Patents

Literature

90results about How to "High creativity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

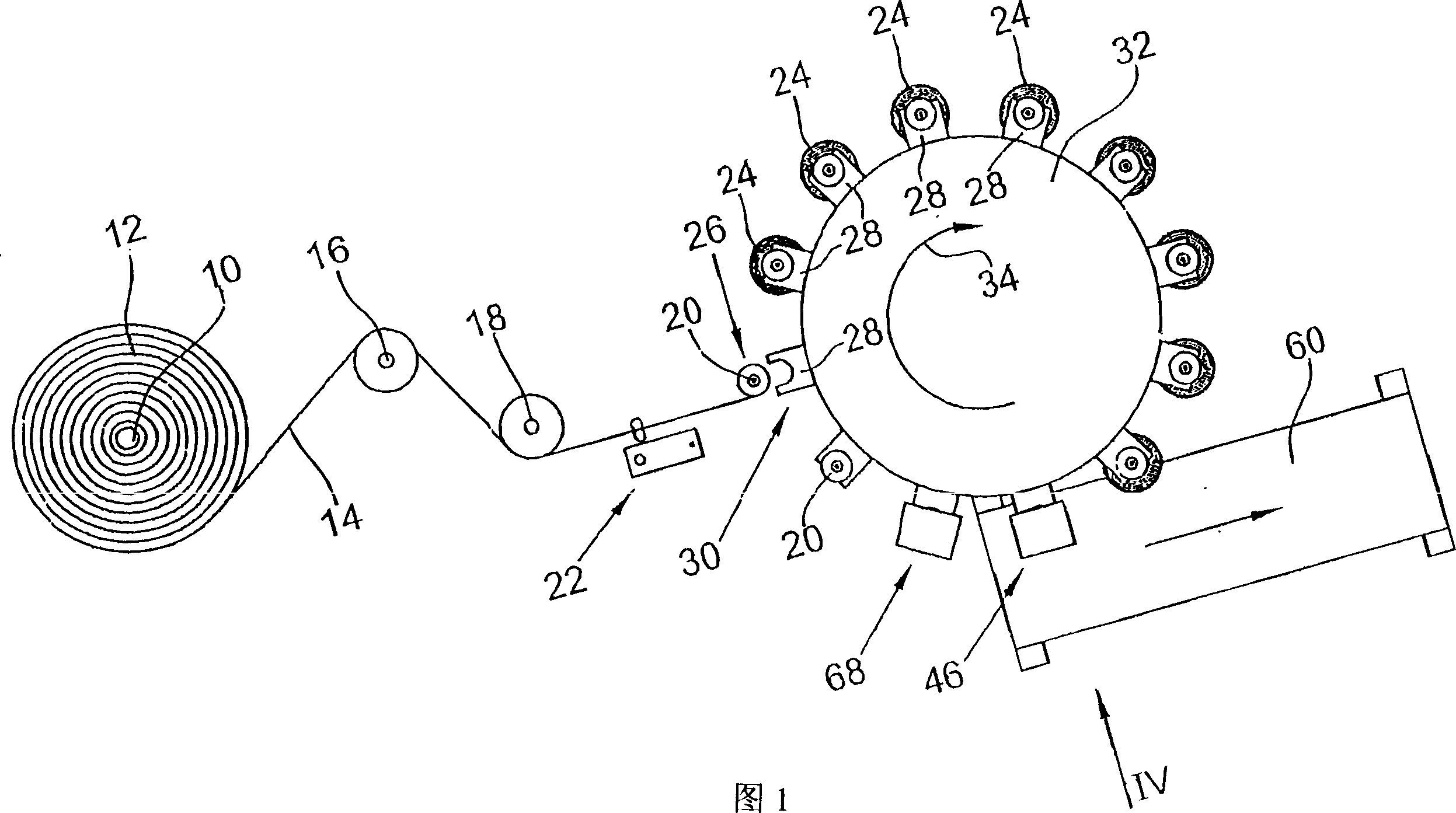

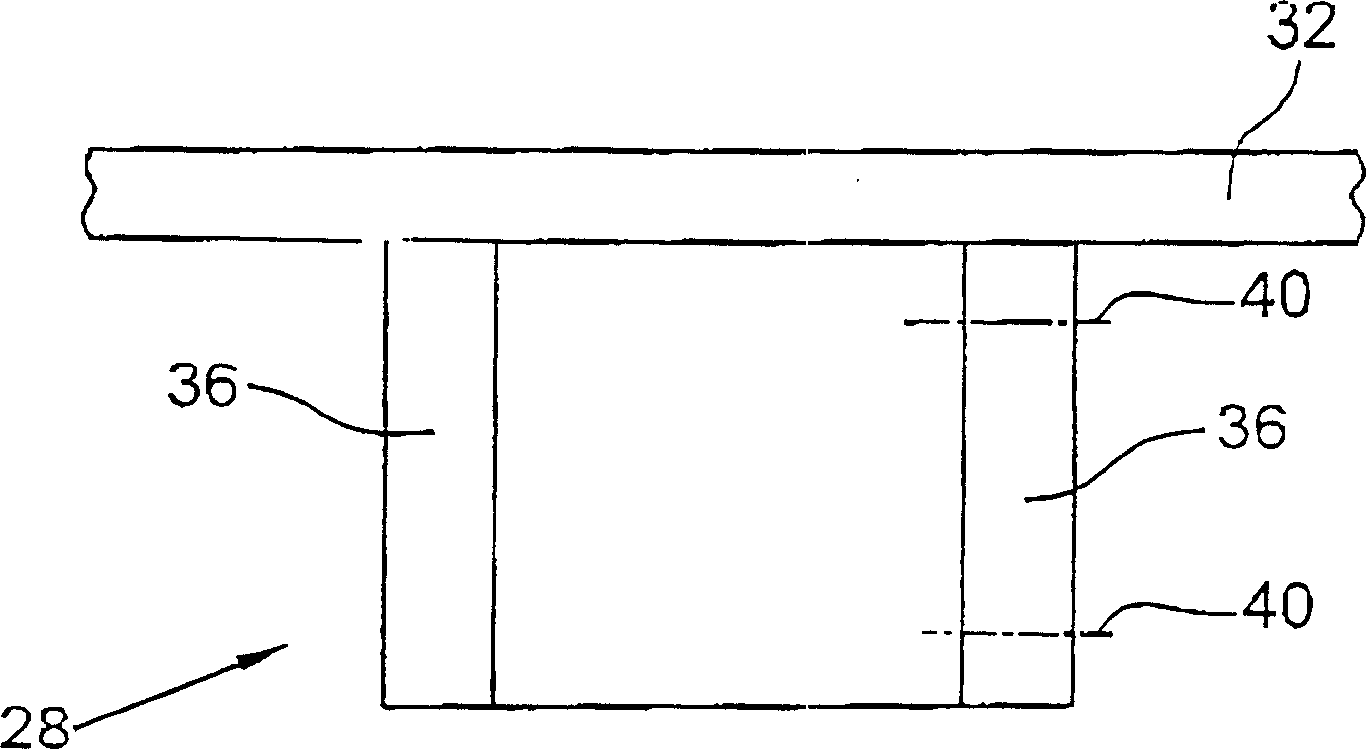

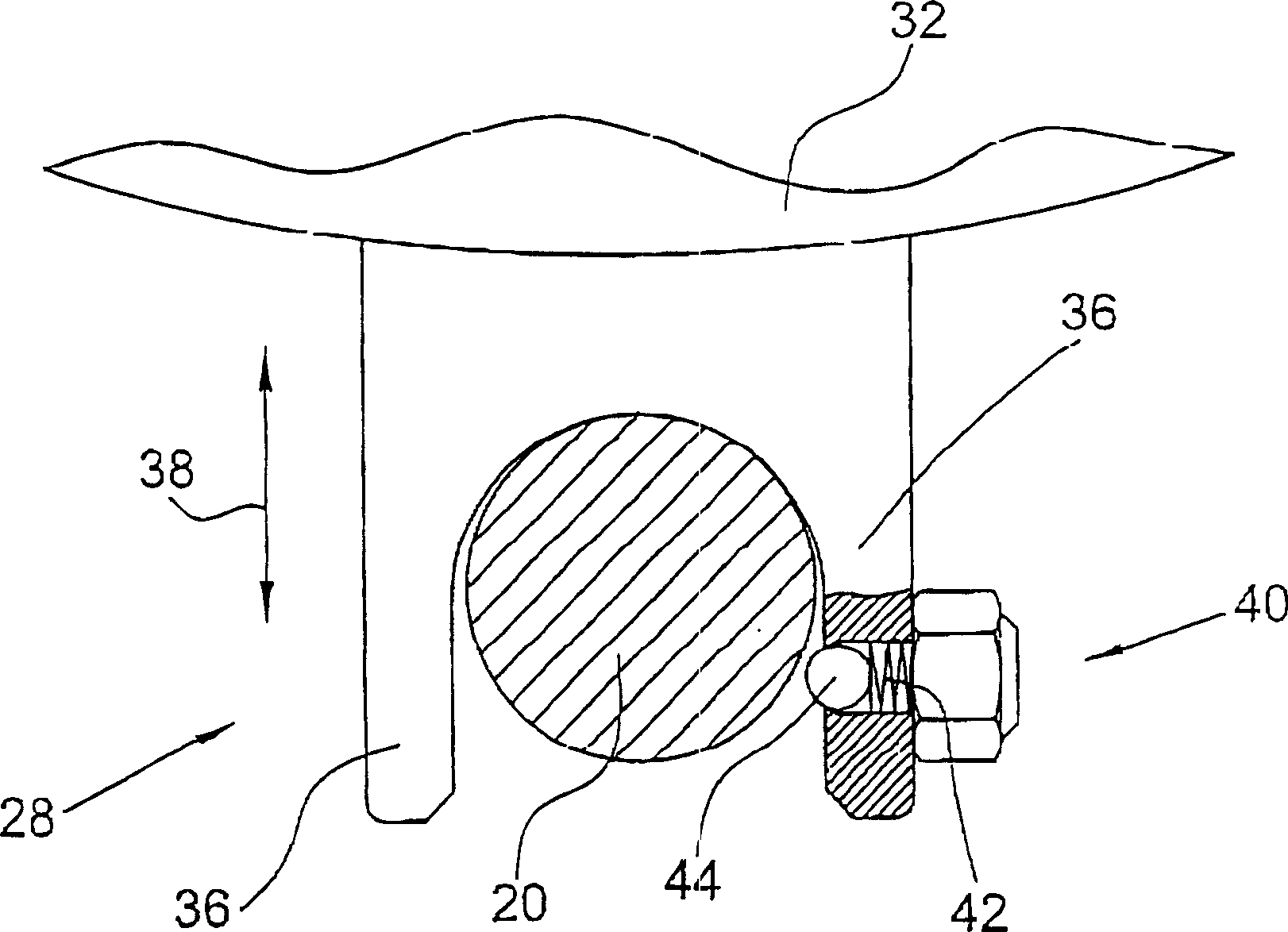

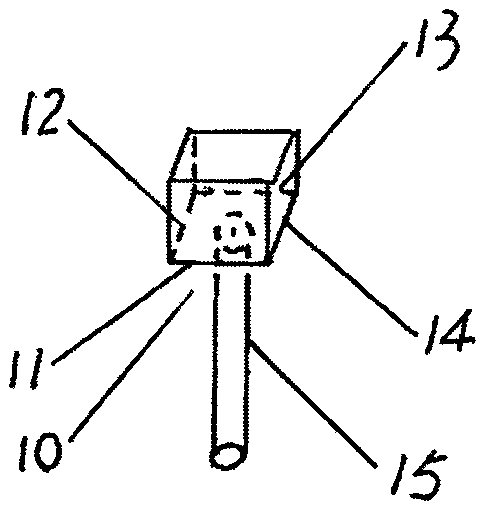

Device for producing foil rolls

InactiveCN1610639AOmit working stepsHigh creativityWebs handlingConductor CoilMechanical engineering

A device for producing film rolls, which is in particular suitable for producing coreless film rolls, comprises a roll holder for receiving a film roll comprising a film sheet to be wound off. The film sheet is wound up to a winding mandrel for producing the preferably coreless film roll. For producing in particular a coreless film roll the winding mandrel comprises a plurality of radially displaceable holding segments extending in longitudinal direction of the winding mandrel. After transfer of the winding mandrel, together with the wound-up film roll, to a transport means, the winding mandrel is transported to a delivery station. The delivery station serving for automatically delivering the wound-up film roll from the winding mandrel comprises a displacement means with the aid of which the holding elements of the winding mandrel are displaced into a delivery position. In this delivery position the outer diameter of the winding mandrel is smaller such that the film roll is delivered from the winding mandrel and falls onto a transport belt.

