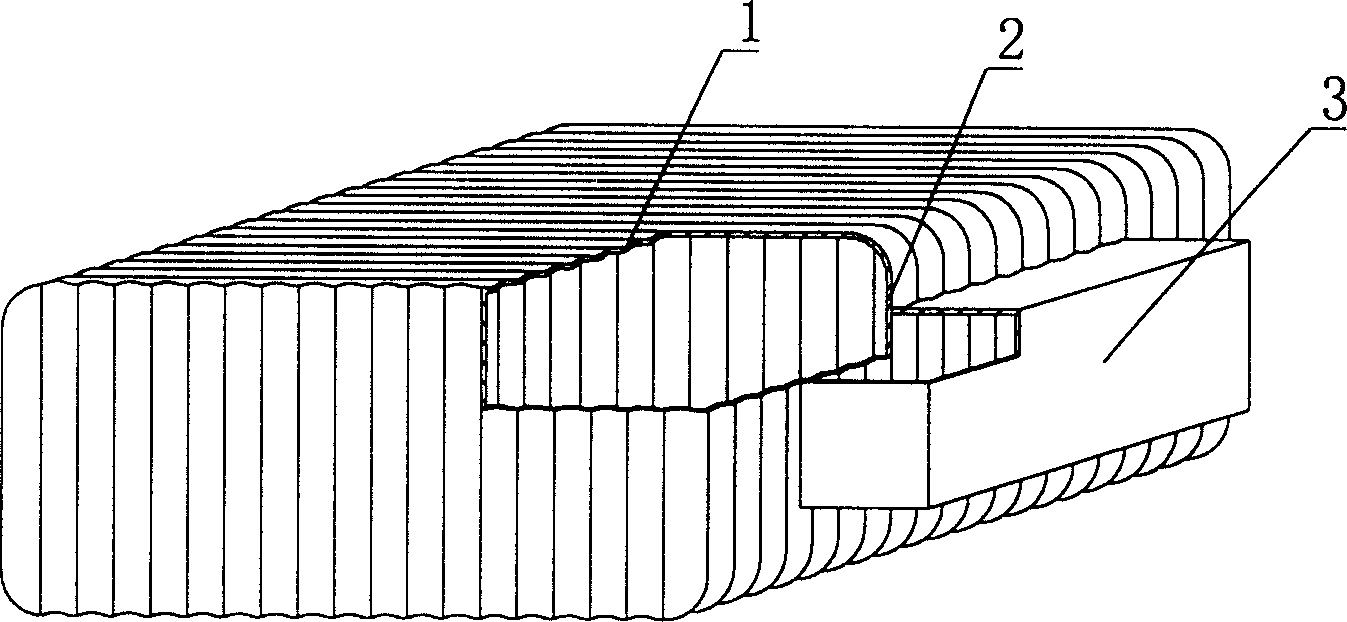

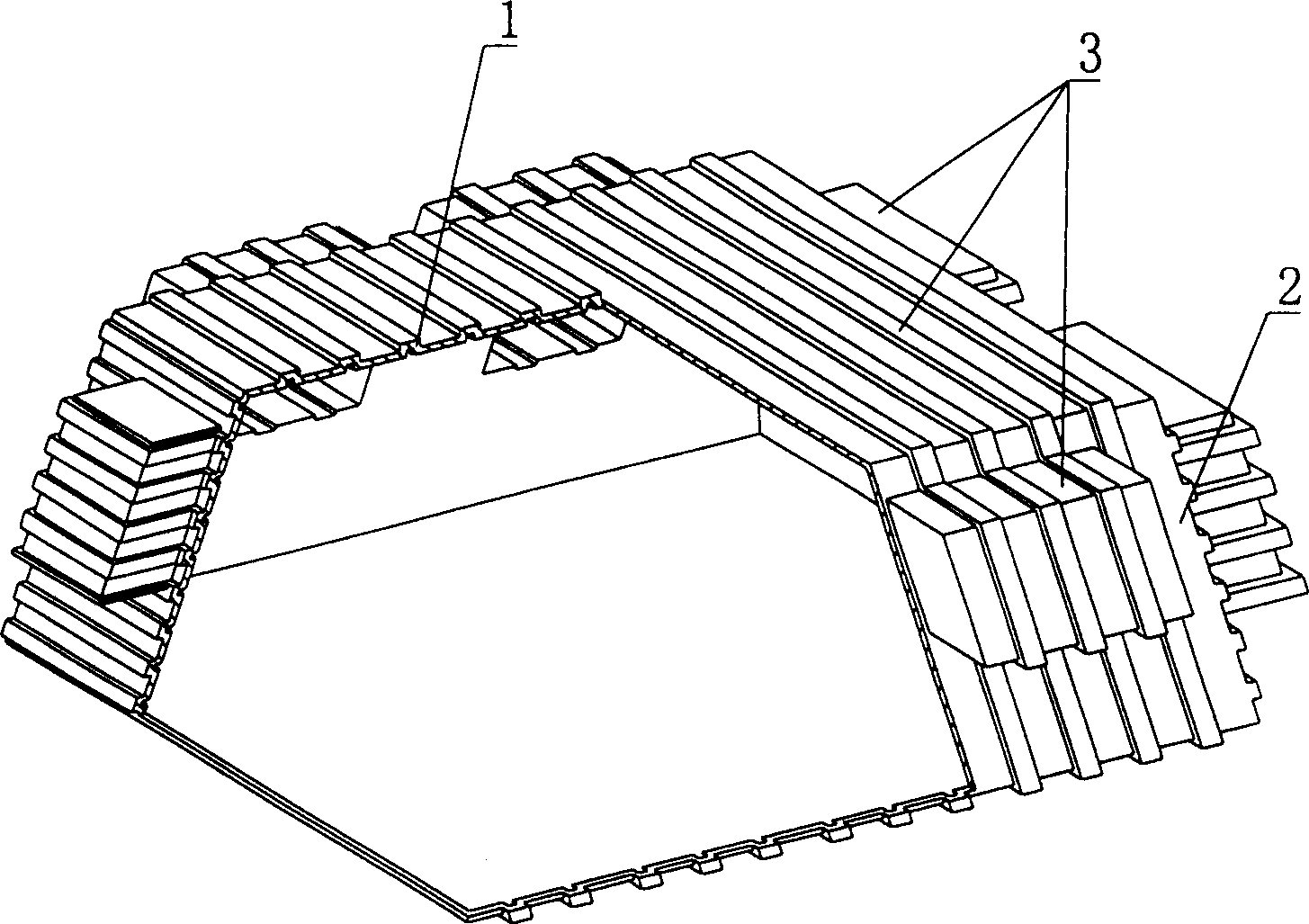

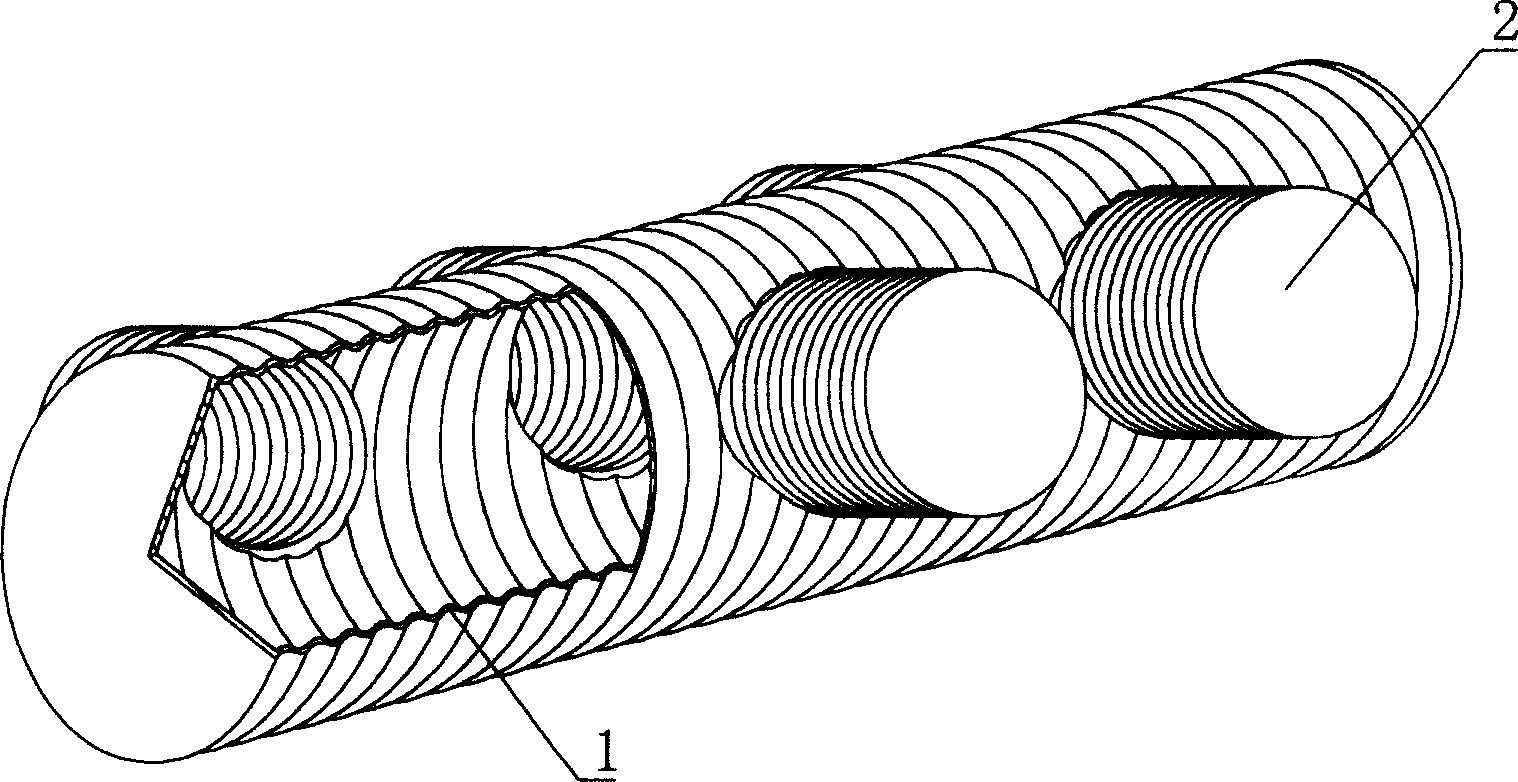

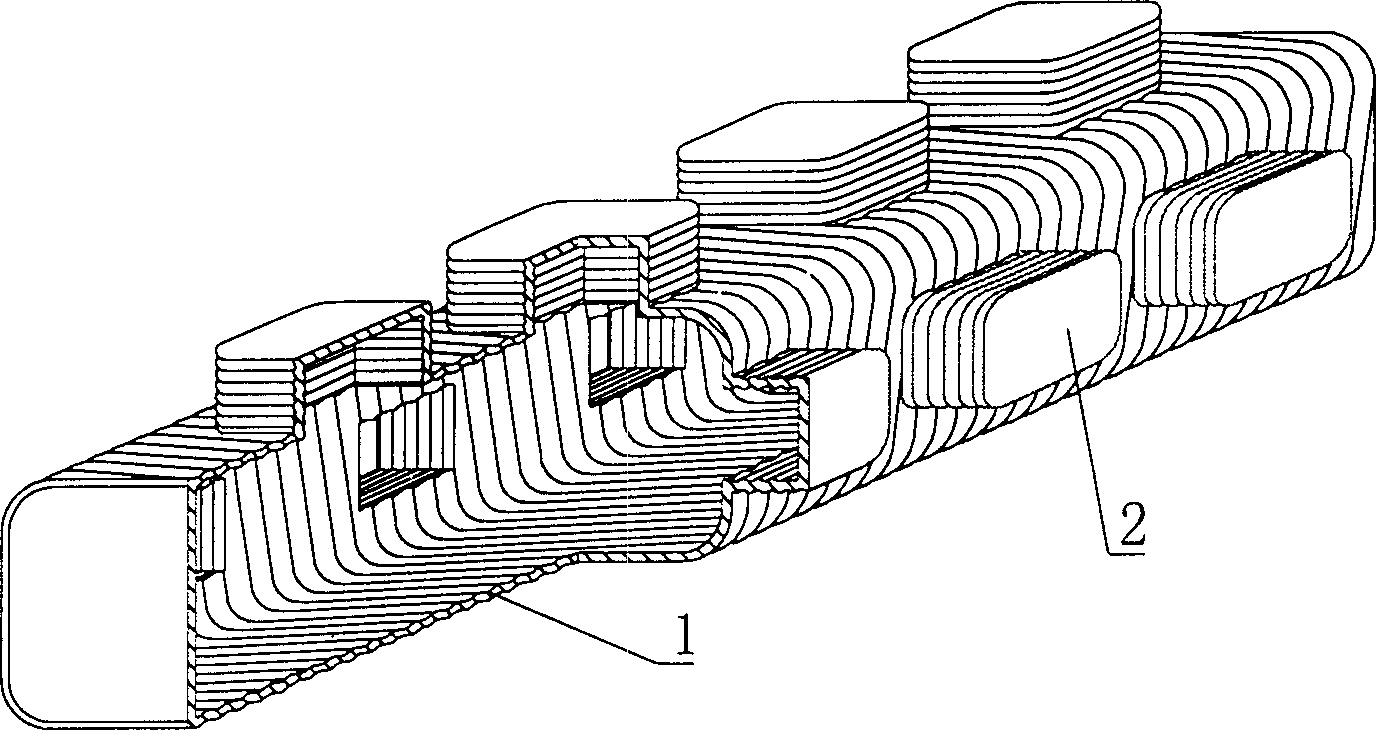

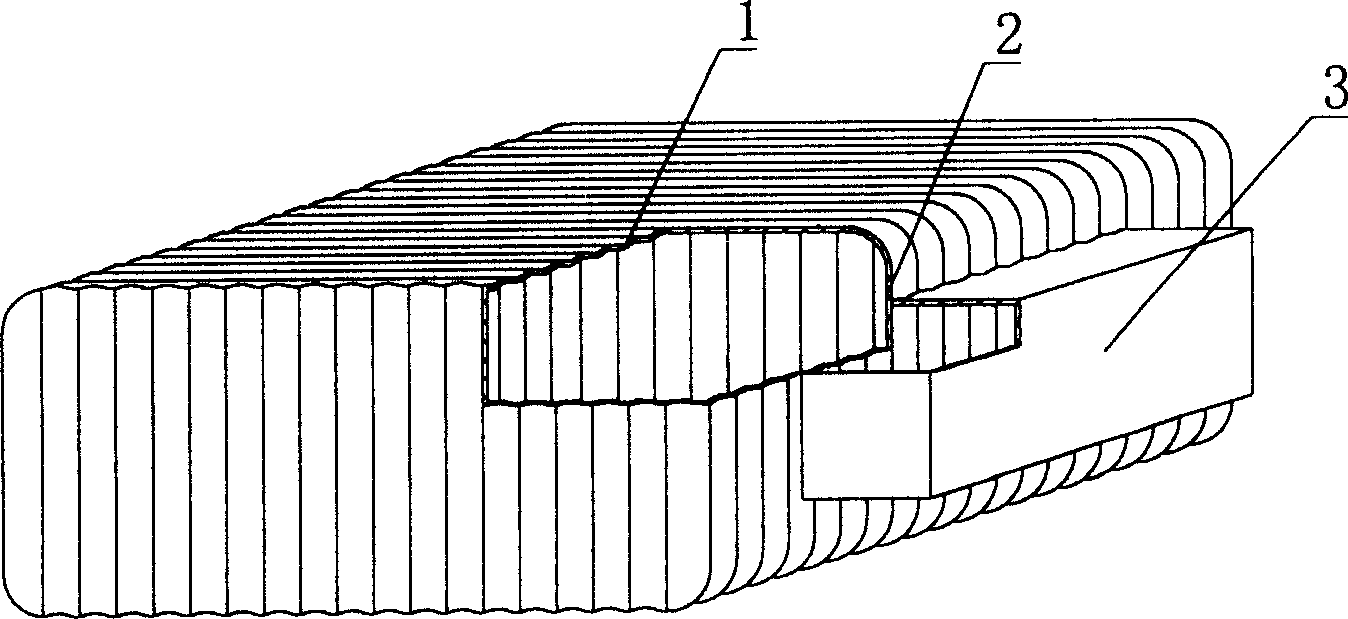

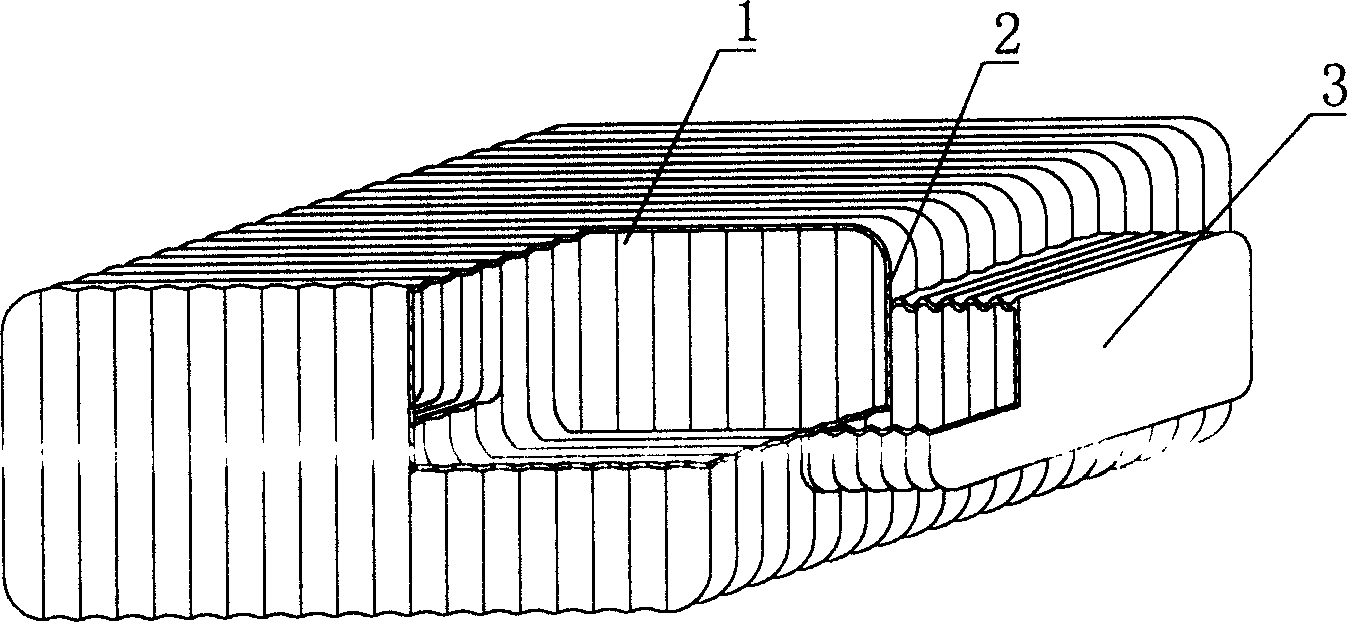

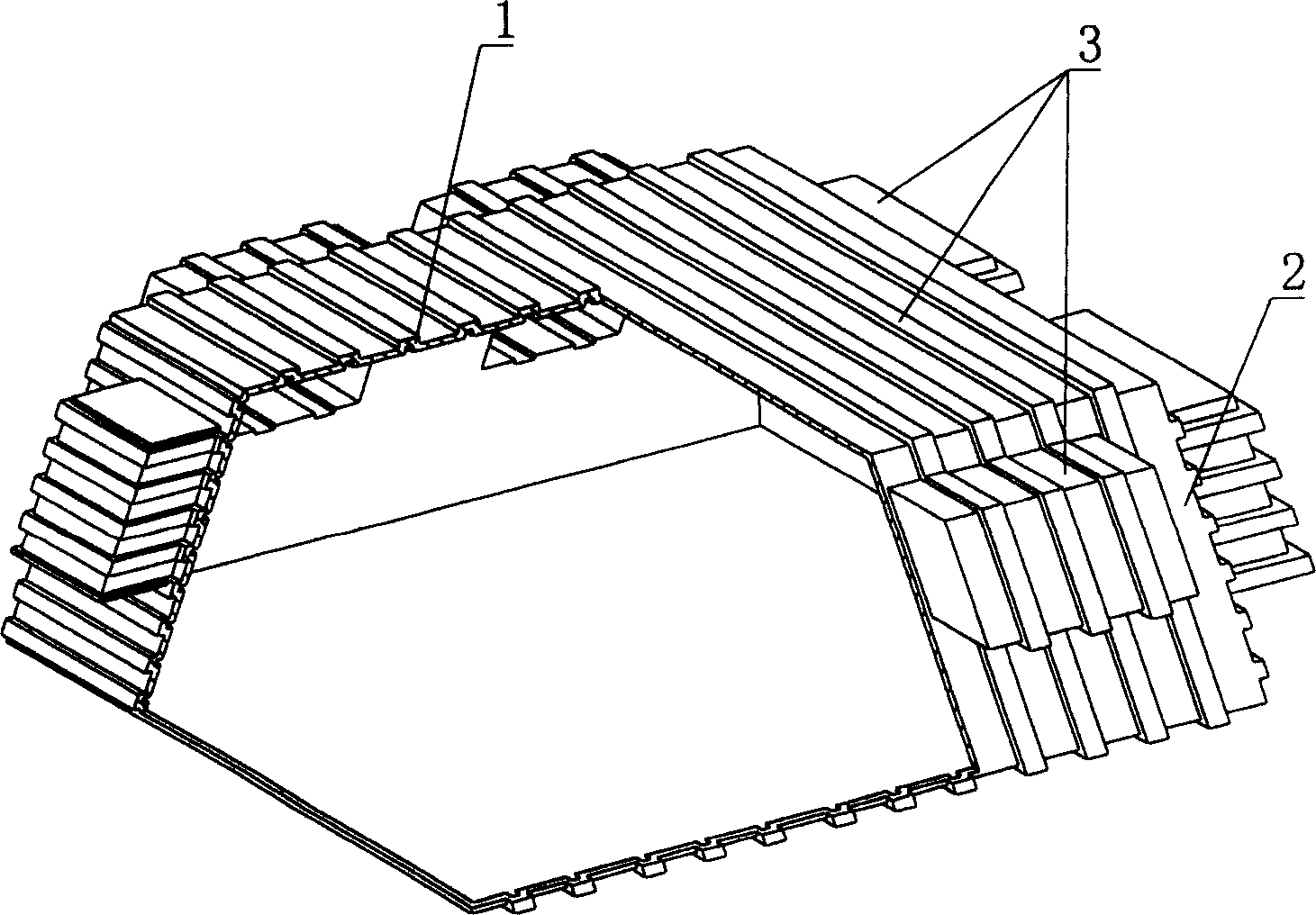

Cast-in-situ reinforcing steel bar concrete floor

InactiveCN101240621ARich varietyReduce production and construction costsWallsFloorsFloor plateFloor slab

A cast-in-situ reinforced concrete floor plate comprises reinforced concretes and hole-forming used component, the invention is characterized in that the hole-forming component is a whole component with cavity assembled by the composite components (1) which are arranged with the connecting components (2) for assembling, and the connecting components (2) are rabbets inside or outside the cavity body, the small step, the roll rim or male-female groove of the component. In this way the floor plate is suitable to be used in various cast-in-situ hollow building roofs, building covers, base plates, walls and hollow bridges.

Owner:湖南邱则有专利战略策划有限公司

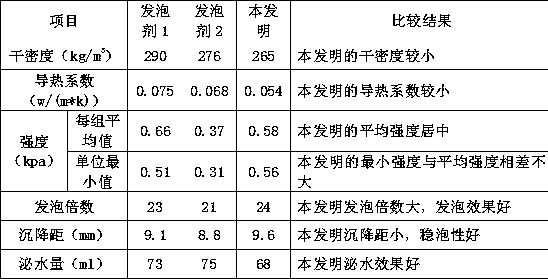

Preparation method for compound type foaming agent

The invention discloses a preparation method for a compound type foaming agent, relates to a preparation method for an additive for a building, in particular to a preparation method for a foaming agent added into concrete. The compound type foaming agent is compounded from an initial product, N,N'-dinitrosopentamethylamine (DPT), diglycol and lauryl alcohol. The compound type foaming agent is prepared on the basis of the original foaming agent, substances with excellent foaming properties are added into the foaming agent, and other additives are added to achieve the effects of increasing foams, stabilizing foams and regulating. The compound type foaming agent prepared by the preparation method is verified in practical production, and has the outstanding characteristics of being great in foaming amount, small in foam loss, small in strength effect and the like. The preparation method is simple to operate, is easy to control and is relatively high in yield.

