Color fixation process of thin suede leather

A suede, thin technology, applied in the field of textiles, can solve the problems of inability to guarantee the friction and water fastness of the fabric, and achieve the effects of improving friction and washing fastness, strong practicability and reducing solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

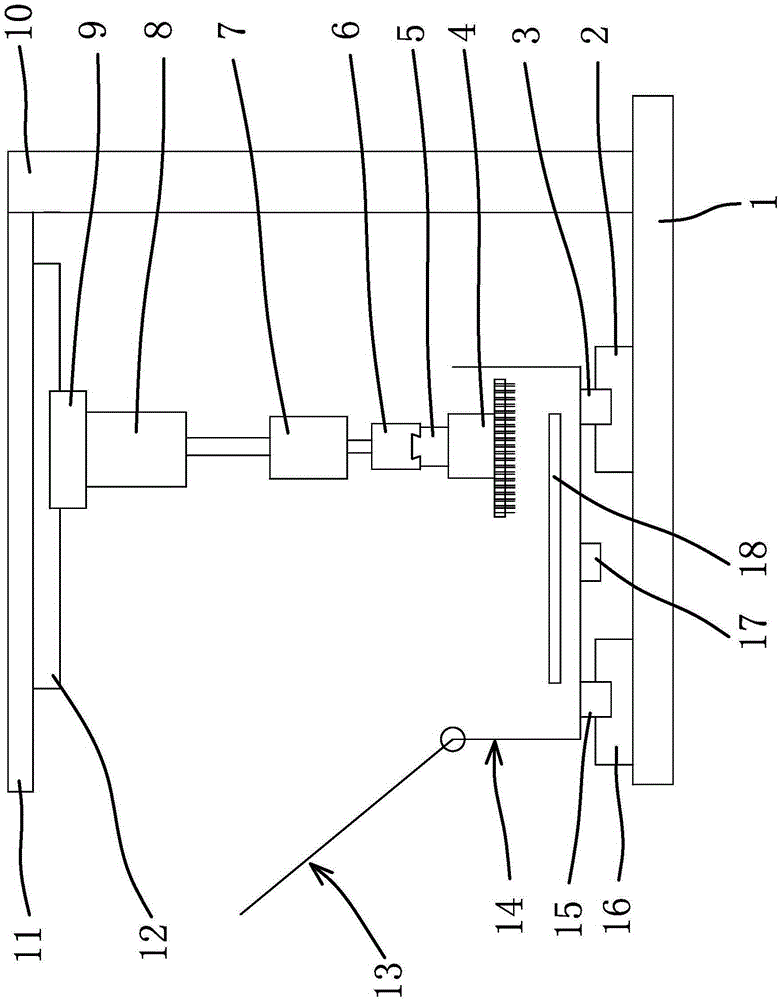

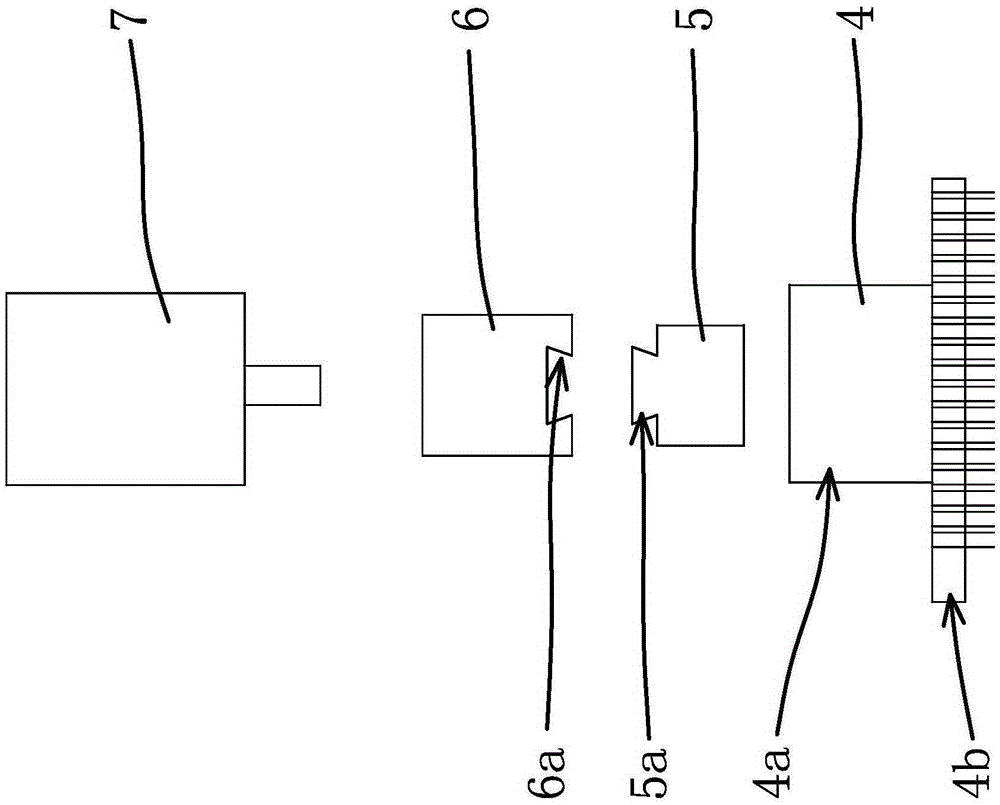

[0041] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

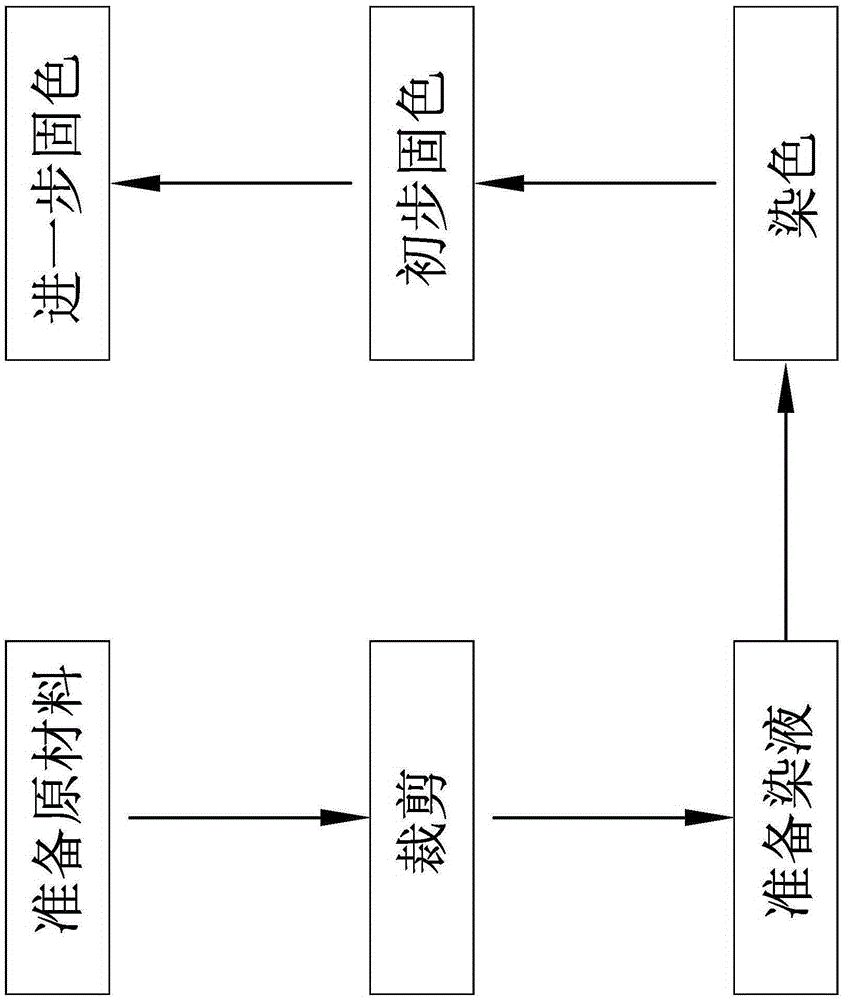

[0042] Such as figure 1 Shown, the color-fixing process of this thin suede, this color-fixing process comprises the following steps:

[0043] S1. Prepare raw materials: buy thin suede leather sold in the market as raw materials;

[0044] S2, cutting: the thin suede leather purchased on the market is cut to a size of 10 meters in length and 2 meters in width to become the base leather for color fixing;

[0045]S3. Prepare the dyeing solution: the components contained in each liter of the dyeing solution are in grams: paint color paste 3-20, sodium phenylsulfonate 1-4, polyethylene glycol 1-6, defoamer 2-6 , Ethyl methacrylate-quaternary ammonium salt copolymer 3~9, sorbitan laurate 2~8, N-vinylpyrrolidone / acrylamide copol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com