Owner:ILLINOIS TOOL WORKS INC

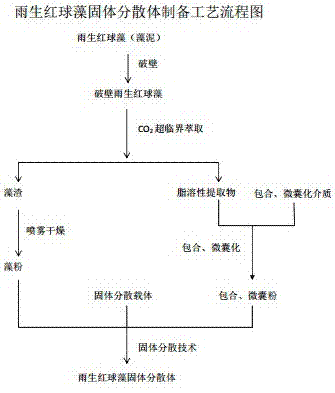

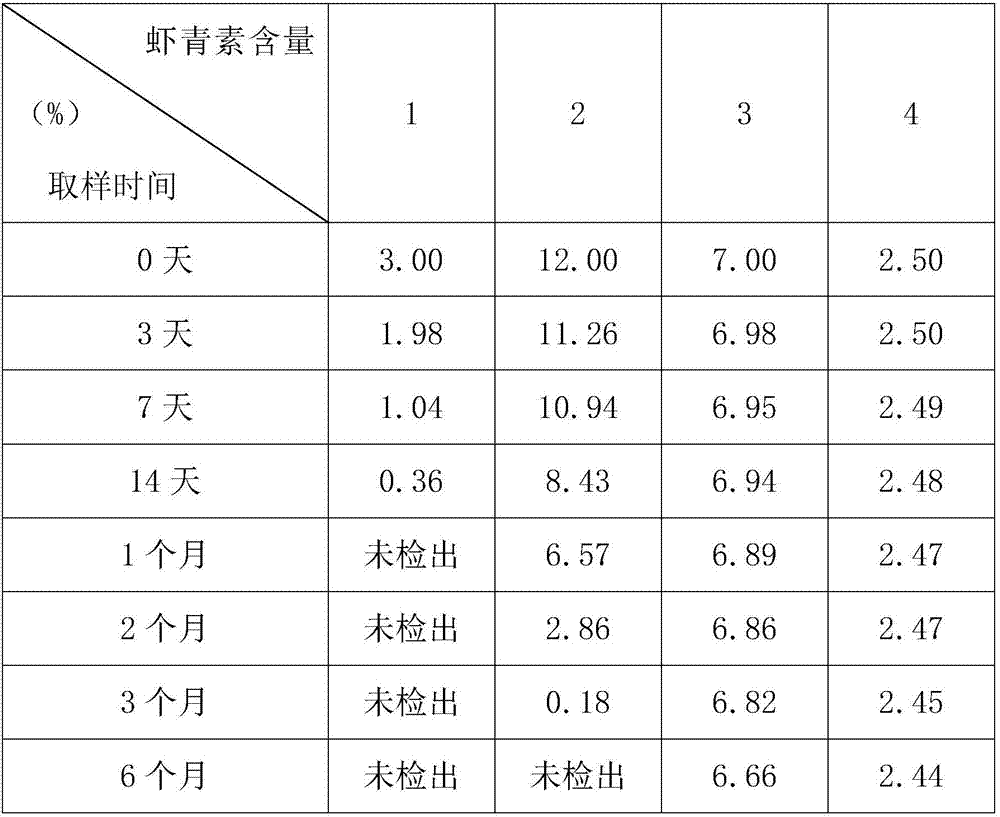

Haematococcus pluvialis solid dispersion, and preparation method and applications thereof

InactiveCN106913589AComprehensive Research ApplicationMaximize research applicationPowder deliverySenses disorderHaematococcus pluvialis extractBetaxanthins

The invention provides a haematococcus pluvialis solid dispersion, and a preparation method and applications thereof. The provided haematococcus pluvialis solid dispersion is composed of three phases namely dry algae residues prepared by subjecting haematococcus pluvialis to CO2 supercritical extraction, microencapsulated powder prepared by subjecting the haematococcus pluvialis extract obtained by CO2 supercritical extraction to microencapsulation, and a solid dispersion carrier. The invention also provides a preparation method and applications of the haematococcus pluvialis solid dispersion. The experiment results show that the astaxanthin stability, bioavailability, and anti-oxidation activity of the haematococcus pluvialis solid dispersion are obviously better than those of the cell-wall-broken haematococcus pluvialis, CO2 supercritical extract, and microencapsulated powder prepared by subjecting the CO2 supercritical extraction extract to microencapsulation.