Owner:云南森博混凝土外加剂有限公司

Method for constructing gas dome barrel of LNG ship in outer field

ActiveCN112078750ASolve the problem of payment lagReduce build timeWaterborne vesselsMarine engineeringMechanical engineering

The invention discloses a method for constructing a gas dome barrel of an LNG ship in an outer field. The method comprises the steps that a carrying lifting ring is installed on a dome deck; the domedeck is inversely placed on a jig frame by utilizing the carrying lifting ring, and an inner deck is normally placed on the jig frame; a framework installation line and a barrel inspection line are drawn on the dome deck according to a construction drawing; a framework and the barrel are welded and fixed to the dome deck according to the framework installation line and the barrel inspection line;after the framework, the barrel and the dome deck are fixed into a whole, the whole is turned over to be aligned and folded with the inner deck; and the barrel and the inner deck are welded and fixed.According to the method for constructing the gas dome barrel of the LNG ship in outer field, the gas dome barrel is independently manufactured in the outer field, so that the problem that the storageperiod of the gas dome barrel lags behind due to the fact that a traditional gas dome barrel is folded in the inner field and sections is effectively solved, and the constructing time of the gas domebarrel is greatly shortened.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

High efficiency solar electricity generator

InactiveCN1293301CPracticalReduce production and construction costsSolar heating energyFrom solar energyEngineeringSolar power

Owner:HEBEI AGRICULTURAL UNIV.

