Water-whitening resistant latex emulsion pressure sensitive adhesive and its production

A pressure-sensitive adhesive, water glue technology, applied in the direction of adhesive, adhesive type, ester copolymer adhesive, etc., to achieve good wettability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A typical formulation of the pressure sensitive adhesive of the present invention is as follows:

[0043] Table 1

[0044] components

Weight % based on latex

water

51.80

0.10

Hitenol BC-10 *

1.12

70% tert-butyl hydroperoxide

0.19

2-Ethylhexyl Acrylate

32.27

7.61

3.81

β-carboxyethyl acrylate

2.48

1.50

Zinc formaldehyde sulfoxylate

0.12

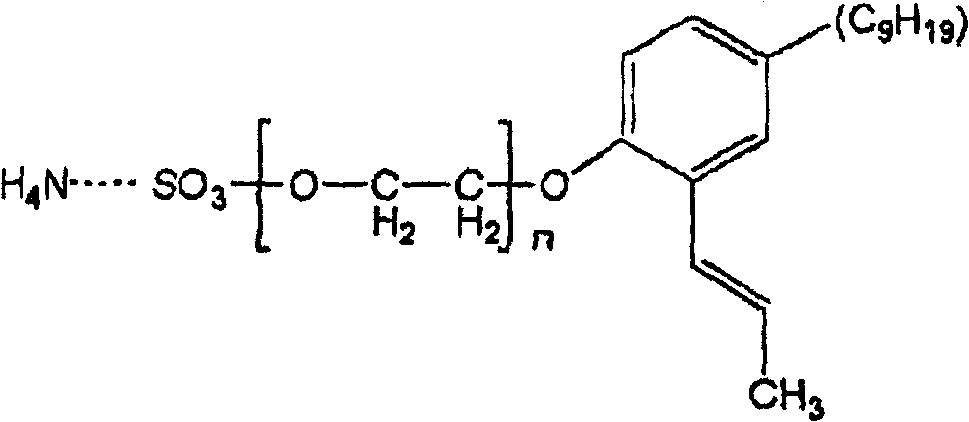

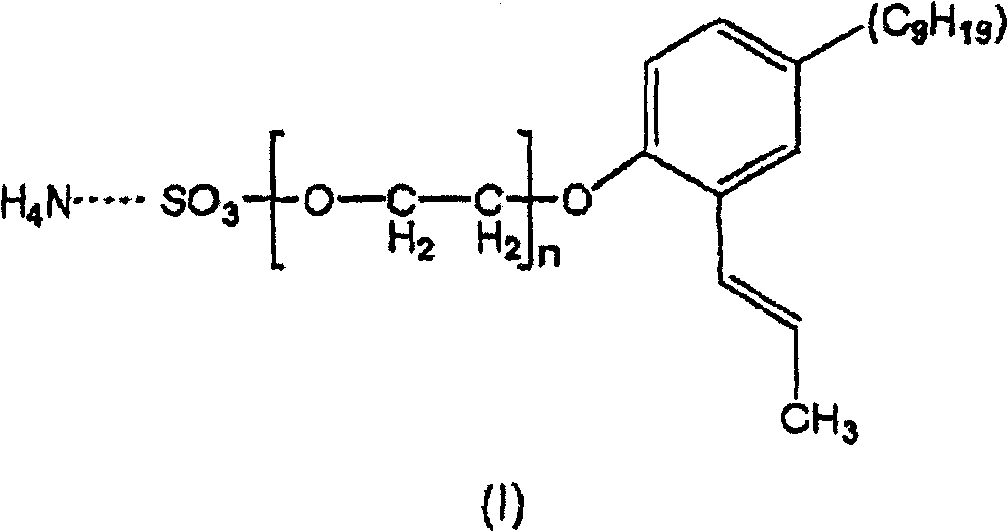

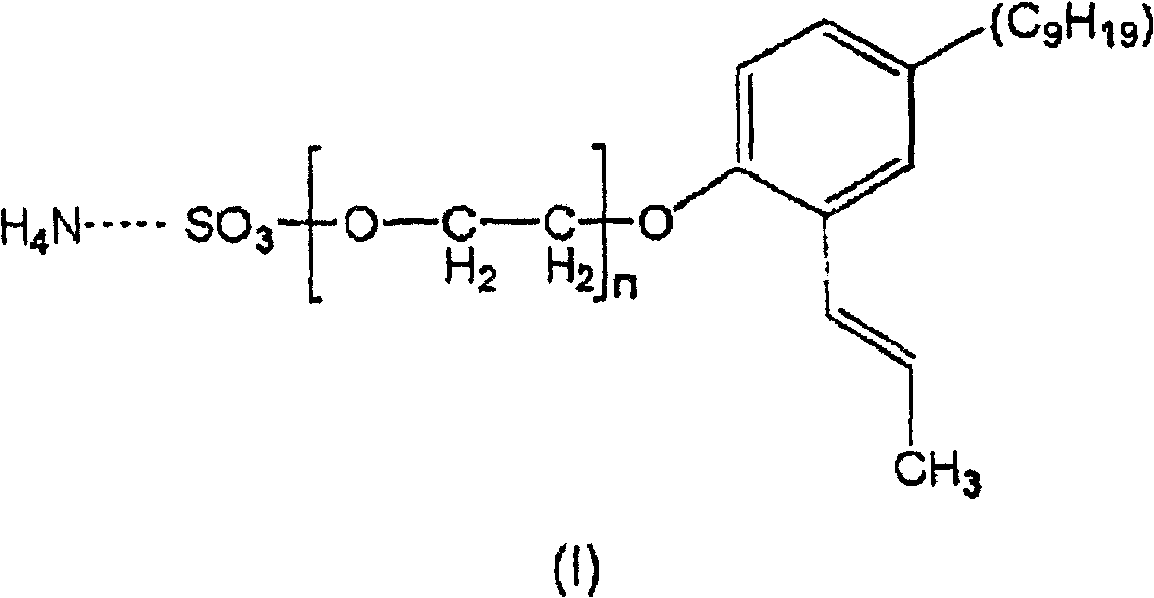

[0045] * Hitenol BC-10 is poly(oxy-1,2-ethanediyl), α-sulfo-ω-(4-nonyl-2-(1-propenyl)phenoxy Base) branched ammonium salt; yellow-brown viscous liquid, 97.0% active matter, combined sulfuric acid content is 8.70-9.70%, pH value is 6.5-8.5 (1% solution).

[0046] A typical synthetic description is as follows:

[0047] Preparation of pre-emulsion

[0048] Into a 500 ml pre-emulsification vessel with a turbine agitator was ad...

Embodiment 12

[0068] Add deionized water (462.0 g) and Hitenol BC-10 to a 2000 ml four-port jacketed glass reactor with turbine stirrer, thermocouple, circulating water bath, nitrogen bubbling and pre-emulsion and reducing agent delivery lines. Polymeric Surfactant (3.60 grams). Start nitrogen bubbling, set the stirring speed at 200 rpm, and turn on the circulating water bath. A monomer mixture consisting of 33.7 grams of carboxyethyl acrylate, 0.2 grams of methacrylic acid, 475.0 grams of 2-ethylhexyl acrylate, and 132.0 grams of styrene was added to a mixture containing 1.3 grams of sodium bicarbonate, 1.9 grams of 70% tert-butyl Hydroperoxide-based initiator and 14.6 grams of Hitenol BC-10 polymerizable anionic surfactant in 217.1 grams of water and stirred long enough to form a stable pre-emulsion material. Separately, a reductant feed containing 1.2 grams of zinc formaldehyde sulfoxylate in 42 grams of water was prepared and added to the storage tank of the peristaltic pump for final ...

Embodiment 13

[0070] Example 12 was repeated except that 0.2 grams of n-dodecanethiol was included in the pre-emulsion mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com