Patents

Literature

116results about How to "Not easy to elute" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

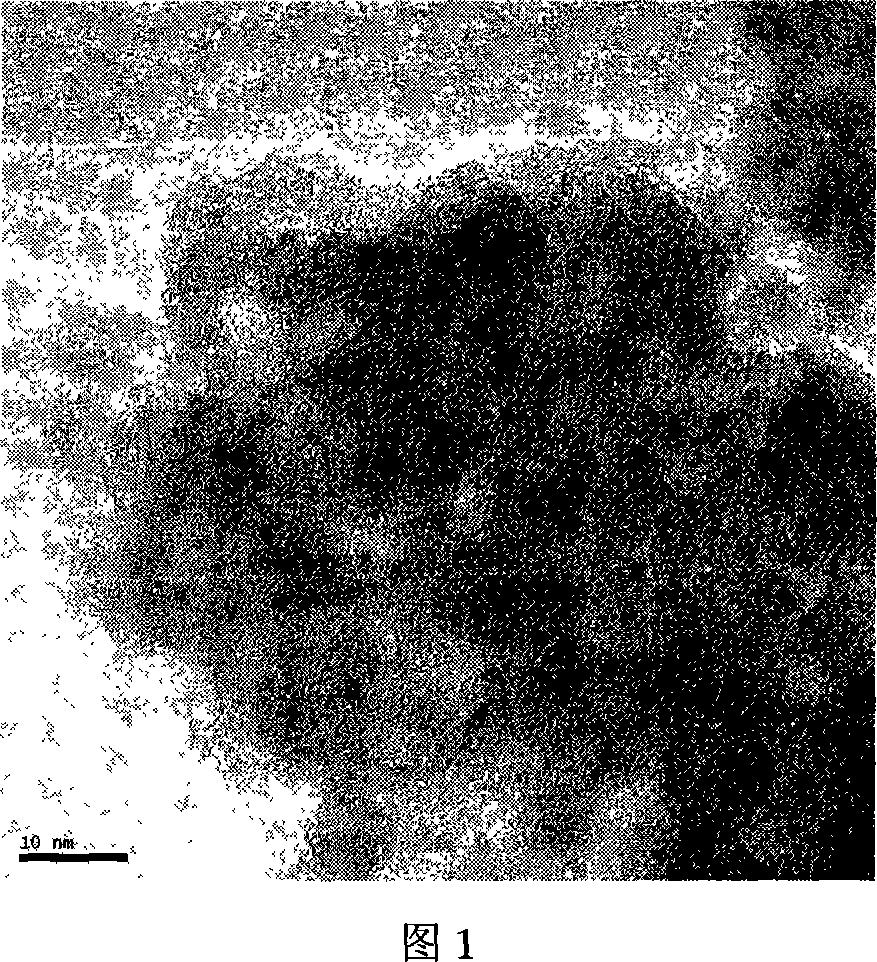

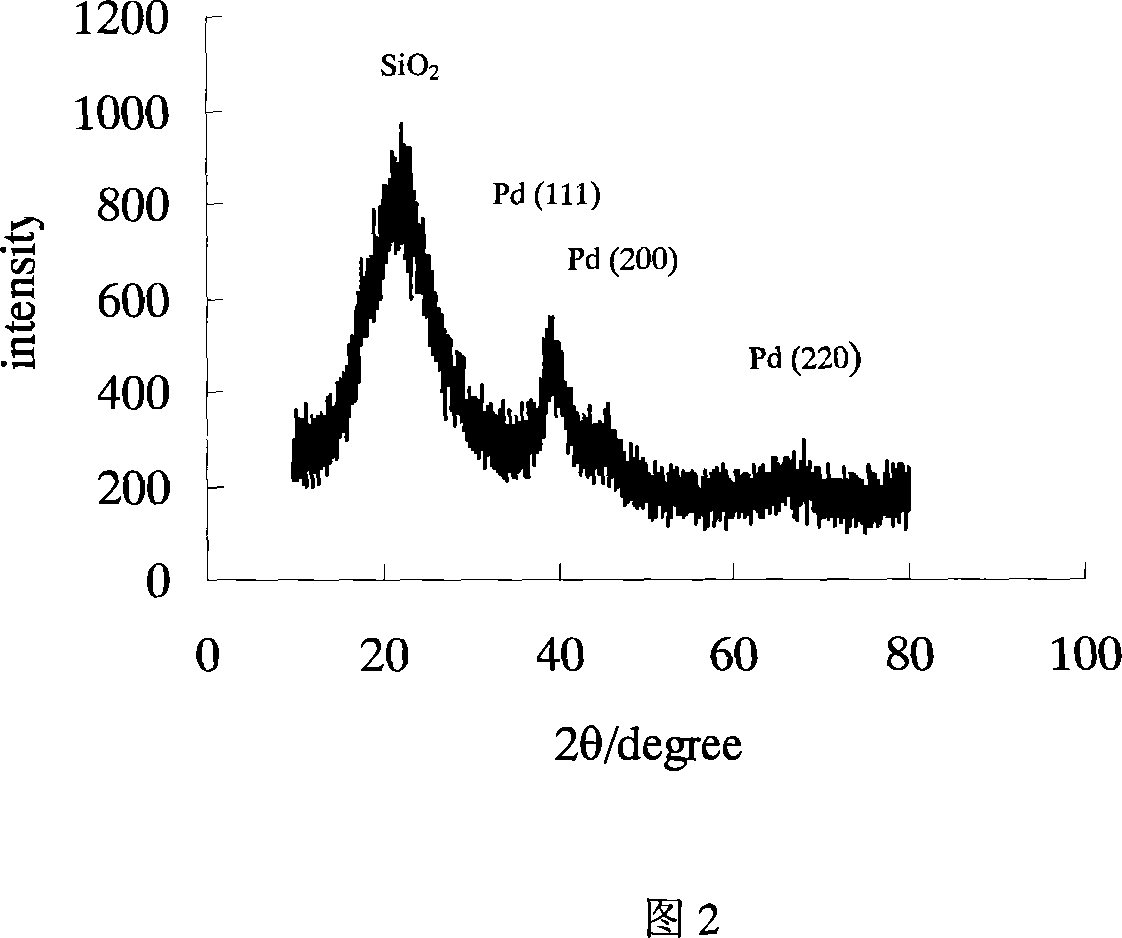

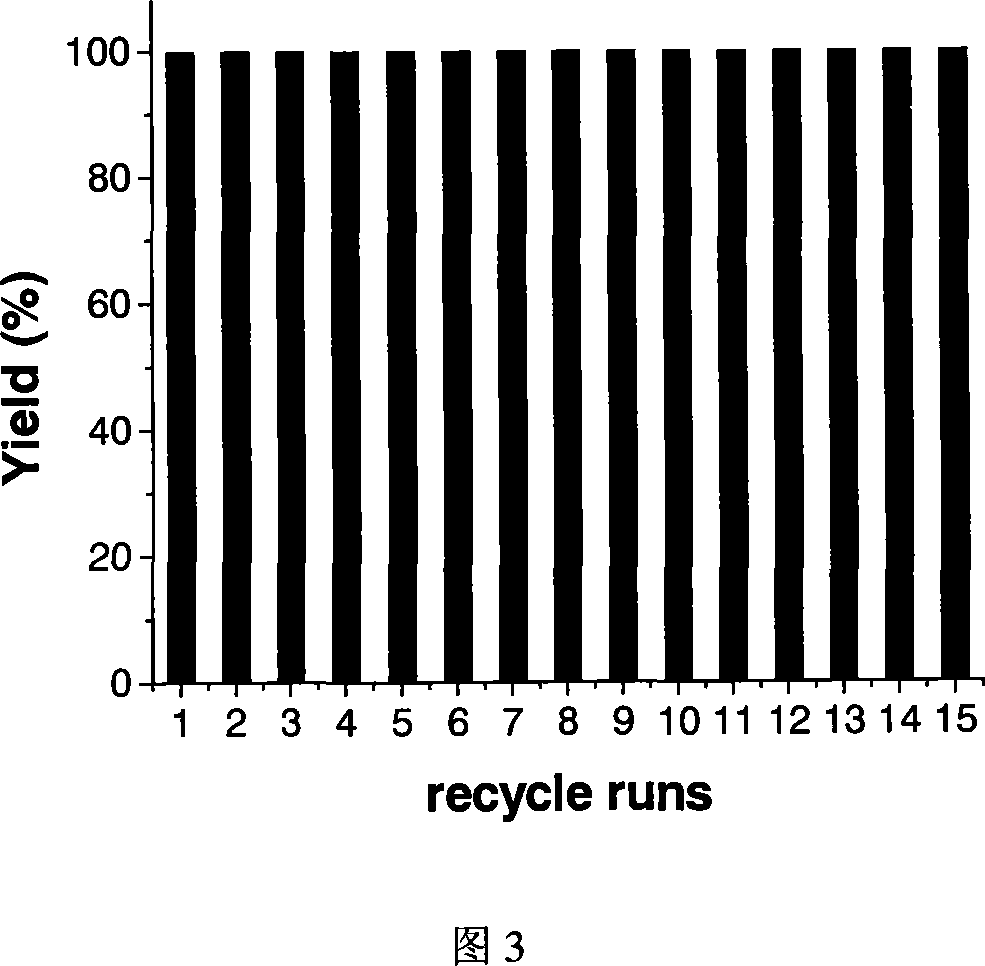

Solid carried ion liquid-nanometer metal particle catalyst, and its preparing method, and application in synthesis of arylamine

InactiveCN101045213AAvoid churnNot easy to eluteOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsNitro compoundMetal particle

A catalyst carrying ionic liquid and metallic nanoparticles for preparing high-quality arylamine by hydrocatalyzing aromatic nitro compound is prepared through preparing immobilized ionic liquid by bonding the ionic liquid onto carrier, binding it with the active component containing transition metal or precursor, and reductive exchange. Its advantages are low reaction temp, long service life and no waste generation.

Owner:SHAANXI NORMAL UNIV

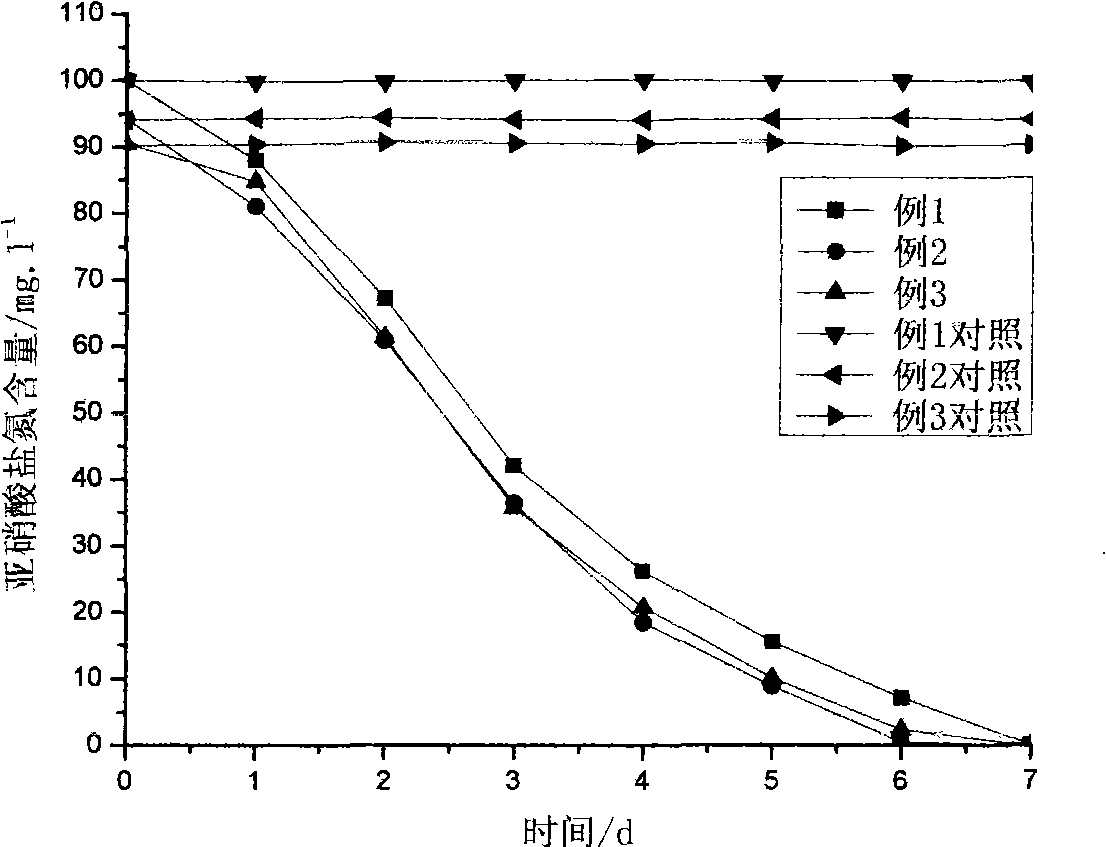

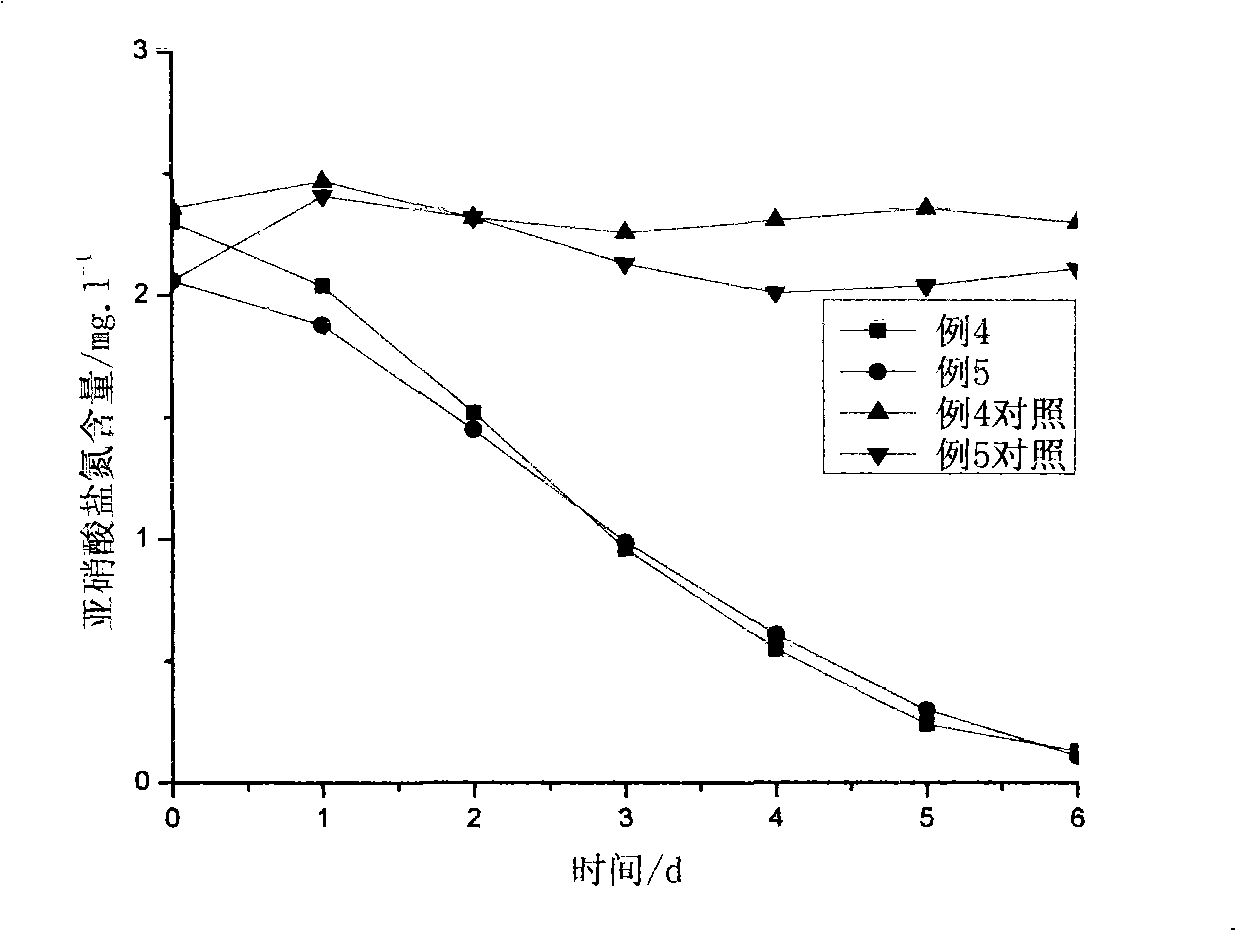

Process for degrading cultivation waste water nitrite using immobilized nitrifying bacteria