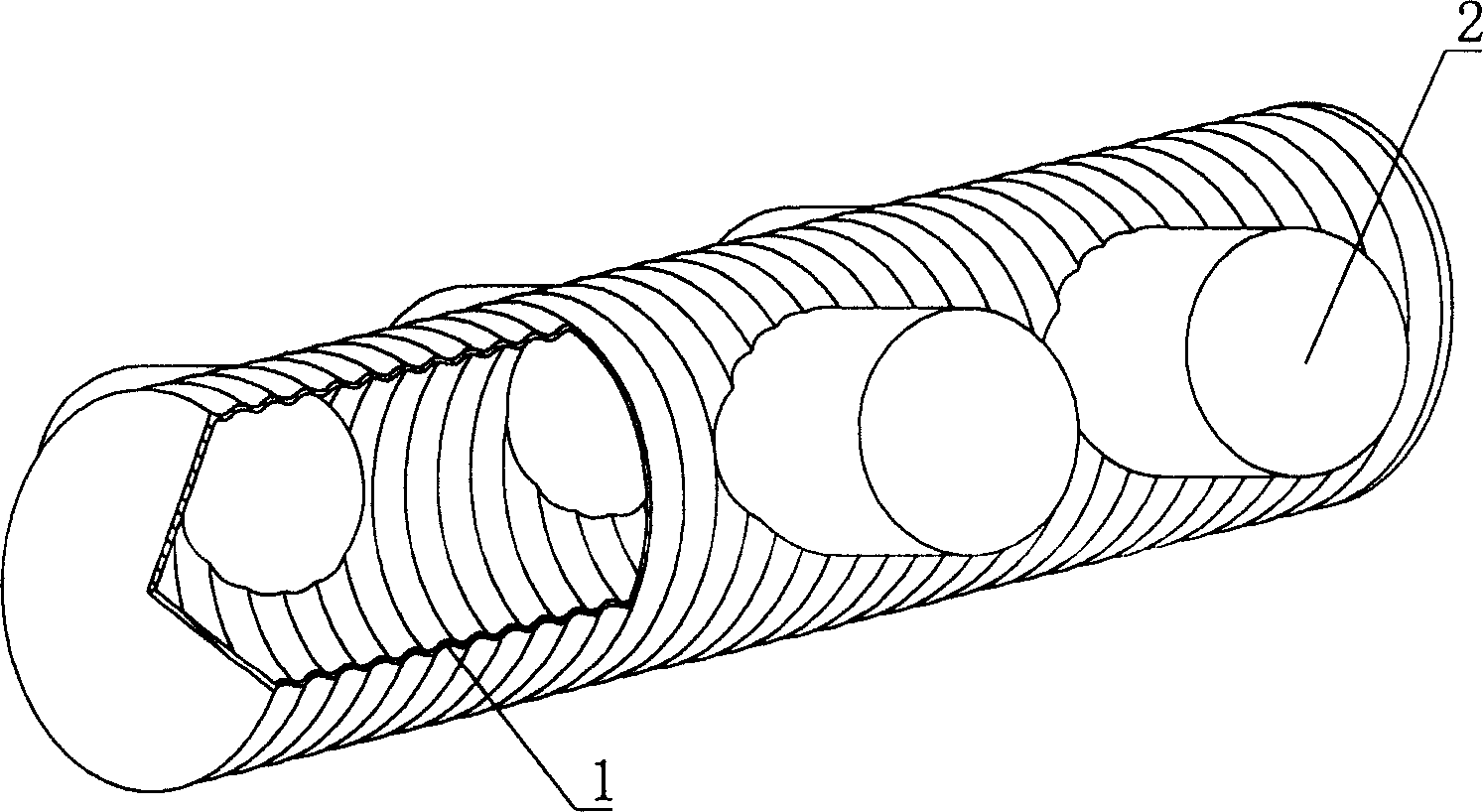

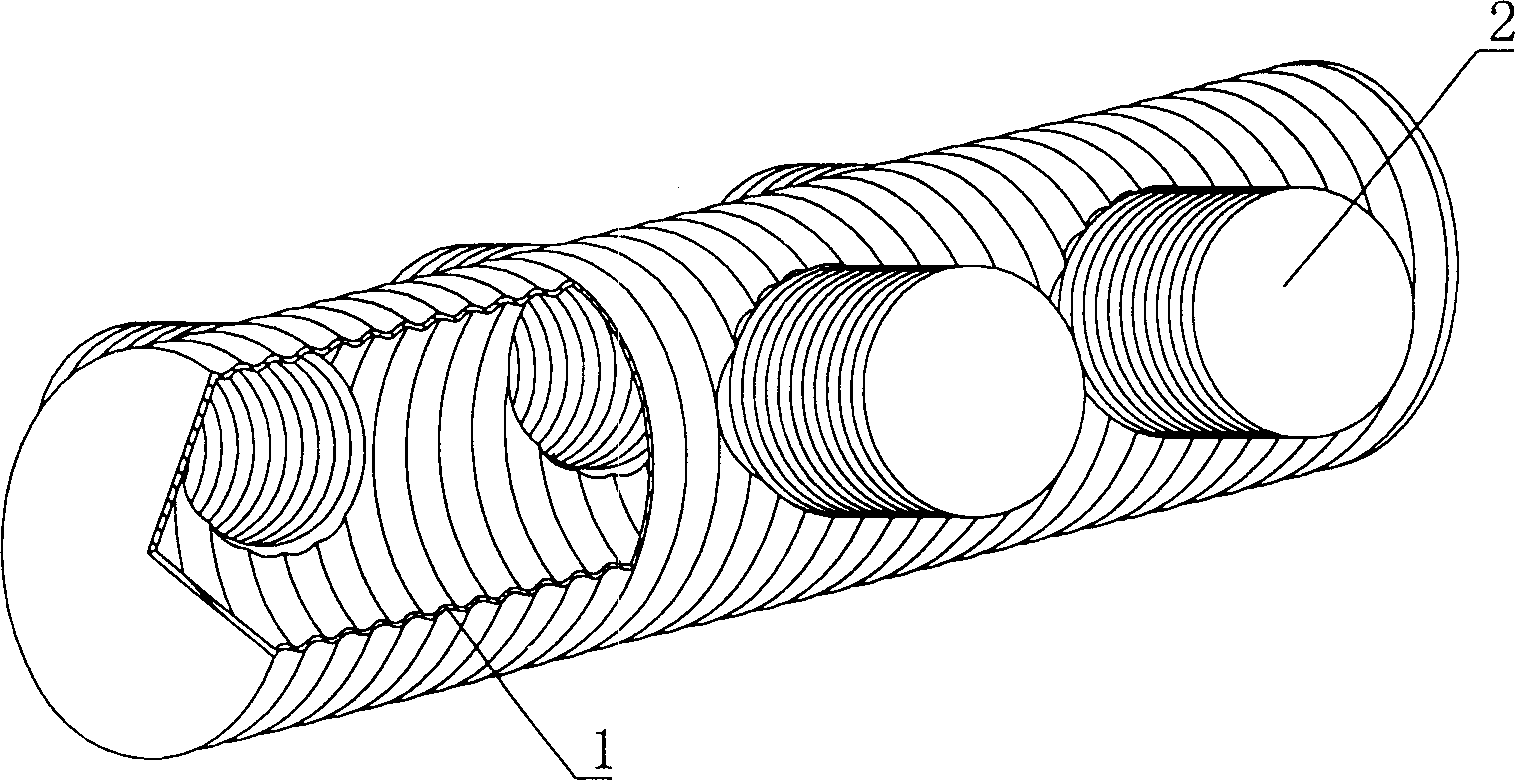

Light stuffing mold member for cast-in-situ steel concrete

The light stuffing mold member for in-situ cast reinforced concrete is one corrugated stuffing mold with at least protrudent block on its one side. After the light stuffing mold member is used in reinforced structure floor board, in-situ cast concrete rib of truss rod is formed, and the in-situ cast concrete rib has greatly reduced weight and saved material consumption, resulting in reduced floor board weight and raised antiseismic performance. With the features of light weight, high strength, simple structure, convenient construction and transport, etc, the light stuffing mold member is suitable for use in in-situ cast hollow beam-less reinforced concrete floor board as well as roofing, base board, wall and hollow bridge.

Owner:湖南邱则有专利战略策划有限公司

A method for constructing an ocean platform

ActiveCN104029789BShorten the timeImprove production and construction efficiencyVessel partsSea trialPoise

The invention discloses a method for constructing an ocean platform and relates to the fields of ocean engineering and shipbuilding. The construction implementation method of the offshore platform of the present invention includes design steps, construction, production and installation steps, launching steps, mooring test steps, navigation test steps and ship delivery steps, wherein the mooring test steps include main mooring test steps and auxiliary system The mooring test step, the main mooring test step is carried out simultaneously with the construction, production and installation steps, and the auxiliary mooring test step is carried out between the launching step and the sailing test step. By adopting the construction implementation method of the ocean platform of the present invention, the time for the main mooring experiment step is saved, the production and construction efficiency is improved, the construction period is shortened, and the production and construction cost is reduced.

