Lithium ion battery negative electrode aqueous adhesive and preparation method thereof

A technology of lithium-ion batteries and water-based binders, applied in battery electrodes, binder types, ester copolymer binders, etc., can solve problems such as environmental pollution, large amount of negative electrode binder usage, and high negative electrode production costs , to reduce production costs, increase energy density, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

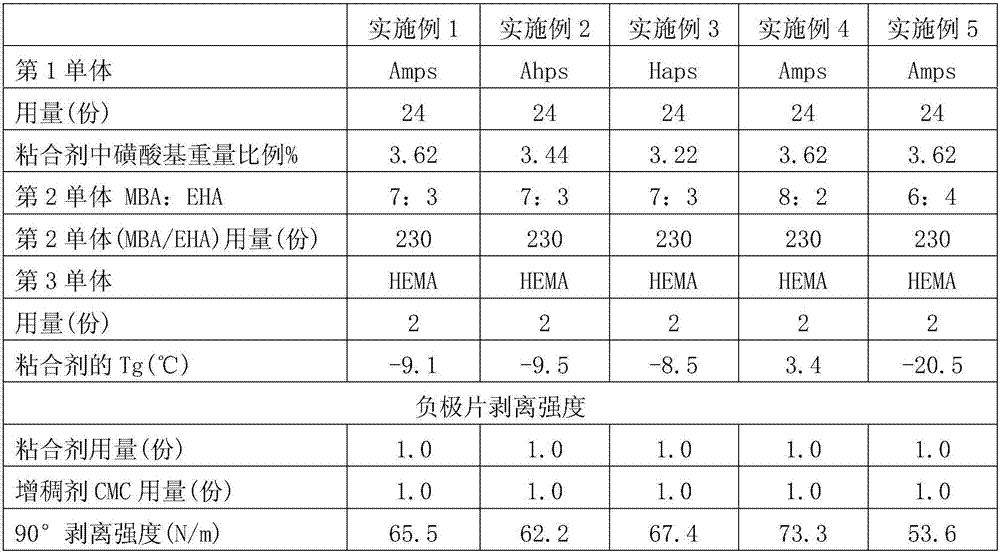

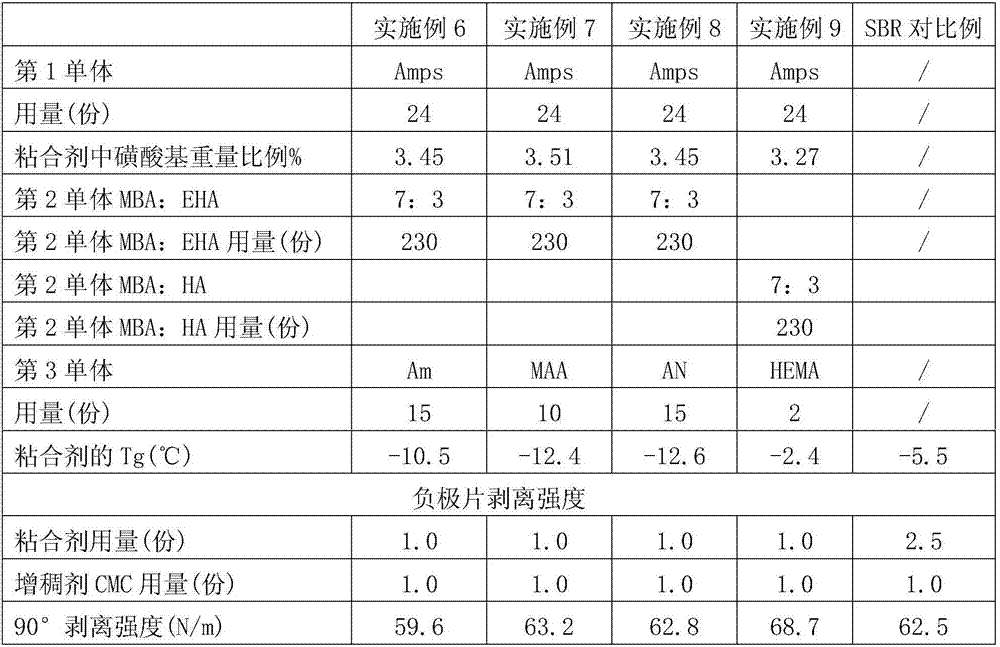

Embodiment 1

[0055] Add 400g of distilled water and 1.5g of sodium dodecylbenzenesulfonate emulsifier to a four-port reaction vessel with condensed water, set the temperature of the reaction vessel at 72°C, and pass nitrogen to remove oxygen for 30 minutes while stirring. After the internal temperature of the reactor reached the set temperature, 1.5g of potassium persulfate was added at one time, and 200 grams of concentration was added dropwise at the same time as 12% 2-acrylamido-2-methylpropanesulfonate (Amps) aqueous solution to mix with 230g of butyl methacrylate (MBA) and 2-ethylhexyl acrylate (EHA) mixed monomer, wherein the weight ratio of MBA to EHA is 7:3, and the dropping time is controlled within 3 to 4 hours. After the monomer was added dropwise, 20 g of 10% N-hydroxyethylacrylamide (HEMA) aqueous solution was added dropwise within half an hour, and the reaction was continued for 3 hours to obtain a white polymer emulsion.

Embodiment 2

[0057] Add 400g of distilled water and 1.5g of sodium dodecylbenzenesulfonate emulsifier to a four-port reaction vessel with condensed water, set the temperature of the reaction vessel at 72°C, and pass nitrogen to remove oxygen for 30 minutes while stirring. After the internal temperature of the reactor reaches the set temperature, 1.5g of potassium persulfate is added at one time, and 200 grams of concentration are added dropwise at the same time. Butyl ester (MBA) and 2-ethylhexyl acrylate (EHA) mixed monomer, wherein the weight ratio of MBA to EHA is 7:3, and the dropping time is controlled within 3 to 4 hours. After completion, 20 g of 10% N-hydroxyethylacrylamide (HEMA) aqueous solution was added dropwise within half an hour, and the reaction was continued for 3 hours to obtain a white polymer emulsion.

Embodiment 3

[0059] Add 400 g of distilled water and 1.0 g of sodium lauryl sulfate emulsifier to a four-port reaction vessel with condensed water, set the temperature of the reaction vessel at 72°C, and pass nitrogen to remove oxygen for 30 minutes while stirring. After the internal temperature of the reactor reaches the set temperature, 1.5g potassium persulfate is added at one time, and 200 grams of concentration are added dropwise at the same time as 12% hydroxypropyl sulfonate (Haps) aqueous solution of methacrylate and 230g butyl methacrylate. Ester (MBA) and 2-ethylhexyl acrylate (EHA) mixed monomer, wherein the weight ratio of MBA to EHA is 7:3, the dropping time is controlled within 3 to 4 hours, and the monomer dropping is completed After that, within half an hour, 20 g of 10% N-hydroxyethylacrylamide (HEMA) aqueous solution was added dropwise, and the reaction was continued for 3 hours, resulting in a white polymer emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com