InactiveCN101348306APromote degradationThe degradation effect lastsWater/sewage treatmentBiological water/sewage treatmentNitrifying bacteriaBiological activation

The invention discloses a process for removing nitrite in aquaculture wastewater by immobilized nitrobacteria. The process comprises the preparation of nitrobacteria concentrated solution, the preparation of nitrobacteria immobilized particles, the activation of the nitrobacteria immobilized particles, the preparation of a nitrobacteria immobilized particle reaction packet and the removal of nitrite in the aquaculture wastewater by the reaction packet, wherein the preparation of the nitrobacteria immobilized particles comprises the steps that an aqueous mixture of polyvinyl alcohol, sodium alginate and silicon dioxide is heated and fully dissolved, and is evenly mixed so as to be made into embedding solution; when the embedding solution is cooled down to room temperature, embedding nitrobacteria concentrated solution is added in the embedding solution; after evenly mixed, the mixed solution is dripped into a crosslinking agent; the crosslinking agent consists of calcium chloride solution and saturated boric acid solution which are mixed according to the volume ratio of between 1 to 1 and 1 to 3; and finally, the immobilized particles are filtered out by a piece of gauze. The process has the advantages that nitrite has quick, continuous and stable degradation effect, and maintains high biological activity for a long time; moreover, the reaction packet can be used repeatedly and has the advantages of simple manufacturing method and low cost, thereby having enormous application prospect.

Owner:SOUTH CHINA UNIV OF TECH

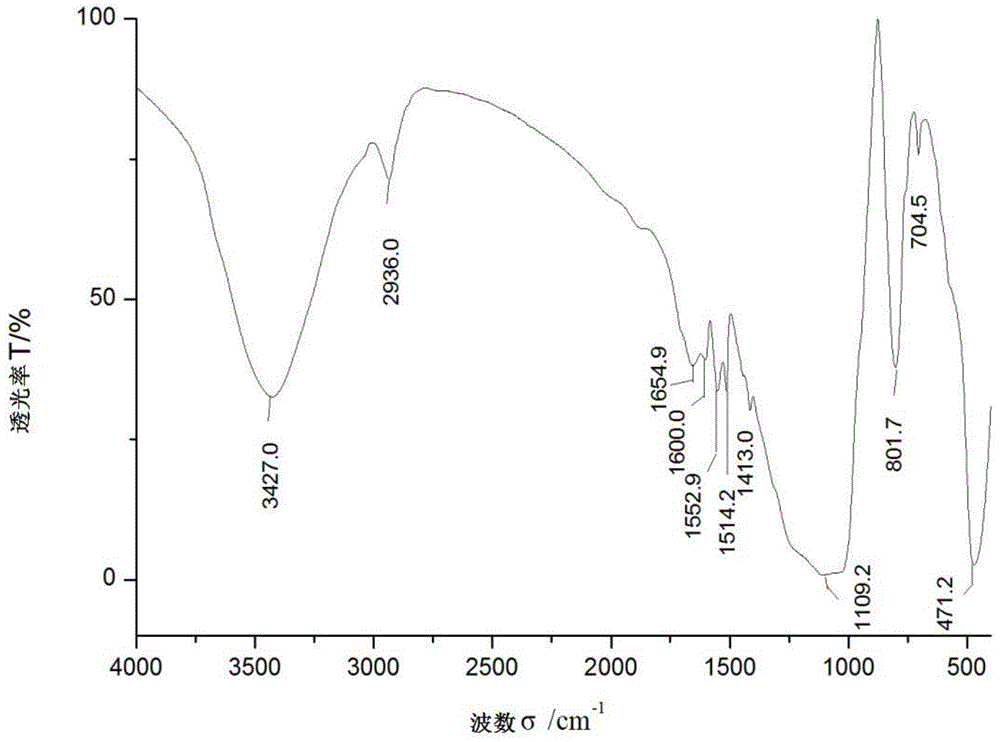

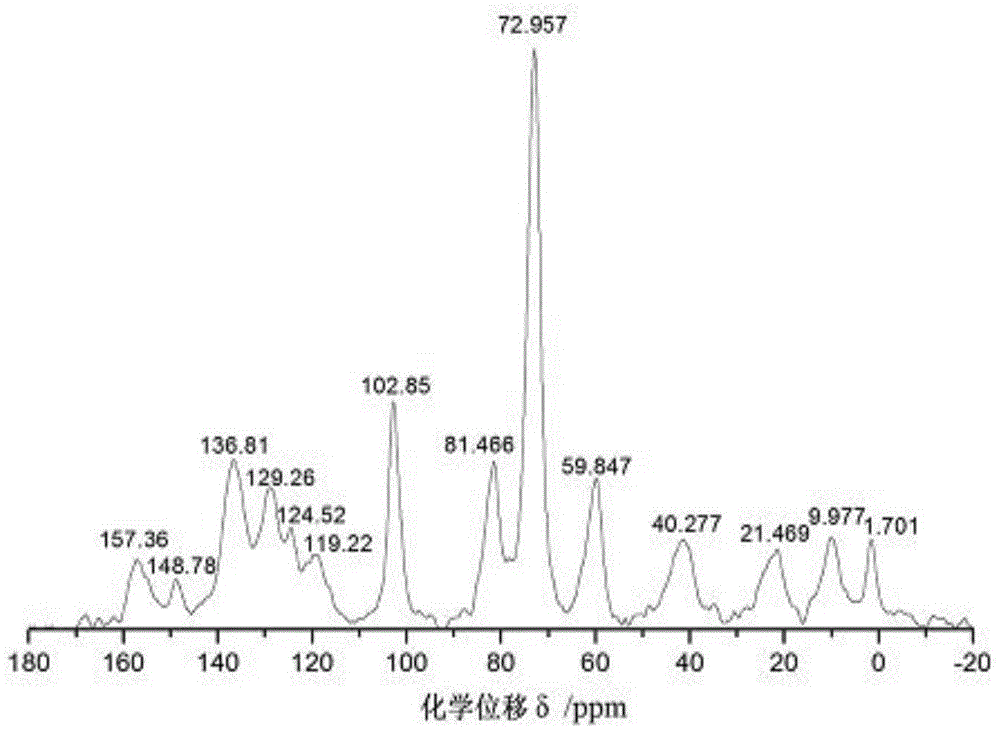

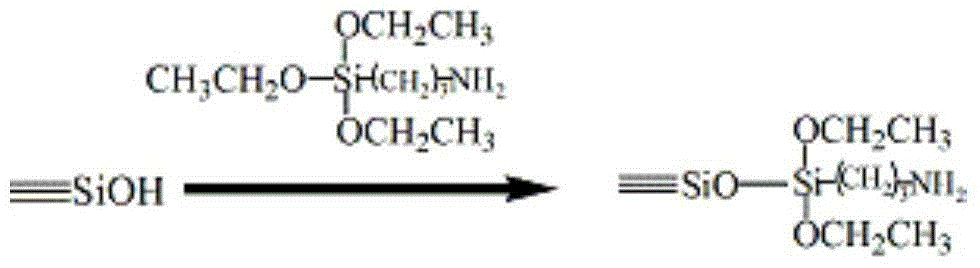

Preparation method for beta-cyclodextrin chiral stationary phase

InactiveCN103601823AHigh creativityAvoid the effects of bonding reactionsOther chemical processesMicrosphereChiral stationary phase

A disclosed preparation method for a beta-cyclodextrin chiral stationary phase comprises: taking SiO2 microballoons as a raw material, and bonding beta-cyclodextrin (beta-CD) to the surface of SiO2 microballoons by employing 3-aminopropyltriethoxysilane (KH550), trimethylchlorosilane and 4,4'-methylenediphenyl diisocyanate (MDI) to obtain the beta-cyclodextrin chiral stationary phase. The method has continuity, simple operation and short synthetic period, and the synthetic product is convenient to be subjected to derivatization; no metal ion-containing catalysts such as NaOH, NaN3, CuI(PPh3) and the like are introduced according to the method, so that the chiral stationary phase is prevented from pollution, and the method relatively accords with the separation requirement of high-purity liquid chromatogram. The method is applicable to separation of benzene ring-containing chiral medicament intermediates and pyrethroid pesticide compounds.

Owner:BEIJING UNIV OF CHEM TECH

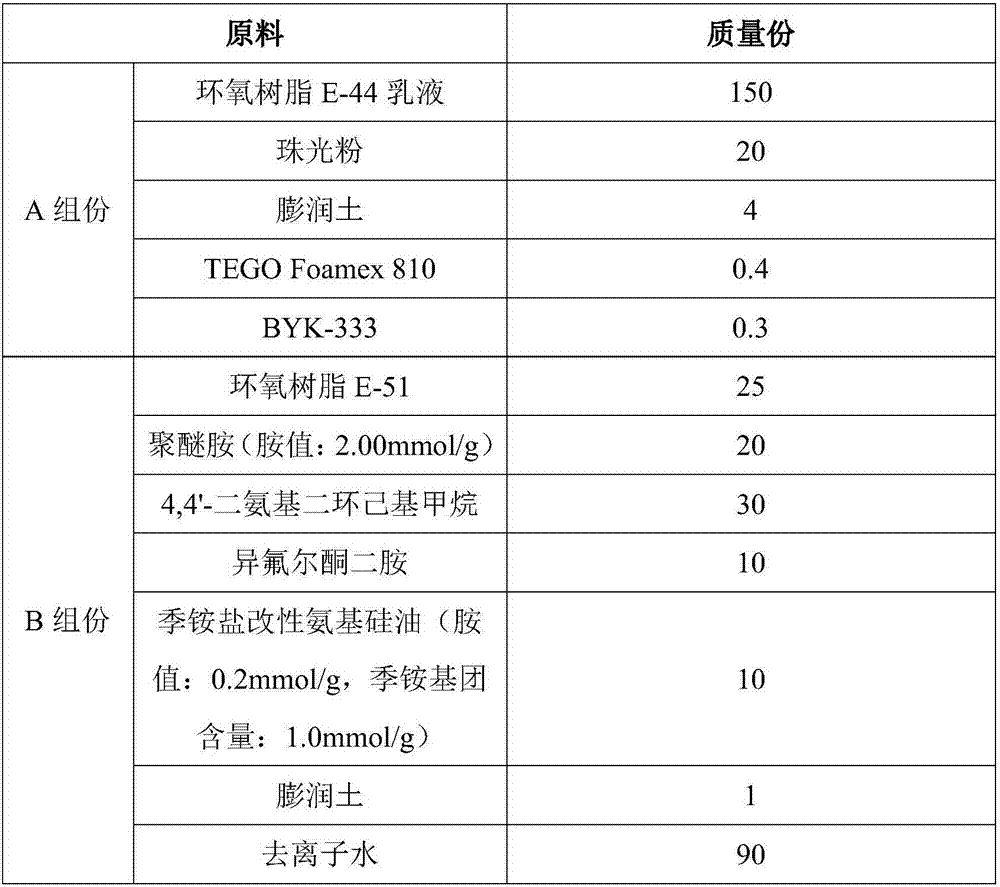

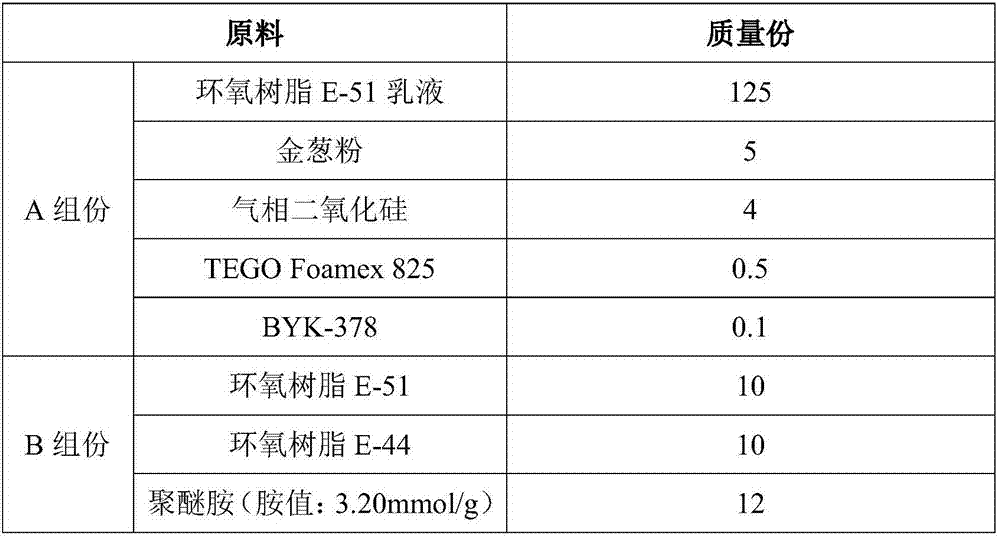

Waterborne bi-component antibacterial and antifouling epoxy sealant and preparation method thereof

ActiveCN107573883AHigh strengthLow shrinkageMacromolecular adhesive additivesEpoxy resin adhesivesEpoxyEmulsion

The invention discloses a waterborne bi-component antibacterial and antifouling epoxy sealant and a preparation method thereof. The epoxy sealant is prepared from a component A and a component B according to the mass ratio of 1 to (0.8 to 1.2), wherein the component A is prepared from the following raw materials in parts by mass: 100 to 150 parts of epoxy resin emulsion, 5 to 20 parts of pigment,1 to 5 parts of thixotropic agent, 0.1 to 0.5 part of defoaming agent and 0.1 to 0.5 part of leveling agent; the component B is prepared from the following raw materials in parts by mass: 15 to 25 parts of epoxy resin, 10 to 20 parts of polyether amine, 15 to 40 parts of amine compounds, 10 to 20 parts of antibacterial antifouling additive, 1 to 5 parts of thixotropic agent and 60 to 100 parts ofwater. The preparation method is simple, materials are mixed first to obtain the component A and the component B, and when used, the component A and the component B are mixed uniformly. The epoxy sealant disclosed by the invention has the advantages of high strength, low shrinkage, strong adhesiveness, high brightness, attractive appearance, long lasting time, good antibacterial and antifungal effect, good hydrophobic and antifouling effect, easy cleaning, low VOC content and safety and environmental protection.