Owner:CIMC OFFSHORE ENG INST +2

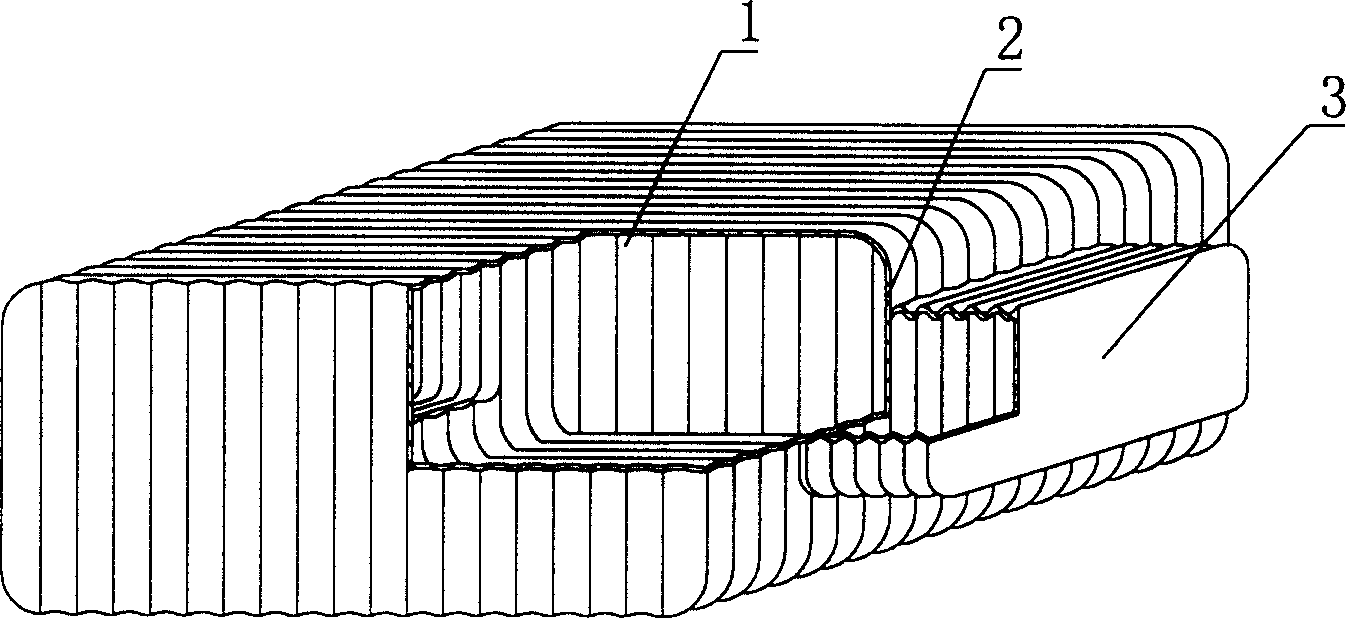

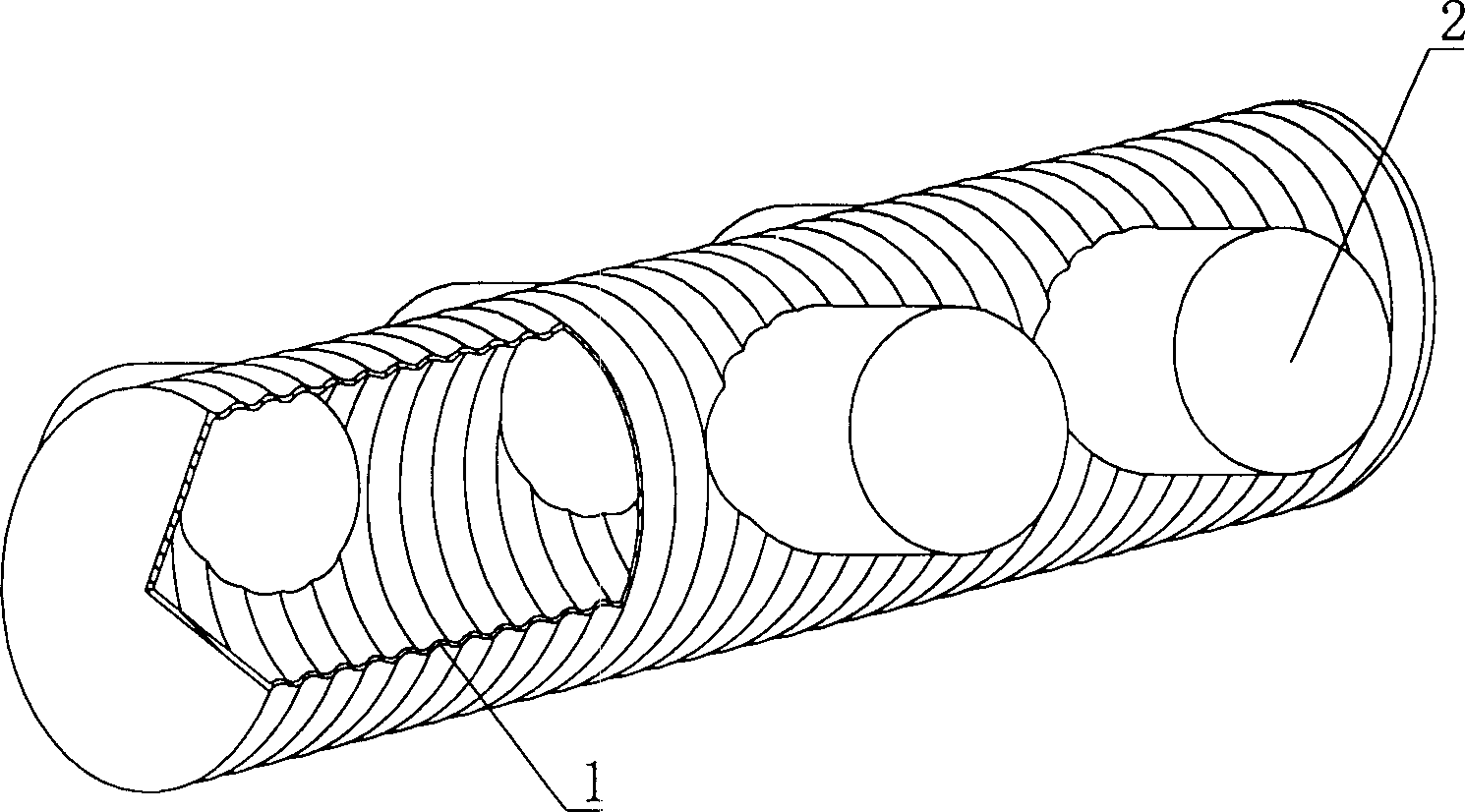

Light tube for filling cast-in-situ steel reinforced concrete

The light pipe for filling in-situ cast steel reinforced concrete is corrugated pipe with at least one protrudent block. The corrugated pipe with protrudent block reduces the consumption of concrete in floor board and dead weight of floor board, strengthens the vibration strength, reduces the longitudinal rigidity and reduces the difference of rigidity in two directions. The present invention has high strength, high deformation and vibration resistance, convenient transportation and other features. The present invention is suitable for use in in-situ cast hollow beam-less reinforced concrete floor board as well as roofing, base board, wall and hollow bridge.

Owner:湖南邱则有专利战略策划有限公司

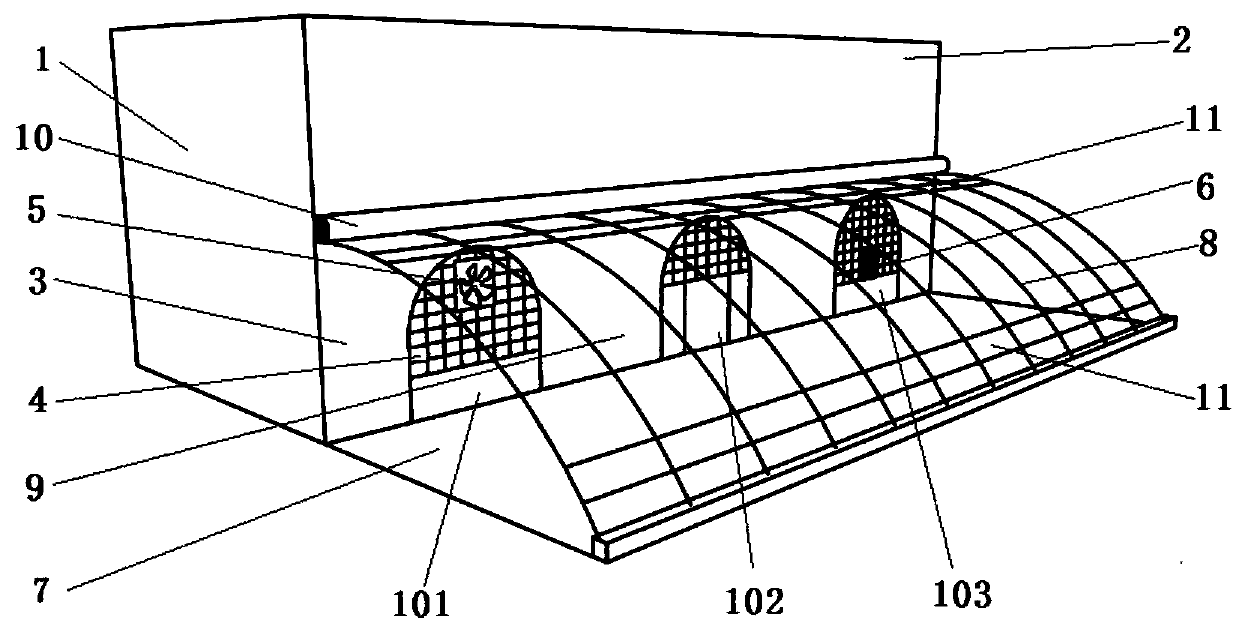

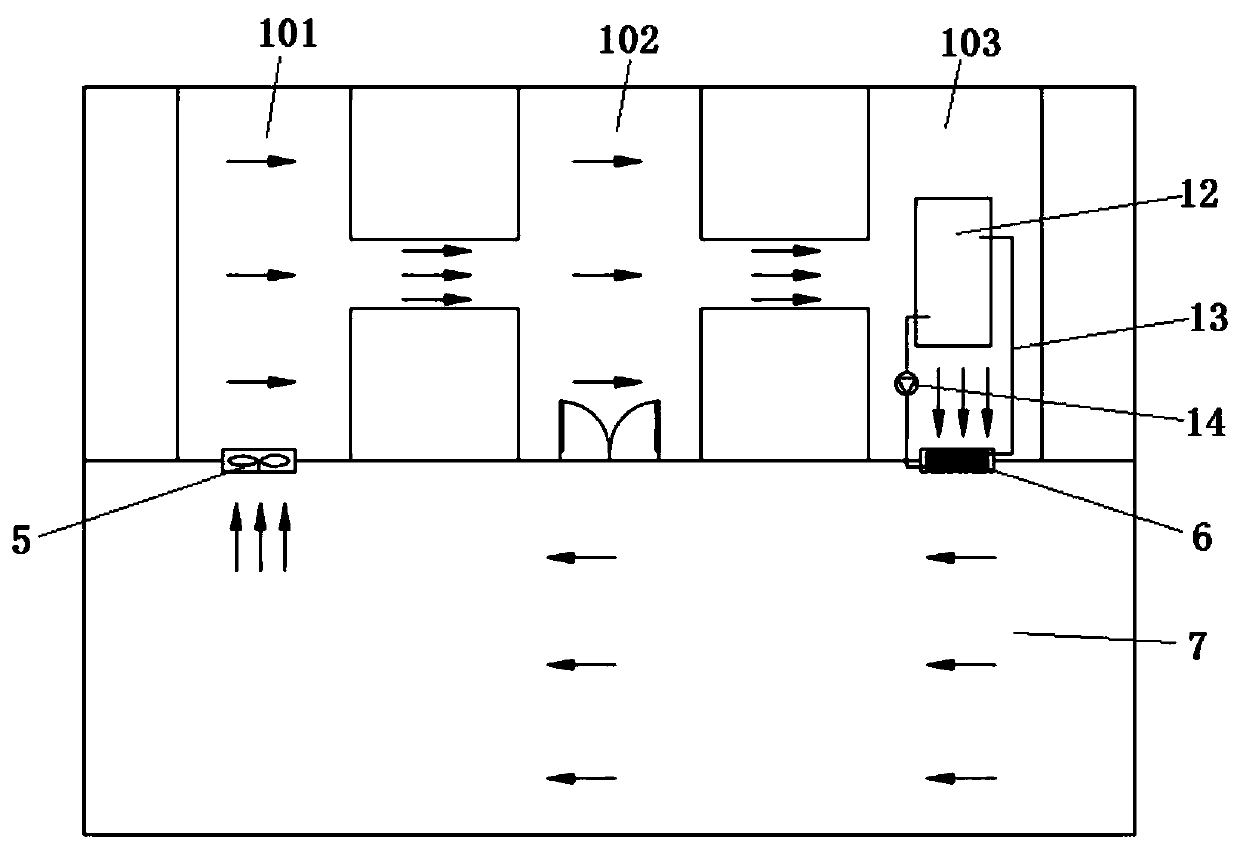

A kind of greenhouse combined with cave and its environmental regulation method

ActiveCN105145177BReduce production and construction costsReduce regulation energy consumptionAgricultural buildingsClimate change adaptationGreenhouse productionEnvironmental regulation

The invention relates to the greenhouse engineering technical field, and especially relates to a greenhouse combined with a cave dwelling and an environment regulation and control method thereof; the greenhouse combined with cave dwelling comprises a kiln body having a plurality of cave dwellings, a support frame used for commonly supporting the greenhouse with an outer riser wall body of the kiln body, and a light transmission cover layer paved on an outer surface of the support frame; a courtyard space is arranged in front of the kiln body; the support frame is arranged in the courtyard space; the support frame, the light transmission cover layer and the outer riser wall body of the kiln body commonly form a plantation room connected with the plurality of cave dwellings; a hole of one cave dwelling is provided with an axial-flow blower used for leading the air from the plantation room to the cave dwelling, and the air in the cave dwelling is discharged to the plantation room from the hole of another cave dwelling, thus forming air exchange. The greenhouse and method fan fully utilize existing building structures and thermal environment characteristics of waste cave dwellings, thus greatly reducing greenhouse production construction cost, reducing greenhouse environment regulation and control energy consumption and cost, so the greenhouse can keep a temperature condition suitable for crop growth.

