Production process for antibacterial breathable down feather silk quilt

A production process and technology for silk quilts, applied in the field of production technology of antibacterial and breathable down silk quilts, can solve the problem that fabrics and liner materials cannot meet market diversification, poor binding fastness of chitin and down fibers, and poor antibacterial properties of down fibers. Persistence and other problems, to achieve the effect of improving the anti-drilling property, enhancing the anti-drilling down property, and good coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

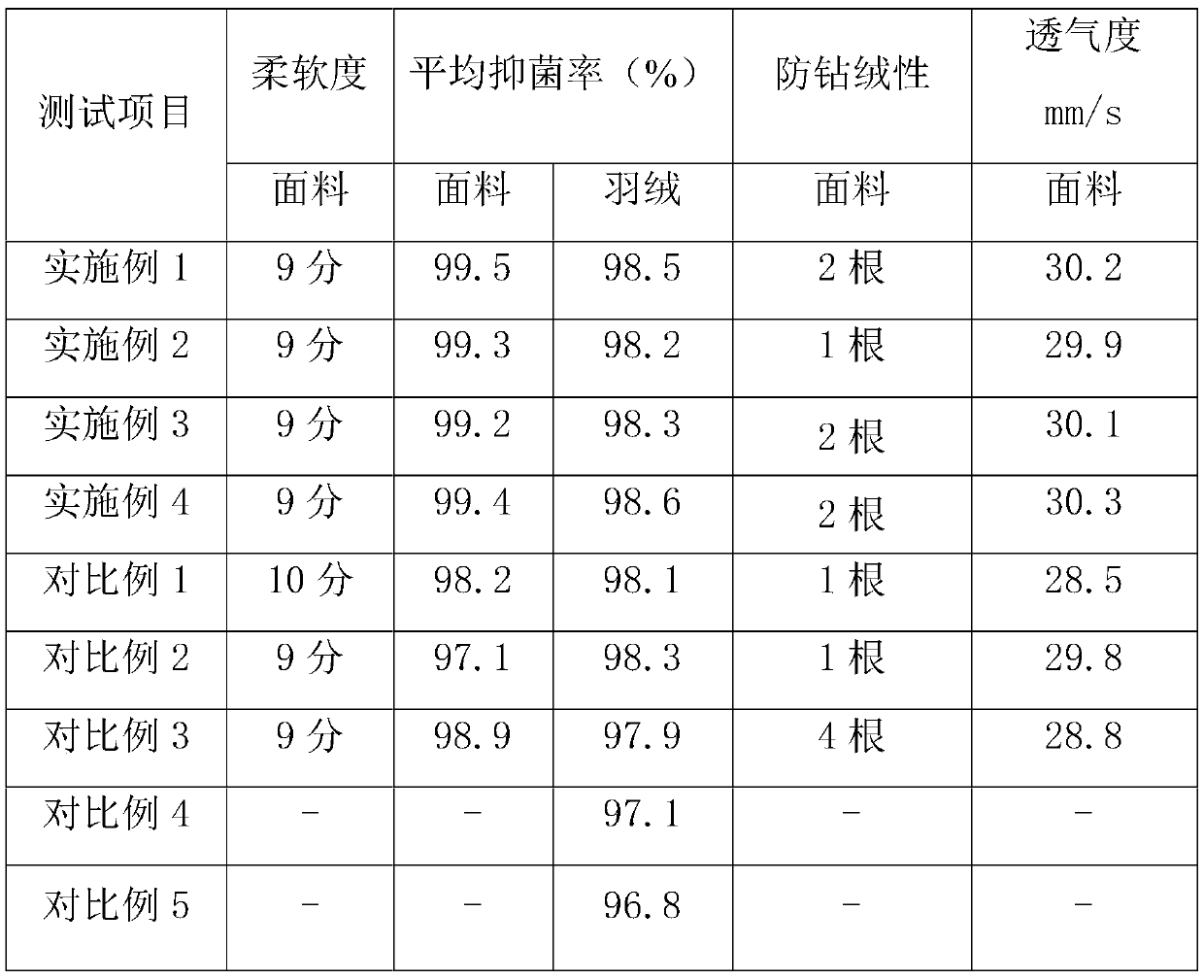

Examples

preparation example 1

[0047] Preparation Example 1: Add 5kg of cationic polyacrylamide, 1kg of N-methylolacrylamide, and 1kg of light rosin pentaerythritol ester into the high-speed mixer in sequence, adjust the speed to 200rpm, stir and mix for 2min, then adjust the speed of the high-speed mixer to 900rpm, and continue stirring Mix for 3 minutes, then add the uniformly mixed material into a ball mill, and grind for 8 hours to obtain a fine powder of calendering agent.

preparation example 2

[0048] Preparation Example 2: Add 6kg of cationic polyacrylamide, 2kg of N-methylolacrylamide, and 2kg of light rosin pentaerythritol ester into the high-speed mixer in sequence, adjust the speed to 250rpm, stir and mix for 2.5min, then adjust the speed of the high-speed mixer to 950rpm, continue Stir and mix for 4 minutes, then add the uniformly mixed material into a ball mill, and grind for 9 hours to obtain a fine powder of calendering agent.

preparation example 3

[0049] Preparation Example 3: Add 7kg of cationic polyacrylamide, 3kg of N-methylolacrylamide, and 3kg of light rosin pentaerythritol ester into the high-speed mixer in sequence, adjust the speed to 300rpm, stir and mix for 3min, then adjust the speed of the high-speed mixer to 1000rpm, and continue stirring Mix for 5 minutes, then put the uniformly mixed material into a ball mill, and grind for 10 hours to obtain a fine powder of calendering agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com