Owner:福州三坊建材有限公司

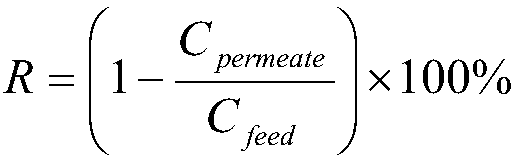

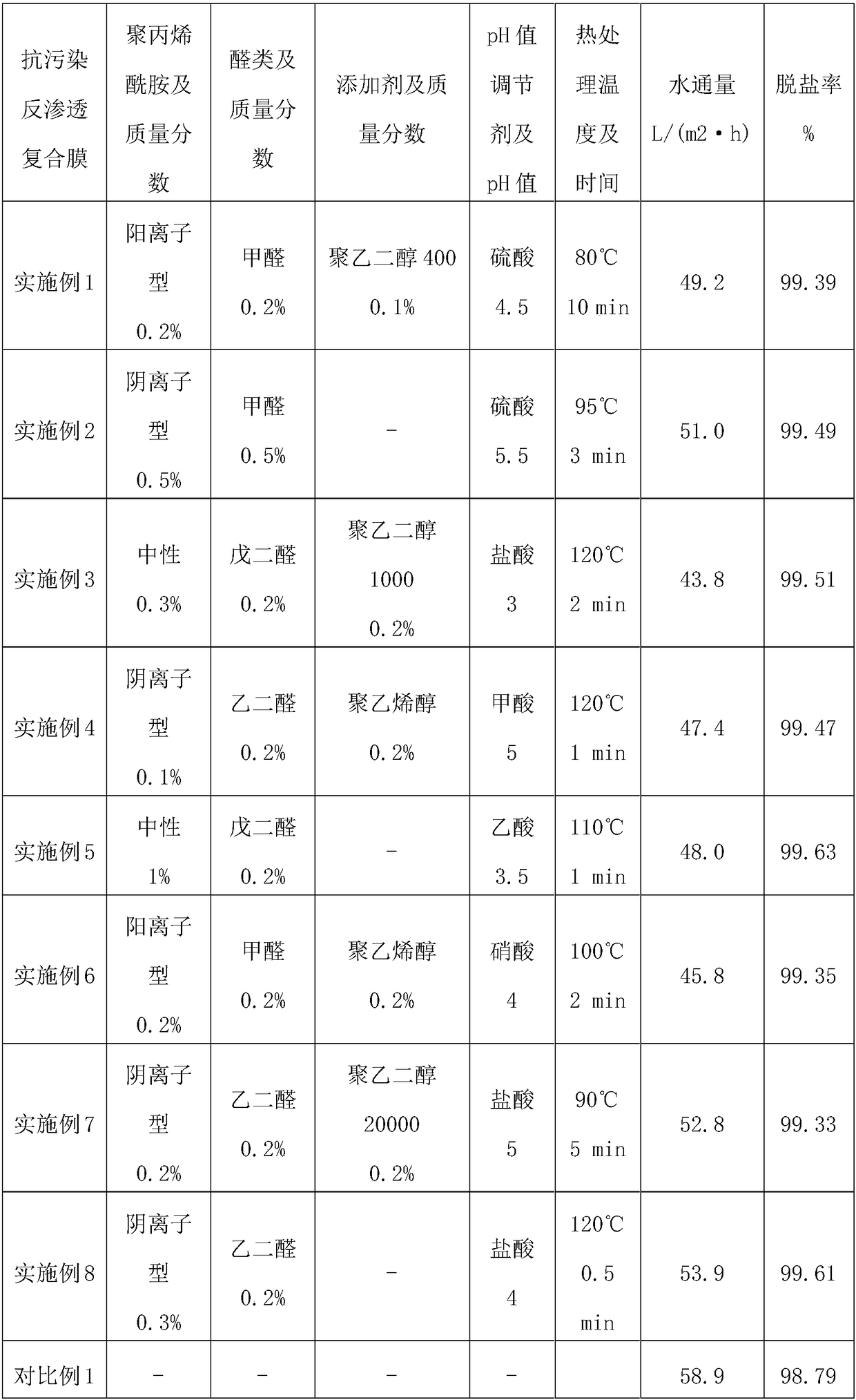

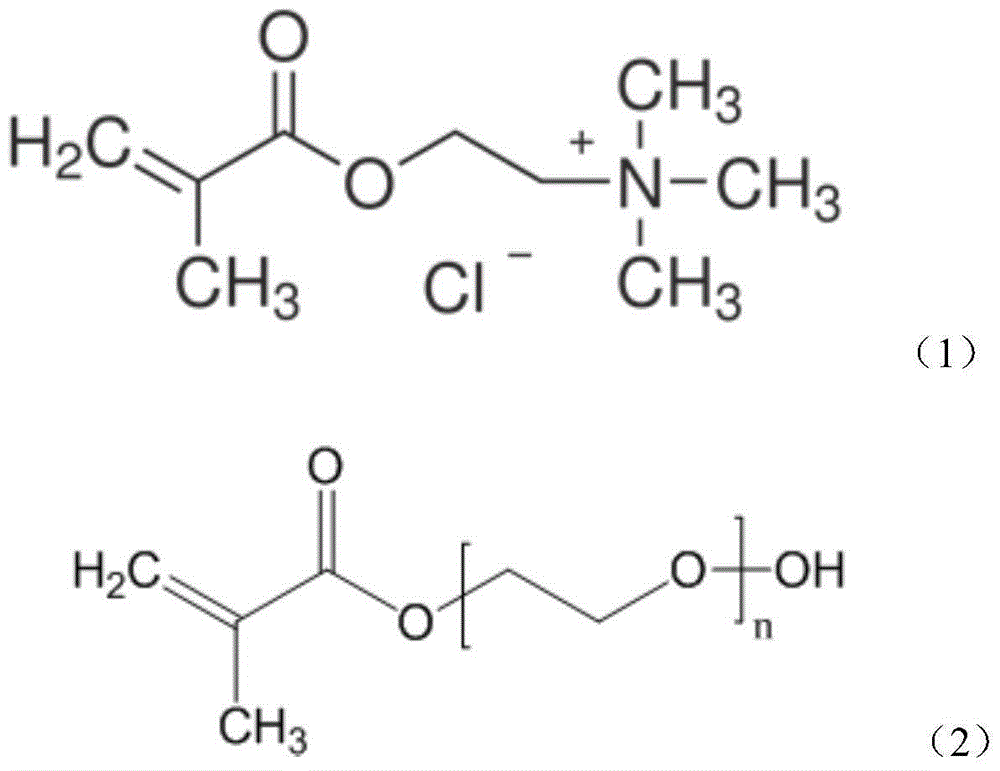

Preparation method of anti-pollution reverse osmosis composite membrane, and reverse osmosis composite membrane

InactiveCN108126530ANot easy to eluteExtended service lifeGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisCross-linkReverse osmosis

The invention discloses a preparation method of an anti-pollution reverse osmosis composite membrane. The preparation method comprises the following steps: contacting a polyamine aqueous phase solution with an aromatic polyhydric acyl chloride organic phase solution on the surface of the polysulfone support membrane for carrying out an interfacial polymerization reaction to form an aromatic polyamide desalination layer, coating a prepared anti-pollution coating liquid on the aromatic polyamide desalination layer, carrying out heat treatment for forming an anti-pollution coating, wherein the anti-pollution coating liquid is an acidic mixed solution containing polyacrylamide and aldehydes. Furthermore, the invention also discloses an anti-pollution reverse osmosis composite membrane preparedby the method. According to the invention, the cross-linked anti-pollution coating is formed on the surface of the polyamide desalination layer, the coating is uniform and smooth and is not easy to elute, so that the service life of the membrane is improved; and polyacrylamide with different electric properties are selected, so that the surface of the anti-pollution reverse osmosis membrane is electrically controllable, and the application field of the prepared reverse osmosis membrane is widened.

Owner:南京湶膜科技有限公司

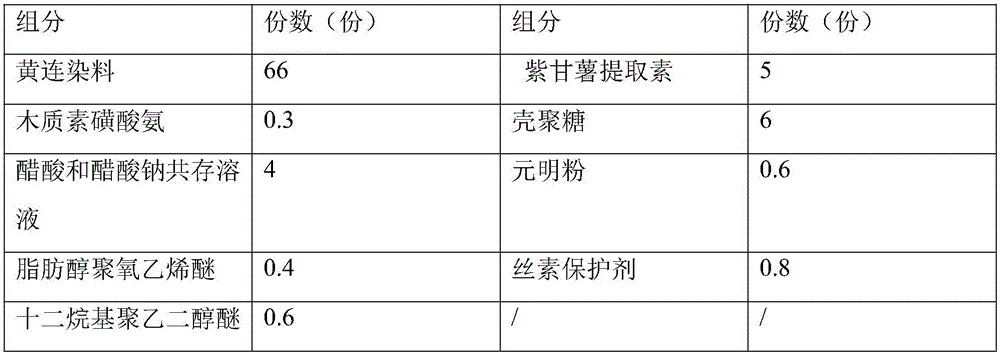

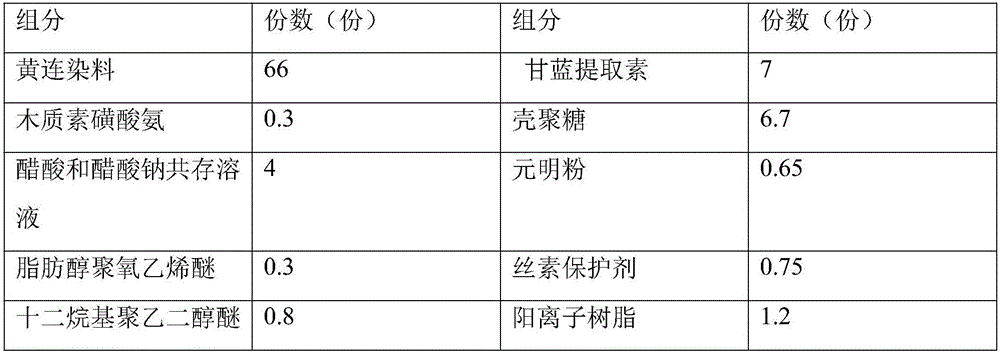

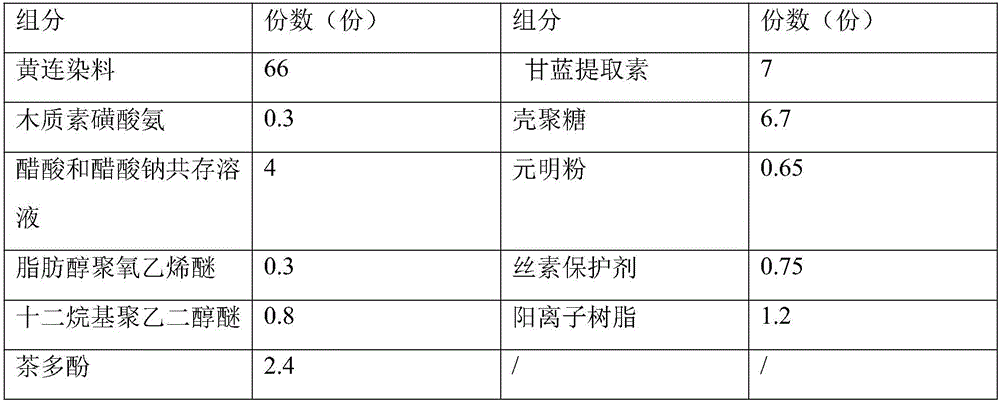

Dyeing agent and process for dyeing real silk by aid of dyeing agent

InactiveCN105970682AIncrease the amount of cationsFirmly attachedLight resistant fibresDyeing processFiberMordant

The invention discloses a dyeing agent and a process for dyeing real silk by the aid of the dyeing agent. According to the technical scheme, the dyeing agent and the process have the advantages that the problem that existing fiber fabrics contain heavy metal ions after being dyed can be solved; purple sweet potato extract elements, cabbage extract elements and purple perilla extract elements in the dyeing agent do not contain heavy metal ions, effects which are identical to effects of a mordant can be realized by the purple sweet potato extract elements, the cabbage extract elements and the purple perilla extract elements, accordingly, post-dye-uptake fiber fabrics are colorful and attractive on the premise that the dyeing agent and the process are favorable for improving the dye-uptake efficiency of the fiber fabrics, and environmental pollution can be prevented.

