Skin-core structured anion moisture-absorption health-care functional fiber and preparation method thereof

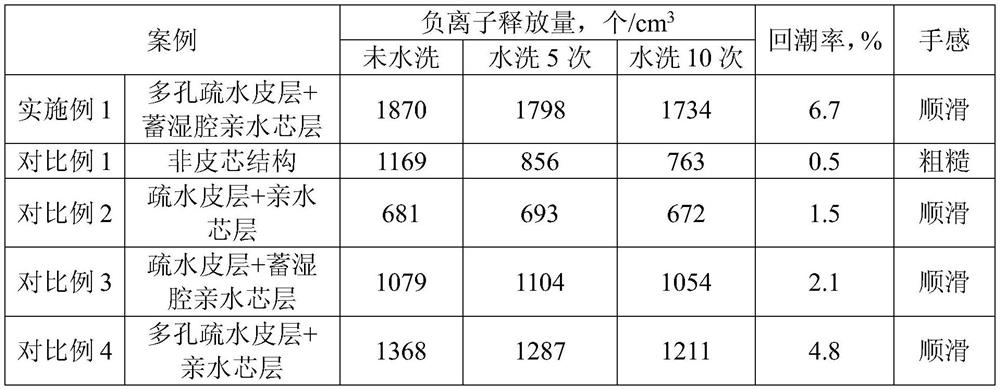

A skin-core structure and functional fiber technology, which is applied in the field of fiber materials, can solve the problems of rough fiber surface, poor skin-adherence, and negative ion powder shedding, etc., and achieve high anion release efficiency, good skin-adherence, firm load and washable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Dry the tourmaline powder of 1-5 microns, and add it to the alkali-soluble copolyester (6 mol% dimethyl isophthalate-5-sulfonic acid) in a molten state at a mass ratio of 1:1 Sodium-1 and 7mol% polyethylene terephthalate (polyethylene terephthalate) are dispersed evenly, and after cooling and solidification, pulverization and ball milling are performed to obtain tourmaline@alkali-soluble copolyester particles with a particle size of 2-10 microns .

[0031] (2) The tourmaline@alkali-soluble copolyester particles and the hydrophilic polyester (polyethylene terephthalate of 5 mol% sorbitol monomer) were melted and co-coated by a twin-screw extruder in a mass ratio of 10:100. After mixing, extrude and granulate, and obtain core layer slices after drying.

[0032] (3) The alkali-soluble copolyester and PET are melted and blended by a twin-screw extruder at a mass ratio of 35:100, then extruded and pelletized, and dried to obtain skin slices.

[0033](4) Melt the cortex...

Embodiment 2

[0036] (1) Dry the tourmaline powder of 5-10 microns, and add it to the alkali-soluble copolyester (containing 6 mol% dimethyl isophthalate-5-sulfonic acid) in a molten state at a mass ratio of 1:0.8 Sodium-1 and 7mol% polyethylene glycol (polyethylene terephthalate) are dispersed evenly, and after cooling and solidification, they are pulverized and ball-milled to obtain tourmaline@alkali-soluble copolyester with a particle size of 10-20 microns particles.

[0037] (2) At a mass ratio of 5:100, the tourmaline@alkali-soluble copolyester particles and hydrophilic polyester (polyethylene terephthalate of 5 mol% sorbitol monomer) were melt-coated through a twin-screw extruder. After mixing, extrude and granulate, and obtain core layer slices after drying.

[0038] (3) The alkali-soluble copolyester and PP are melt-blended by a twin-screw extruder at a mass ratio of 30:100, then extruded and pelletized, and dried to obtain skin slices.

[0039] (4) Melt the cortex slices and the ...

Embodiment 3

[0042] (1) Dry the tourmaline powder of 5-10 microns, and add it to the alkali-soluble copolyester (containing 6 mol% dimethyl isophthalate-5-sulfonic acid) in a molten state at a mass ratio of 1:0.6 Sodium-1 and 7mol% polyethylene glycol (polyethylene terephthalate) are dispersed evenly, and after cooling and solidification, they are pulverized and ball-milled to obtain tourmaline@alkali-soluble copolyester with a particle size of 10-20 microns particles.

[0043] (2) The tourmaline@alkali-soluble copolyester particles and the hydrophilic polyester (polyethylene terephthalate of 5 mol% sorbitol monomer) were melt-coated by a twin-screw extruder in a mass ratio of 15:100. After mixing, extrude and granulate, and obtain core layer slices after drying.

[0044] (3) The alkali-soluble copolyester and PA are melt-blended by a twin-screw extruder at a mass ratio of 40:100, then extruded and granulated, and dried to obtain skin slices.

[0045] (4) Melt the cortex slices and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com