Owner:BEIJING RES CENT OF INTELLIGENT EQUIP FOR AGRI

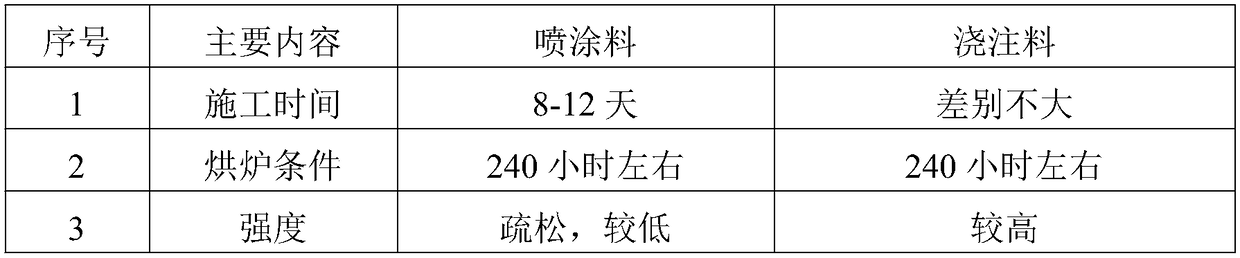

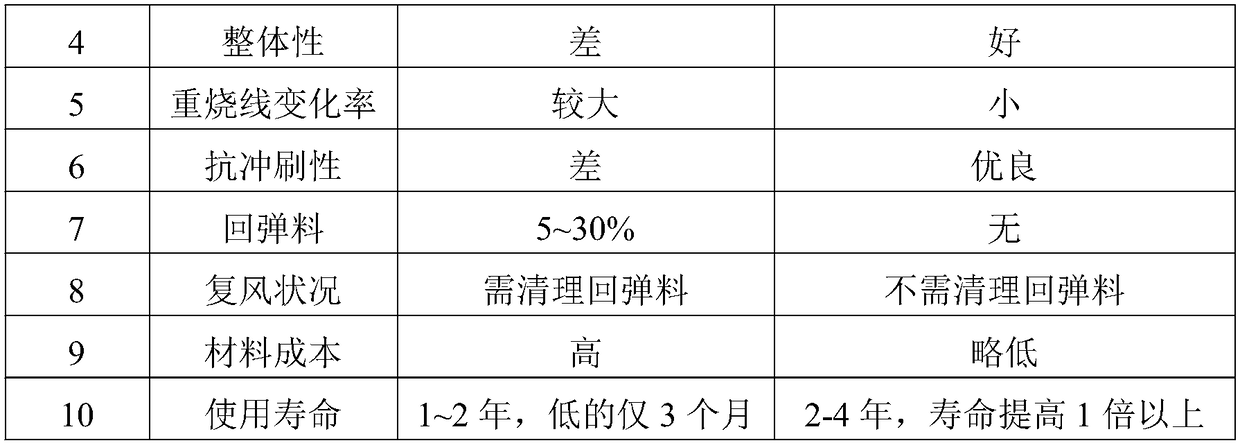

A construction method of integral pouring of blast furnace lining instead of spray paint and refractory bricks

ActiveCN106435073BExcellent technical performance indexHigh refractorinessBlast furnace componentsBlast furnace detailsMulliteSpray coating

The invention discloses a blast furnace liner overall pouring construction method for replacing spraying materials and refractory bricks, and relates to the field of blast furnace repair and new construction. The method comprises the following steps: damaged parts of a furnace hearth and a furnace body of a blast furnace are determined; the furnace hearth and the furnace body are cleaned; a pouring material is prepared; the furnace hearth, a furnace bosh, a furnace waist, the lower part of the furnace body and the upper part of the furnace body respectively adopt a high-strength ultrafine powder combined corundum-SiC pouring material, the high-strength ultrafine powder combined corundum-SiC pouring material, a high-strength ultrafine powder combined high-aluminum-SiC pouring material and a high-strength ultrafine powder combined high-aluminum-mullite pouring material; templates / molds are mounted in the blast furnace from bottom to top; the pouring materials are poured from bottom to top by a vibration or self-flowing pouring forming method to form a pouring liner body; the poured templates / molds are dismounted from top to bottom; after the hardness of the pouring liner body reaches the requirements, the templates / molds are dismounted; and the natural drying and the baking are performed. The method can obtain the blast furnace liner body with more compact structure, higher fire resistance and longer service life.

Owner:WUHAN HONGCHENG METALLURGICAL MATERIAL

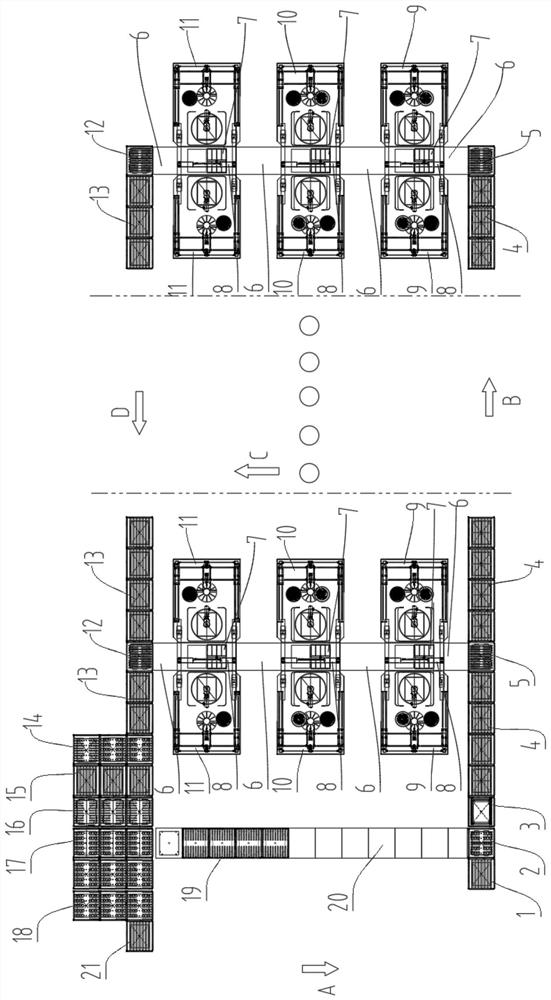

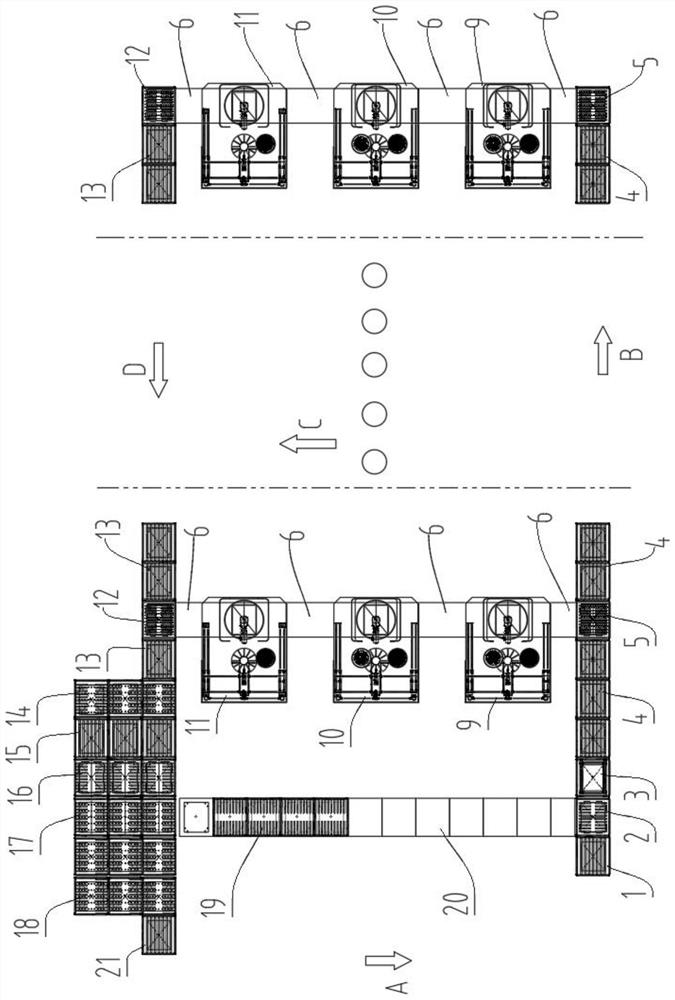

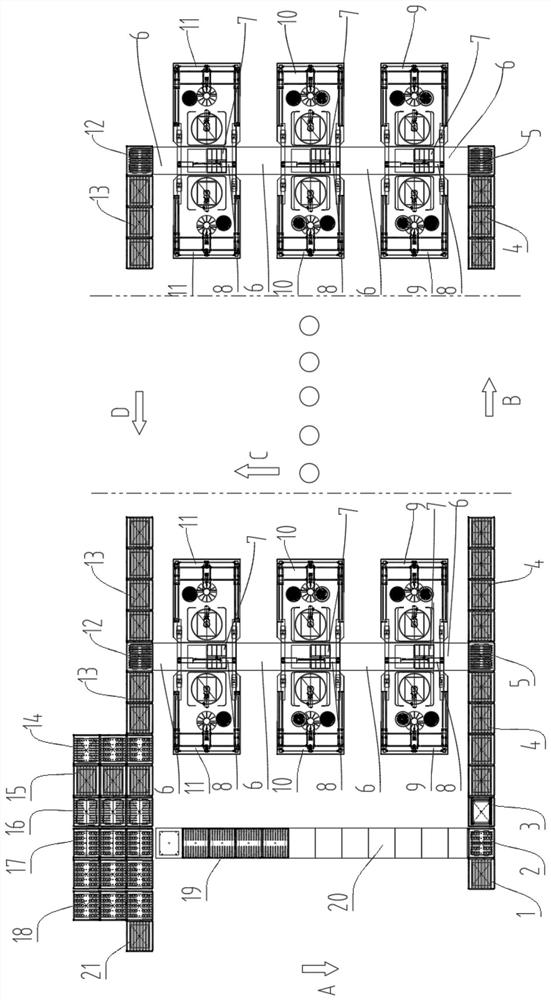

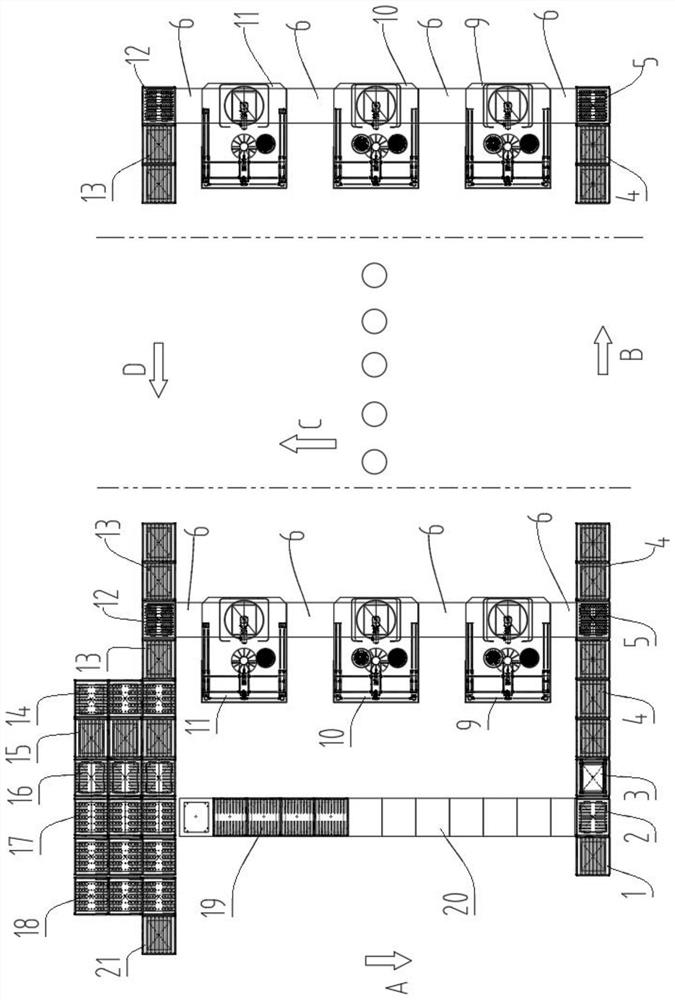

Substrate glass surface polishing production line system and substrate glass surface polishing production method

ActiveCN112792717BMeet the needs of polishingEasy to manage on sitePolishing machinesGrinding feedersProduction lineComposite material

Owner:河北光兴半导体技术有限公司 +2

Substrate glass surface polishing production line system and substrate glass surface polishing production method

ActiveCN112792717AMeet the needs of polishingEasy to manage on sitePolishing machinesGrinding feedersProduction lineComposite material

The invention relates to a substrate glass surface polishing production line system and a substrate glass surface polishing production method. The substrate glass surface polishing production line system comprises a tray supply line, a glass input line, polishing operation lines and a glass output line, wherein the tray supply line comprises a tray transporting device; the glass input line comprises a glass bearing table and a sheet loading device, and the tray transporting device is next to the sheet loading device; the glass input line comprises a laminating device and input transfer devices; the polishing operation lines comprise transitional transfer devices and polishing units, and the transitional transfer devices are next to the input transfer devices; and the glass output line comprises output transfer devices next to the transitional transfer devices, a sheet stripping device used for separating polished substrate glass and trays, a glass transfer device and a tray transfer device, the sheet stripping device transfers the substrate glass to the glass transfer device, and transfers the trays to the tray transfer device, and the tray transfer device is next to an input end of the tray supply line. According to the technical scheme, the requirements of polishing the substrate glass produced by adopting a float method can be met.