Owner:杭州余杭兴隆绸厂

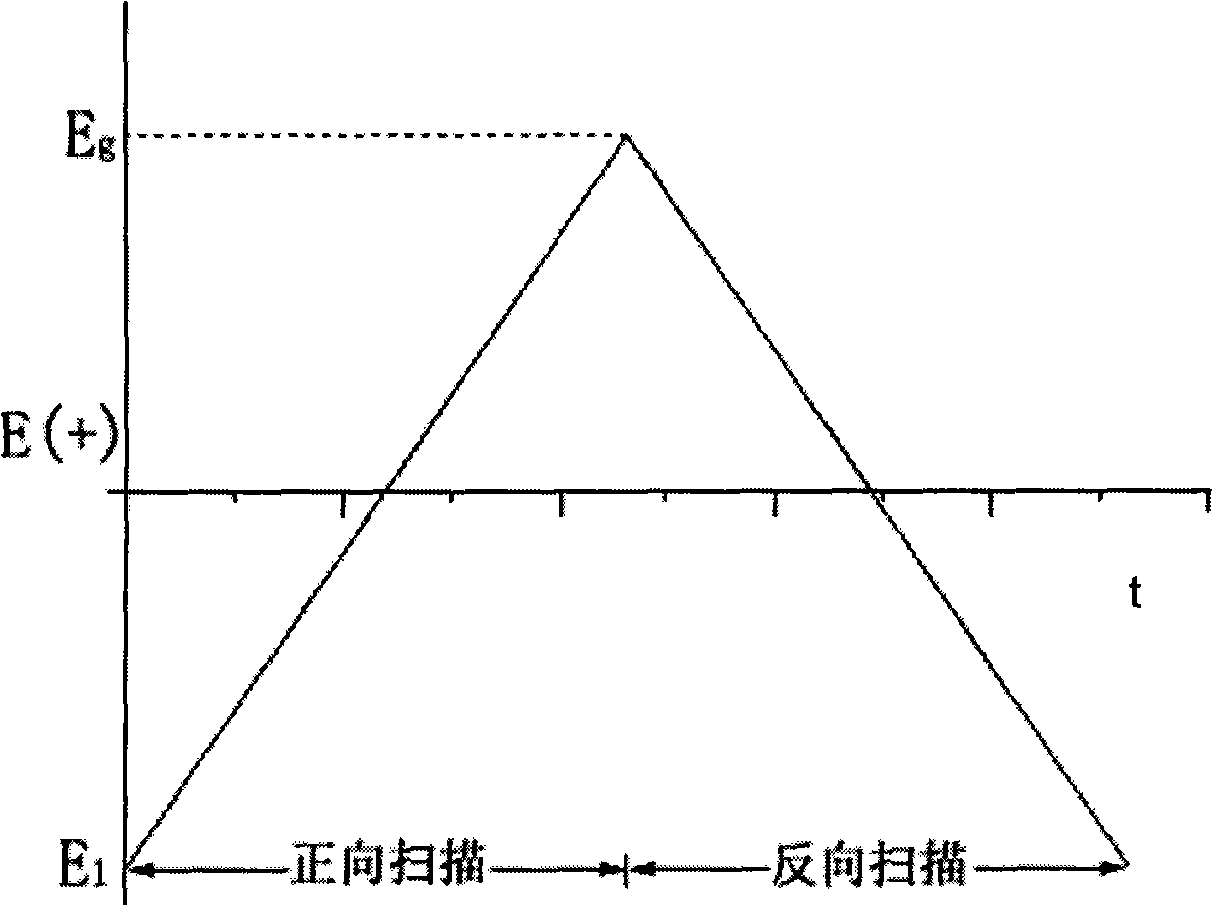

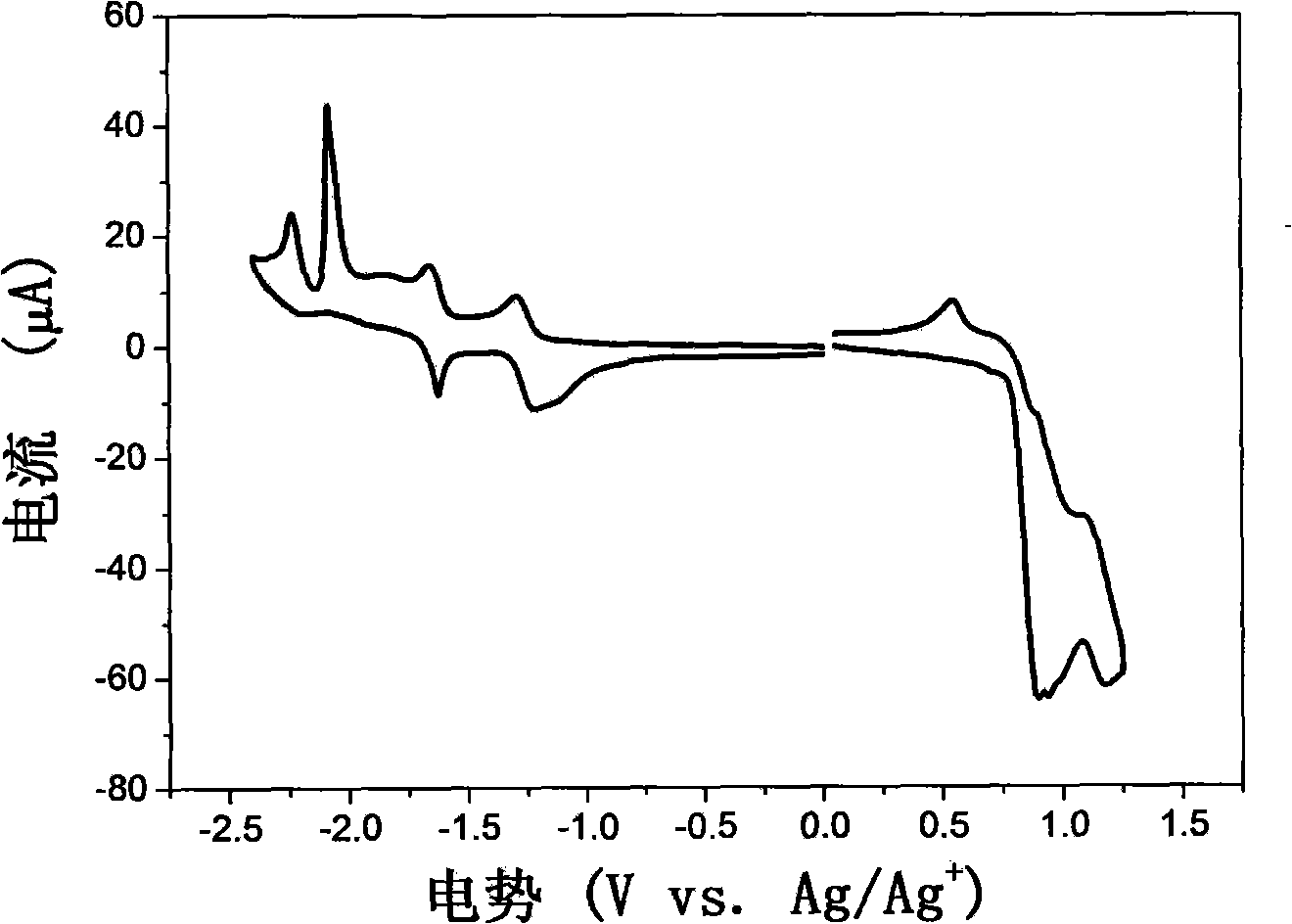

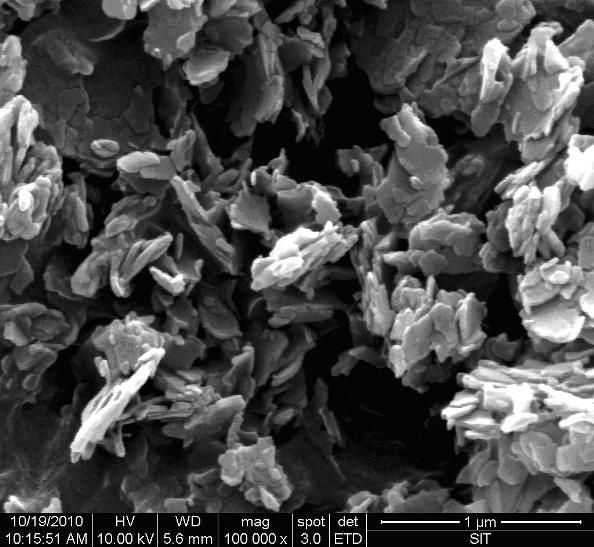

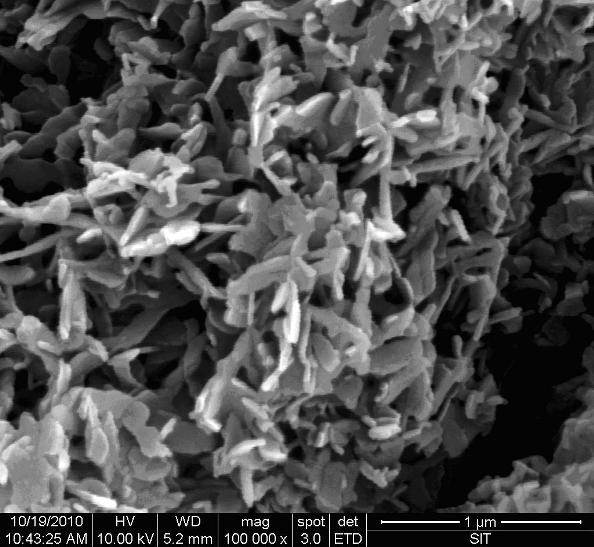

Phosphorescent metallo complexes and organic electrophosphorescent device prepared by electrochemical deposition

InactiveCN101358127AChemically stableStable electrochemical propertiesSolid-state devicesSemiconductor/solid-state device manufacturingStructural formulaElectrochemistry

The present invention relates to the field of organic luminescence, in particular to a phosphorescent metal complex containing electroactive radical and an application of the complex in an organic electrophosphorescent device. By utilizing the method of electrochemical deposition, the complex is prepared into a stable, firm film which is used as the luminous layer of the organic electrophosphorescent device. The structural formula of the complex is shown as follows: X is electroactive units; Z is the metal complex serving as a phosphorescence-emitting center; the X and the Z are connected together by a Y chain; m represents the number of the electroactive units. The phosphorescent metal complex containing the electroactive radical, which is prepared by the present invention, is characterized by stable chemical and electrochemical properties and can still stably illuminate after the electrochemical process of repetitive oxidation reduction; the film prepared by electrochemical codeposition is uniform and cannot easily be washed off; the organic electrophosphorescent device prepared with the deposited film shows good device performance and has a wide application prospect.

Owner:JILIN UNIV

Bamboo charcoal viscose fiber rich in nano-copper and preparation method of bamboo charcoal viscose fiber

ActiveCN103556272AImprove breathabilityHigh strengthArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceSpinning

The invention provides a bamboo charcoal viscose fiber rich in nano-copper and a preparation method of the bamboo charcoal viscose fiber in order to meet demands of clients in a product market and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The bamboo charcoal viscose fiber rich in nano-copper is characterized by being prepared by mixing a nano-copper bamboo charcoal solution with viscose throug injection before spinning, and carrying out wet spinning and post-treatment; the nano-copper bamboo charcoal solution is formed by mixing masterbatches containing the nano-copper and a bamboo charcoal solution. The fiber comprises the components by weight percent: 0.01-5 percent of nano-copper and 0.1-10 percent of bamboo charcoal; the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The bamboo charcoal viscose fiber rich in the nano-copper has functions of ultraviolet prevention and deodorization and is high in air permeability and absorptivity; furthermore, the antibacterial effect of the bamboo charcoal viscose fiber is better than that of the common bamboo charcoal fiber; the breaking strength of the fiber is high, and the cost is low.

Owner:YIBIN HIEST FIBER +1

Method for extracting lactic acid from corn starch wastewater fermentation liquid by using anion exchange resin

InactiveCN101880225AImprove adsorption capacityReduce process stepsCarboxylic compound separation/purificationIon-exchange resinFermentation

The invention discloses a method for extracting lactic acid from corn starch wastewater fermentation liquid by using an anion exchange resin and relates to a method for extracting the lactic acid from the corn starch wastewater fermentation liquid. The method solves the problem that the extraction ratio is low, the problem that extractant of an extraction method is toxic, the problem that the lactic acid cannot be separated from the extractant easily, and the problem that in a high molecular resin adsorption method, the selectivity of a high molecular resin and the static exchange capacity are low of the conventional, traditional and improved calcium lactate crystallization-acidolysis methods. The method comprises the following steps of: performing centrifugal filtration, active carbon decoloration and cation exchange resin column decalcification on the corn starch wastewater fermentation liquid; performing adsorption by using a 315-type anion exchange resin; and performing elution byusing deionized water to extract the lactic acid. The method has the advantages of fewer steps, simple operation, high selectivity and static exchange capacity, lactic acid extraction ratio of 78 to 80 percent, lactic acid purity of 85 to 86 percent and non-toxic and easily-separated eluant. The method is used for extracting the lactic acid in the corn starch wastewater fermentation liquid.

Owner:HARBIN INST OF TECH

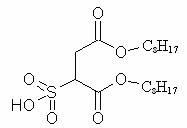

Synthesis method of azoic coupling component AS-D series pigment for aqueous application system and product obtained by synthesis method

ActiveCN102093742AEasy to eluteHigh COD contentMonoazo dyesInksChemical oxygen demandSynthesis methods

The invention belongs to the field of pigment synthesis and provides a synthesis method of azoic coupling component AS-D series pigment for an aqueous application system and a product obtained by the synthesis method. The synthesis method comprises the steps of coupling azoic coupling component AS-D as a coupling component with substituted aromatic amine diazonium salt to obtain the azoic coupling component AS-D series pigment with a structure satisfying a general formula (I), wherein sulfonated succinic acid surfactant activated agent with the structure satisfying a formula (II) is used, andthe formulas (I) and (II) are as shown in the specification, in the formulas, R1 is selected from CH3, NO2, OCH3 or Cl, R2 is selected from NO2, H, Cl, CH3 or SO2NHCH3, R3 is selected from H, Cl, NO2or CONH2, and R is selected from C4H9, C5H11,C6H13, C8H17, C10H21, C12H25, C13H27 or C18H37. The invention also provides the product obtained by the synthesis method. By using the synthesis method, the problems that in the existing pigment synthesis, chemical oxygen demand (COD) in waste water is over high, environment is polluted, and the like are solved. The pigment product prepared by the synthesis method is easy to disperse in aqueous solution and has bright color and high tinting power.

Owner:杭州百合辉柏赫颜料有限公司

Magnetic tea residue adsorbing material and preparation method thereof

InactiveCN107321315AImprove use valueImprove environmental benefitsOther chemical processesWater contaminantsPollutionMethylene blue

The invention provides a novel magnetic tea residue adsorbing material and a preparation method thereof. The material uses waste tea residues and nano-Fe3O4 as main components. The preparation method mainly comprises tea residue washing, de-coloring, drying, crushing, addition of nano-Fe3O4 powder for a modification reaction, washing after the reaction, solid-liquid separation, drying and grinding. The preparation method fully utilizes the tea residue advantages of pore structure, surface functional group, large specific surface area and good adsorption performance and utilizes combination with nano-Fe3O4 characteristics to produce the novel magnetic tea residue adsorbing material. The novel magnetic tea residue adsorbing material has the characteristics of low price and high recovery rate. Experiment results show that the decolorization efficiency of methylene blue can reach 98.0% or more, has adsorption stability, does not cause secondary pollution, has a very high use value and opens up a new way for the comprehensive utilization of waste tea residues.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

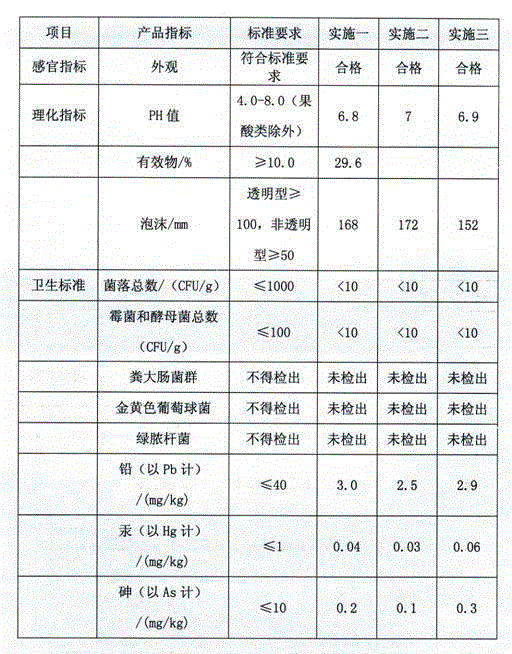

Tea bran shampoo

InactiveCN104434613AClean hairHas anti-inflammatory and anti-disease effectsCosmetic preparationsHair cosmeticsAdditive ingredientPolyethylene glycol

The invention discloses a tea bran shampoo, and belongs to the technical field of bath supplies. The effective ingredients of the tea bran shampoo are prepared from the following raw materials in percentage by weight: 23-25% of tea bran extract, 1-3% of tea oil, 1-2% of guar gum quaternary ammonium salt, 0.3-0.6% of ethylene glycol stearate, 0.7-1% of polyethylene glycol bisstearate, 0.85-1.23% of white vinegar and the balance of water. The tea bran shampoo disclosed by the invention is reasonable and simple in raw material components, convenient and practical; various unnecessary additives are reduced, thus the tea bran shampoo is more natural and safer, and has the great functions of cleaning, nourishing, preventing hair loss and resisting diseases.

