Preparation method for colored silicon oxide aerogel

A technology of silica aerogel and silica sol, which is applied in the field of materials, can solve the problems of single color, poor fastness and poor color rendering of silica aerogel, and achieves high color fastness, difficult elution and chemical segregation. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

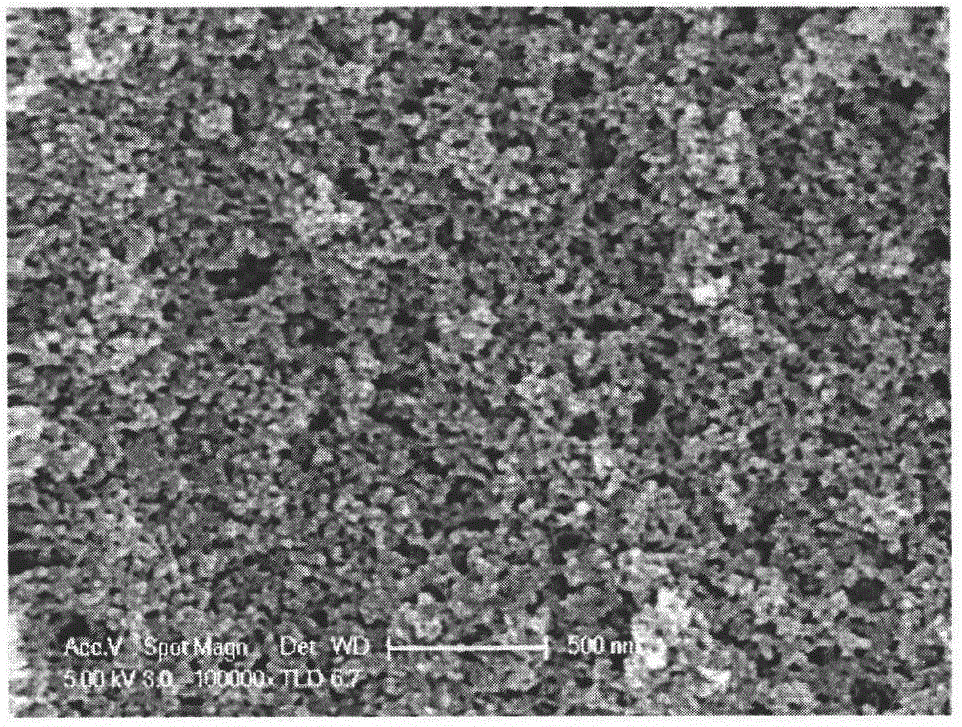

[0032] Mix TEOS and ethanol evenly (the molar ratio of the two is 1:20), mix well, and add an aqueous solution containing neodymium nitrate (the molar ratio of water and TEOS is 1:2, and the mass of neodymium accounts for 0.1% of the gel matrix. %), after mixing evenly, add ammonia water with a molar ratio of 0.001 to TEOS, stir vigorously, and leave to form a gel. After aging at room temperature for 3 hours, the gel is washed with 200ml of ethanol for three times. The gel is then placed in an autoclave, using ethanol as a drying medium, and the purple aerogel can be obtained after drying. Its SEM scanning electron microscope pictures are shown in figure 1 .