Owner:河北光兴半导体技术有限公司 +2

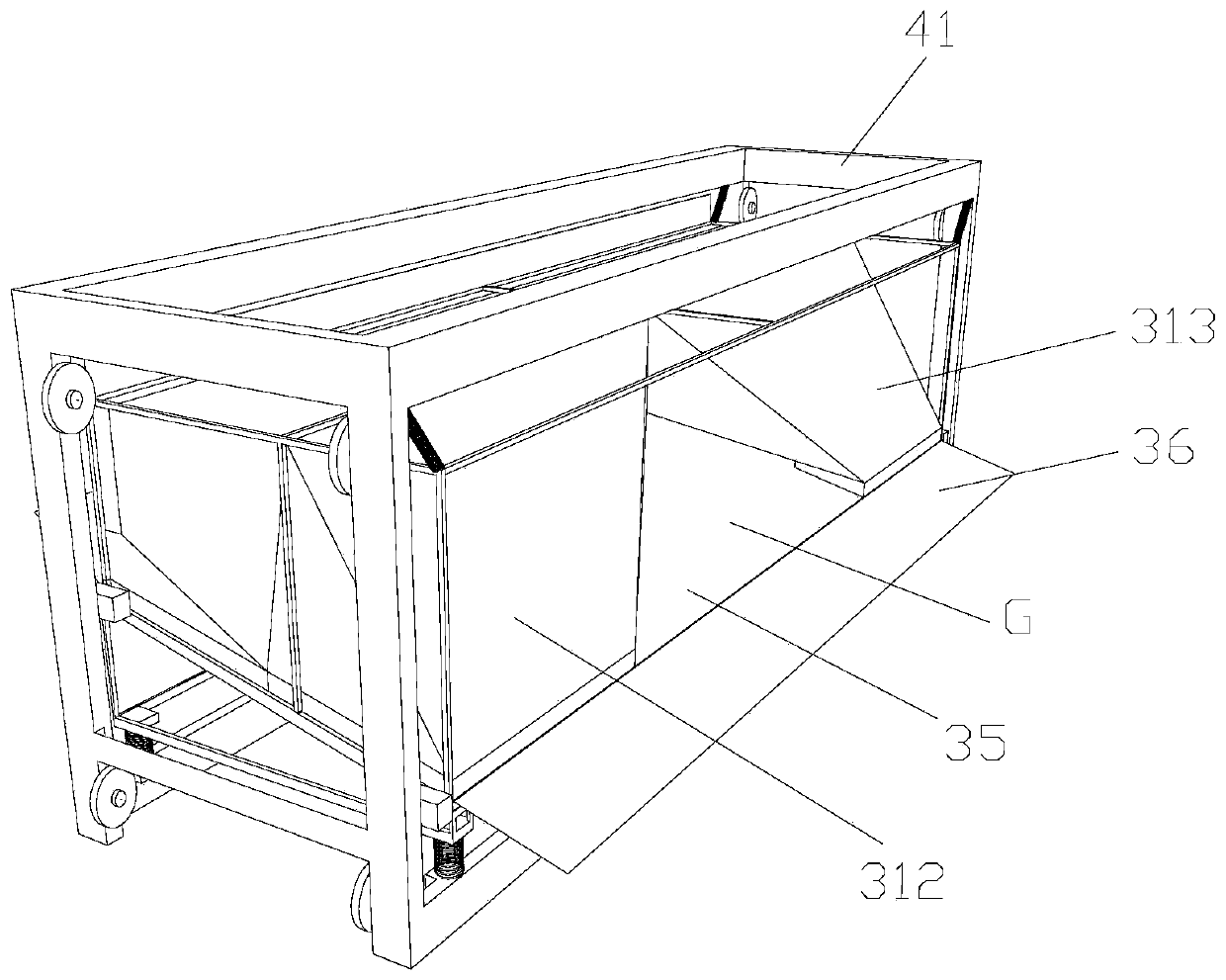

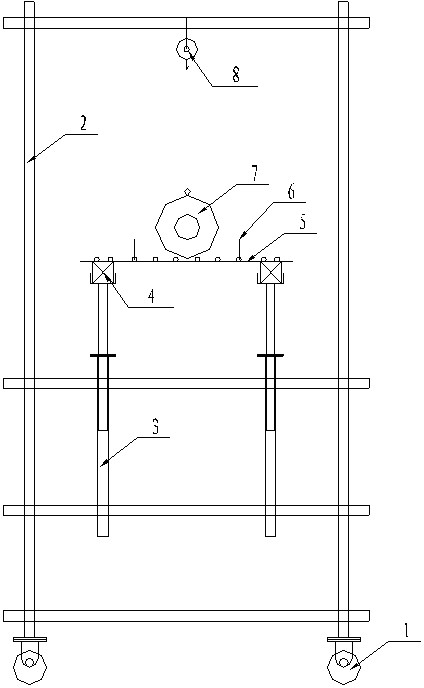

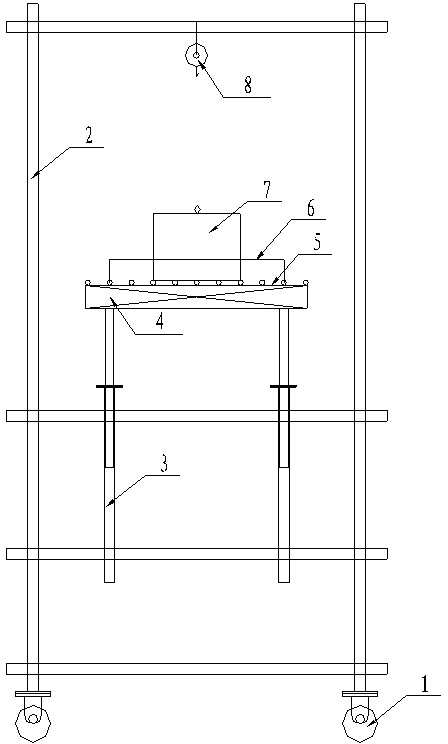

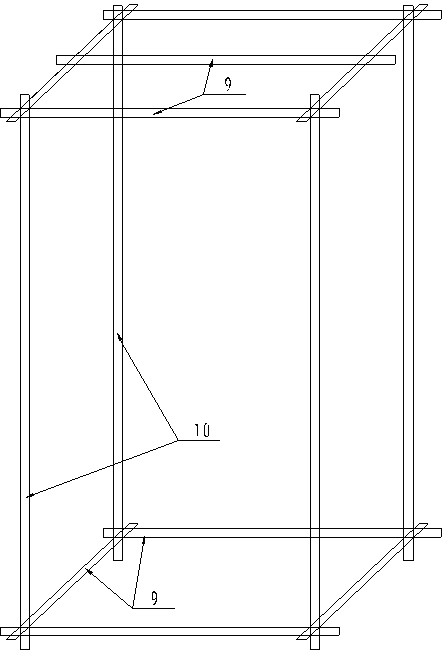

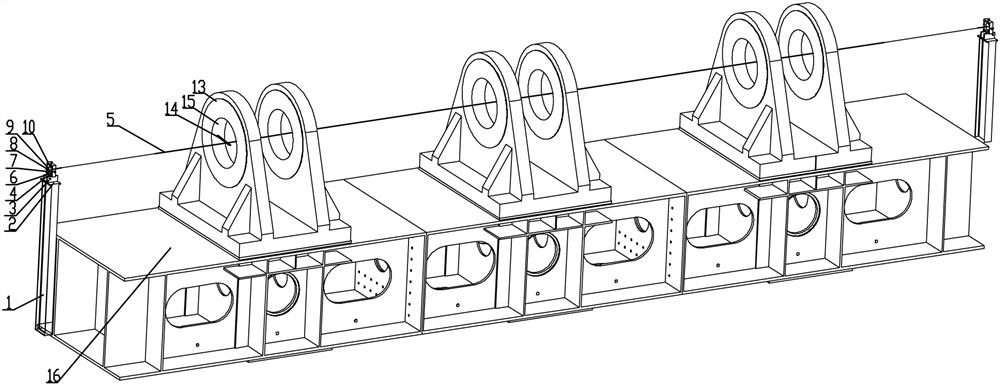

Prestressed tension auxiliary construction stage device

The invention discloses a prestressed tension auxiliary construction stage device used for engineering such as railways, roads, industrial buildings, water conservation, energy and rock and soil anchorage. The prestressed tension auxiliary construction stage device comprises an outer formwork, an inner formwork, an anchor pedestal, a tensioning anchor and a pulley component, the outer formwork and the inner formwork consist of scaffold steel pipes, the inner formwork is placed in the outer formwork, the anchor pedestal is placed on the inner formwork, the tensioning anchor is placed on the anchor pedestal, the pulley component is connected onto the outer formwork, and universal rotating wheels are disposed at the bottom of the outer formwork. The anchor pedestal consists of square timber, a reinforcing mesh and reinforcing guardrails, the reinforcing mesh is placed on the square timer, and the reinforcing guardrails are placed on the reinforcing mesh. The prestressed tension auxiliary construction stage device is simple in structure and convenient to operate, and materials of the prestressed tension auxiliary construction stage device are available easily. In addition, engineering practices show that tensioning speed is fast, construction is safe, and construction expense is lowered after the novel stage device is used.

