Processing technology and inspection device for textile fabric

A technology for textile fabrics and processing technology, which is applied in the field of textile fabric processing technology and inspection devices, can solve the problems of fabric quality degradation, high weft density, thinness, etc., and achieve the goals of reducing raw material costs, accelerating drying, and saving energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

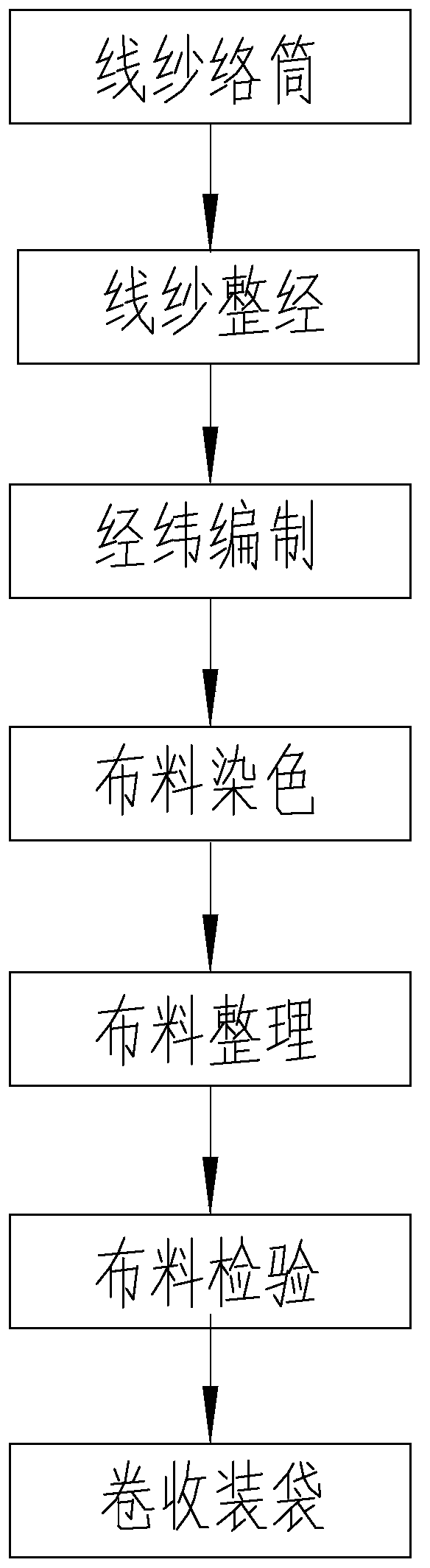

[0046] Embodiment 1: refer to figure 1 , is the processing technology of a kind of textile cloth disclosed by the present invention, comprises the following steps:

[0047] a. Yarn winding: rewind the finished white bobbin with a winding machine to make bobbins;

[0048] b. Yarn warping: adopt the warping machine to wind the cheese on the warp beam in parallel, and pass every two warp threads on the warp beam into a heddle eye and steel reed;

[0049] c. Warp and weft weaving: use a shuttleless loom to criss-cross the weft and warp, and weave white gray fabric in a way that every two warps and one weft are interlaced up and down. A weft thread interweaves up and down;

[0050] d. Cloth dyeing: soak the woven gray cloth in the dyeing solution prepared by water, dyes and dyeing auxiliaries, and carry out dyeing treatment. The temperature range of the dyeing solution is 100-130°C;

[0051] e. Fabric finishing: place the dyed fabric at room temperature for 24 hours, then dry it...

