Adhesive composition used for solar energy and preparation method thereof

A composition and solar backsheet technology, applied in the field of solar cells, can solve the problems of not being able to cooperate well, the adhesion of the polyester film, and insufficient adhesion, etc., to achieve good environmental erosion resistance and improve photoelectric conversion efficiency , The effect of short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

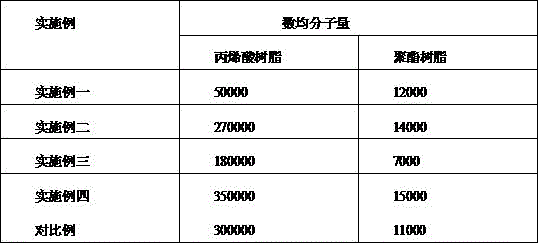

Examples

example 1

[0020] 1) Preparation of polyester modified acrylic resin:

[0021] Dissolve 3.64kg of 2-methylene-1,3-dioxepane, 3.9kg of butyl methacrylate, 7.22kg of trifluoroethyl methacrylate and 16g of initiator azobisisobutyronitrile in 50L of toluene , added to the reactor, mixed evenly, and then under the protection of nitrogen, the temperature was raised to 60-70 ° C for 2 hours. Precipitate and purify with n-hexane, and dry in vacuum to obtain a polyester-modified acrylic resin.

[0022] 2), the preparation of polyester resin:

[0023] Put 1.66kg of terephthalic acid, 4.15kg of isophthalic acid, 12.2kg of azelaic acid, 3.4kg of ethylene glycol, 8.8kg of 1,6-hexanediol, and 4.4g of isopropyl titanate into the reactor. Replace the exhausted air with nitrogen, stir and raise the temperature to 220-255°C for reaction. When the by-product reaches the theoretical value, the temperature is raised to keep the reaction temperature between 250-280°C, and the polymerization is reduced unde...

example 2

[0026] 1) Preparation of polyester modified acrylic resin:

[0027] 4.56 kg 2-methylene-1,3-dioxepane, 2.52 kg trifluoroethyl methacrylate, 6.36 kg lauryl methacrylate, 4.17 kg isobornyl acrylate and 16 g initiator azo Dissolve diisobutyronitrile in 50L of toluene, add it into the reaction kettle, mix well, and then raise the temperature to 60-70°C for 2 hours under the protection of nitrogen. Precipitate and purify with n-hexane, and dry in vacuum to obtain a polyester-modified acrylic resin.

[0028] 2), the preparation of polyester resin:

[0029] Put 2.49kg terephthalic acid, 2.58kg 1,4-cyclohexanedicarboxylic acid, 10.2kg adipic acid, 3.7kg ethylene glycol, 7.3kg neopentyl glycol, 4.4g isopropyl titanate into the reactor middle. Replace the exhausted air with nitrogen, stir and raise the temperature to 220-255°C for reaction. When the by-product reaches the theoretical value, the temperature is raised to keep the reaction temperature between 250-280°C, and the polymer...

example 3

[0032] 1) Preparation of polyester modified acrylic resin:

[0033] 5.13kg2-methylene-1,3-dioxepane, 3.1kg butyl methacrylate, 3.6kg lauryl acrylate, 4.17kg isobornyl acrylate and 16g initiator azobisisobutyronitrile, Dissolve it in 50L of toluene, add it to the reaction kettle, mix well, and then raise the temperature to 60-70°C for 2 hours under the protection of nitrogen. Precipitate and purify with n-hexane, and dry in vacuum to obtain a polyester-modified acrylic resin.

[0034] 2), the preparation of polyester resin:

[0035] Put 1.66kg of terephthalic acid, 5.8kg of isophthalic acid, 10.3kg of azelaic acid, 3.7kg of ethylene glycol, 7.3kg of neopentyl glycol, and 5.6g of dibutyltin oxide into the reaction kettle. Replace the exhausted air with nitrogen, stir and raise the temperature to 220-255°C for reaction. When the by-product reaches the theoretical value, raise the temperature to keep the reaction temperature between 250-280°C, reduce the pressure and compress, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com