Dyeing process of regenerated polyester yarn

A recycled polyester and process technology, which is applied in the field of polyester dyeing technology, can solve the problems such as the difficulty of dyeing recycled polyester, and achieve the effect of uniform and firm dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

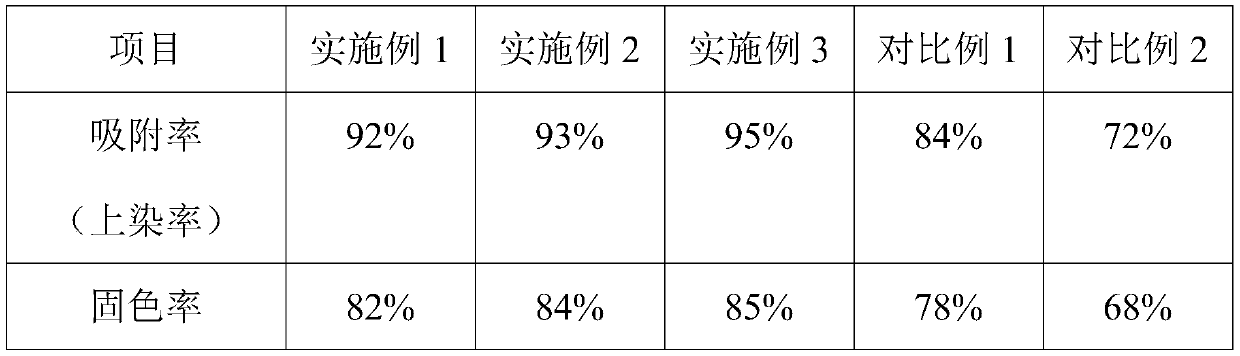

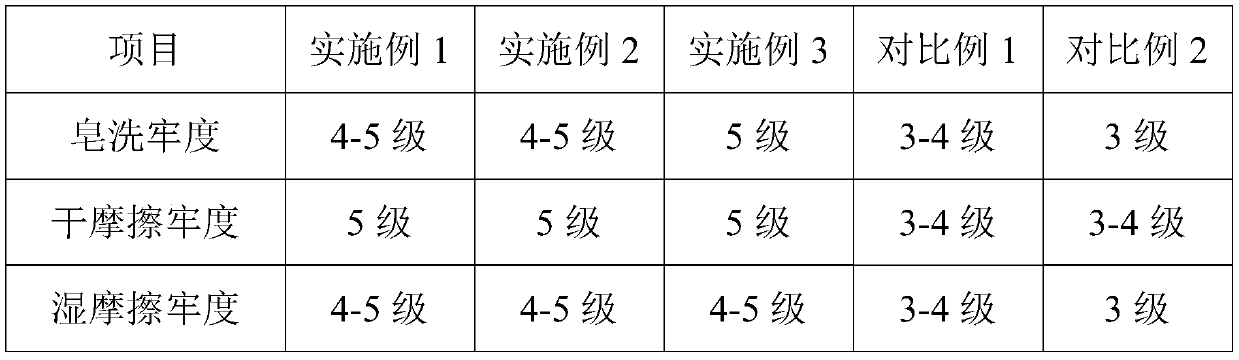

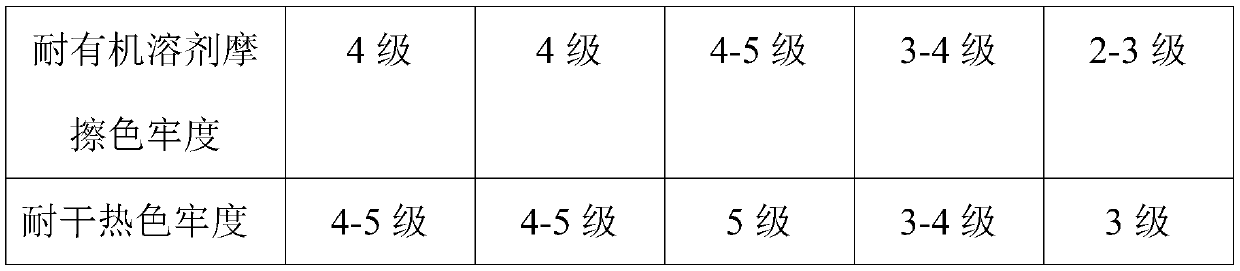

Examples

Embodiment 1

[0030] A dyeing process of regenerated polyester yarn, comprising the following steps:

[0031] S1, pre-processing

[0032] Soak the regenerated polyester yarn in an aqueous solution with a degreasing agent content of 2%, raise the temperature to 130°C, keep it warm for 20min, and then cool down to 25°C (room temperature); the degreasing agent contains 35-40wt.% surface active agent.

[0033] S2, dyeing

[0034] S2.1. Soak the regenerated polyester yarn after pretreatment in the dyeing solution, which contains 0.5% leveling agent and 0.6% dark dye by mass percentage in the dyeing solution, and adjust the pH value to 4-5 by adding acetic acid ; The leveling agent contains 25% polyoxyalkylene ether sulfate ester salt, 45% ethoxy ester compound, 10% solvent, and 20% water by mass percentage.

[0035] S2.2. Raise the temperature to 80°C at a rate of 1.5°C / min, and keep it warm for 10 minutes.

[0036] S2.3. Then raise the temperature to 130°C at a rate of 1.5°C / min, keep it wa...

Embodiment 2

[0043] A dyeing process of regenerated polyester yarn, comprising the following steps:

[0044] S1, pre-processing

[0045] Soak the regenerated polyester yarn in an aqueous solution with a degreasing agent content of 2.5%, raise the temperature to 125°C, keep it warm for 25min, and then cool down to 25°C (room temperature); the degreasing agent contains 35-40wt.% surface active agent.

[0046] S2, dyeing

[0047] S2.1. Soak the regenerated polyester yarn after pretreatment in the dyeing solution, which contains 0.45% leveling agent and 0.6% dark dye by mass percentage in the dyeing solution, and adjust the pH value to 4-5 with acetic acid ; The leveling agent contains 25% polyoxyalkylene ether sulfate ester salt, 45% ethoxy ester compound, 10% solvent, and 20% water by mass percentage.

[0048] S2.2. Raise the temperature to 85°C at a rate of 1.5°C / min, and keep it warm for 10 minutes.

[0049] S2.3. Then raise the temperature to 135°C at a rate of 1.5°C / min, keep it warm...

Embodiment 3

[0056] A dyeing process of regenerated polyester yarn, comprising the following steps:

[0057] S1, pre-processing

[0058] Soak the regenerated polyester yarn in an aqueous solution with a degreasing agent content of 2%, raise the temperature to 130°C, keep it warm for 25min, and then cool down to 25°C (room temperature); the degreasing agent contains 35-40wt.% surface active agent.

[0059] S2, dyeing

[0060] S2.1. Soak the regenerated polyester yarn after pretreatment in the dyeing solution, which contains 0.6% leveling agent and 0.7% light-colored dye by mass percentage, and adjust the pH value to 4-5 by adding acetic acid ; The leveling agent contains 25% polyoxyalkylene ether sulfate ester salt, 45% ethoxy ester compound, 10% solvent, and 20% water by mass percentage.

[0061] S2.2. Raise the temperature to 80°C at a rate of 1.5°C / min, and keep it warm for 10 minutes.

[0062] S2.3. Then raise the temperature to 130°C at a rate of 1.5°C / min, keep it warm for 30 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com