Owner:SINOHYDRO BUREAU 14 CO LTD

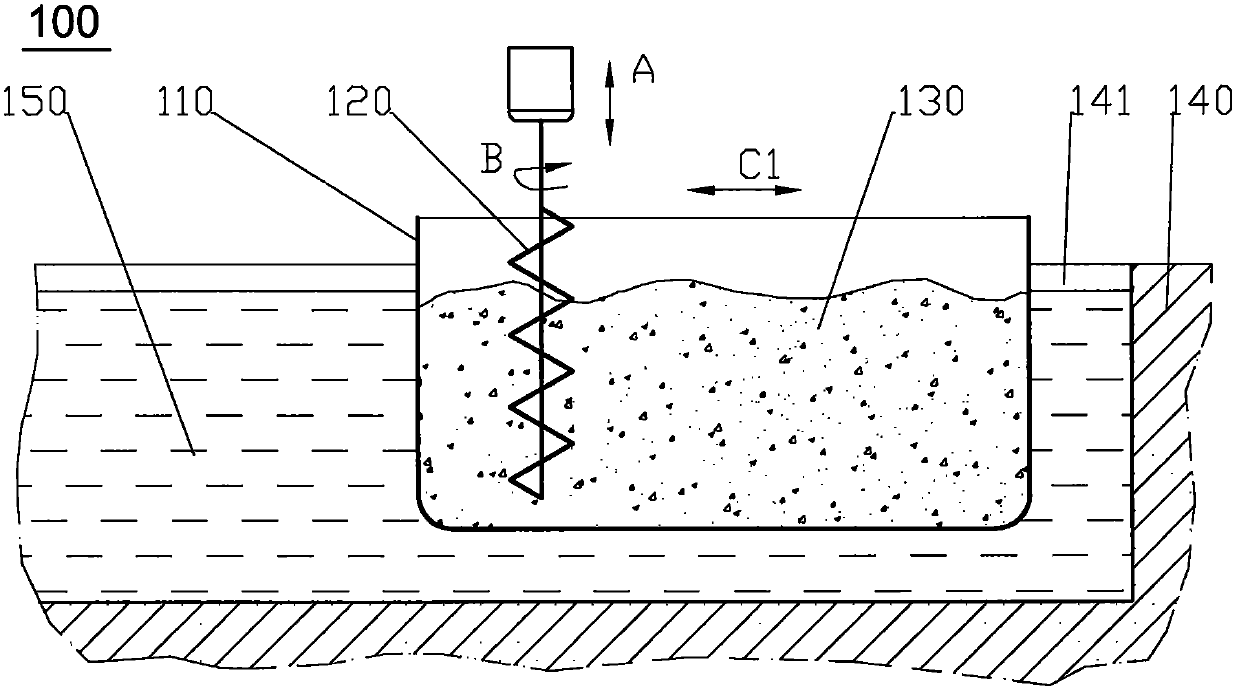

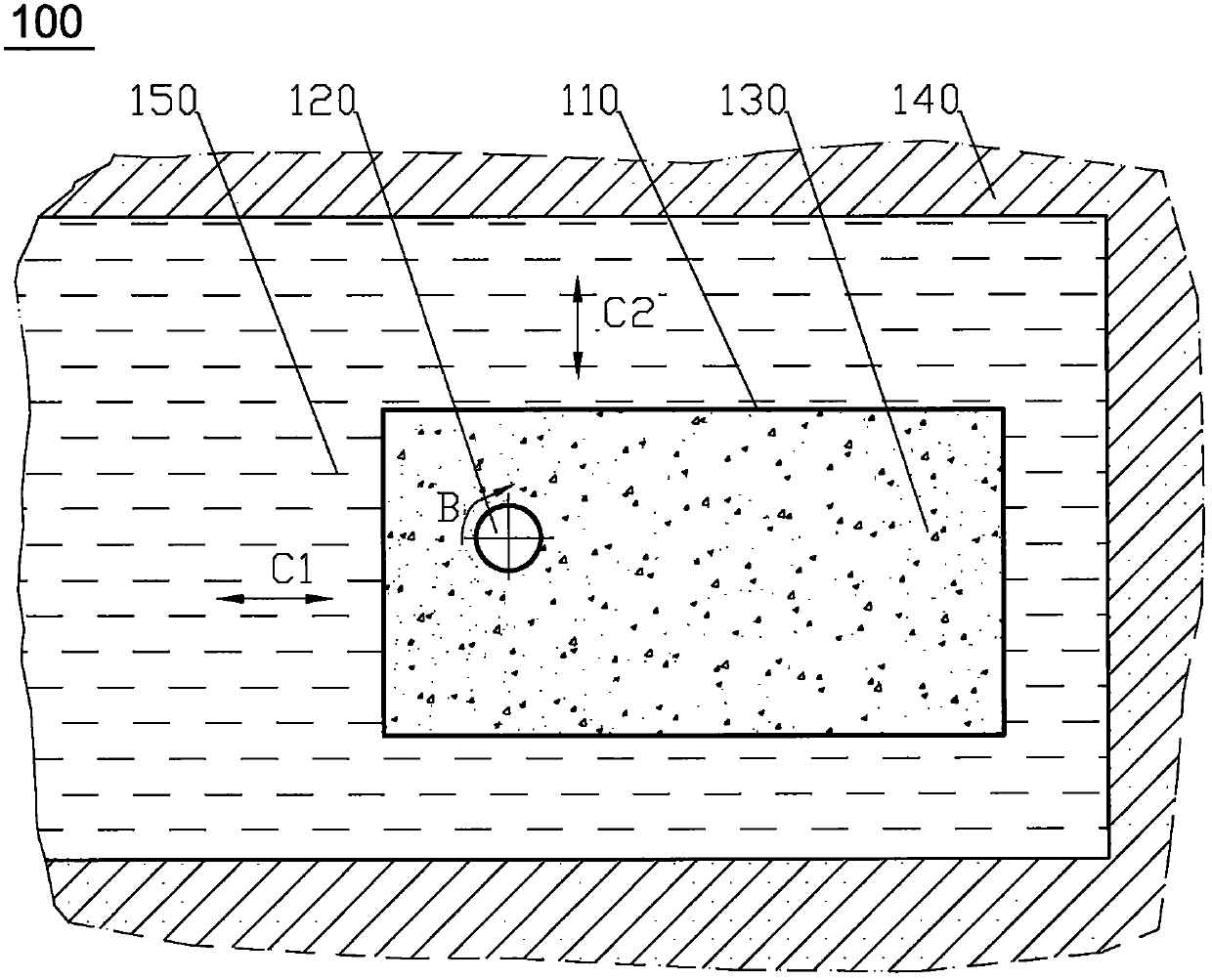

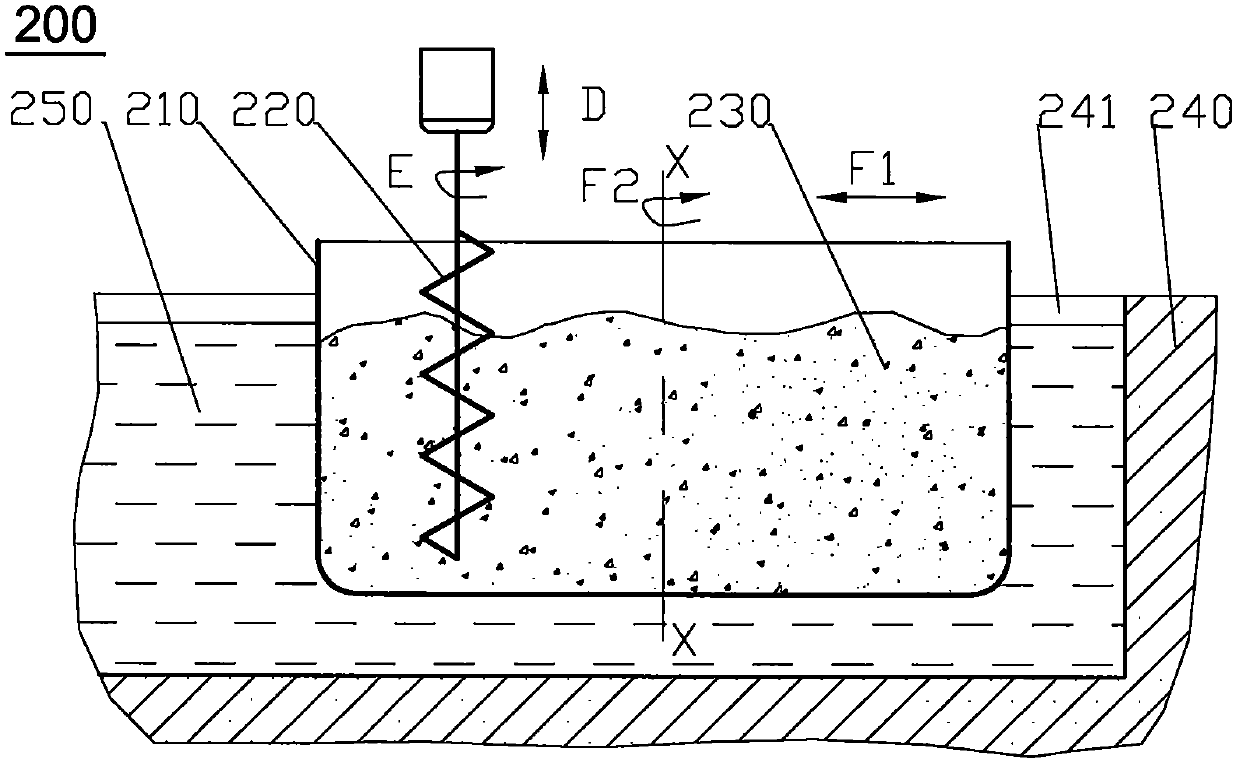

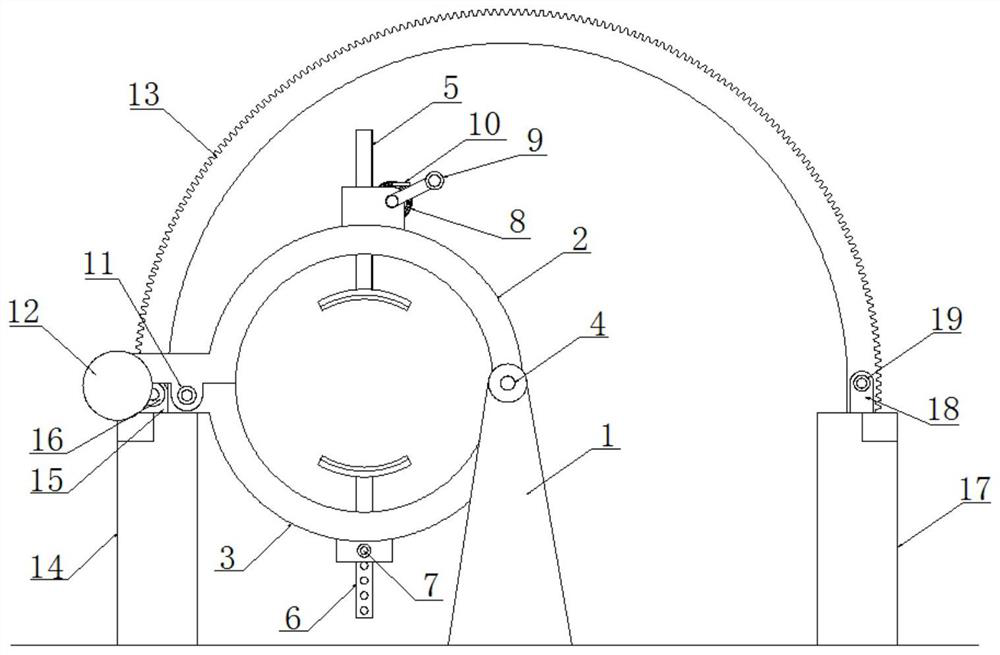

Solid material pile mechanical operation device with bearing liquid, and solid material pile mechanical operation method

InactiveCN110819518AReduce production and construction costsImprove operational efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsClassical mechanicsStructural engineering

The invention discloses a mechanical operation device (100) for conducting mechanical operation on a solid material pile (130). The mechanical operation device (100) includes a pile container (110) and an execution part (120), wherein the pile container (110) is used for containing the solid material pile (130), and the execution part (120) is used for conducting mechanical operation on the solidmaterial pile (130); and the mechanical operation device (100) is characterized by further including a bearing liquid (150) and a bearing container (140) which is used for containing the bearing liquid (150), wherein the pile container (110) is located in the bearing liquid (150). The invention further discloses a method of using the mechanical operation device (100) for conducing mechanical operation on the solid material pile (130).

