Multifunctional vinyl ether and resin composition containing same

A resin composition, vinyl ether technology, applied in the direction of unsaturated ether copolymer adhesives, organic chemistry, adhesive types, etc., can solve the problems of low solubility of polymerization initiators, achieve low skin irritation, Excellent curability and low odor properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

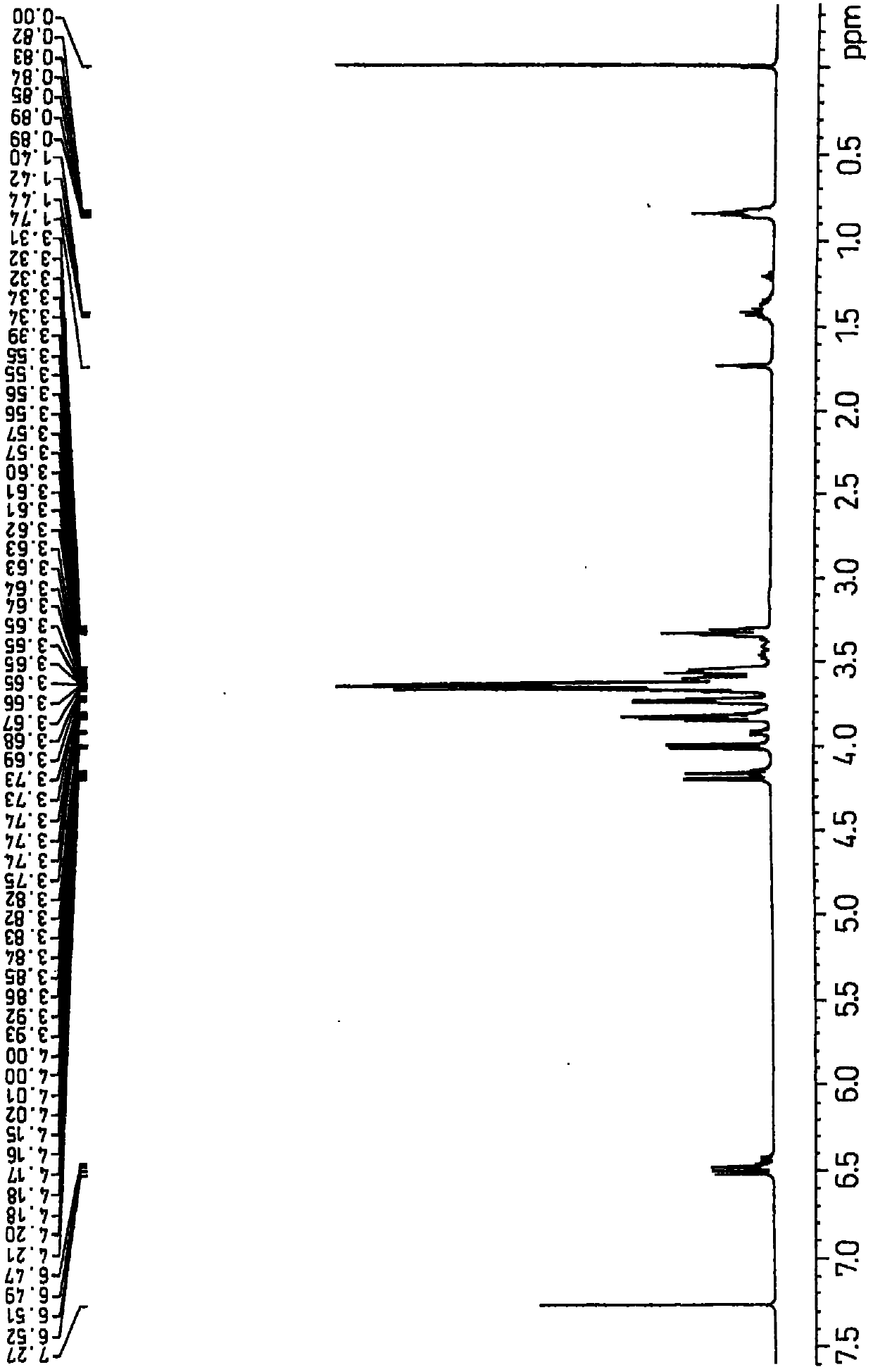

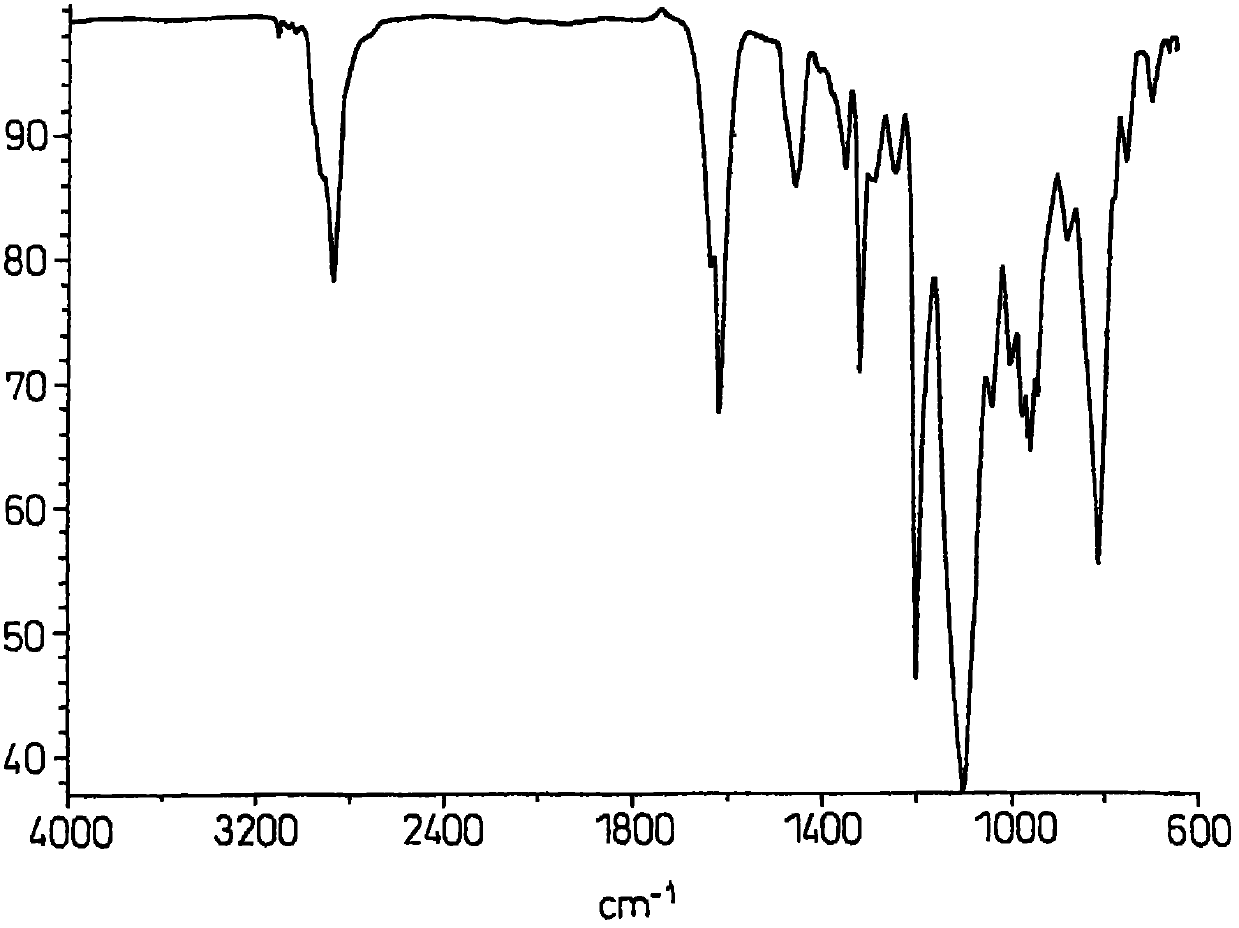

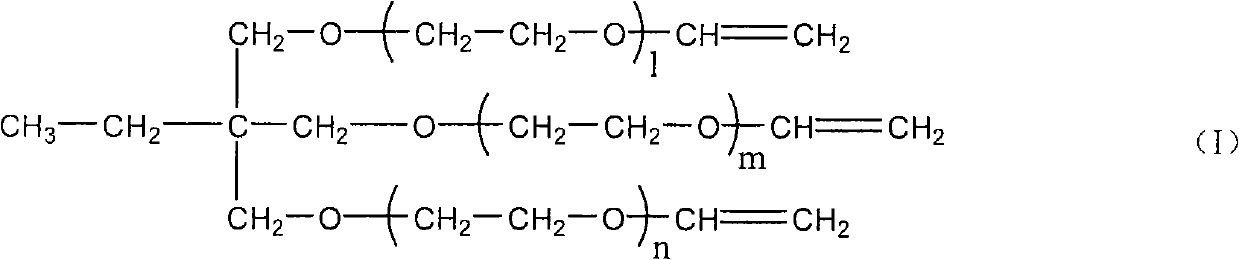

[0034] 150 g of dimethyl sulfoxide, trimethylolpropane ethyloxy addition Alcohol body (in the above formula (II), p+q+r=4) 50 g, as a catalyst, 30 mol% of potassium hydroxide with a purity of 95% by weight was added to the raw material alcohol. While stirring, nitrogen gas was flowed in to replace the inside of the reaction container with nitrogen, and then the reaction container was sealed, and acetylene gas was added into the reaction container at a pressure of about 0.18 MPa. Then, while maintaining the gauge pressure at about 0.18 MPa, the temperature inside the reaction vessel was raised to 120° C., and the reaction was performed at a reaction temperature of 120° C. until the consumption of acetylene decreased. During this period, acetylene gas was gradually added to keep the pressure in the reaction vessel at about 0.18 MPa. After the reaction was completed, the residual acetylene gas was blown off to obtain 209 g of the reaction liquid. Then the reaction solution was ...

Embodiment 2

[0036] The reaction was carried out in the same manner as in Example 1 except that the raw material used was changed to 50 g of a trimethylolpropane ethyloxy-added alcohol (in the above formula (II), p+q+r=5). After the reaction was completed, the remaining acetylene gas was blown off to obtain 207 g of the reaction liquid. Then the reaction solution was extracted with ether, washed with water, and distilled off to obtain 50 g (yield 82%) of the multifunctional vinyl ether of the present invention (in the above formula (I), l+m+n=5).

Embodiment 3

[0038] The raw material used was changed to 50 g of trimethylolpropane ethyloxy-added alcohol (in the above formula (II), p+q+r=6), and the reaction was carried out in the same manner as in Example 1 . After the reaction was completed, the remaining acetylene gas was blown off to obtain 207 g of the reaction liquid. Then, the reaction solution was extracted with ether, washed with water, and distilled off to obtain 52 g (yield 87%) of the multifunctional vinyl ether of the present invention (in the above formula (I), l+m+n=6).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com