A construction method of integral pouring of blast furnace lining instead of spray paint and refractory bricks

A technology of integral pouring and construction method, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as loose refractory brick lining, poor bonding of blast furnace lining structure, and difficult to deal with new and old joint surfaces. Achieve the effects of quick-drying and explosion-proof performance, good thermal shock stability, and low reburning change rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

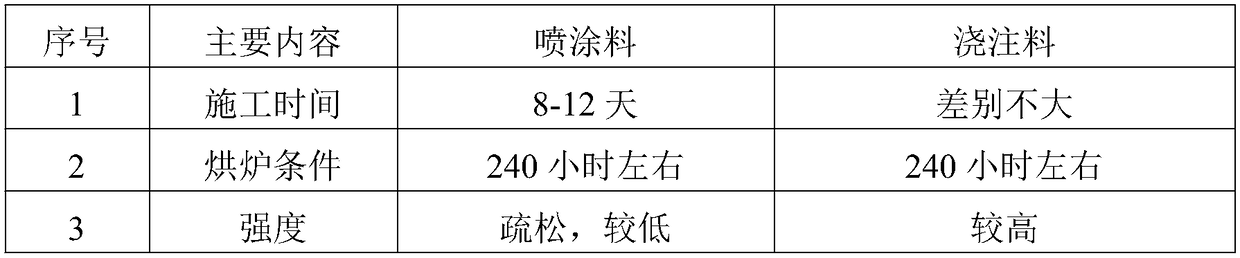

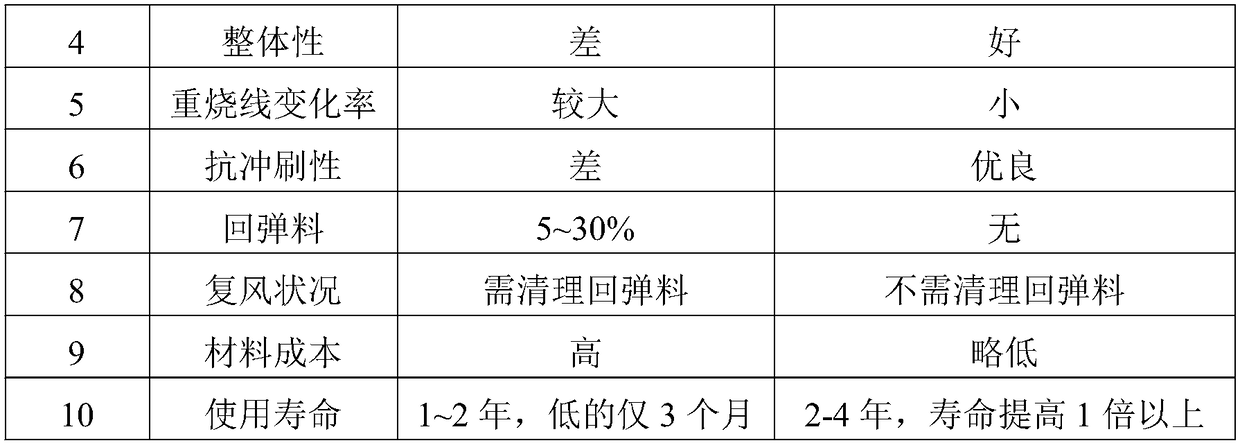

[0033] The present invention will be described in further detail below in conjunction with the attached tables and examples of implementation.

[0034] Referring to shown in table 1, the embodiment of the present invention provides a kind of integral pouring construction method of blast furnace lining that replaces spray paint and refractory brick, comprises the following steps:

[0035] S1. Determine the damaged parts of the hearth and shaft of the blast furnace. The hearth includes the taphole and tuyere belt, and the shaft includes the bosh and waist: confirm the eroded parts and erosion conditions of the hearth and shaft of the blast furnace; confirm The depth, area and volume of the damaged parts of the hearth and shaft of the blast furnace; at the same time, confirm whether the hearth and shaft of the blast furnace are in good condition, and confirm the repair and construction plan according to the overall damage status.

[0036] S2. Clean up the furnace hearth and shaft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com