Owner:北京安吉蓝天科技发展有限公司

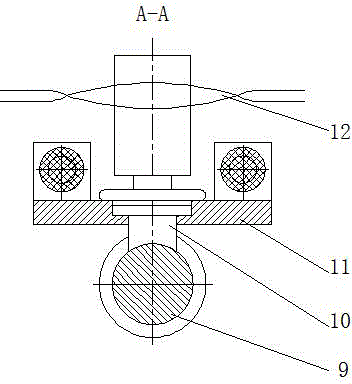

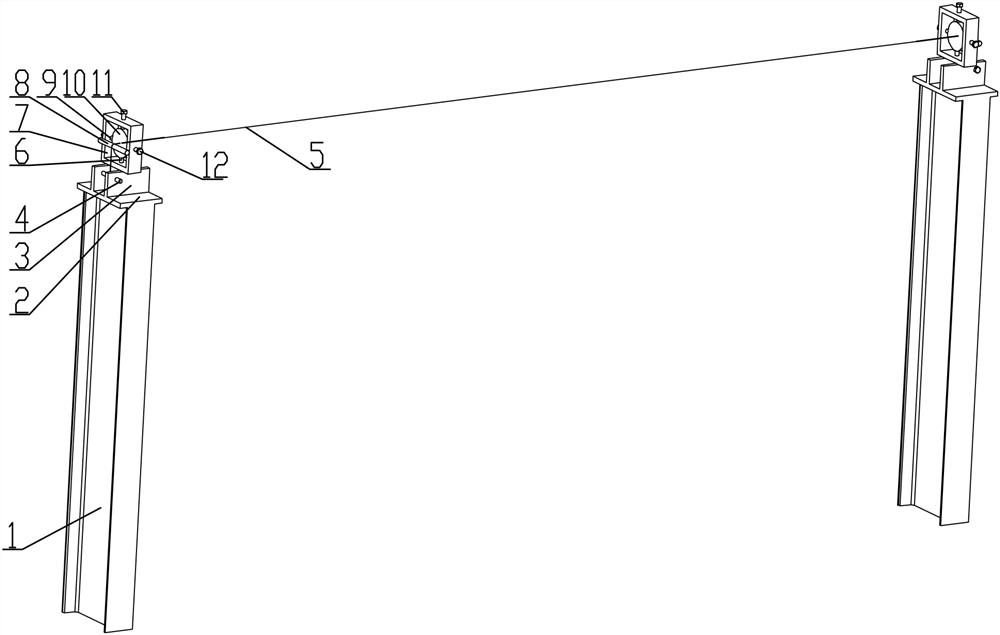

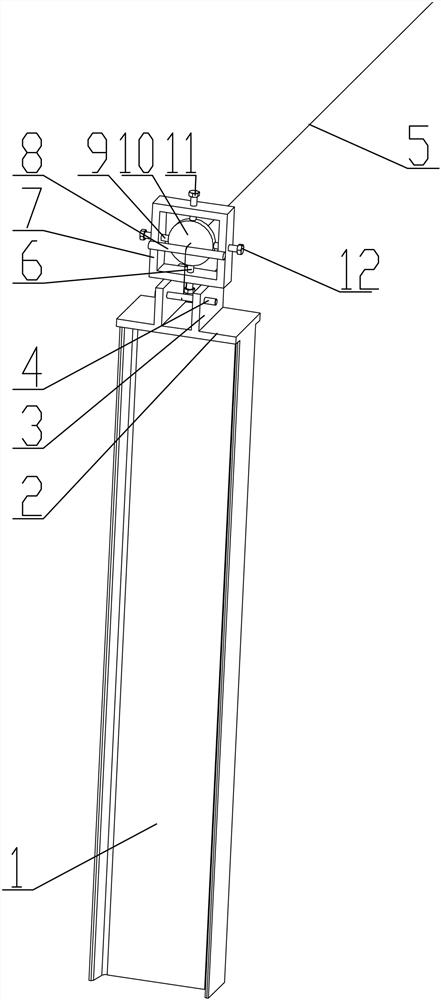

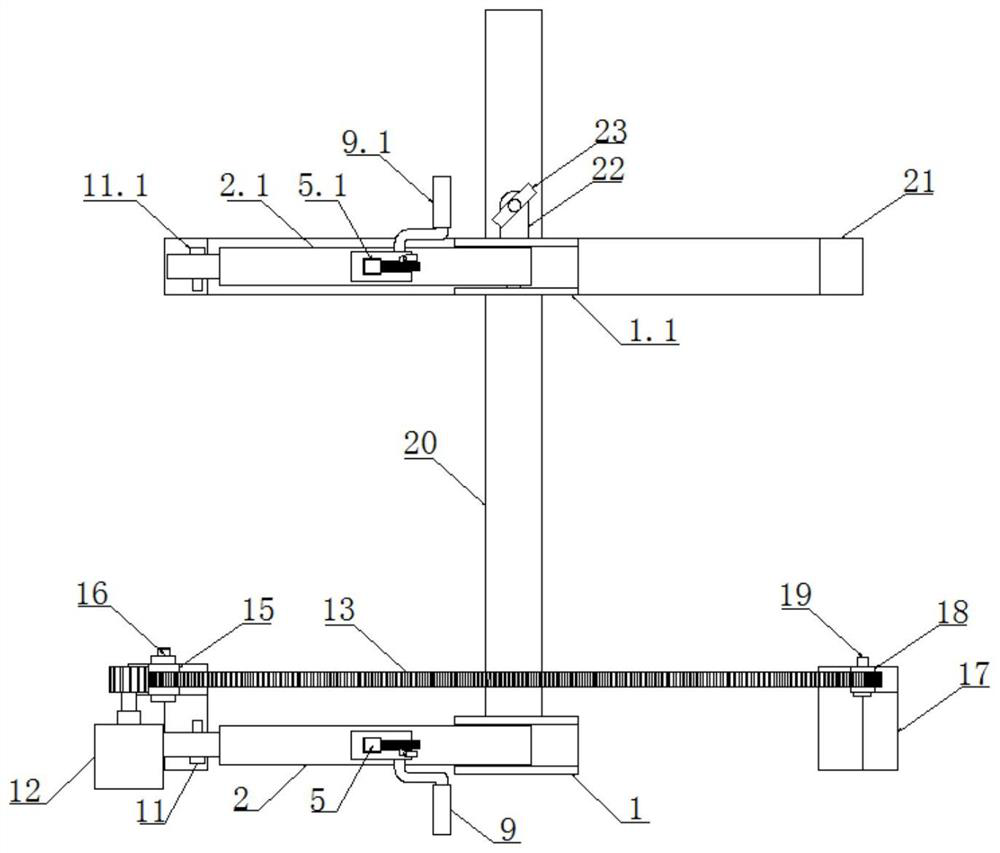

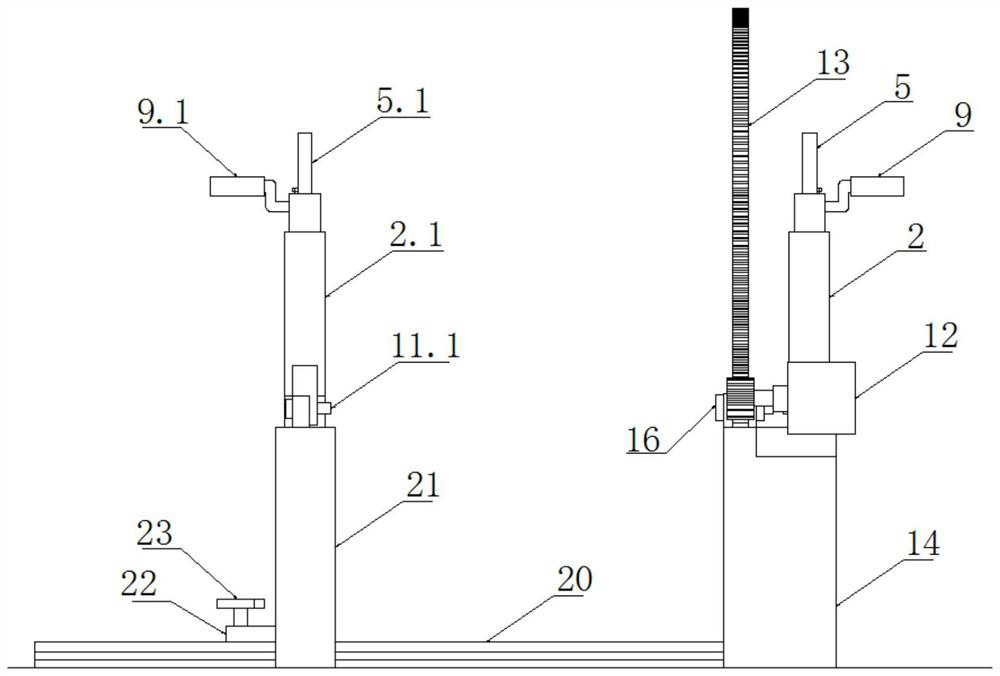

Device and method for adjusting and detecting coaxiality of multiple trunnions

PendingCN112697028ASolve the problem of porous coaxiality measurementGood effectMechanical measuring arrangementsCircular discStructural engineering

The invention discloses a device for adjusting and detecting the coaxiality of multiple trunnions, wherein the device comprises measurement supports; a top plate is fixed at the top of each measurement support, vertical plates are symmetrically fixed at the top of each top plate, an adjustment frames are fixed at the tops of the vertical plates, and an adjustment disc is supported in each adjustment frame through an adjustment bolt assembly; a center hole is formed in the center of each adjusting disc, a steel wire penetrates through the center holes, one end of the steel wire is wound around a supporting transverse rod and then fixed to a steel wire tensioning bolt, each supporting transverse rod is fixed to the outer side wall of the adjustment frame, and each steel wire tensioning bolt is fixed to the vertical plates. The device can accurately and visually measure the coaxiality of the trunnions, and has the advantages of simplicity, directness, reliable precision, high working efficiency, low cost and the like.

Owner:CHINA GEZHOUBA GROUP MACHINERY & SHIP

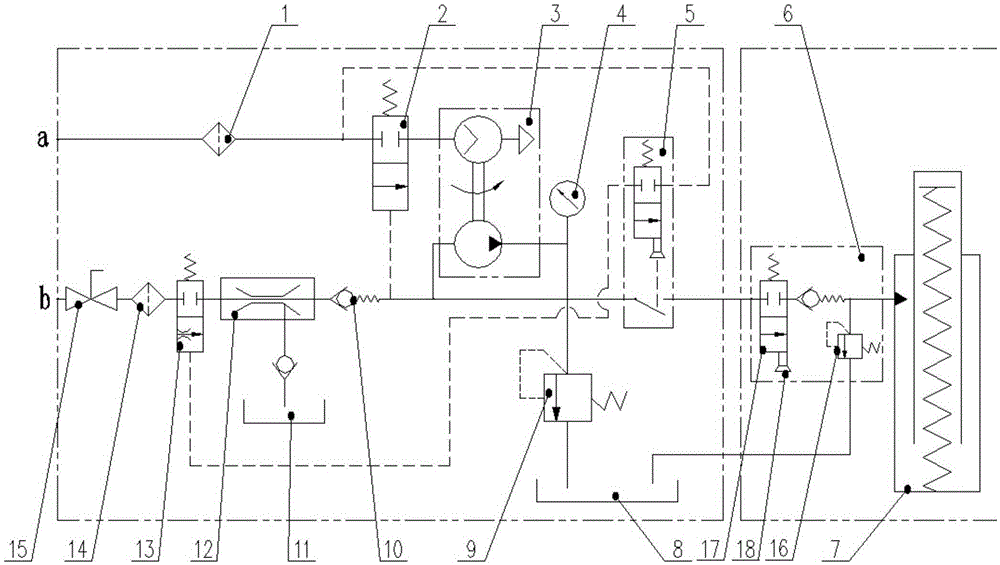

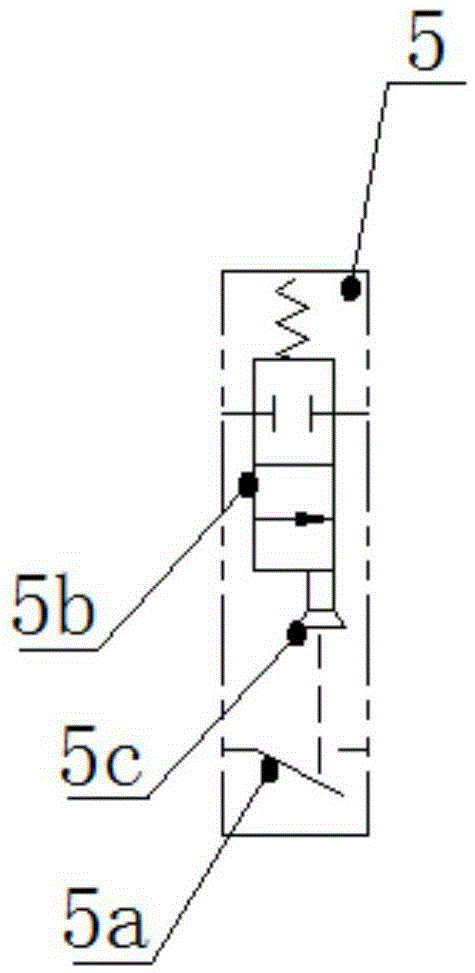

Portable large-flow pump station device

A portable large-flow pump station device comprises a hydraulic control system and a pneumatic control system. In the hydraulic control system, water is divided into two channels after flowing through a liquid inlet, a ball valve, a pneumatic operated directional valve, an automatic emulsion proportioning instrument and a one-way valve, the first channel of water directly flows into a hydraulic prop via a pneumatic operated switch handle and a three-purpose valve, and the second channel of water flows through a pressure intensifier controlled by a pilot operated directional control valve, and then flows into the hydraulic prop via the pneumatic operated switch handle and the three-purpose valve. In the pneumatic control system, after compressed air flows through an air inlet opening, one channel of the compressed air enters the pressure intensifier via the pilot operated directional control valve, and the other channel of the compressed air enters the pneumatic operated directional valve via the pneumatic operated switch handle. The portable large-flow pump station device is light in weight and convenient to use and maintain, workload of underground coal mine temporary supports is reduced effectively, and construction and production costs are reduced; and the efficiency is high, when in no load, low-pressure and large-flow emulsion is provided to enable the portable large-flow pump station device to act quickly and effectively, when in load, the portable large-flow pump station device is switched on, construction speed is increased, and moreover, the portable large-flow pump station device is high in safety, is energy-saving and environment-friendly, and has a wide application prospect.

Owner:XUZHOU LIEQI COMMERCE & TRADE CO LTD

Light tube for filling cast-in-situ steel reinforced concrete

The light pipe for filling in-situ cast steel reinforced concrete is corrugated pipe with at least one protrudent block. The corrugated pipe with protrudent block reduces the consumption of concrete in floor board and dead weight of floor board, strengthens the vibration strength, reduces the longitudinal rigidity and reduces the difference of rigidity in two directions. The present invention has high strength, high deformation and vibration resistance, convenient transportation and other features. The present invention is suitable for use in in-situ cast hollow beam-less reinforced concrete floor board as well as roofing, base board, wall and hollow bridge.

Owner:湖南邱则有专利战略策划有限公司

Light stuffing mold member for cast-in-situ steel concrete

The light stuffing mold member for in-situ cast reinforced concrete is one corrugated stuffing mold with at least protrudent block on its one side. After the light stuffing mold member is used in reinforced structure floor board, in-situ cast concrete rib of truss rod is formed, and the in-situ cast concrete rib has greatly reduced weight and saved material consumption, resulting in reduced floor board weight and raised antiseismic performance. With the features of light weight, high strength, simple structure, convenient construction and transport, etc, the light stuffing mold member is suitable for use in in-situ cast hollow beam-less reinforced concrete floor board as well as roofing, base board, wall and hollow bridge.

Owner:湖南邱则有专利战略策划有限公司

Turnover type pipe welding device and using method thereof

ActiveCN113941818AImprove welding efficiencyAvoid damageWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryStructural engineering

The invention discloses a turning-over type pipe welding device and a using method thereof. The device comprises two clamping mechanisms which are symmetrically arranged, a connecting rod for connecting the two clamping mechanisms, and a transmission mechanism which stretches across one clamping mechanism and is connected with a driving motor fixed at the end part of the clamping mechanism so as to enable the two clamping mechanisms to turn over. A pipe to be welded is clamped through the two symmetrical clamping mechanisms, the pipe to be welded can be rapidly turned over under the driving of the transmission mechanism, the problems that a traditional operation mode is low in efficiency and wastes time and labor are effectively solved, and the welding efficiency of the pipe is greatly improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Environment-friendly modified asphalt for microsurfacing

InactiveCN110591393AReduce production and construction costsDoes not affect sprayingBuilding insulationsNeopreneAsphalt

The invention discloses environment-friendly modified asphalt for microsurfacing. The problems that in the prior art, emulsified asphalt is insufficient in anti-deformation capacity, too long in molding time and not ideal enough in pavement performance are solved. The environment-friendly modified asphalt is prepared from the following components in parts by weight: 3-5 parts of cationic styrene-butadiene latex, 1.5-2.5 parts of neoprene latex, 2.5-3 parts of oleyl promethylene diamine, 1.8-2.2 parts of industrial hydrochloric acid, 1.6-2.0 parts of Mqk-1m, 1.5-2.5 parts of PAMAM, and 15-20 parts of matrix asphalt. The environment-friendly modified asphalt has the advantages of being high in adaptability, quick in molding, good in adhesive property and coating property, long in storage time and the like.

Owner:田纹绮

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com