Owner:广西三椿生物科技有限公司

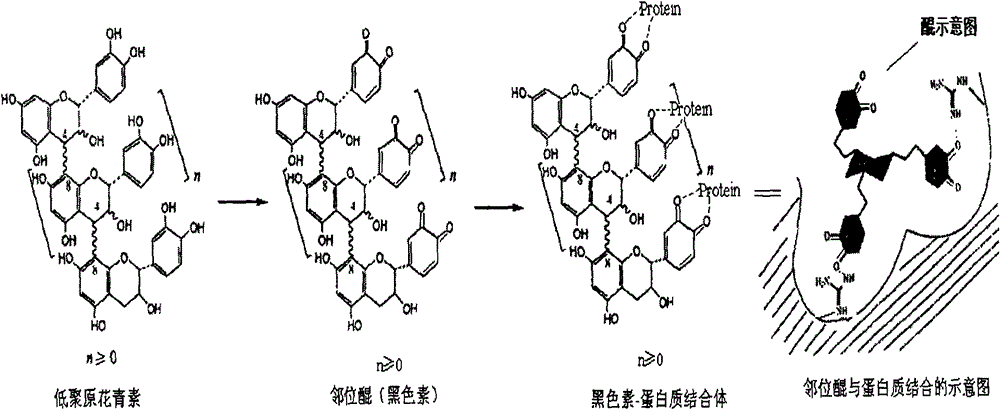

Natural hair dye adopting water-soluble plant melanin, preparation method thereof and hair dyeing method thereof

ActiveCN102743306AImprove uniformityReduce liquidityCosmetic preparationsHair cosmeticsVaccinium bracteatumHair dyes

The invention relates to a natural hair dye prepared through adopting water-soluble plant melanin, a preparation method thereof and a hair dyeing method thereof. The hair dye comprises 10-20wt% of Vaccinium bracteatum leaf melanin, 20wt% of ethanol, 5-10wt% of a surfactant, 5-15wt% of a thickener, and the balance water. The hair dye is uniformly smeared on clean hair, hair dyeing is carried out at 50-60DEG C for 30-50min, and then the hair is cleaned and is dried through blowing, so the hair has a natural brownish black color. Compared with hair dyes using synthesized melanin or a metal chelator, the hair dye adopting the natural plant melanin as the main body of the hair dye of the invention has a reliable safety.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

Manufacturing method for chromium-free aldehyde-free tanned pigskin shoe lining leather

InactiveCN102747172ASuitable for industrial applicationCollapsible noodlesTanning treatmentPre-tanning chemical treatmentAcetic acidChromium free

The invention provides a manufacturing method for chromium-free aldehyde-free tanned pigskin shoe lining leather. The method comprises the following steps: placing bare pigskin in a rotary drum and then adding industrial salt, sodium bicarbonate, peregal and disodium ethylenediaminetetraacetate; then adding a zirconium tanning agent, sodium bicarbonate and an aluminum tanning agent into the rotary drum, heating an obtained mixture to a temperature of 40 DEG C, allowing the rotary drum to rotate for 180 min, stopping the rotary drum and standing the rotary drum overnight; in the next day, taking the pigskin out from the rotary drum, carrying out washing, adding the washed pigskin into the rotary drum, then adding water, neutralization tannin and sodium bicarbonate into the rotary drum again and draining off water; adding water, Tara powder, a penetrating agent, sulfited fish oil, sulfited rape oil and formic acid into the drained rotary drum, taking the pigskin out from the rotary drum and stacking and standing the pigskin; and carrying out toggling, milling, toggling, trimming, ironing, grading and measuring according to a conventional process so as to obtain the chromium-free aldehyde-free tanned pigskin shoe lining leather. According to the invention, through addition of disodium ethylenediaminetetraacetate as a masking agent, a pH value is reasonably adjusted, process balance that the surface of the zirconium tanning agent is not excessively tanned and the aluminum tanning agent is not easily eluted is achieved, and manufacturing of the chromium-free aldehyde-free tanned pigskin shoe lining leather is made possible.

Owner:湖南省怀其皮革集团制革有限公司

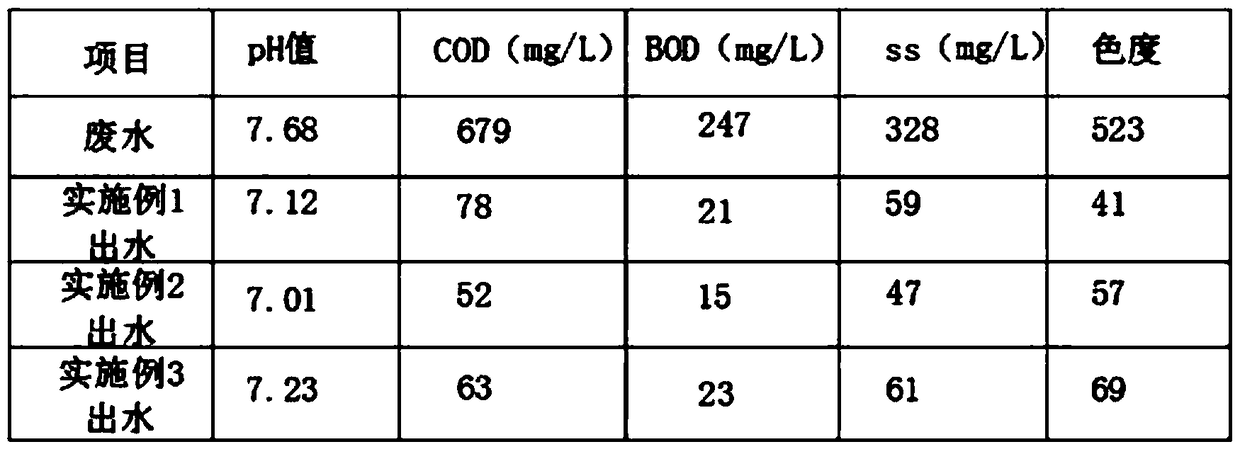

Chemical wastewater treatment agent and preparation method thereof

InactiveCN108821356AReduce dosageEliminate odorWater treatment parameter controlSpecific water treatment objectivesSodium BentoniteWastewater

The invention discloses a chemical wastewater treatment agent and a preparation method thereof, and belongs to the field of wastewater treatment. The chemical wastewater treatment agent comprises thefollowing raw materials in parts by mass: 25-38 parts of an inorganic-organic flocculant, 15-27 parts of an adsorbent, 10-18 parts of cured bayberry tannin, 10-18 parts of sulfuric acid modified pineleaves, 10-15 parts of a composite biochemical adsorbent, 8-12 parts of activated bentonite, 5-8 parts of fly ash, 8-8 parts of turf, 3-8 parts of modified zeolite, 3-8 parts of diatomite and 3-8 parts of modified kaolin.

Owner:俞金晶

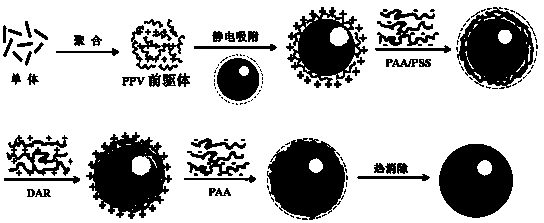

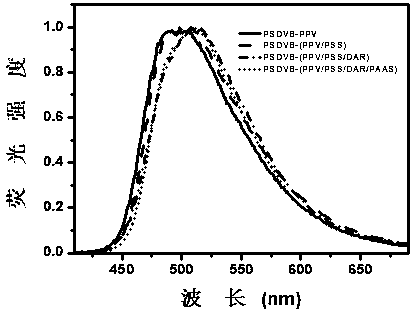

Surface-carboxylated fluorescent microspheres in crosslinked shell structure and preparation method thereof

ActiveCN104371708ASimple manufacturing processNo complicated chemical reactionsLuminescent compositionsMicroballoon preparationDivinylbenzenePolystyrene

The invention discloses surface-carboxylated fluorescent microspheres in a crosslinked shell structure and a preparation method thereof, belonging to the technical field of fluorescent sensing materials. The preparation method comprises the following steps: by using surface-sulfonated polystyrene-divinylbenzene crosslinked microspheres as the core, carrying out layer-by-layer self-assembly deposition on a p-phenylene ethylene precursor, poly(sodium-p-styrenesulfonate), diazo resin and polyacrylic acid on the core surface under the driving action of the electrostatic force, carrying out heat treatment, and carrying out crosslinking reaction on the diazo group and the carboxyl or sulfo group to generate the stable crosslinked shell structure, thereby obtaining the surface-carboxylated fluorescent microspheres. A layer-by-layer self-assembly process is adopted to modify the microsphere surface to introduce the carboxyl functional group with bioactivity, thereby simplifying the preparation technique. The method is convenient to operate and suitable for industrial production. The fluorescent microspheres have favorable dispersibility in water and multiple organic solvents, and can be applied to the fields of biological detection, medical diagnosis and the like.

Owner:SUZHOU UNIV

Anticoagulant composite hollow fiber membrane and preparation method thereof

InactiveCN109603591AGood biocompatibilityImprove solubilityMembranesSemi-permeable membranesDialysis membranesDisease

The invention belongs to the field of biological materials, and particularly relates to an anticoagulant composite hollow fiber membrane and a preparation method thereof. The fiber membrane comprisespolyethersulfone, maleylated chitosan and a water-soluble polymer pore-forming agent, wherein the polyethersulfone is in a porous grid framework structure, and after being modified by the maleylated chitosan, the biocompatibility of the polyethersulfone is increased, the platelet aggregation is reduced, and the anticoagulant performance is improved; by adding the water-soluble polymer pore-formingagent, on one hand, the inner diameter, pore diameter and porosity of the fiber membrane can be adjusted, so that the permeability of the fiber membrane is controlled; on the other hand, the water-soluble polymer pore-forming agent is embedded in the porous grid framework structure and is matched with the maleylated chitosan, so that the stability is good, the water-soluble polymer pore-forming agent is not easy to elute and can be used for a long time. The fiber membrane is used as a dialysis membrane to carry out hemodialysis on a patient without using heparin, so that the diseases such asosteoporosis, low coagulation performance and the like of the patient are avoided. The preparation method is simple and suitable for industrial production.

