Preparation method of photo-curing integrated white coating ink

A light-curing, white pigment technology, used in inks, household appliances, applications, etc., can solve the problem of light-curing pigment digital inkjet printing fabrics, the color fastness to rubbing and washing resistance is difficult to achieve reactive dye printing, pigment particles and film forming. Material lack of binding force and other problems, to achieve the effect of improving color fastness and improving photopolymerization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

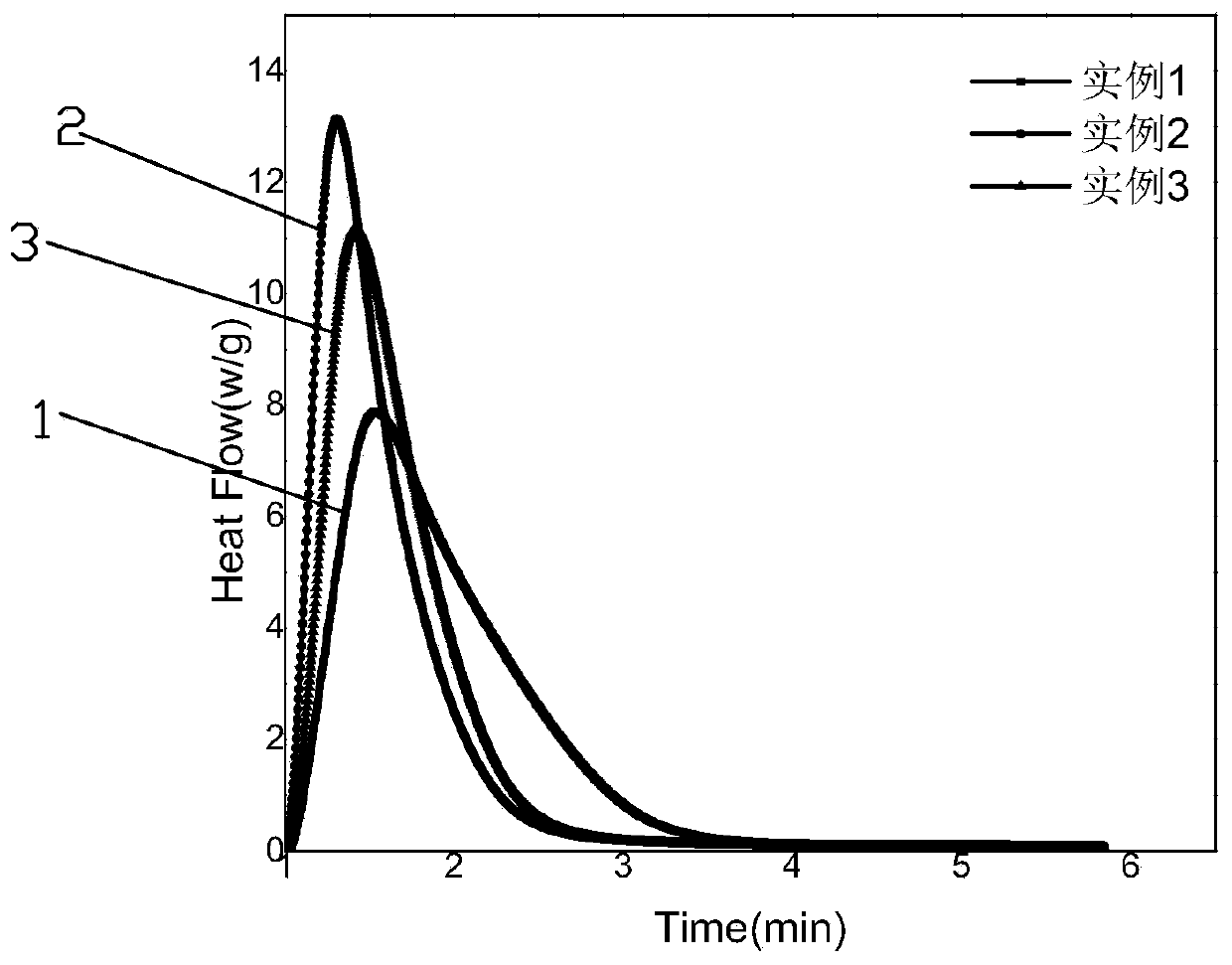

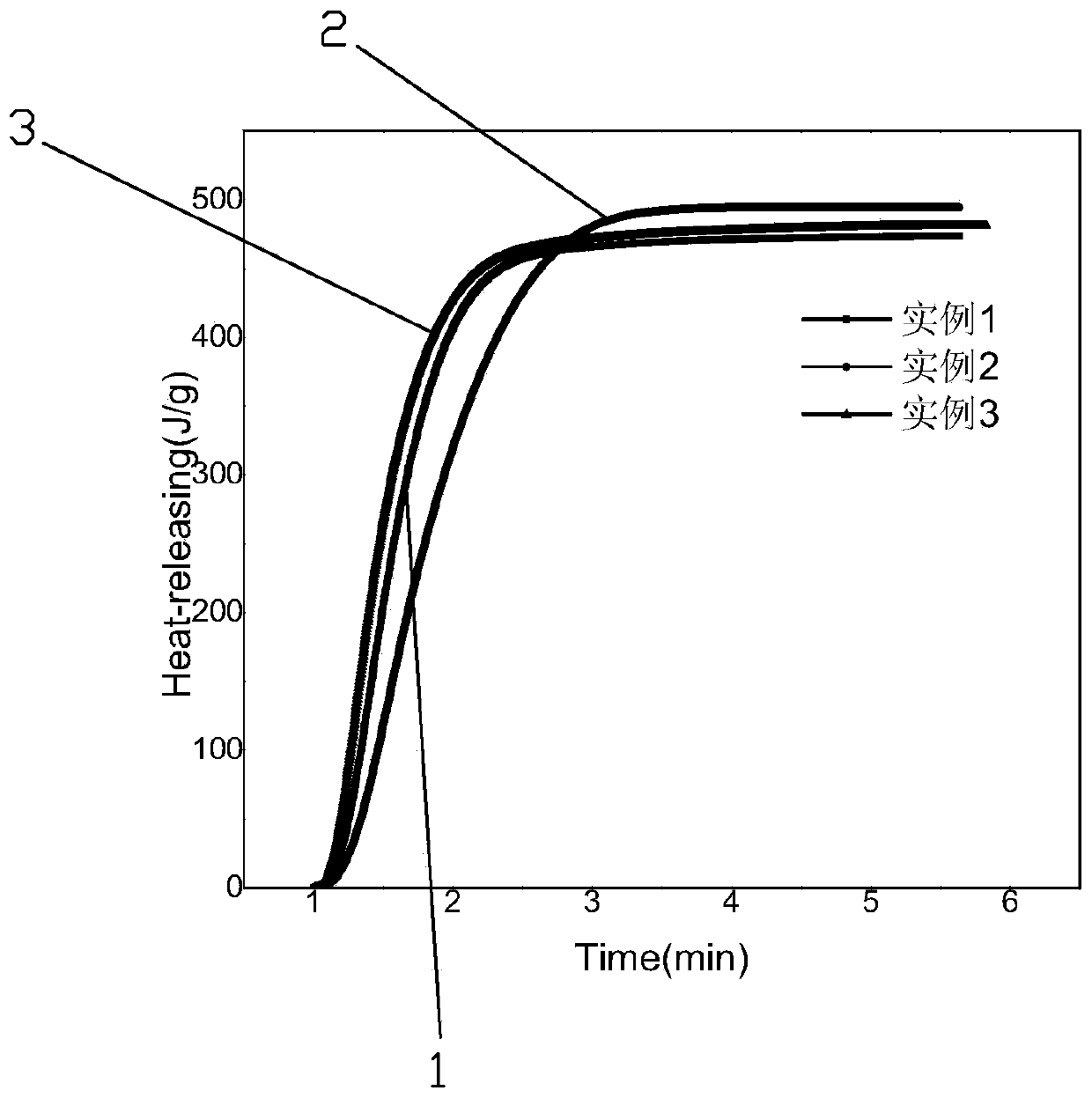

Embodiment 1

[0035] A kind of preparation method of photocuring integrated coating ink, its preparation method is as follows:

[0036] (1) Add 1g of white titanium dioxide to 24ml of ethanol and 6ml of deionized aqueous solution, carry out ultrasonic dispersion for 30min, and at the same time add 0.6g of 3-aminopropyltriethoxysilane to 80ml of ethanol and 20ml of deionized aqueous solution for hydrolysis reaction 30min. After the hydrolysis reaction is completed, add the separated white titanium dioxide, adjust the pH to 7, and adjust the temperature to 70°C for 1 hour. After the reaction is completed, centrifuge and wash three times (10000 rpm, 10 minutes / time). Dry and set aside.

[0037] (2) Weigh 2.22g of isophorone diisocyanate and add it to a three-necked flask filled with nitrogen, weigh 5g of polypropylene glycol and slowly add it dropwise to the above-mentioned three-necked flask and gradually heat up to 80°C, add 1-2 drops of Catalyst, react for 3 hours, lower the temperature t...

Embodiment 2

[0040] A kind of preparation method of photocuring integrated coating ink, its preparation method is as follows:

[0041] (1) Add 1g of white silicon dioxide to 24ml of ethanol and 6ml of deionized aqueous solution, carry out ultrasonic dispersion for 30min, and at the same time add 0.7g of 3-aminopropyltrimethoxysilane to 80ml of ethanol and 20ml of deionized aqueous solution for hydrolysis React for 30 minutes. After the hydrolysis reaction is completed, add the separated white silica, adjust the pH to 7, and adjust the temperature to 70°C for 1 hour. After the reaction is completed, centrifuge and wash three times (10000 rpm, 10 minutes / time). Dry and set aside.

[0042](2) Weigh 2.22g of diphenylmethane diisocyanate and add it to a three-necked flask filled with nitrogen, weigh 4.5g of polypropylene glycol and slowly add it dropwise to the above-mentioned three-necked flask and gradually heat up to 70°C, drop 1-2 Drop the catalyst, react for 4 hours, lower the temperatur...

Embodiment 3

[0045] A kind of preparation method of photocuring integrated coating ink, its preparation method is as follows:

[0046] (1) Add 1g of white calcium carbonate to 24ml of ethanol and 6ml of deionized aqueous solution, and carry out ultrasonic dispersion for 30min, while adding 0.4g of 3-aminopropyltriethoxysilane to 80ml of ethanol and 20ml of deionized aqueous solution for hydrolysis React for 30 minutes. After the hydrolysis reaction is completed, add the separated white calcium carbonate, adjust the pH to 7, and adjust the temperature to 70°C for 1 hour. After the reaction is completed, centrifuge and wash three times (10000 rpm, 10 minutes / time). Dry and set aside.

[0047] (2) Weigh 2.22g of isophorone diisocyanate and add it to a three-necked flask filled with nitrogen, weigh 4.5g of polyethylene glycol and slowly add it dropwise to the above-mentioned three-necked flask and gradually heat up to 80°C, drop 1 - 2 drops of catalyst, react for 3 hours, lower the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com