Owner:YUNNAN DECAITANG BIOMEDICAL TECH

Waste recycling process for automobile disassembling

ActiveCN108856243AAchieve rust removal effectImprove qualitySolid waste disposalDrying gas arrangementsEngineeringWaste recycling

The invention discloses a waste recycling process for automobile disassembling. A fixed base is included, a fourth supporting column is fixedly connected to the left side of the top of the fixed base,a breaking box is fixedly connected to the top of the fourth supporting column, the top of the breaking box communicates with a feeding baffle, the left side of the breaking box is fixedly connectedwith a fixed block, and the top of the fixed block is fixedly connected with a second motor. Through cooperative use of a first motor, a rust removal box, a rust remover storage box, a water pump, spraying holes, rotary nozzles, an inner ball pipe, a rotating groove, an outer ball pipe, a hard connecting pipe, a second gear and a fourth gear, the waste rust removal effect is achieved, rust on thewaste surface can be removed thoroughly, the condition that during recasting, the iron reduces the quality of the waste after recasting is avoided, the waste quality after recasting can be greatly improved, the application field of the waste after recasting is widened, the process creativeness is enhanced, the waste utilization rate is improved, and the process is suitable for being used and popularized.

Owner:广东拓展资源综合利用开发有限公司

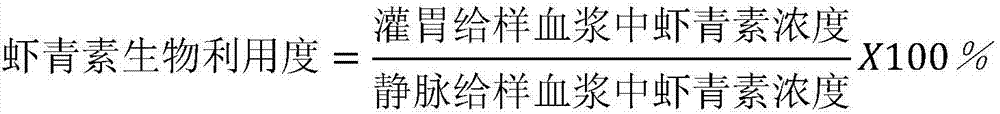

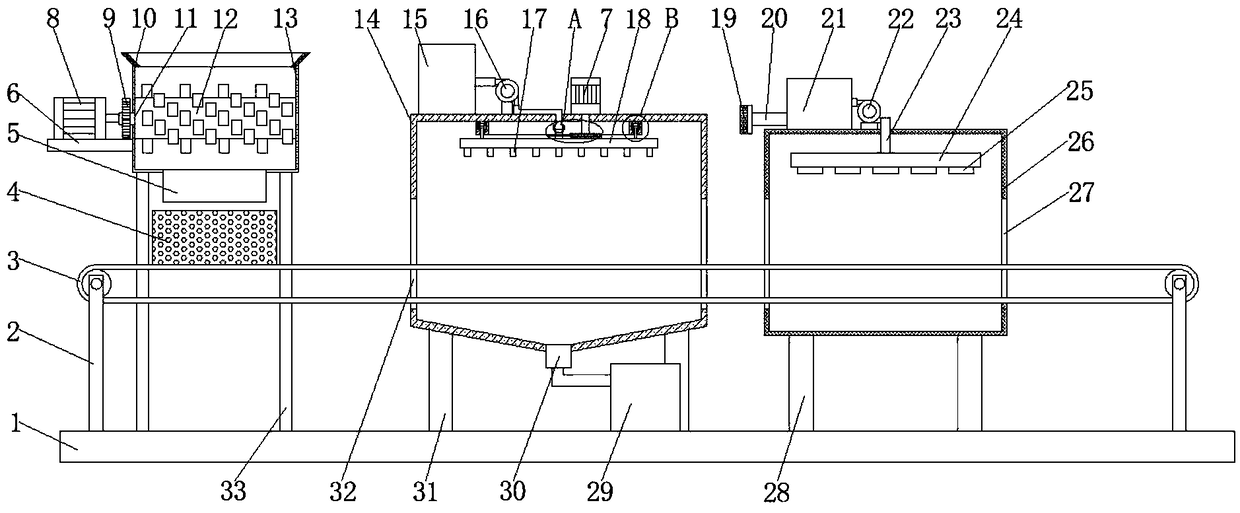

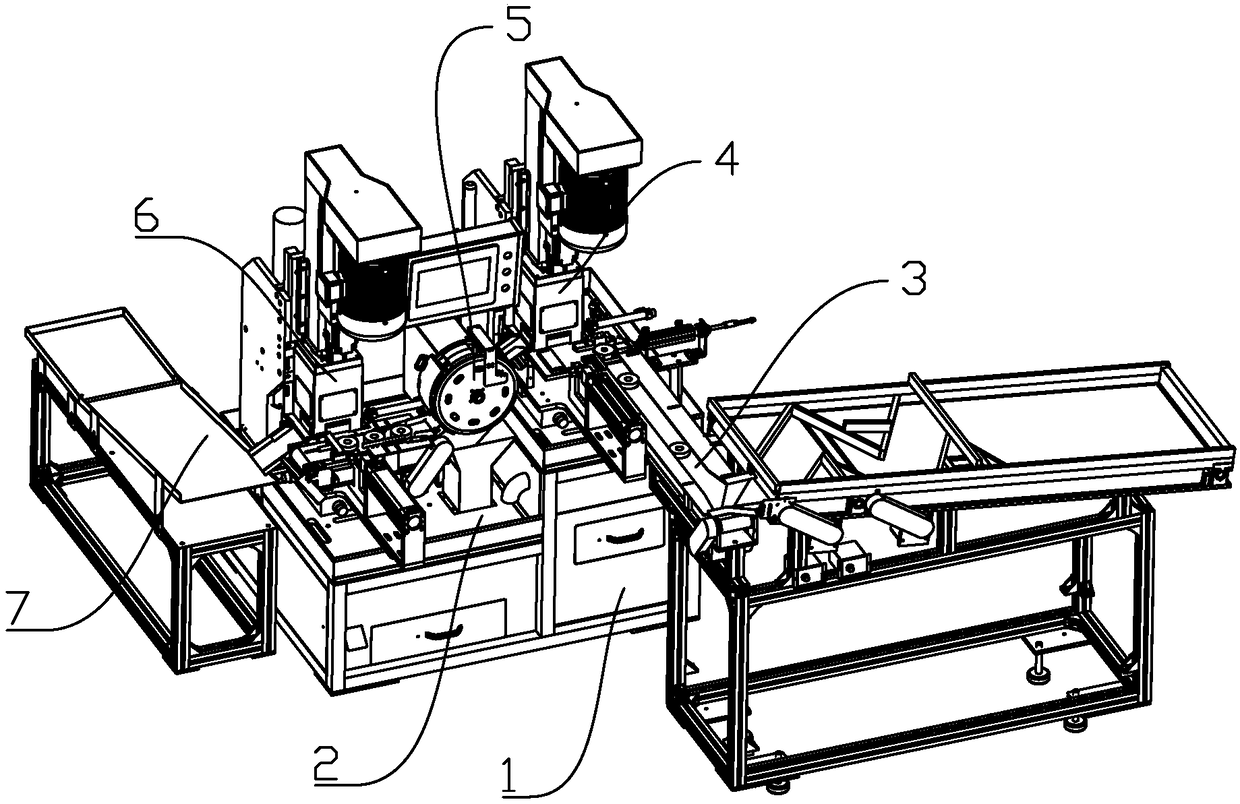

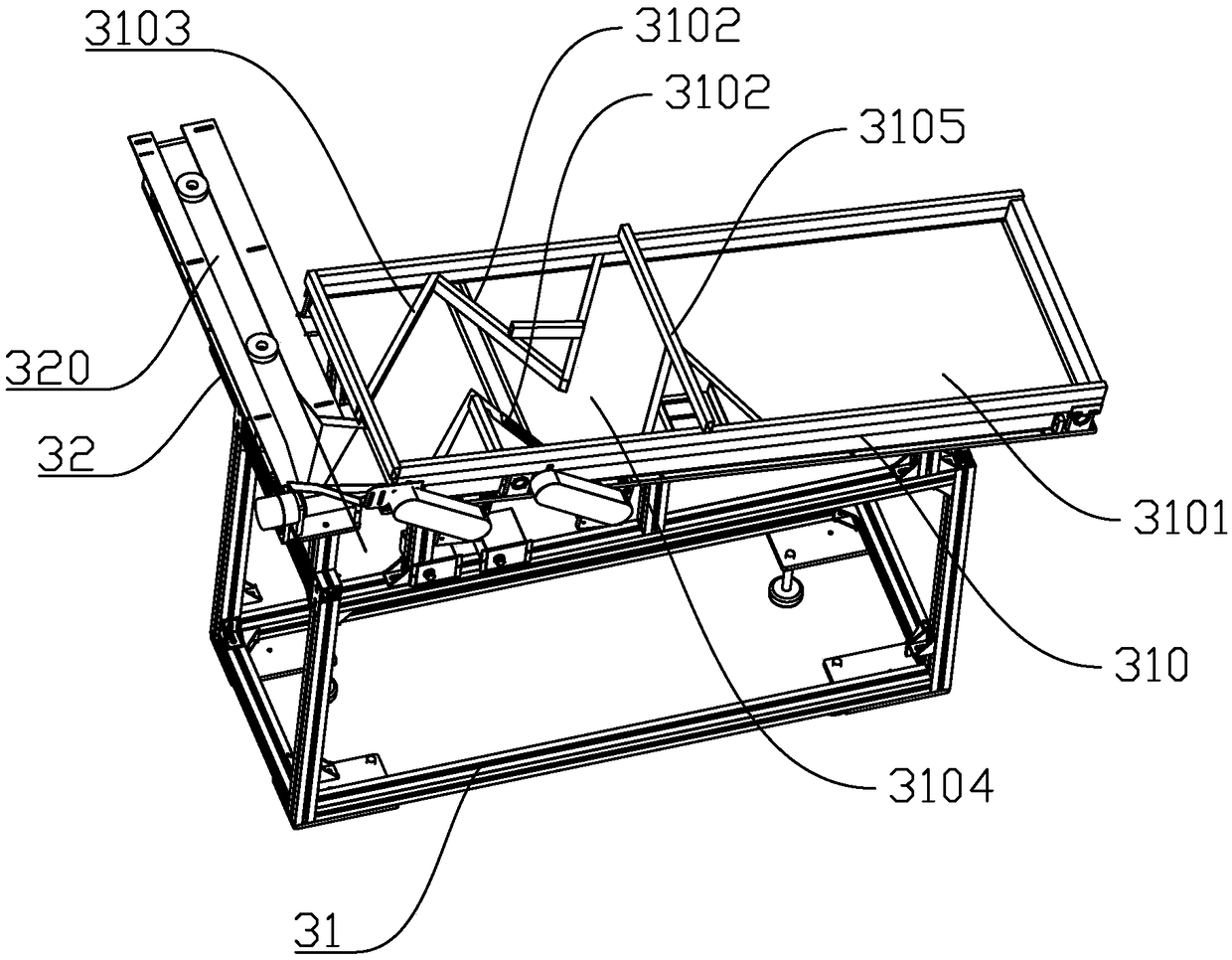

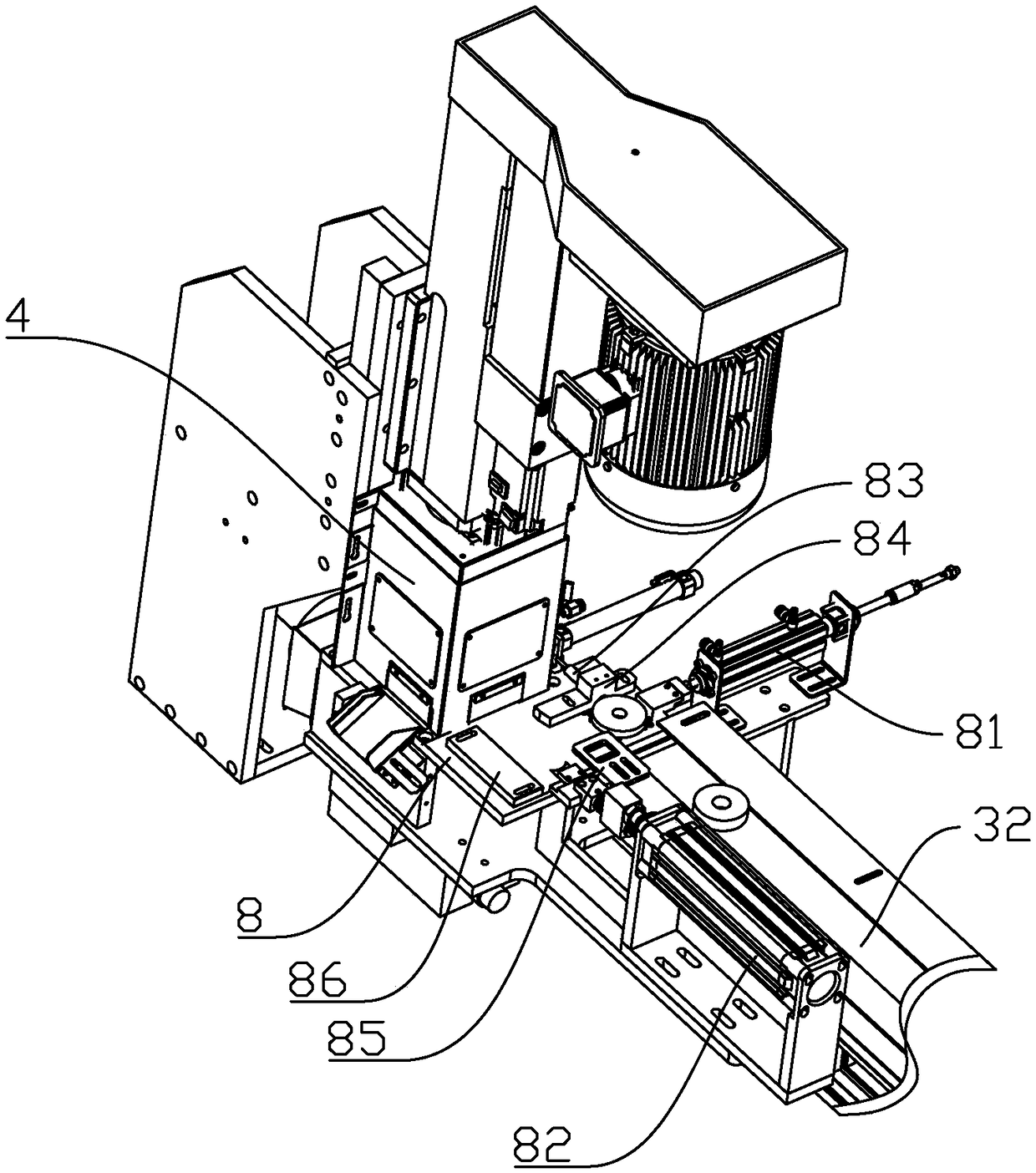

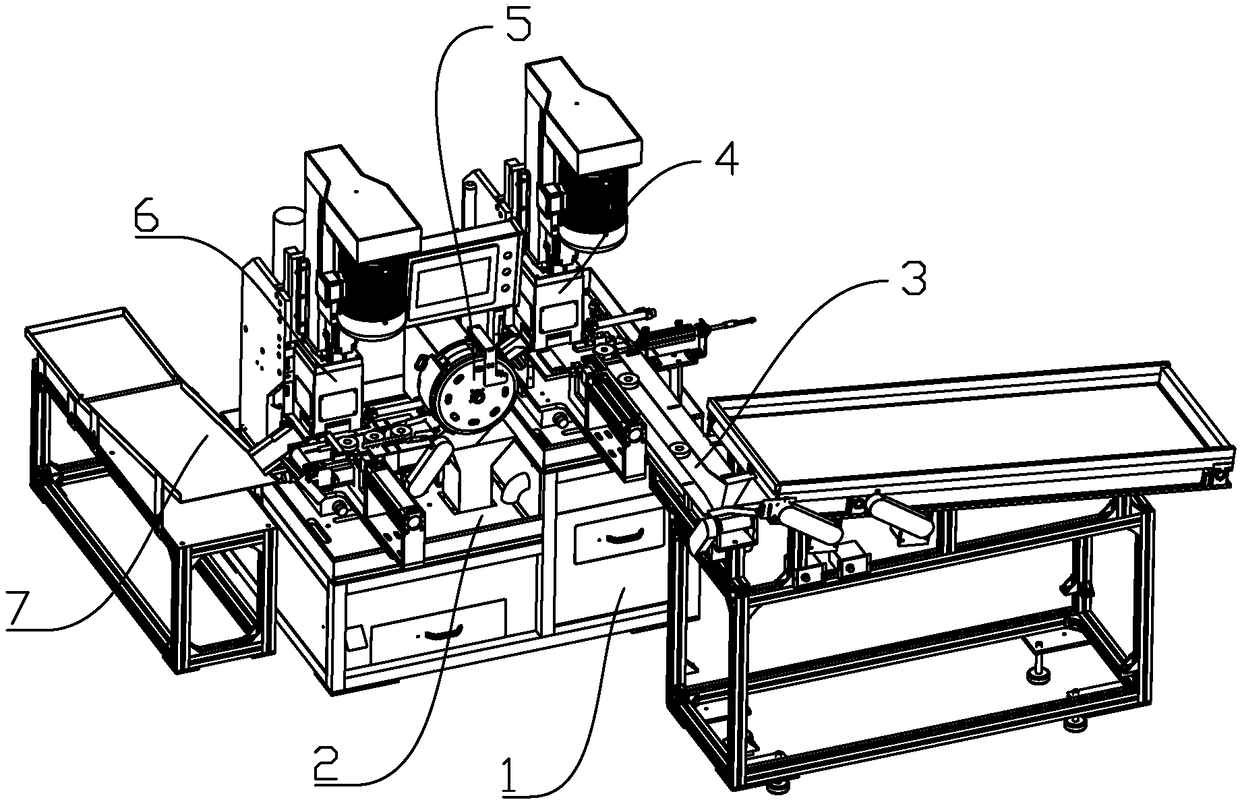