Owner:SUZHOU JUN KANG MEDICAL TECH

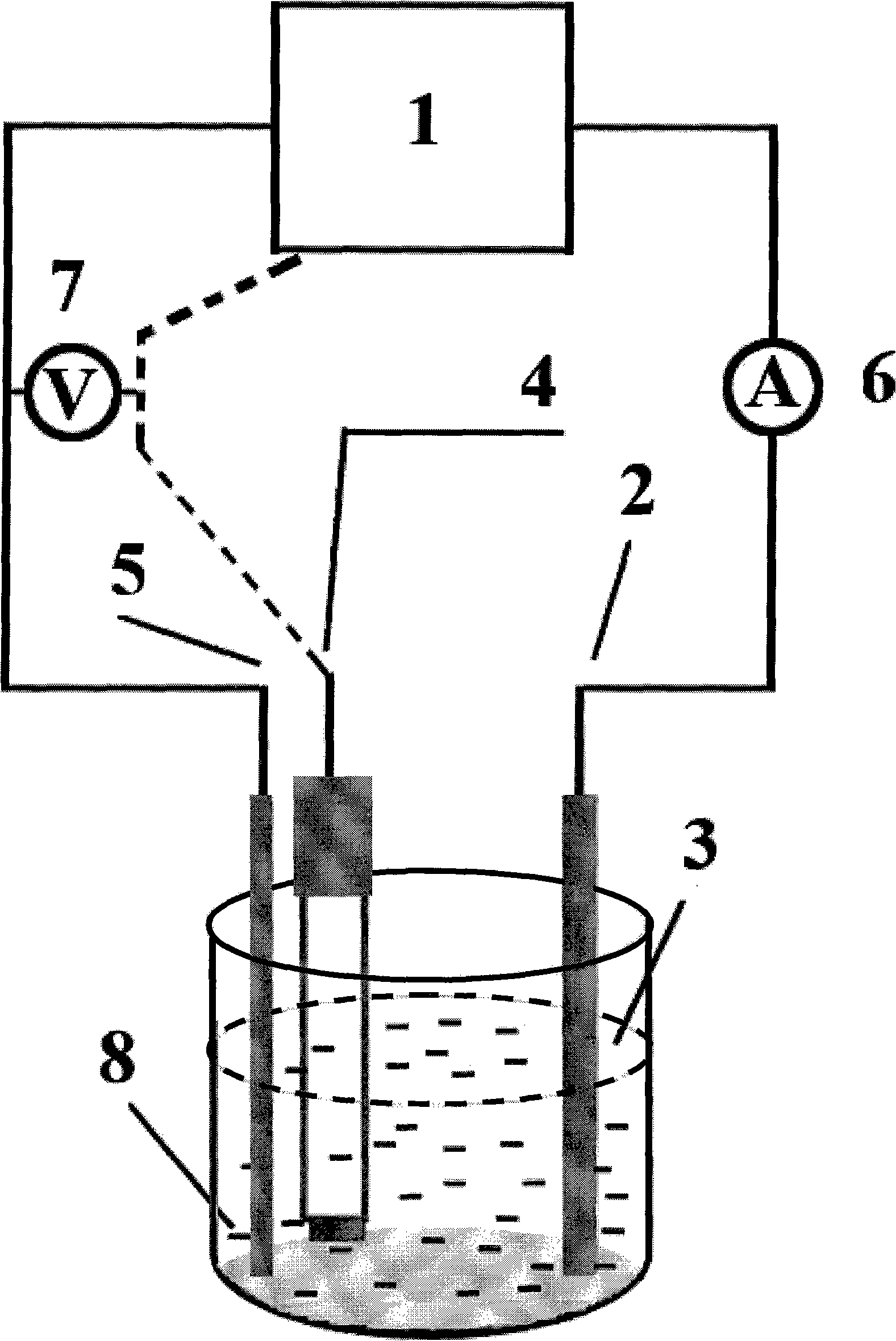

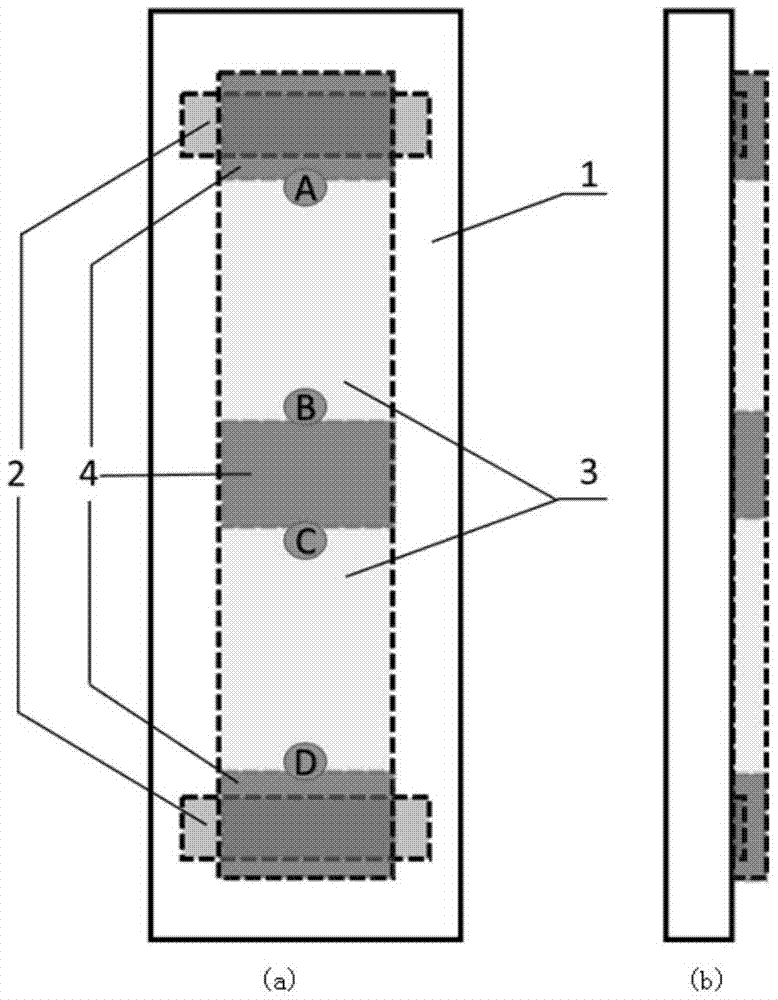

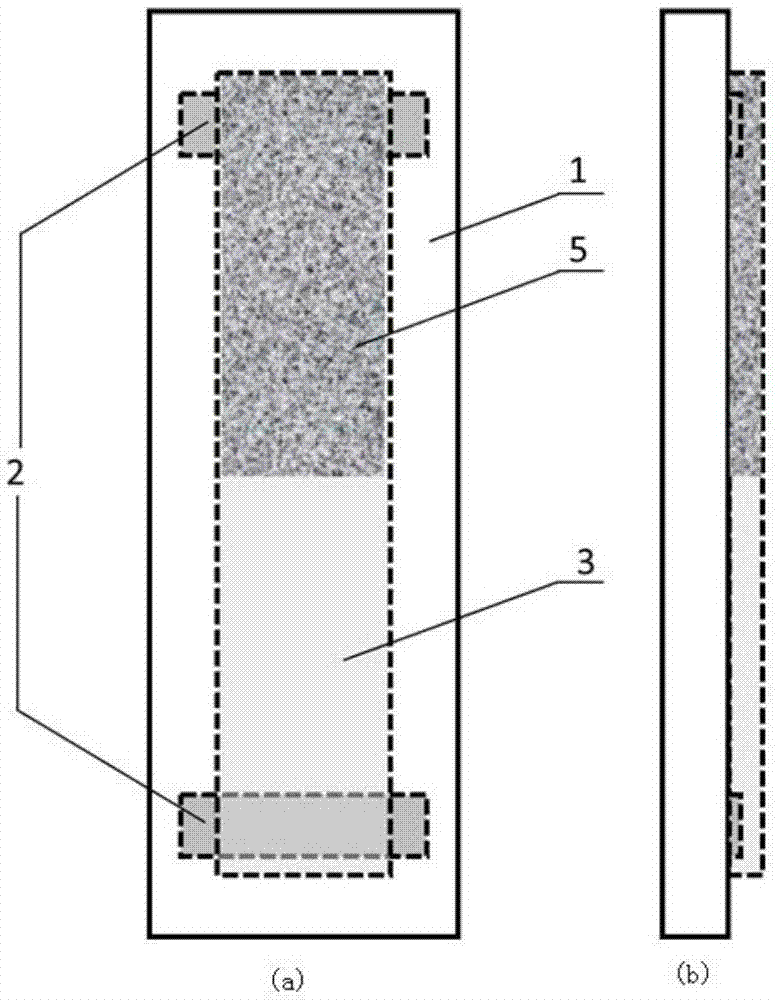

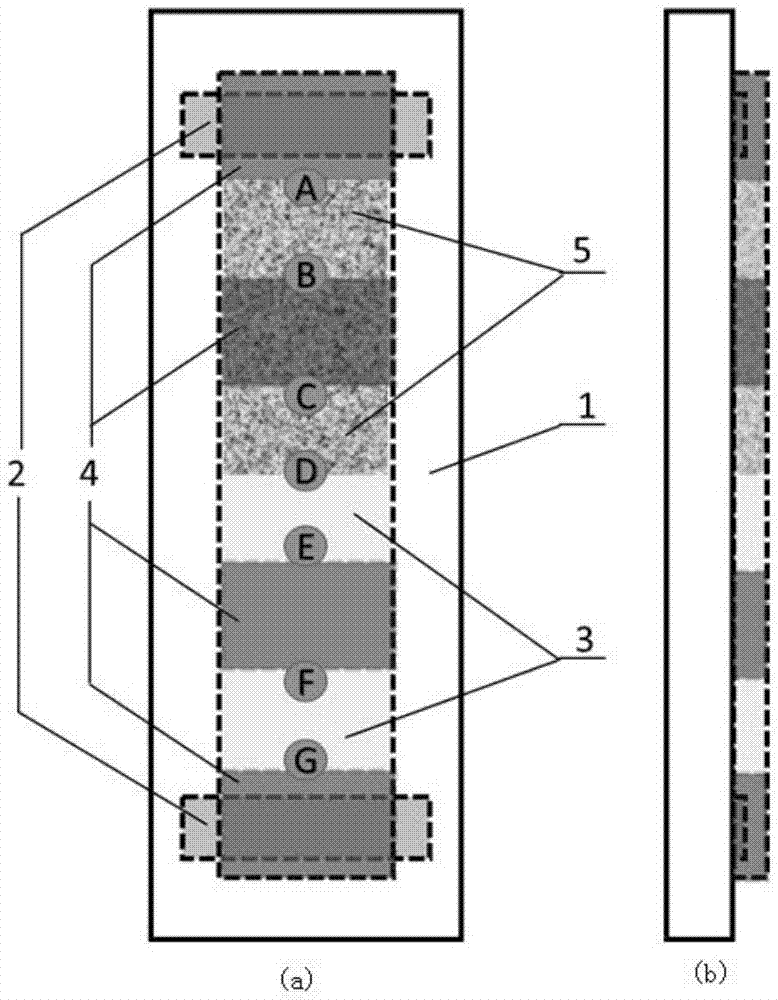

Liquid drop flow power generation device and manufacturing method thereof

ActiveCN106899235AAchieve directional flowAddress controllabilityKinetic-electric generatorVoltageElectrical and Electronics engineering

The invention discloses a liquid drop flow power generation device and a manufacturing method thereof. The device comprises a slide, electrodes, a flow power generation layer, a hydrophobic layer and a surface potential modification layer. The manufacturing method particularly comprises steps: two mutually-non interactive electrodes are formed on the insulated slide through a deposition or printing mode; a layer of flow power generation layer formed by solid micro nano powder is formed between the two electrodes through a deposition or printing mode; after activating treatment, surface treatment is then carried out on a specified flow power generation layer area, and the hydrophobic layer and / or the surface potential modification layer are / is formed; and a liquid drop drops on the flow power generation layer of the device, the liquid drop flows in the flow power generation layer in a directed mode, and thus, a potential difference and current are generated between the two electrodes in the flow radial direction. According to the manufacturing method provided by the invention, on-demand modification is carried out on the flow power generation layer, hydrophobicity or a feature of enabling the surface potential to be turned is realized, and the directions and the magnitudes of voltage and current outputted by the power generation devices can thus be changed.

Owner:HUAZHONG UNIV OF SCI & TECH

Antibacterial moisture absorption and desorption coating and preparation method thereof

InactiveCN107118654ANot easy to change colorEasy to eluteAntifouling/underwater paintsPaints with biocidesDesorptionMoisture absorption

The invention discloses an antibacterial moisture absorption and desorption coating and a preparation method thereof. The antibacterial moisture absorption and desorption coating is prepared from the following components in parts by mass: 40 to 60 parts of water, 20 to 35 parts of a macropore silicate molecular sieve, 1 to 3 parts of a silver-carrying zeolite molecular sieve, 5 to 8 parts of emulsion, 0.2 to 0.6 part of sodium carboxymethylcellulose, 3 to 6 parts of fumed silica and 2 to 4 parts of an aqueous colorant. The emulsion can be acrylic acid emulsion or aqueous epoxy emulsion according to different applications. Compared with an organic antibacterial agent, a silver-carrying antibacterial agent used for the antibacterial moisture absorption and desorption coating has the characteristics of high weather resistance and long-acting bacteria inhibition property. Compared with a dispersing body such as nano silver / monomer silver, the silver-carrying antibacterial agent is difficult to discolor and elute; as a coating additive, the silver-carrying antibacterial agent is a semi permanent-permanent antibacterial mildew preventive.

Owner:AMERIASIA ACTIVATED CARBON PROD CO LTD

Preparation method for colored silicon oxide aerogel

InactiveCN105084374ADyeing component ratio is easy to controlSmall chemical segregationSilicaSilicon oxideAerogel

The invention relates to a preparation method for a colored silicon oxide aerogel. The preparation method is characterized by comprising the following steps: adding a developing carrier into a silicon oxide sol precursor solution; uniformly stirring the solution and adding a gelation catalyst; and after the gel is aged, drying the gel to obtain the colored silicon oxide aerogel. The preparation method provided by the invention is small in environmental pollution, high in coloring firmness, difficult to elute, easy to control component and small in chemical segregation.

Owner:SICHUAN KENINGTAI TECH CO LTD

Method for solid phase extraction separating of components in heavy oil

ActiveCN105273742ANot easy to eluteLarge amount of processingPreparing sample for investigationSolid sorbent liquid separationAlkaneFuel oil

A method for solid phase extraction separating of components in heavy oil comprises the following steps: heavy oil is diluted and added into a stationary phase, the stationary phase is washed orderly by C5-C6 alkanes to obtain saturated hydrocarbon components, the stationary phase is washed by a solvent with the volume ratio of aromatic hydrocarbon and C5-C6 alkanes of 1: 15-25 to obtain light aromatic hydrocarbon components, the stationary phase is washed by a solvent with the volume ratio of aromatic hydrocarbon and C5-C6 alkanes of 1: 3 to 5 to obtain middle aromatic hydrocarbon components, the stationary phase is washed by aromatic hydrocarbon to obtain heavy aromatic hydrocarbon components, the stationary phase is washed by a solvent with the volume ratio of aromatic hydrocarbon and monohydric alcohol of 1: 0.8 to 1.5 to obtain colloid components, the stationary phase is silver-ion-supported alumina, and supported silver ions accounts for 0.5 to 12% of the mass of alumina. According to the method, the silver-ion-supported alumina is used as the stationary phase for separating hydrocarbons with different polar components in the heavy oil, and the stationary phase is easy to be eluted compared with the supported silver ions which are large in sample processing capacity, and high in separation efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anti-mosquito wallpaper and preparation method thereof

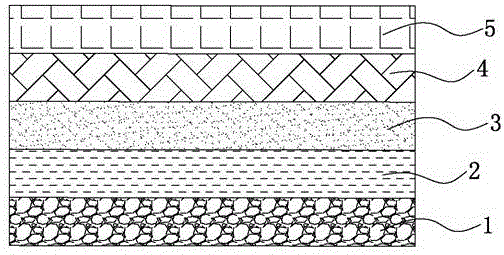

ActiveCN106368397AGood mosquito repellentWith waterproof functionWax coatingsAntifouling/underwater paintsEmulsion polymerizationCore shell

The invention relates to the technical field of wallpaper, in particular to anti-mosquito wallpaper which sequentially comprises a base material layer, a resin layer, an ink layer, an anti-mosquito adhesion layer and a waterproof breathable layer from bottom to top. The anti-mosquito wallpaper is good in mosquito repellent effect and high in water resistance and breathability. According to the anti-mosquito wallpaper, each layer is composited through various coating and printing methods, the waterproof breathable layer is prepared by combination with a core-shell emulsion polymerization process, the anti-mosquito adhesion layer is prepared through a microcapsule process, so that the prepared anti-mosquito wallpaper is good in mosquito repellent effect and high in water resistance and breathability.

Owner:GUANGDONG YULAN GRP

Fragrant wool fiber and preparation method thereof

The invention discloses a fragrant wool fiber and a preparation method thereof. Chitosan and sodium tripolyphosphate are used for coating a damascone spice, nanocapsules with chitosan as an outer shell are formed, then amino of chitosan and amino of a wool fiber are crosslinked through glutaraldehyde, and the nanocapsules coated with the damascone spice are immobilized on the wool fiber by chemical bonds; at the same time, vanillin is directly chemically immobilized on the surface of the wool fiber; and the fragrant wool fiber simultaneously loaded with the vanillin and the damascone spice is prepared. The prepared fragrant wool fiber is simultaneously loaded with the vanillin and the damascone spice, and has vanilla bean aroma of the vanillin spice and strong milk aroma, and fruity flavor, green grass fragrance, flower fragrance, wood fragrance and berry fragrance of the damascene spice; the fragrance is lasting, is slowly released, and is not easy to elute; the obtained wool fiber has the skin friendly performance, and has good application prospects.

