Preparation method for compound type foaming agent

A foaming agent and composite technology, which is applied in the field of preparation of construction admixtures, can solve the problems of environmental protection, harmlessness, instability, irritation, etc., and achieve fast foaming speed, controlled decomposition speed, and stable easy to store effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

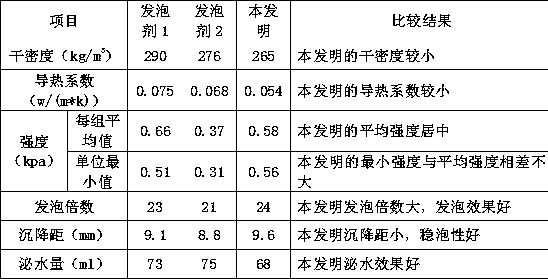

Image

Examples

Embodiment 1

[0038] The composite foaming agent of the present invention comprises: sodium lauryl sulfate, silicone resin polyether emulsions, saponin, lauryl polyoxyethylene ether, sodium bicarbonate, stearic acid , aluminum powder, polyethylene glycol, N-N , - Dinitrosopentamethylenetetramine (DPT), diethylene glycol, lauryl alcohol, sodium hydroxide;

[0039] Its preparation method is:

[0040] a. Initial configuration:

[0041] (1) According to the formula of the initial product, add the components of the initial product into the dry powder reaction kettle according to the ratio. The stirring speed of the reaction kettle is 30 rpm for the first 15 minutes, and the rotation speed is increased to 50 rpm for the next 30 minutes;

[0042] (2) After the added components are stirred evenly, move the primary product of the powder foaming agent to the storage tank for storage;

[0043] b. Compounding:

[0044] (1) Take a certain amount of the primary product of powder foaming agent and mix...

Embodiment 2

[0049] The composite foaming agent of the present invention comprises: sodium lauryl sulfate, silicone resin polyether emulsions, saponin, lauryl polyoxyethylene ether, sodium bicarbonate, stearic acid , aluminum powder, polyethylene glycol, N-N , - Dinitrosopentamethylenetetramine (DPT), diethylene glycol, lauryl alcohol, sodium hydroxide;

[0050] Its preparation method is:

[0051] a. Initial configuration:

[0052] (1) According to the formula of the initial product, add the components of the initial product into the dry powder reaction kettle according to the ratio. The stirring speed of the reaction kettle is 30 rpm for the first 15 minutes, and the rotation speed is increased to 50 rpm for the next 30 minutes;

[0053] (2) After the added components are stirred evenly, move the primary product of the powder foaming agent to the storage tank for storage;

[0054] b. Compounding:

[0055] (1) Take a certain amount of the primary product of powder foaming agent and mix...

Embodiment 3

[0060] The composite foaming agent of the present invention comprises: sodium lauryl sulfate, silicone resin polyether emulsions, saponin, lauryl polyoxyethylene ether, sodium bicarbonate, stearic acid , aluminum powder, polyethylene glycol, N-N , - Dinitrosopentamethylenetetramine (DPT), diethylene glycol, lauryl alcohol, sodium hydroxide;

[0061] Its preparation method is:

[0062] a. Initial configuration:

[0063] (1) According to the formula of the initial product, add the components of the initial product into the dry powder reaction kettle according to the ratio. The stirring speed of the reaction kettle is 30 rpm for the first 15 minutes, and the rotation speed is increased to 50 rpm for the next 30 minutes;

[0064] (2) After the added components are stirred evenly, move the primary product of the powder foaming agent to the storage tank for storage;

[0065] b. Compounding:

[0066] (1) Take a certain amount of the primary product of powder foaming agent and mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com