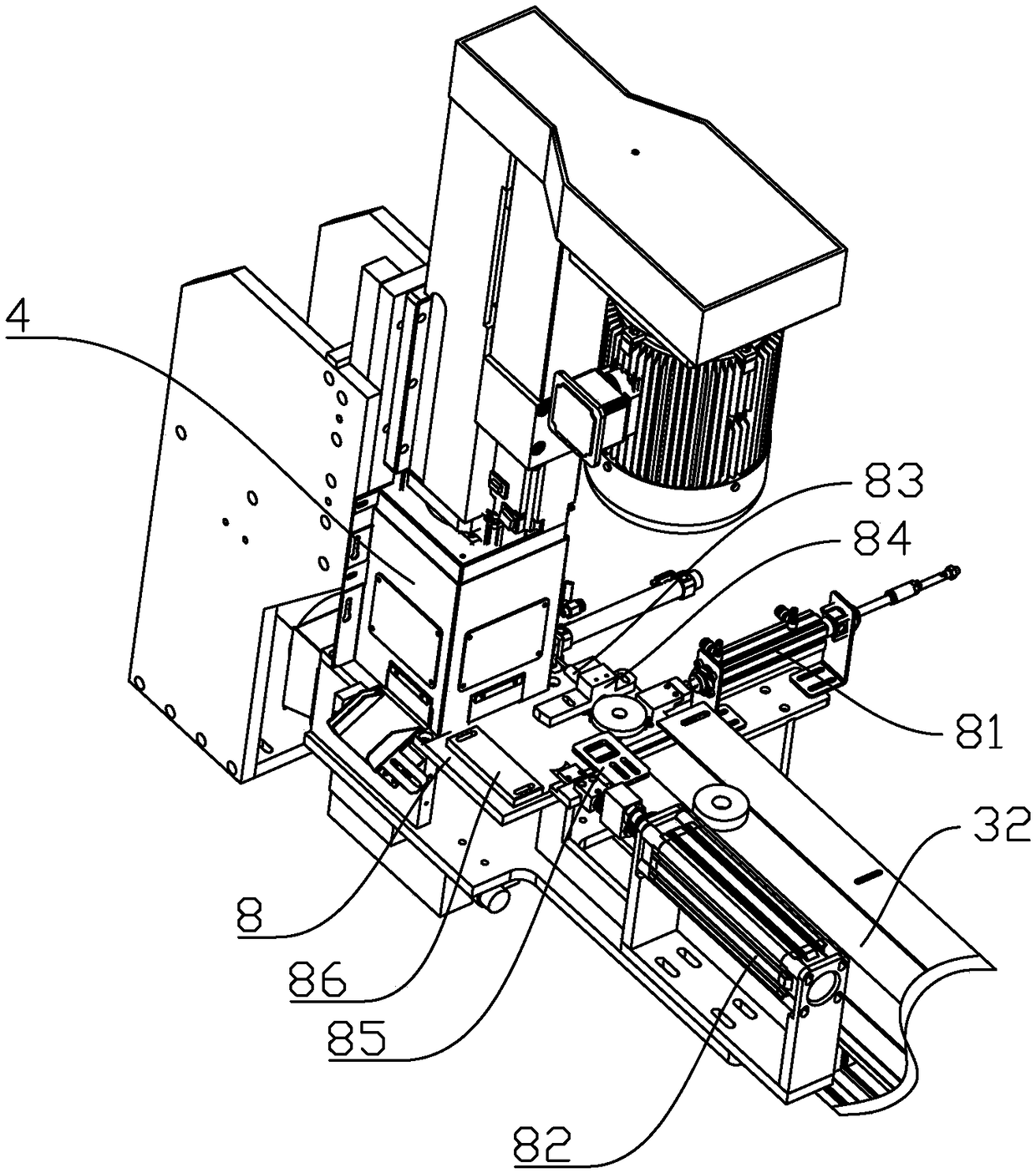

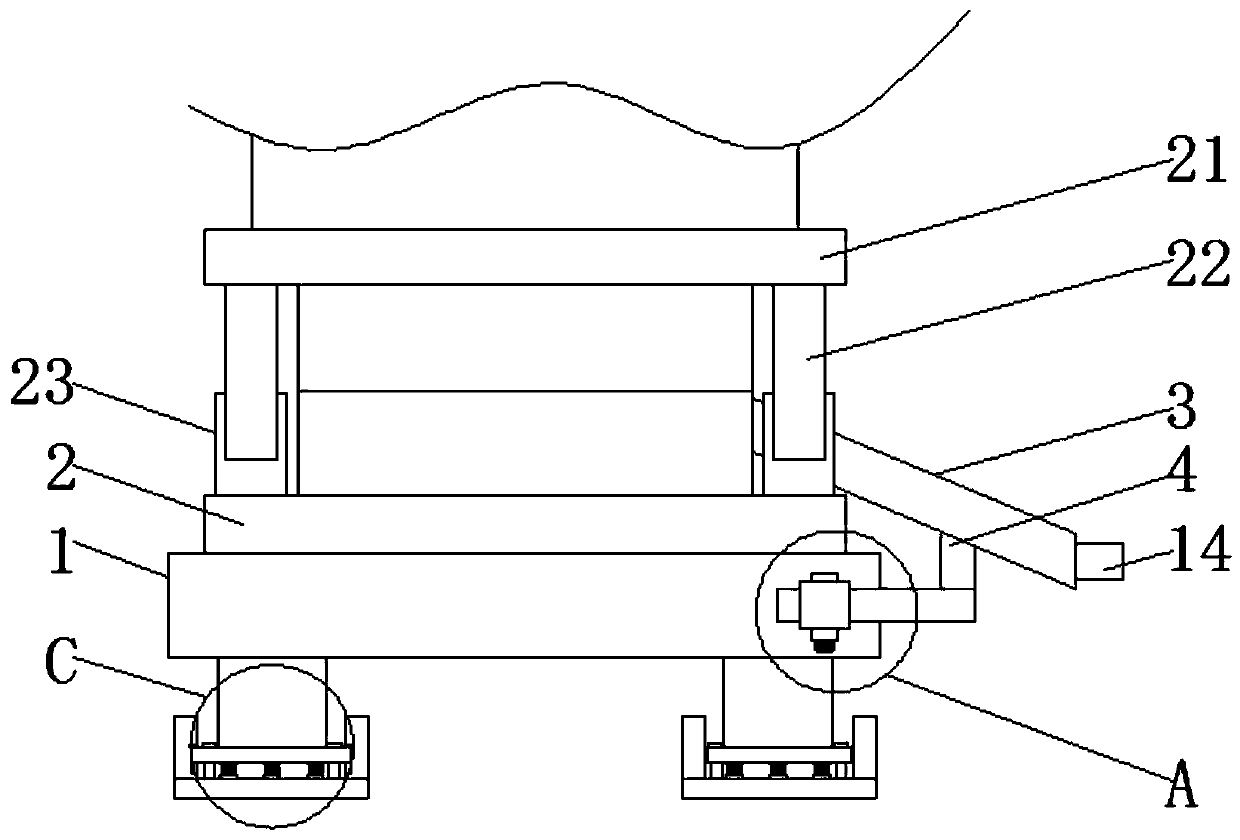

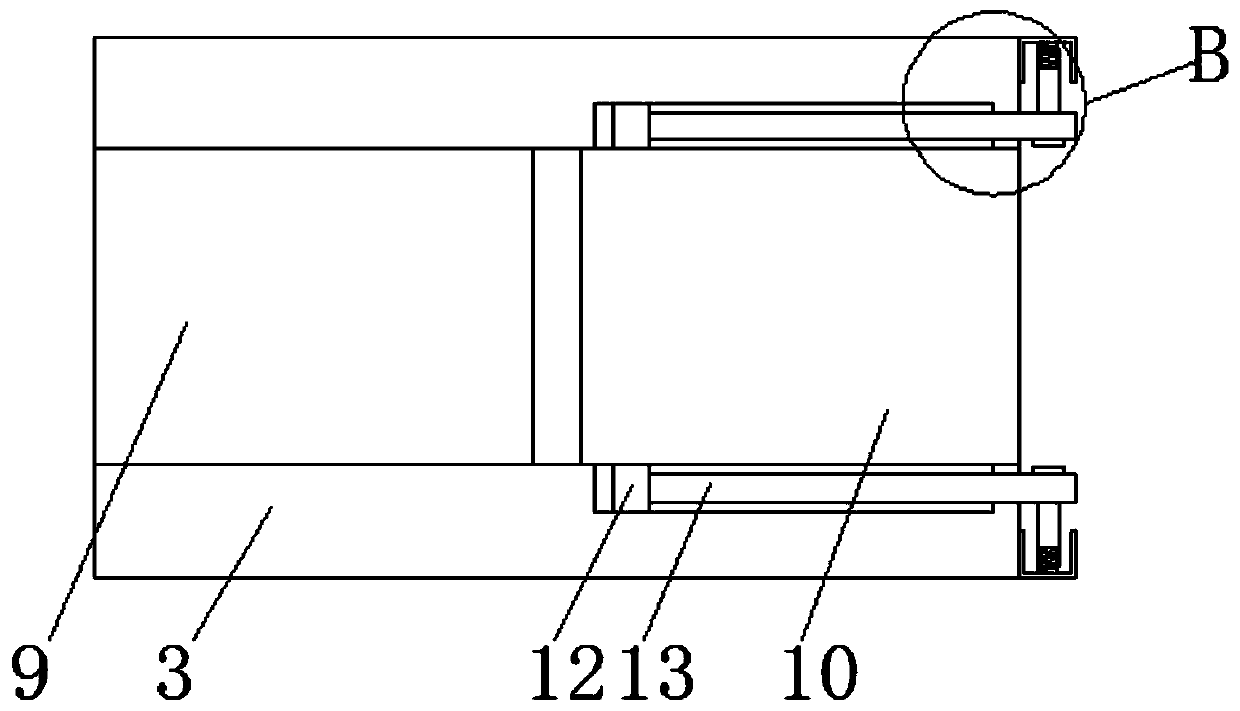

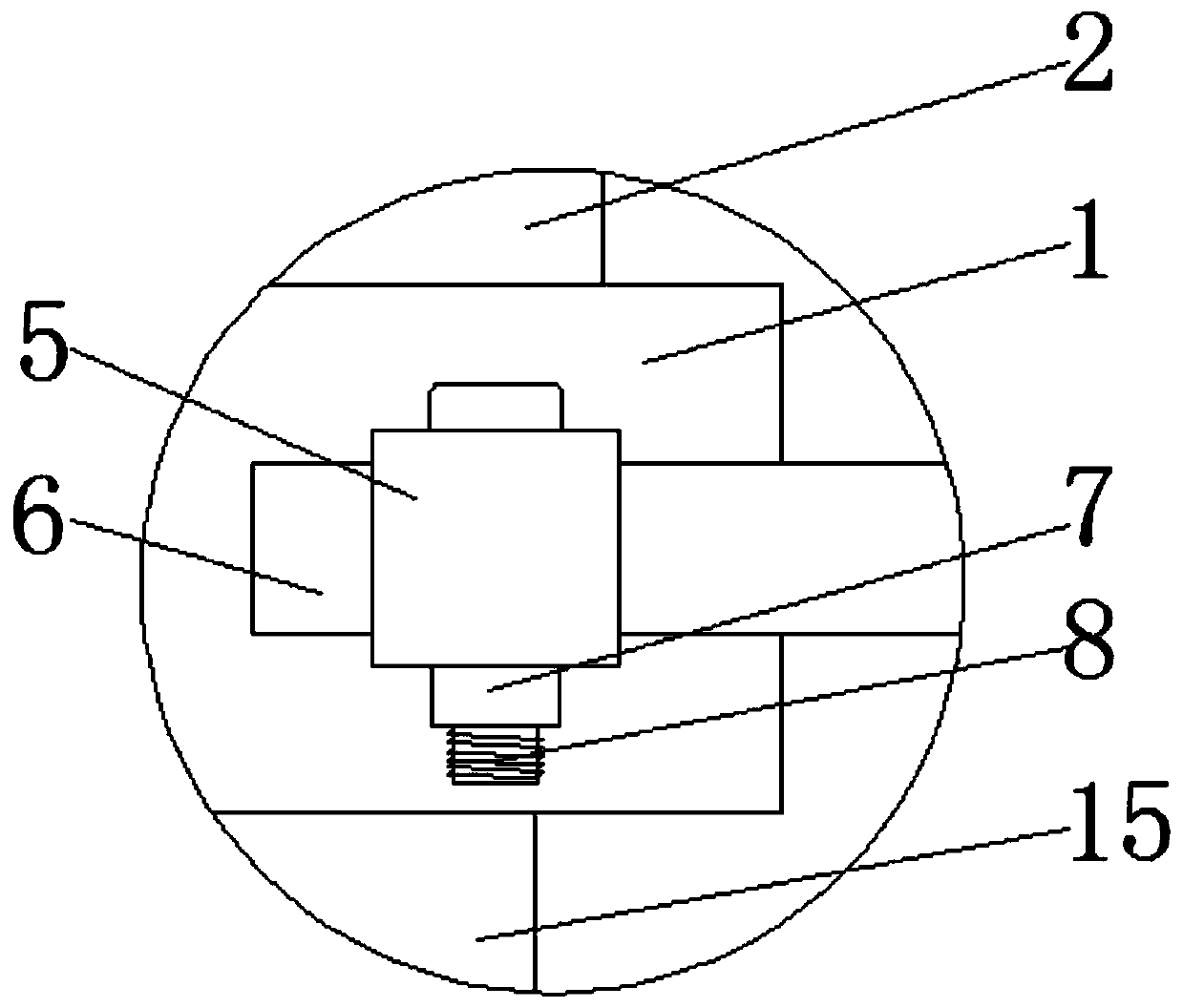

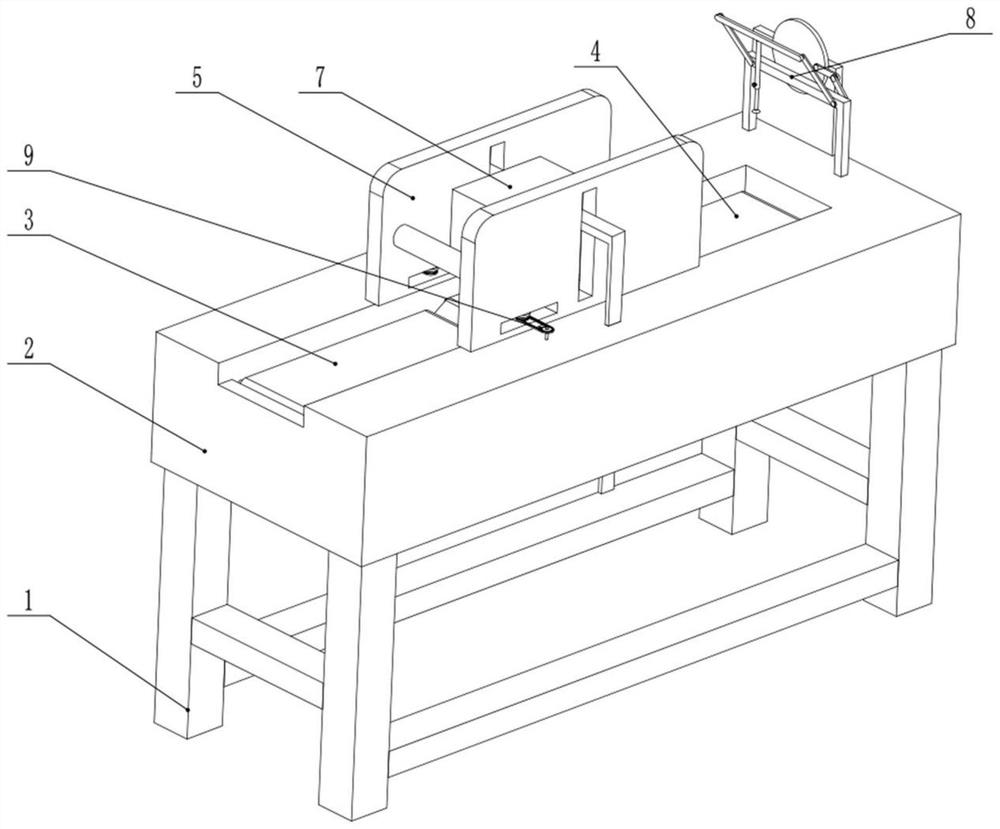

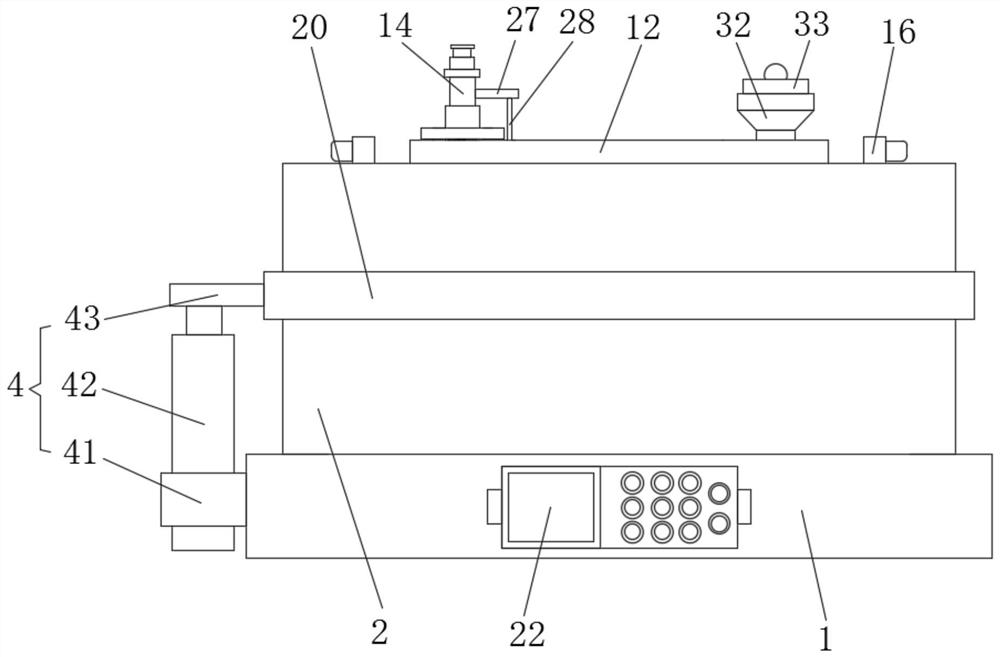

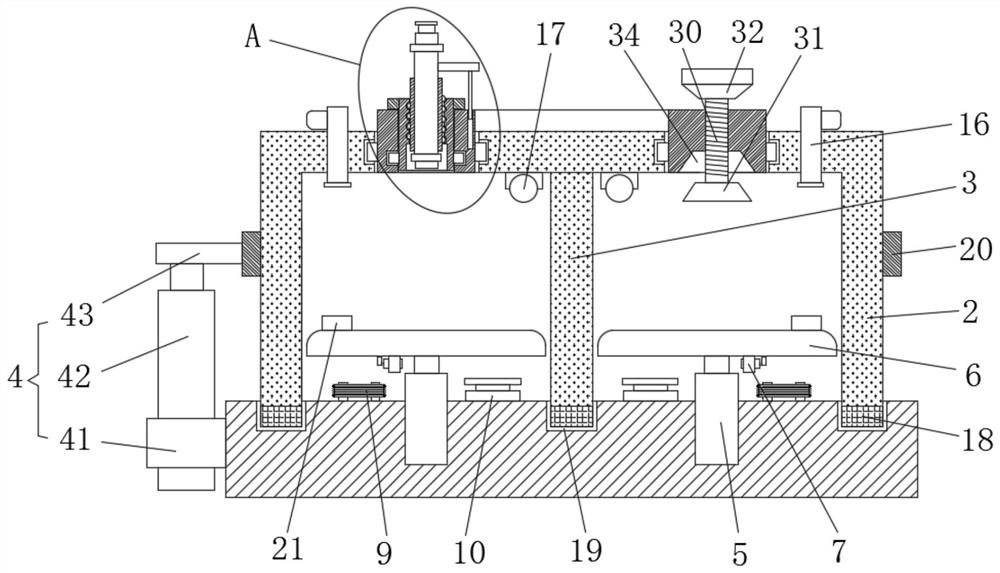

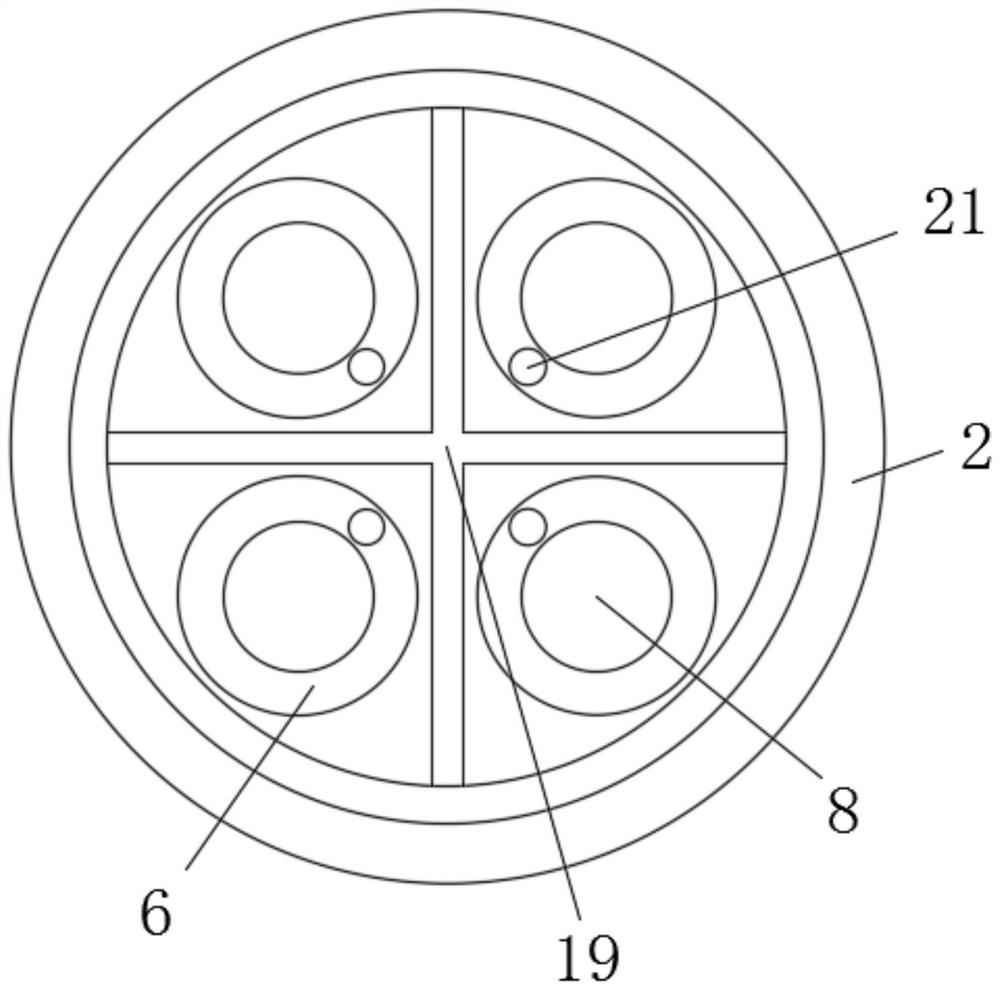

Fully-automatic magnetic ring chamfering-grinding equipment capable of carrying out dust removal on magnetic ring