Owner:珠海威丝曼股份有限公司

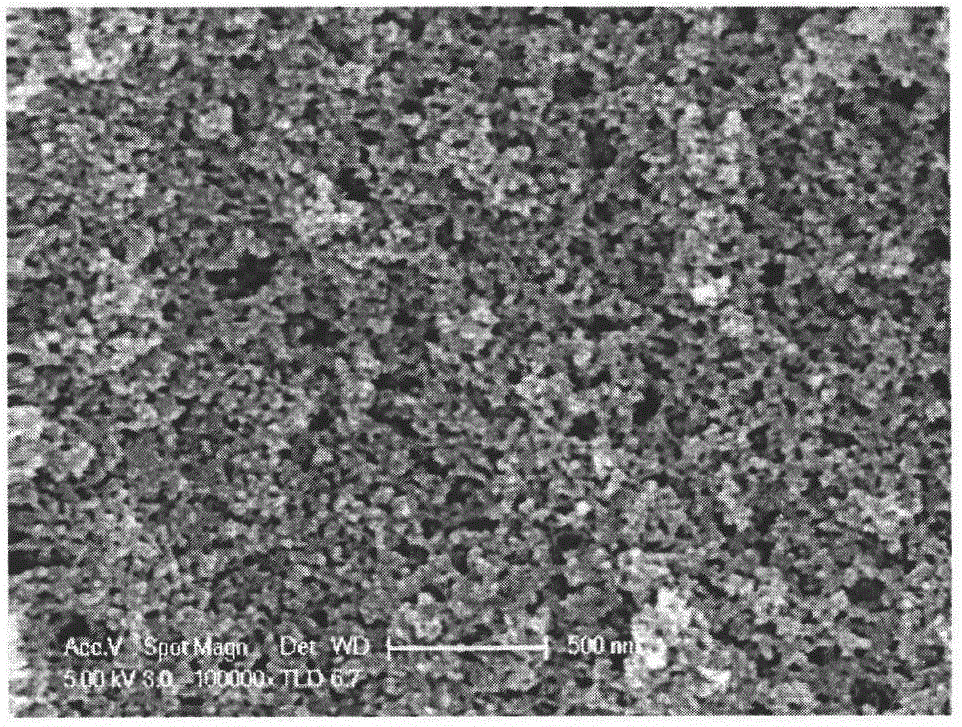

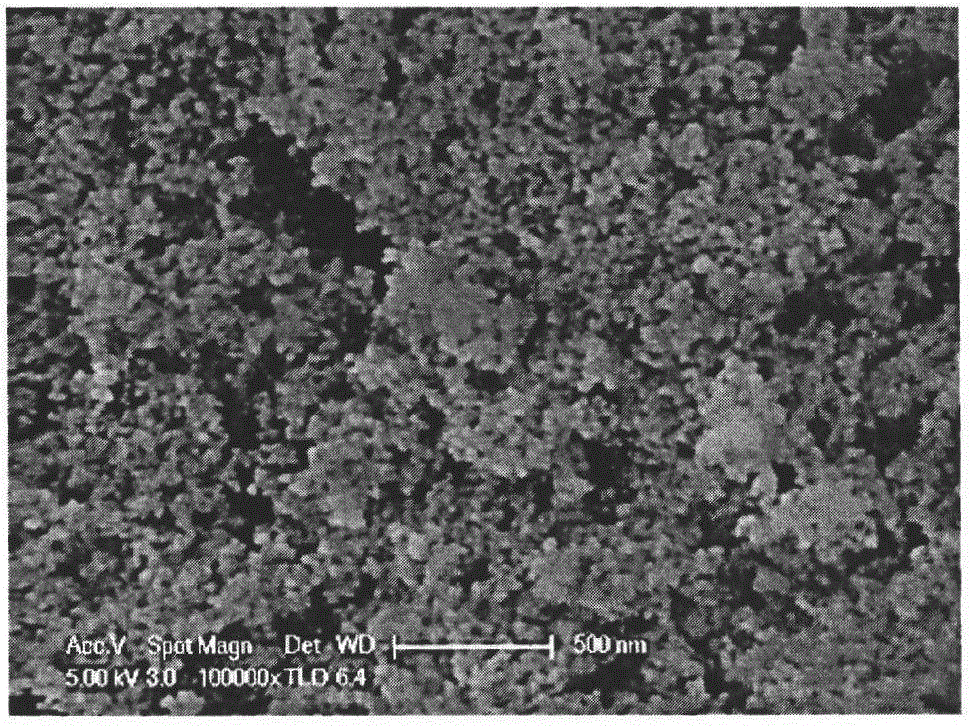

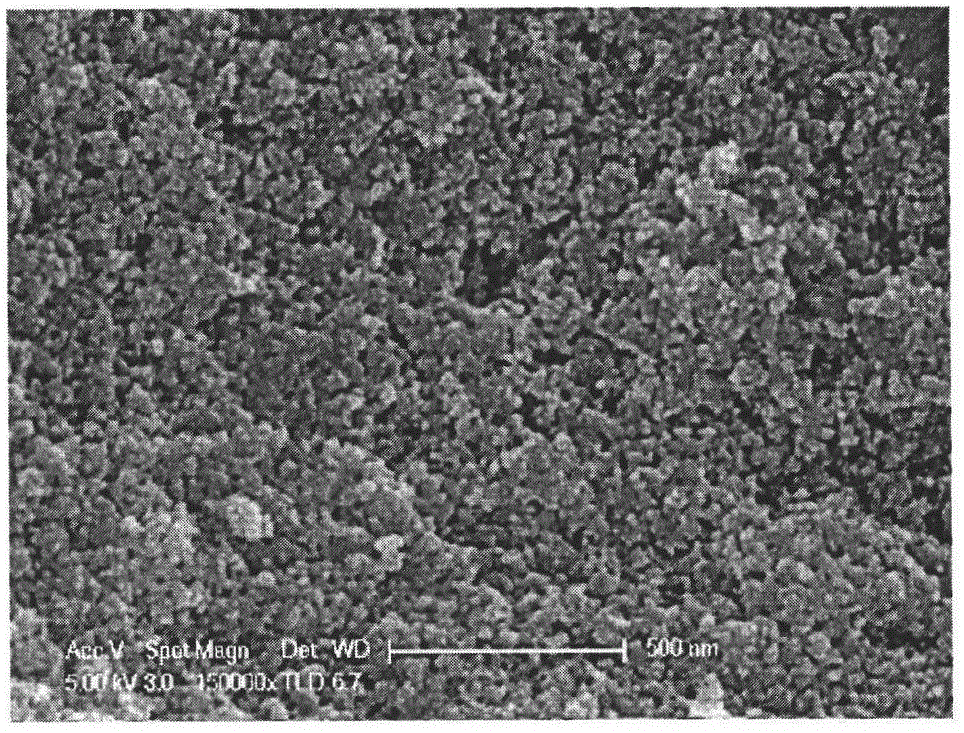

Method for preparing noble metal platinum nano catalyst

InactiveCN107855122ASimple preparation processEasy to operateGroup 4/14 element organic compoundsCatalyst activation/preparationNano catalystPlatinum

The invention belongs to the field of noble metal catalysts, and particularly relates to a method for preparing a noble metal platinum nano catalyst. The method for preparing the noble metal platinumnano catalyst comprises the following steps of: step 1, adding platinum tetra-amino acetate into water for dissolution, then adding an acidifying agent, and performing ultrasonic stirring to obtain aplatinum ion solution; step 2, performing a sealed reaction on the platinum ion solution for 2-4 hours, and then performing gentle heating reduced pressure concentration to obtain a concentrated solution; and step 3, dissolving sodium sulfite in the concentrated solution, and adding an electrolyte into the concentrated solution, conducting an electrolysis reaction for 2-4 hours so as to obtain suspension, and performing filtration to obtain the noble metal platinum nano catalyst. The method for preparing the noble metal platinum nano catalyst has the advantages of a simple preparation process,easy operation, low content of noble metal and a high industrial value.

Owner:SHAOXING UNIVERSITY

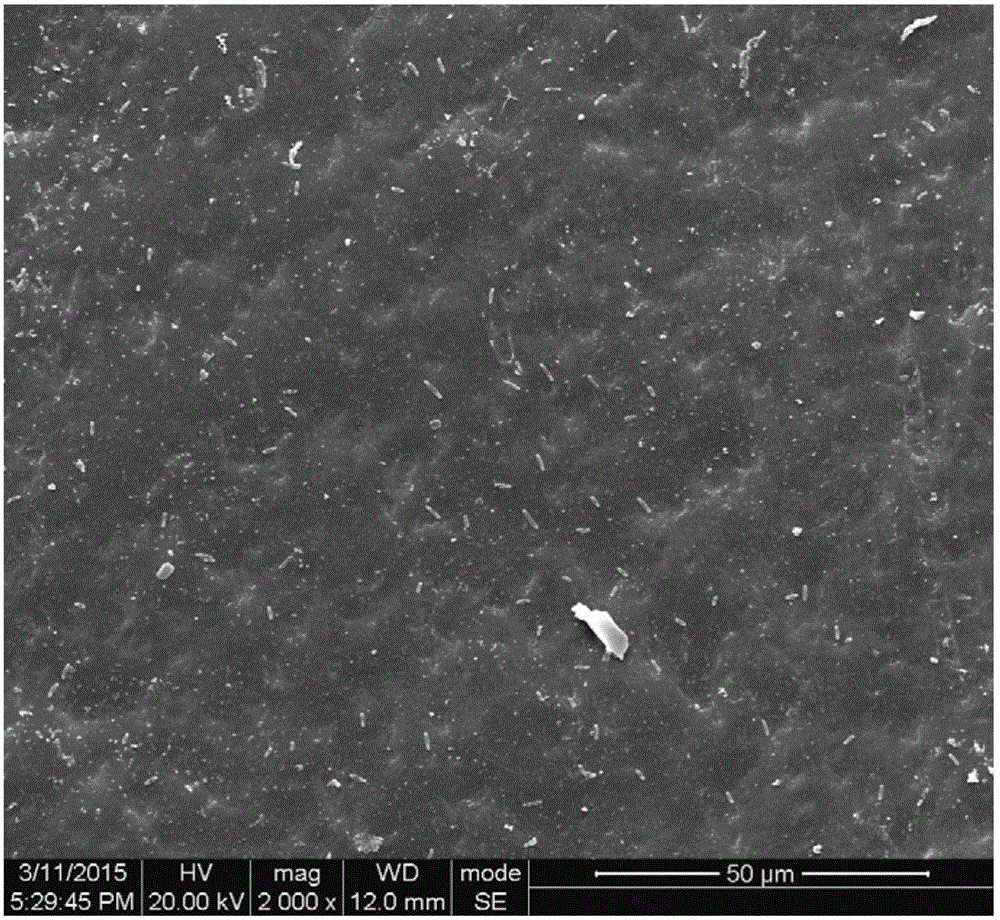

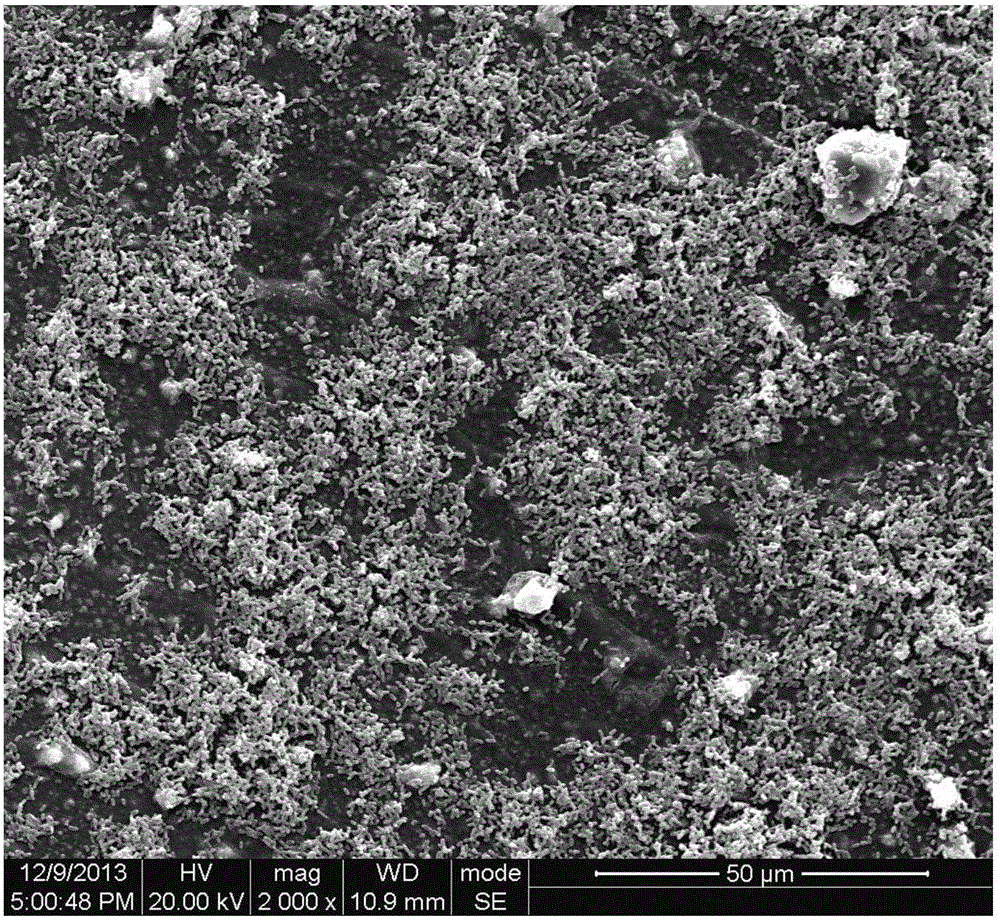

Hollow fiber ultrafiltration membrane with antibacterial and antipollution functions and preparation method thereof

ActiveCN105056774AImprove antibacterial propertiesImprove pollutionSemi-permeable membranesFiberHollow fibre

The invention provides a preparation method for a hollow fiber ultrafiltration membrane with antibacterial and antipollution functions. The method comprises the following steps: (1) subjecting a reaction monomer, a crosslinking agent, an initiator and a solvent to mixing, carrying out reaction under stirring at 70 to 95 DEG C for 10 to 24 hours so as to obtain a crosslinking microgel, then adding a membrane substrate and carrying out stirring until the membrane substrate and the crosslinking microgel are uniformly mixed, and carrying out filtering, defoaming, standing and curing so as to obtain spinning liquid; and (2) extruding the spinning liquid out from a spinning nozzle composed of two concentric tubes, allowing 8 to 40 cm of the extruded spinning liquid to be in air and then entering water bath for consolidation forming so as to obtain the hollow fiber ultrafiltration membrane, and carrying out draw twisting and then carrying out soaking in water so as to remove impurities. The hollow fiber ultrafiltration membrane prepared by using the above-mentioned method has an inner diameter of 200 to 1000 [mu]m, a membrane wall thickness of 50 to 200 [mu]m, a membrane wall pore diameter of 0.005 to 0.4 [mu]m and a pure water ultrafiltration coefficient of 120 to 600 mL / m2.h.mmHg, and has good antibacterial and antipollution abilities at the same time.

Owner:SICHUAN UNIV

A drug-coated titanium nail with chitosan gelatin as carrier

The invention belongs to the field of medical devices, and specifically relates to a drug-coated titanium nail with chitosan gelatin as a carrier, which is characterized in that: the thickness of the coating on the titanium nail is 0.001-10 mm; Titanium nails are used for open and endoscopic anastomotic staplers, skin sutures, linear staplers, and clip applicators. The diameter of the titanium nails is 0.1-5.0. The titanium nails are made of TA1, TA2 and the metal nails are made of 316LVM stainless steel, self-reinforced poly-L A coating of lactide SR-PLLA12 nails and self-reinforced poly-L-polyglycolide SR-PGA nails, the chitosan gelatin titanium nails can perform chitosan for human implants, artificial organs, catheters Sugar gelatin coating treatment or coating treatment using chitosan gelatin as drug controlled release carrier, the method is simple and easy, the prepared chitosan gelatin coated titanium nail meets the clinical application requirements, chitosan gelatin coated titanium nail can It promotes tissue healing, has good stability, is not easy to wash off, is safe to use, is suitable for large-scale industrial production, and is simple to operate and low in cost.

Owner:王学凡

Modified polyether sulfone and preparation method and application thereof

ActiveCN110052187AEasy to eluteChemically stableSemi-permeable membranesChemical reactionClick chemistry

The invention discloses modified polyether sulfone and a preparation method and application thereof. Modified polyether sulfone is prepared by grafting slightly-hydrolyzed polyvinylpyrrolidone onto polyether sulfone through click chemical reaction. By grafting slightly-hydrolyzed polyvinylpyrrolidone onto polyether sulfone through click chemical reaction, polyvinylpyrrolidone is less prone to elution, so that a prepared polyether sulfone hollow fiber membrane is more stable in chemical property, heat-resistant, more stable in hydrophilicity and water wettability and high biocompatibility and antifouling performance.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

