Adhesive

An adhesive and adherend technology, applied in the directions of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of difficult wafer fixing, low softening point, and adhesive flow, etc. Effects of natural peeling, excellent coatability, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

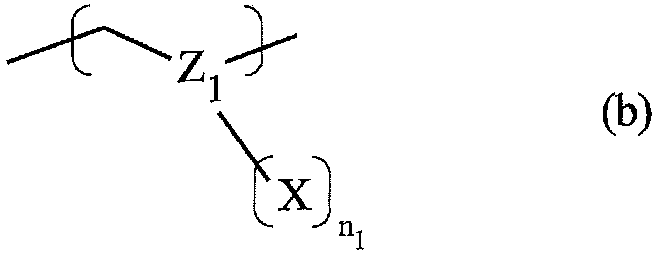

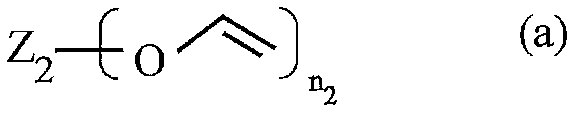

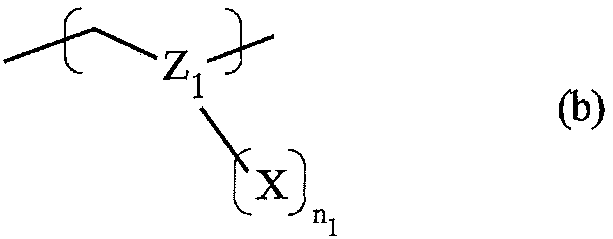

Method used

Image

Examples

Embodiment 1~12、 comparative example 1

[0238] Each component was added and mixed according to the formulation (unit: part by weight) described in the following table|surface, and the adhesive agent was prepared. Using the obtained adhesive, the following evaluations were performed.

[0239]

[0240] 1. Softness

[0241] 1-1: Whether natural peeling due to cooling occurs

[0242] On a silicon wafer (φ4 inches), 0.1 g of the adhesive was applied to a thickness of 10 μm. Thereafter, the silicon wafer was cut into a size of 1.5 cm x 1.5 cm, stacked on a glass plate of the same size, heated at 140° C. for 2 minutes, then heated at 200° C. for 2 minutes, and further carried out at 230° C. for 4 minutes. By heat treatment, a laminated body [silicon wafer / adhesive / glass plate] is obtained. After leaving the obtained laminate at 25° C. for 0.5 hours, whether or not natural peeling occurred between the silicon wafer and the glass plate was observed with the naked eye, and evaluated according to the following criteria. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com