Fluorine-containing resin mixture and copper-clad plate prepared from same

A fluorine-containing resin and mixture technology, applied in synthetic resin layered products, adhesive types, adhesive additives, etc., can solve the problem of uneven dielectric properties, mechanical properties and thermal expansion coefficients of copper clad laminates The interaction force of foil is not high and the viscosity of fluorine-containing resin emulsion is low, so as to achieve the effect of good adhesion, meeting performance requirements and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

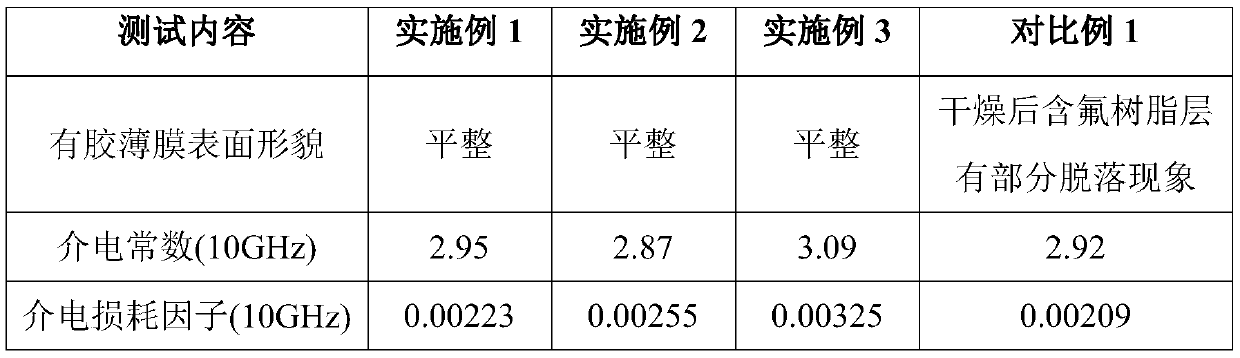

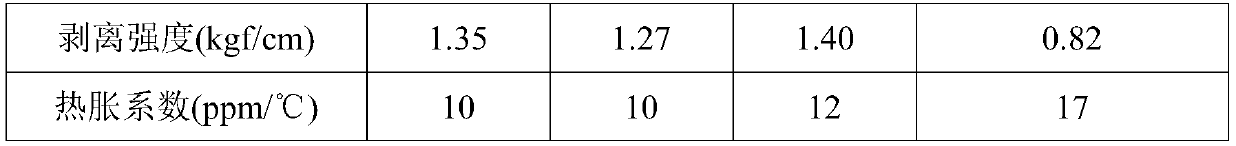

Examples

preparation example Construction

[0024] The preparation method of the fluorine-containing resin emulsion in this application can be any one well-known to those skilled in the art, for example, the fluorine-containing resin is uniformly dispersed in N-methylpyrrolidone, and the solid content can be adjusted according to the amount of raw materials, and can also be added appropriately Dispersants improve emulsion stability.

[0025] Prepolymers of thermoplastic polymers

[0026] In some preferred embodiments, the prepolymer main chain of the thermoplastic polymer contains ether groups; more preferably, the prepolymer main chain of the thermoplastic polymer contains ether groups and bisphenol A structure ; Furthermore, the main chain of the prepolymer of the thermoplastic polymer contains ether groups and bisphenol A structure, and the main chain or side chain also contains ester groups.

[0027] The ether group structure in the present application can exemplify the molecular structure in formula 1, the bisph...

Embodiment 1

[0054] Example 1 provides a fluorine-containing resin mixture, which includes 114 parts of fluorine-containing resin emulsion, 12 parts of thermoplastic polymer prepolymer, and 2 parts of cyanate ester in parts by weight.

[0055] The fluorine-containing resin in the fluorine-containing resin emulsion is polytetrafluoroethylene, produced by AGC, and the brand is EA2000; the solid content of the fluorine-containing resin emulsion is 40 wt%, and the solvent is N-methylpyrrolidone.

[0056] The main chain of the prepolymer of the thermoplastic high polymer contains ether group and bisphenol A structure, and the side chain contains ester group; the solid content of the prepolymer of the thermoplastic high polymer is 20 wt%.

[0057] The prepolymer of the thermoplastic polymer is in parts by weight, and its formula is as follows: 756 parts of BAPP, 105 parts of APAB, 569 parts of ODPA, and 100 parts of PMDA. The above raw materials are all produced by Wakayama Seika Industry Co., Lt...

Embodiment 2

[0063] Embodiment 2 provides a fluorine-containing resin mixture, which is the same as Embodiment 1.

[0064] This example also provides a copper clad laminate, which is different from Example 1 in that the film substrate is an LCP film.

[0065] This example also provides a method for preparing the above-mentioned copper clad laminate, which is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com