Embodiment 2

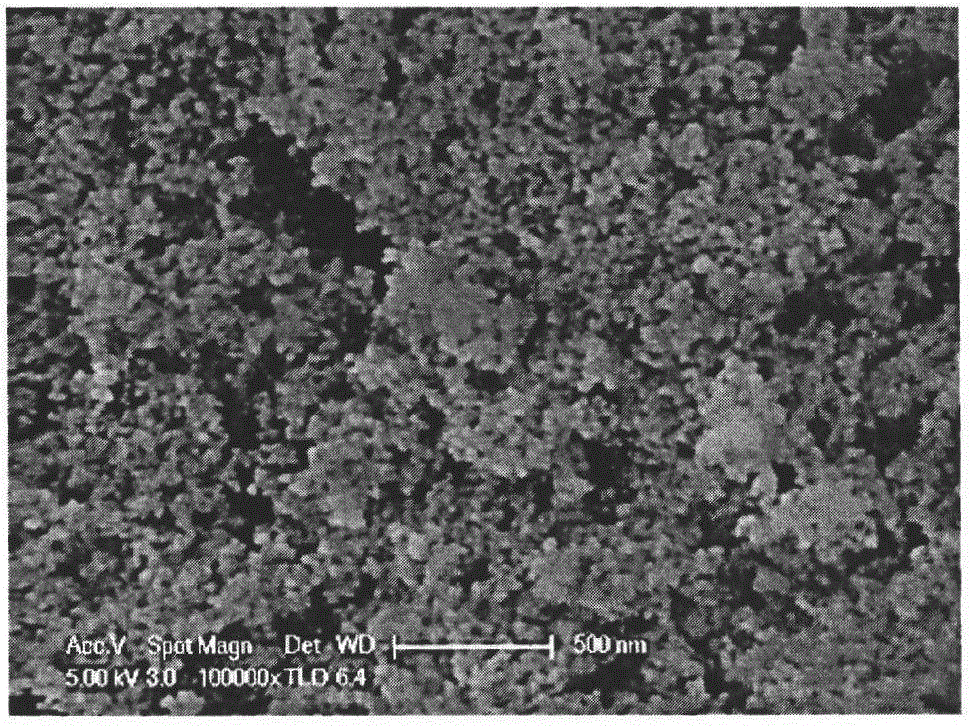

[0034] Mix TMOS and methanol evenly (the molar ratio of the two is 1:12), mix well, and add an aqueous solution containing ferric nitrate (the molar ratio of water and TMOS is 1:4, and the mass of iron accounts for 10% of the gel matrix. %), after mixing evenly, add citric acid with a molar ratio of 0.1 to TMOS, stir vigorously, seal the sol and place it in an oven at 40°C for aging for 48h, and then wash it with 200ml methanol for three times. Then the gel is placed in an autoclave, and methanol is used as a drying medium. After drying, a brown airgel can be obtained. The SEM scanning electron microscope picture is shown in figure 2 .

Embodiment 3

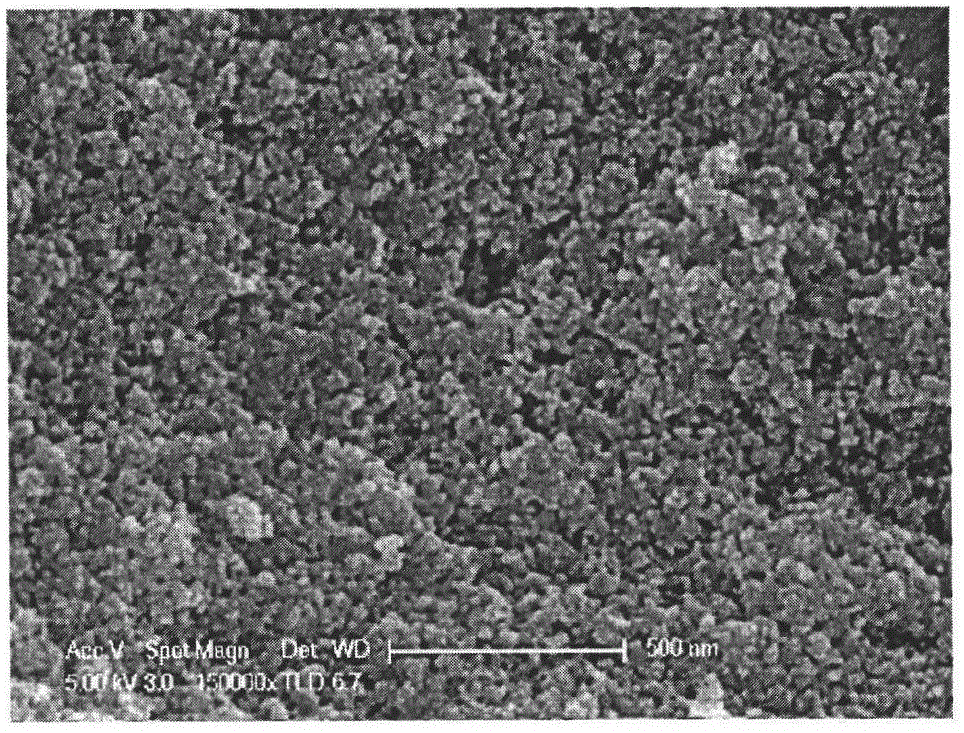

[0036] Mix TMOS and ethanol evenly (the molar ratio of the two is 1:8), mix well, and add the aqueous solution containing nano-Cu particles (the molar ratio of water and TMOS is 1:4, and the mass of Cu accounts for 1% of the gel matrix. 5%), after mixing evenly, adding hydrochloric acid with a molar ratio of 0.01 to TEOS, stirring vigorously, standing to form a gel, aging the gel for 3 hours, washing with 200ml ethanol, three times in total. The gel was then placed in an autoclave with CO 2 As a drying medium, black airgel can be obtained after drying, and its SEM scanning electron microscope picture is shown in image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com