Dyeing process for FDY bright fiber yarn

A filament and bright technology, applied in dyeing method, liquid/gas/vapor yarn/filament treatment, liquid/gas/vapor removal, etc., can solve the problem of large web loss, high cost, and unstable FDY filament quality and other problems, to achieve the effect of improving the color fastness and dyeing evenly and firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of FDY light fiber filament dyeing process, comprises the following steps:

[0039] S1, two-for-one twist

[0040] The two-for-one twister is used to twist the FDY bright fiber yarn. The spindle speed of the two-for-one twister is 5000 rpm, the winding speed is 100 m / min, the overfeed speed is 116 m / min, and the yarn twist is 100 twists.

[0041] S2, stereotypes

[0042] Put the two-for-one twisted FDY bright fiber yarn into a setting machine for setting, the setting temperature is 80°C, and the setting time is 12 hours.

[0043] S3, loose tube

[0044] The shaped FDY bright fiber filaments are loosened by a loose winding machine.

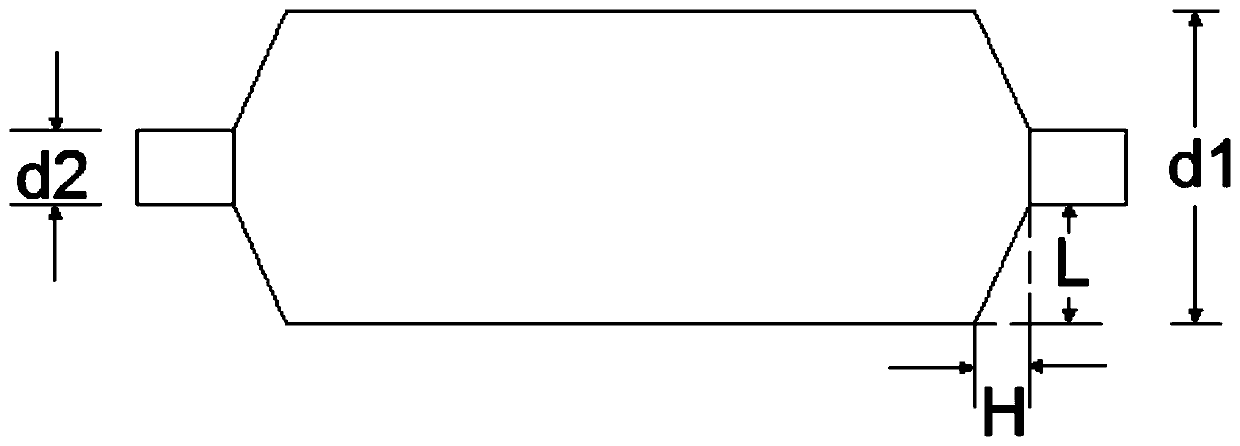

[0045] See attached figure 1 , 500gFDY bright light fiber filament loose tube rear outer diameter d1 is 180mm (the outer diameter d2 of barrel core is 63mm), the yarn two ends of winding and barrel core form oblique cone surface, and the inclination of inclined cone surface is H / L= 55 / 58.5 = 1:1.06.

[0046] S4, degreasing

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com