Embodiment 2

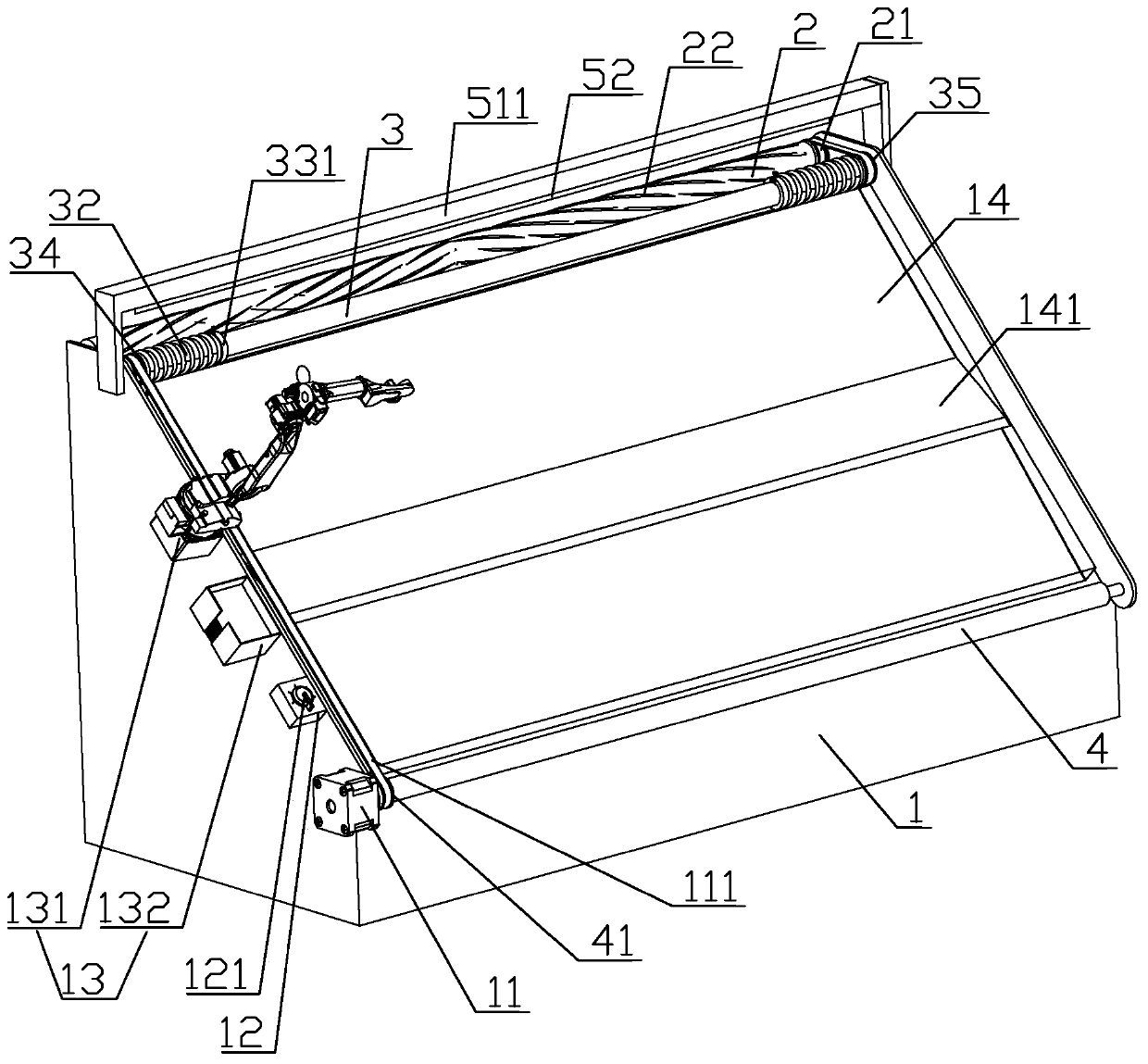

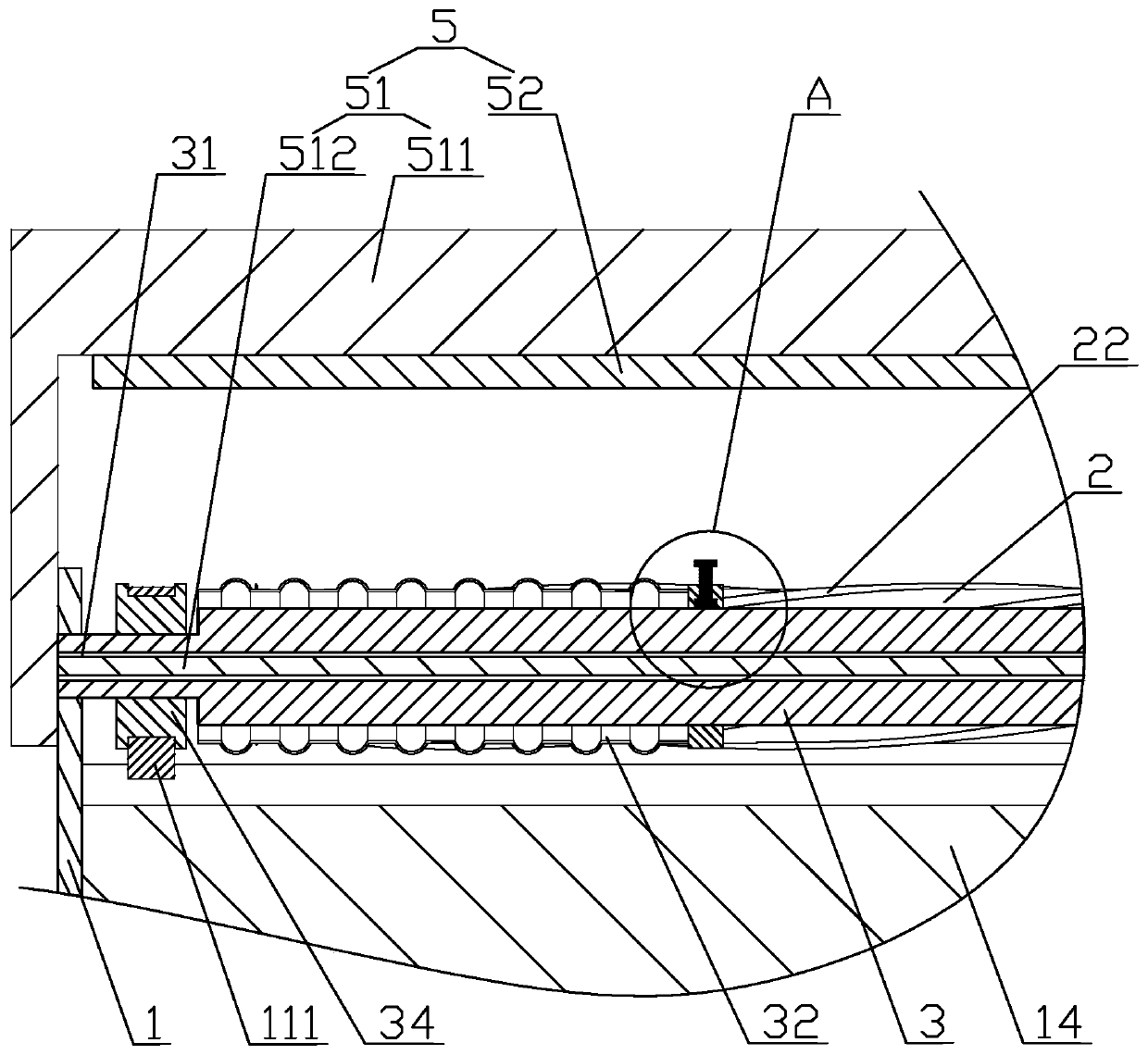

[0055] Embodiment 2: refer to figure 2 , is an inspection device applied to the processing technology of textile cloth disclosed by the present invention, including a frame 1, a cloth feeding roller 3 and an automatic inspection mechanism. Along the conveying direction of the cloth, a flattening roller 2 , a cloth feeding roller 3 , a cloth inspection table 14 and a cloth discharging roller 4 are sequentially arranged on the frame 1 . The flattening roller 2, the cloth feeding roller 3 and the cloth discharging roller 4 are all circular roller-shaped structures, and their length direction is consistent with the length direction of the frame 1, and the two inner walls opposite to the frame 1 at both ends rotate connect.

[0056] refer to figure 2 The frame 1 is provided with a drive motor 11 fixedly installed on the side wall of the cloth discharge roller 4, and the output shaft of the drive motor 11 penetrates the frame 1 and is fixedly connected with the end of the cloth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com