Online operation management method and system based on ship three-dimensional model and terminal

A technology of 3D model and management method, which is applied in transmission system, 3D modeling, image data processing, etc. It can solve problems such as inability to realize circle reading, large amount of 3DPDF file data, and high application cost, so as to reduce design changes and manufacturing rework, Ensure uniqueness and readiness, reduce the effect of input and output operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

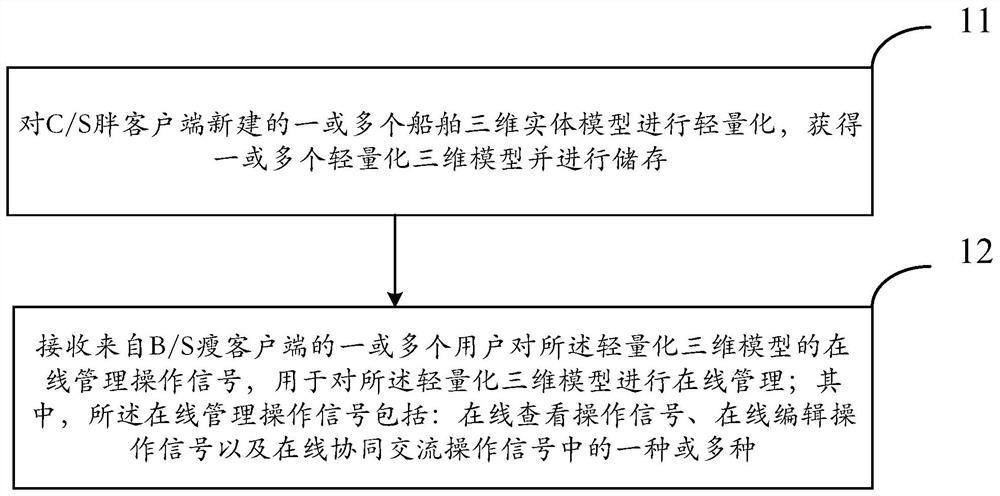

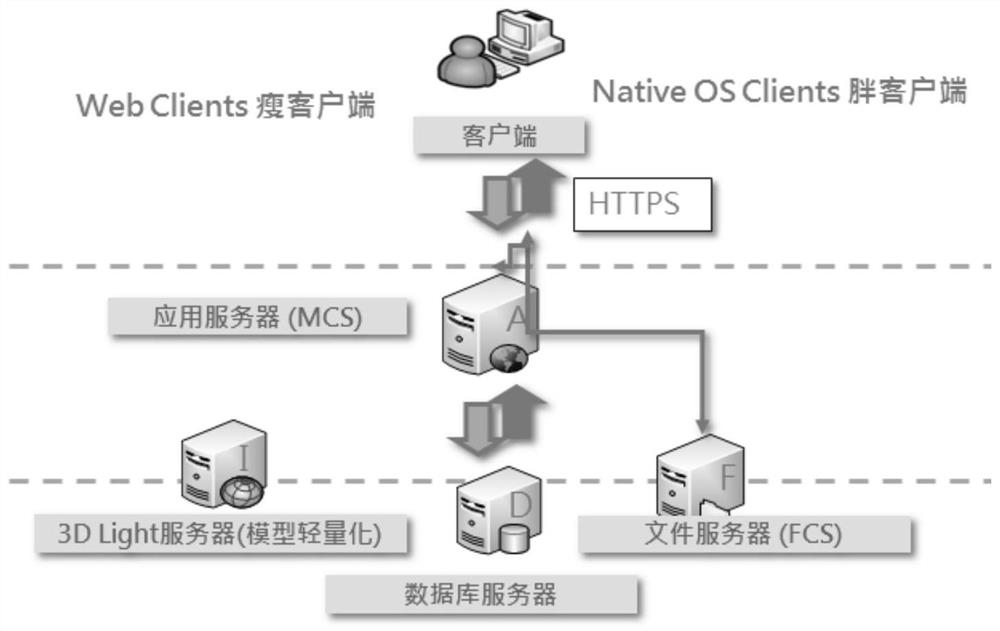

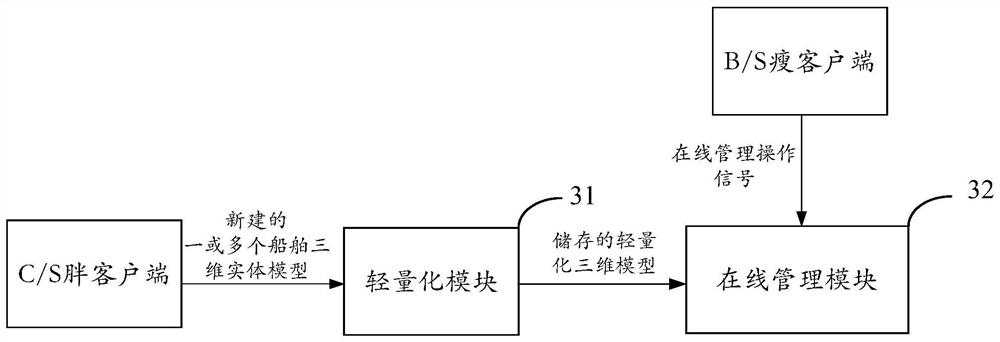

[0063] like image 3 Shown is a schematic structural diagram of an online operation management system based on a three-dimensional model of a ship in an embodiment of the present invention.

[0064] The system includes:

[0065]The lightweight module 31 is used to lightweight one or more three-dimensional solid models of ships newly created on the C / S fat client, and obtain and store one or more lightweight three-dimensional models;

[0066] The online management module 32 is connected to the lightweight module 31, and is used to receive an online management operation signal of the lightweight 3D model from one or more users of the B / S thin client, and is used to control the lightweight 3D model. conduct online management;

[0067] Wherein, the online management operation signal includes: one or more of an online viewing operation signal, an online editing operation signal, and an online collaborative communication operation signal.

[0068] Optionally, one or more three-di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com