Solid material pile mechanical operation device with bearing liquid, and solid material pile mechanical operation method

A technology for mechanical operation and material stacking, which is applied in the field of mechanically operated devices and can solve the problems of increasing the manufacturing and operating costs of containers and their supporting bases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

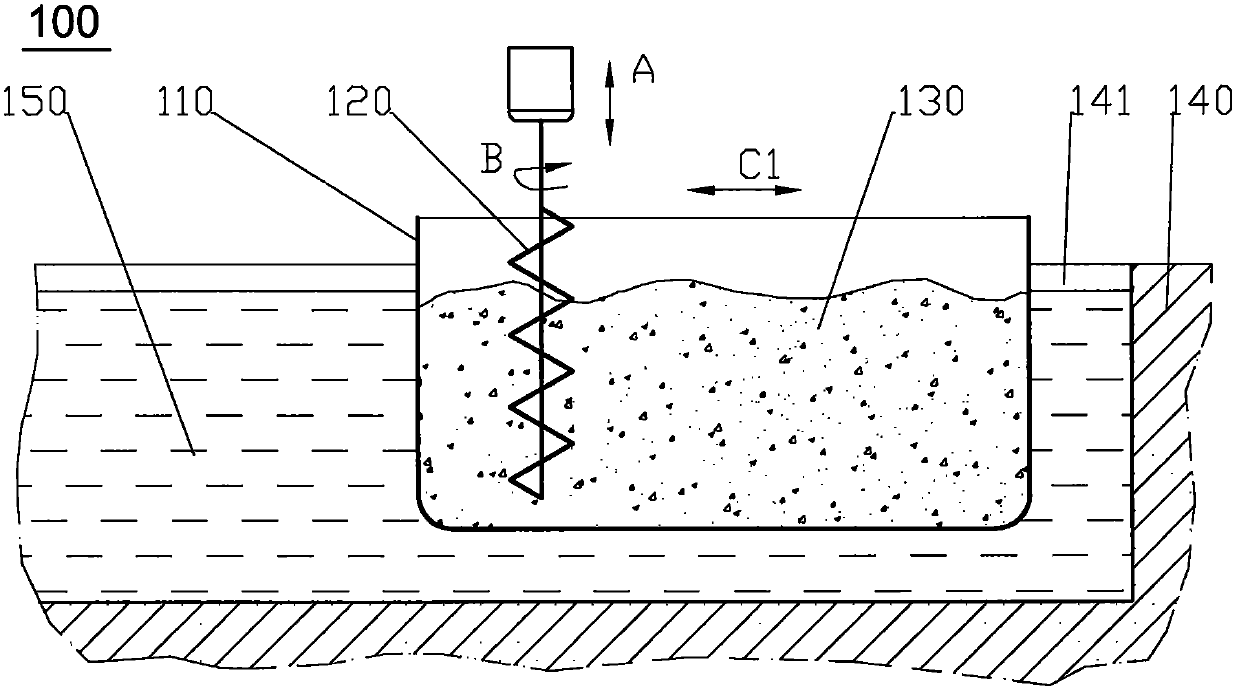

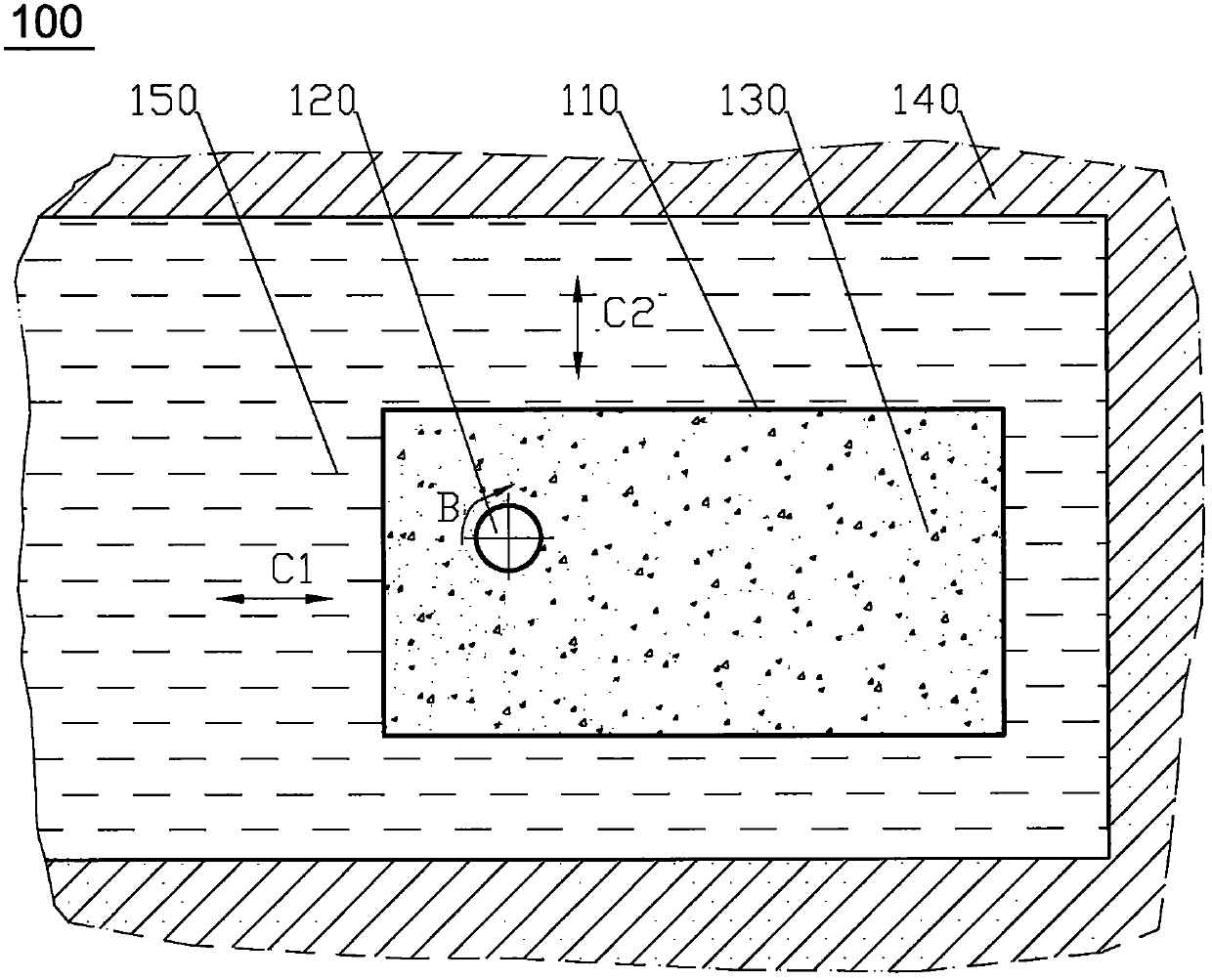

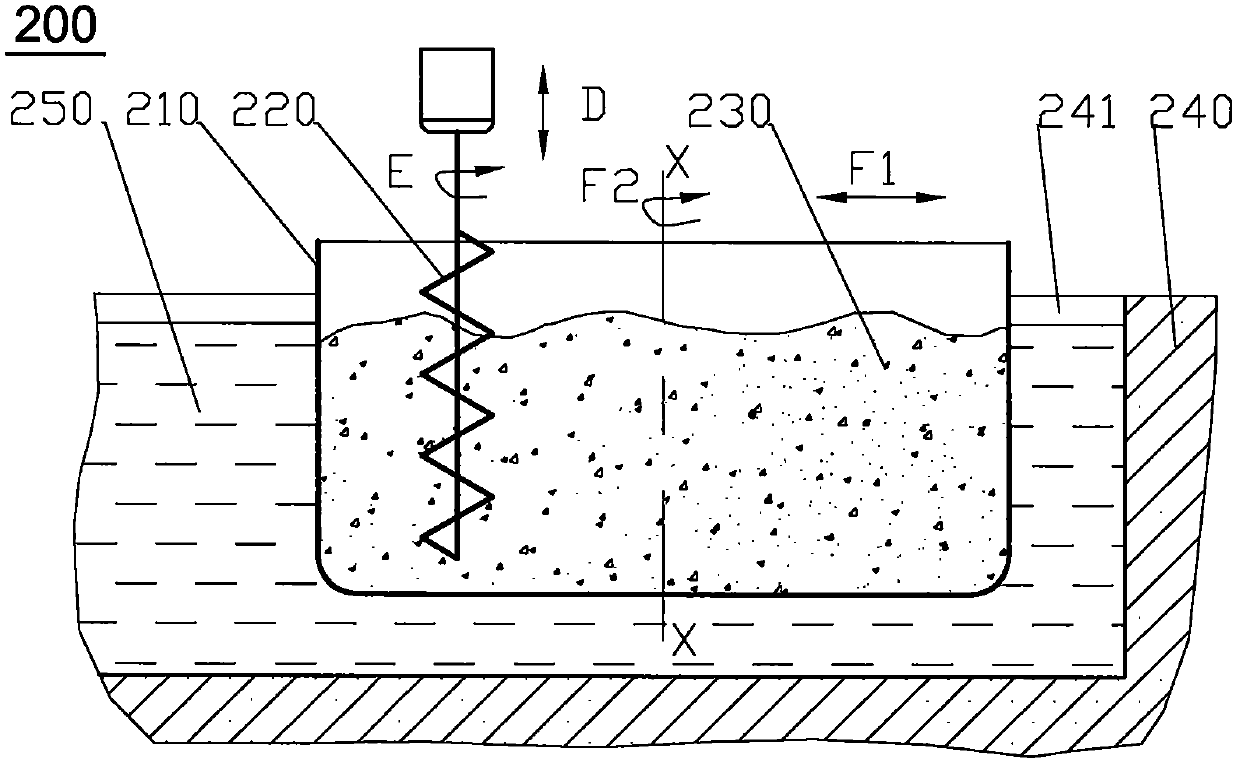

[0019] exist figure 1 Shows the vertical section of the mechanical operation device 100 of the first embodiment of the present invention, wherein the solid material pile 130 is accommodated in the box-shaped pile container 110, when the vertical rotation axis of the actuator 120 rotates in the direction indicated by the arrow B, The executive part, that is, the cantilever screw auger 120, performs local mechanical agitation on the solid material pile 130;

[0020] Although the solid material heap 130 has a huge size and volume, the bottom of the heap container 110 does not need to add any road wheels and driving devices therefor. Adopt clear water to be the carrying liquid 150, because the specific gravity of water and the material in the material pile body 130 is close, the inner and outer pressures suffered by the side walls and the bottom plate of the pile body container 110 basically cancel each other out, so the pile body container 110 can be made of very thin material M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com