Transmission mechanism of small-section strip steel coiling machine

A technology of transmission mechanism and small section, applied in the direction of transmission device, mechanical equipment, belt/chain/gear, etc., can solve the problems of high cost, high price, unsuitable coiling, etc., to reduce production and construction costs, increase storage capacity, Satisfy the effect of matching regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

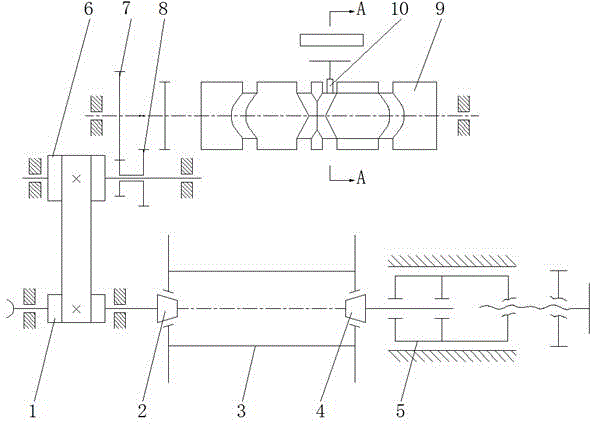

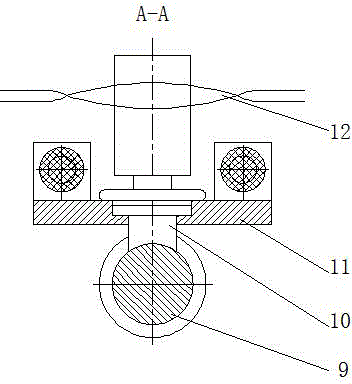

[0017] Such as figure 1 and figure 2 As shown, a transmission mechanism of a small-section strip steel coiler includes a speed-regulating motor, a reducer, an active synchronous pulley 1, a rotating cone wheel 2, a coiling disc 3, a moving cone wheel 4, a sliding cylinder 5, and a passive Synchronous belt pulley 6, passive duplex gear 7, active duplex gear 8, bidirectional cylindrical cam 9, shuttle-shaped slide block 10, moving frame 11.

[0018] The helical layered winding motion of the small-section steel strip 12 can be decomposed into a cylindrical motion around the coil 3 and a movement along the axial direction of the coil 3. When moving in a helical manner, it can freely rotate around the axis of its own cylinder in the moving frame 11 . After being decelerated by the speed reducer, the rotation of the speed-regulating mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com