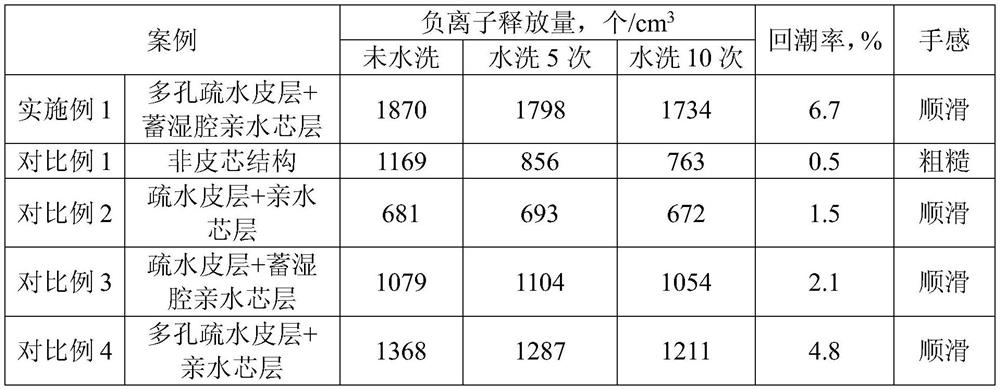

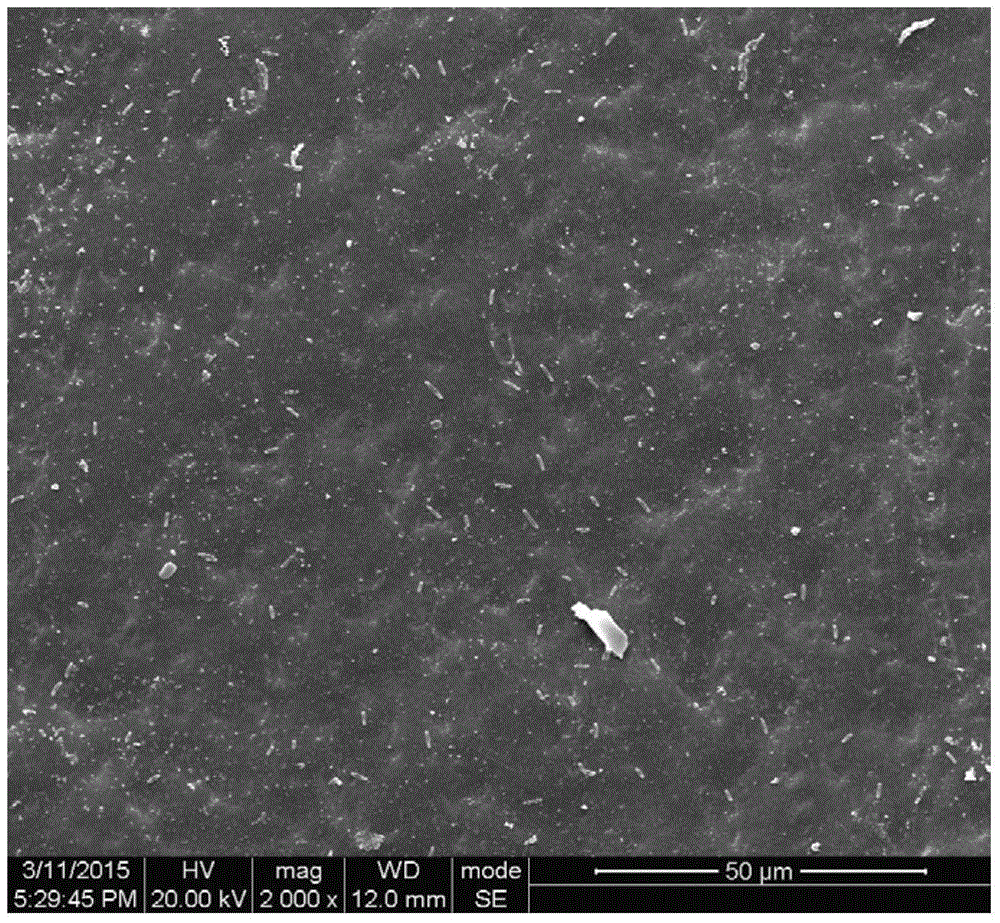

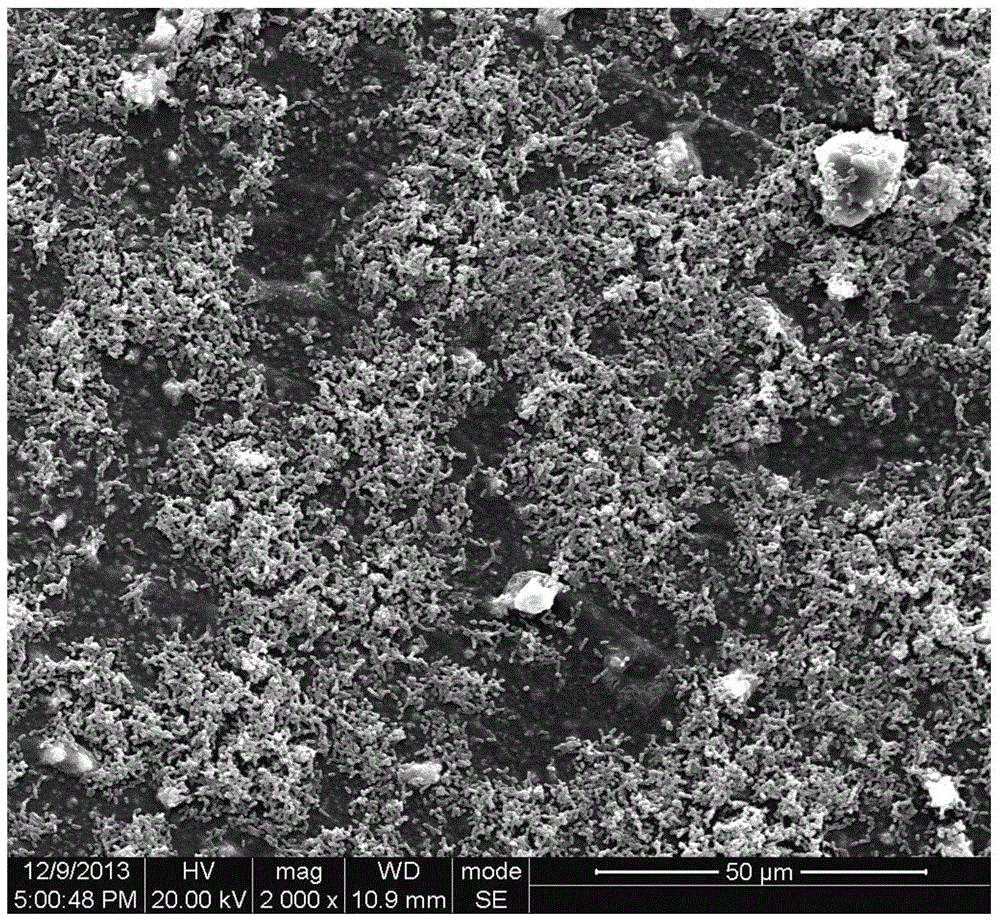

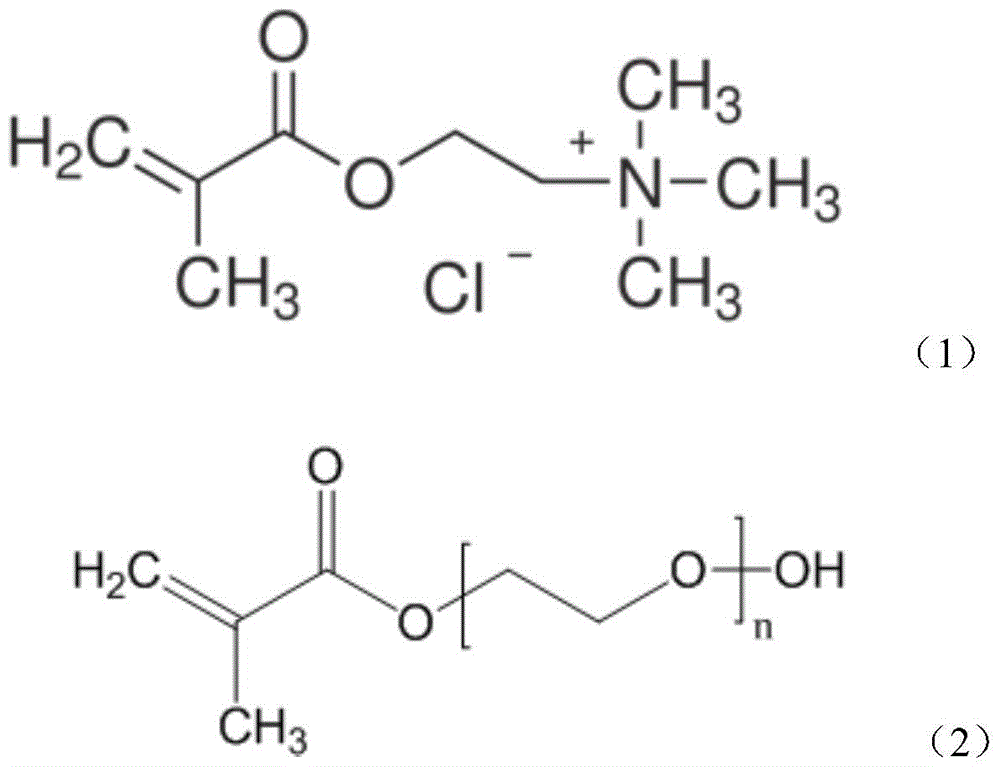

Skin-core structured anion moisture-absorption health-care functional fiber and preparation method thereof

PendingCN114032627AStrong loadEasy to eluteFilament/thread formingConjugated synthetic polymer artificial filamentsFiberPolyester

The invention relates to the field of fiber materials, and discloses a skin-core structured anion moisture-absorption health-care functional fiber and a preparation method thereof. The skin-core structure of the fiber is formed by a porous hydrophobic skin layer and a hydrophilic core layer; and the porous hydrophobic skin layer is PET, PP or PA, the hydrophilic core layer is hydrophilic polyester containing a moisture storage cavity, and negative ion powder is contained in the moisture storage cavity. The anion moisture-absorption health-care functional fiber has the characteristics that the anion powder is firmly loaded and washable, the anion release efficiency is high, and the skin fitting property is good.

Owner:龙青容

Hollow fiber ultrafiltration membrane with antibacterial and antifouling functions and preparation method thereof

ActiveCN105056774BImprove antibacterial propertiesImprove pollutionSemi-permeable membranesWater bathsHollow fibre membrane

The invention provides a preparation method for a hollow fiber ultrafiltration membrane with antibacterial and antipollution functions. The method comprises the following steps: (1) subjecting a reaction monomer, a crosslinking agent, an initiator and a solvent to mixing, carrying out reaction under stirring at 70 to 95 DEG C for 10 to 24 hours so as to obtain a crosslinking microgel, then adding a membrane substrate and carrying out stirring until the membrane substrate and the crosslinking microgel are uniformly mixed, and carrying out filtering, defoaming, standing and curing so as to obtain spinning liquid; and (2) extruding the spinning liquid out from a spinning nozzle composed of two concentric tubes, allowing 8 to 40 cm of the extruded spinning liquid to be in air and then entering water bath for consolidation forming so as to obtain the hollow fiber ultrafiltration membrane, and carrying out draw twisting and then carrying out soaking in water so as to remove impurities. The hollow fiber ultrafiltration membrane prepared by using the above-mentioned method has an inner diameter of 200 to 1000 [mu]m, a membrane wall thickness of 50 to 200 [mu]m, a membrane wall pore diameter of 0.005 to 0.4 [mu]m and a pure water ultrafiltration coefficient of 120 to 600 mL / m2.h.mmHg, and has good antibacterial and antipollution abilities at the same time.

Owner:SICHUAN UNIV

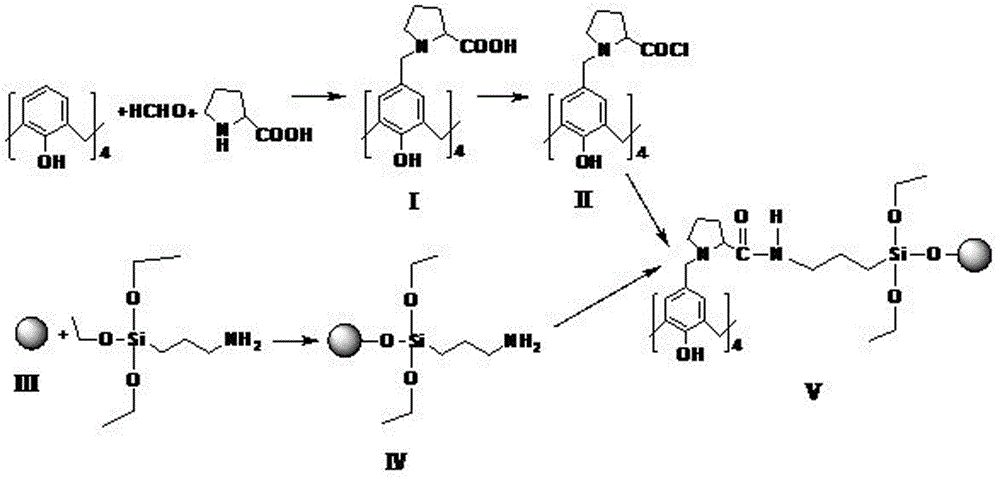

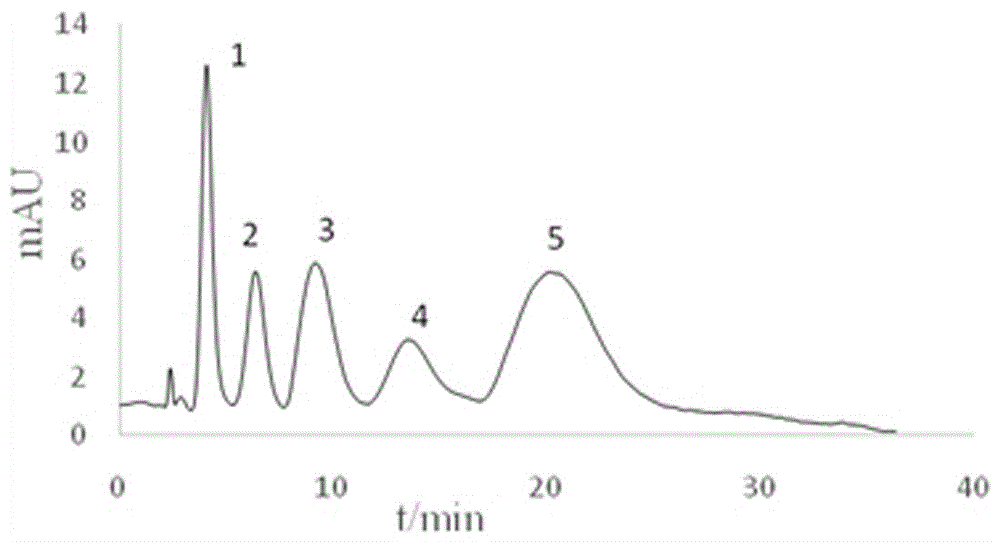

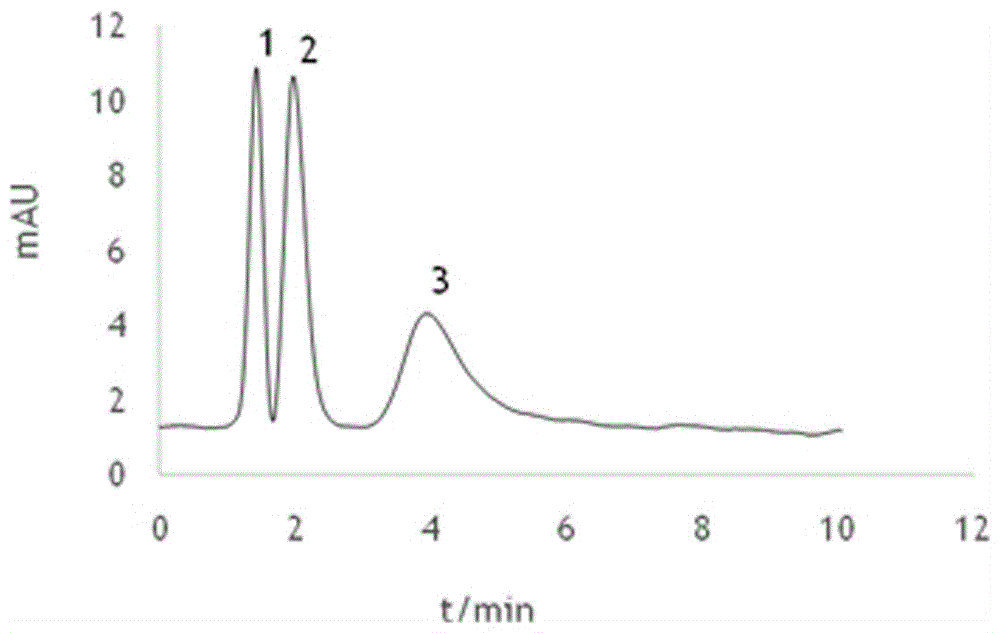

Calixarene amide derivative stationary phase and preparation method and application thereof

ActiveCN105771939AEasy to prepareMild preparation methodIon-exchange process apparatusOther chemical processesStationary phaseTriethoxysilane

The invention provides a calixarene amide derivative stationary phase and a preparation method and application thereof. The stationary phase comprises calixarene groups, praline groups and aminopropyl triethoxy bonded silica gel groups. It is found through research that the stationary phase has RPLC / HILIC mixed mode behaviors and has obvious advantages in the aspect of separation and analysis of complex samples, that is, hydrophobic retention characteristics are displayed under an organic phase in a low proportion; hydrophilic retention characteristics are displayed under the organic phase in a high proportion; hydrophobic compounds can be separated out under the RPLC mode, and polar micromolecular compounds or biological samples can be separated out under the HILIC mode. The preparation method includes the steps of synthesis of a calixarene amide derivative, acylating chlorination of the calixarene amide derivative, preparation of aminopropyl triethoxy bonded silica gel and preparation of a calixarene amide derivative stationary phase finished product. The preparation method is simple, mild, high in bonding amount, small in toxicity and good in reproducibility.

Owner:ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com