Method for dyeing with non-washing dispersing dye

A technology of disperse dyes and dyes, applied in dyeing methods, textiles and papermaking, etc., to achieve the effect of improving color fastness and reducing dyeing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0011] The level dyeing properties and color fastness of disperse red 60, disperse blue 56 and microcapsule dyed polyester fabrics were measured respectively as follows:

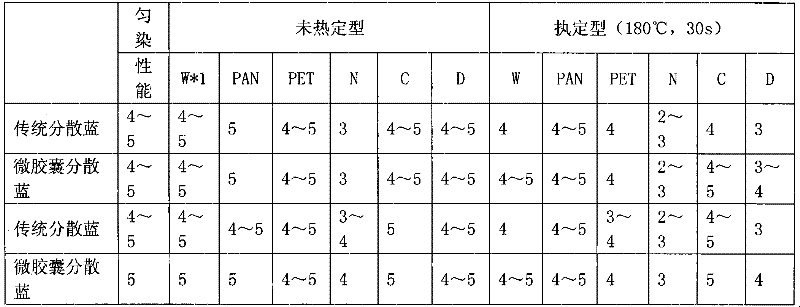

[0012] Washing fastness is shown in Table 1:

[0013] Table 1 Washing fastness of polyester dyed with different disperse dyes under high temperature and high pressure

[0014] Standard depth = 1 / 1

[0015]

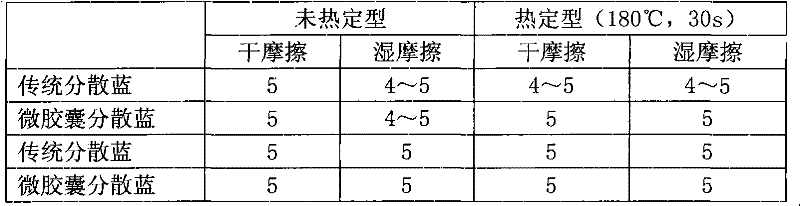

[0016] *1: The color fastness to rubbing of w wool, PAN polyacrylonitrile, PET polyester, N nylon, C cotton, D acetate fiber is shown in Table 2:

[0017] Table 2 Color fastness to rubbing of polyester dyed with different disperse dyes under high temperature and high pressure

[0018] Standard depth = 1 / 1

[0019]

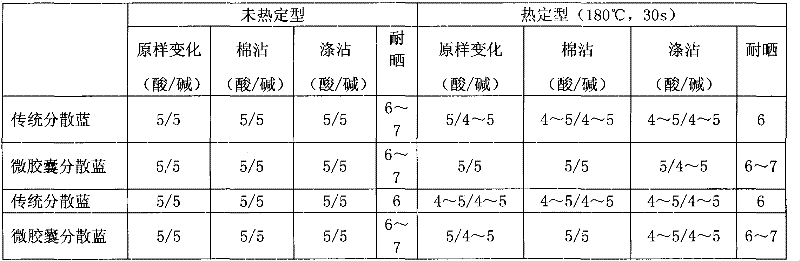

[0020] The color fastness to perspiration and light is shown in Table 3:

[0021] Table 3 Color fastness to perspiration and light of polyester dyed with different disperse dyes under high temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com