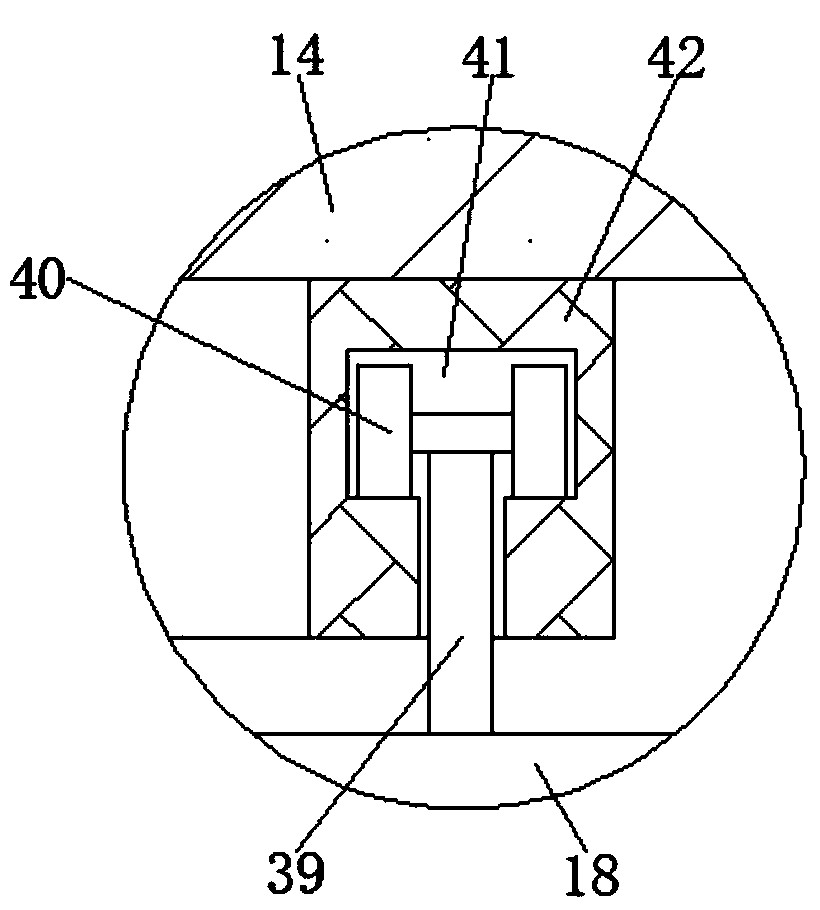

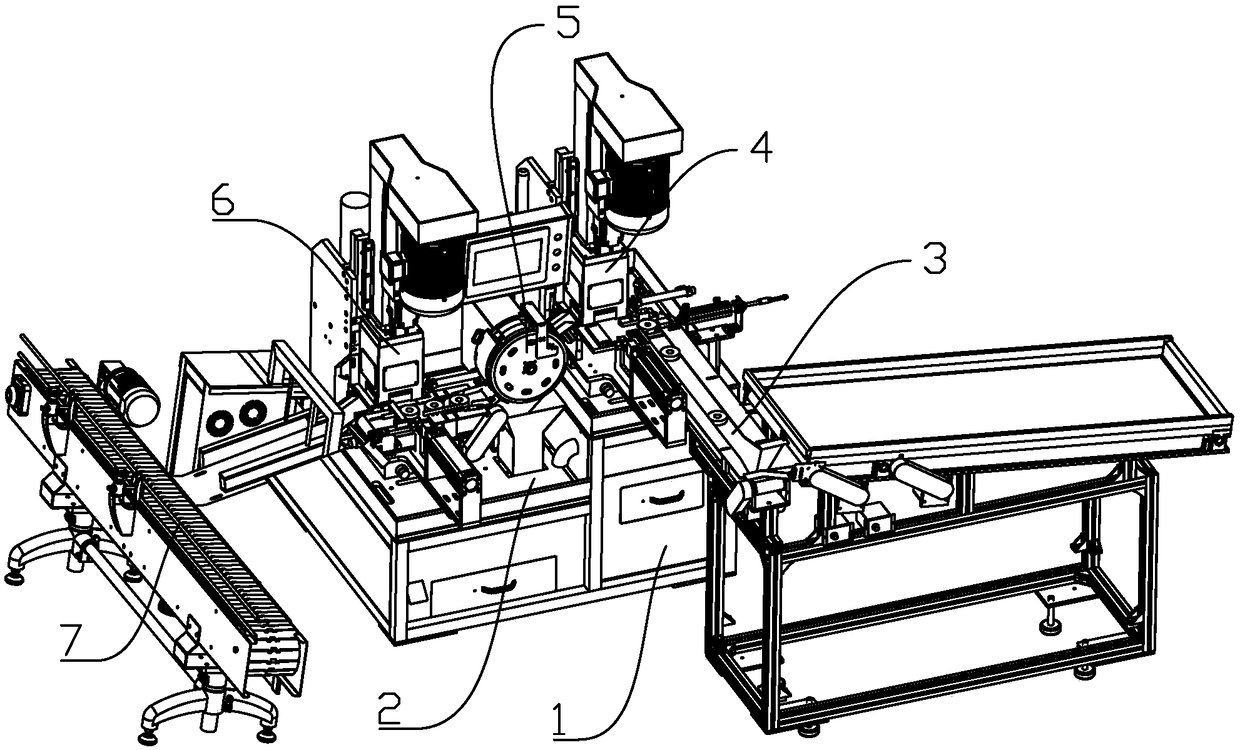

ActiveCN109304650AAchieve finishingImprove consistencyEdge grinding machinesGrinding carriagesEngineeringFully automatic

The invention discloses fully-automatic magnetic ring chamfering-grinding equipment capable of carrying out dust removal on a magnetic ring. The fully-automatic magnetic ring chamfering-grinding equipment comprises a seat, a loading mechanism, a first grinding mechanism, an overturning mechanism, a second grinding mechanism and an unloading mechanism, wherein each of the first grinding mechanism and the second grinding mechanism comprises a chamfering head assembly and a push-out assembly, each chamfering head assembly comprises a main shaft motor, a main shaft support, a power head and a chamfering disc, each main shaft motor is connected with the corresponding chamfering disc through the corresponding power head, each chamfering disc is provided with two chamfering tool installation blocks, through holes are formed in each two chamfering tool installation blocks, each chamfering disc is provided with a cross hole, and each two chamfering tool installation blocks correspond to the inner rings and the outer rings of the magnetic ring in position separately, and fixed by virtue of screws; a limit block is arranged below each chamfering head assembly, and the section of each limit block is lower than the magnetic ring; and each push-out assembly comprises a push-out cylinder and a push-out block. The fully-automatic magnetic ring chamfering-grinding equipment has the following advantages and effects: chamfering-grinding can be carried out on the inner rings and the outer rings of the two end surfaces of the magnetic ring separately, the labor is much saved, and the productionefficiency is increased.

Owner:WENZHOU POLYTECHNIC

Full-automatic magnetic ring chamfering grinding equipment for continuously conveying magnetic rings

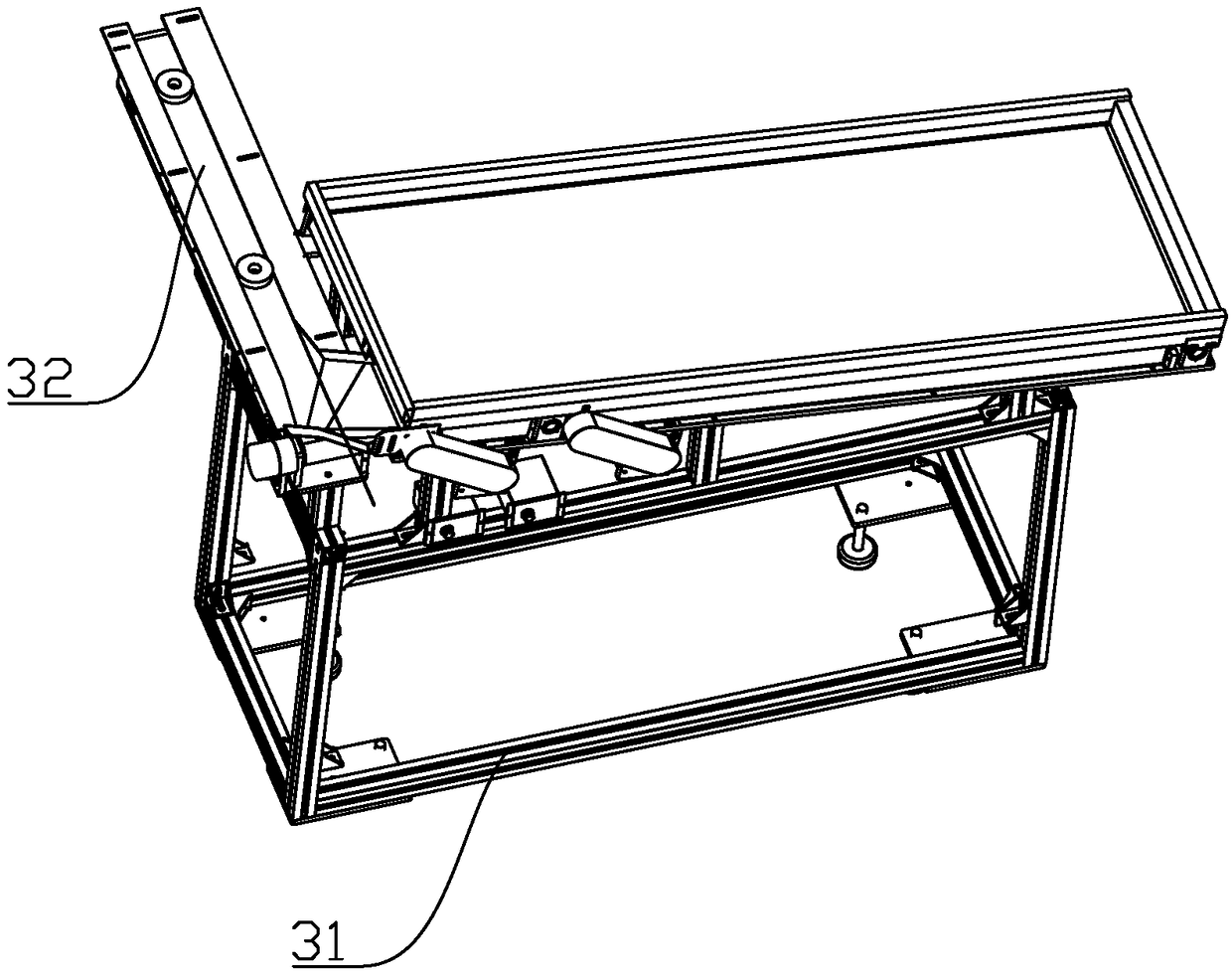

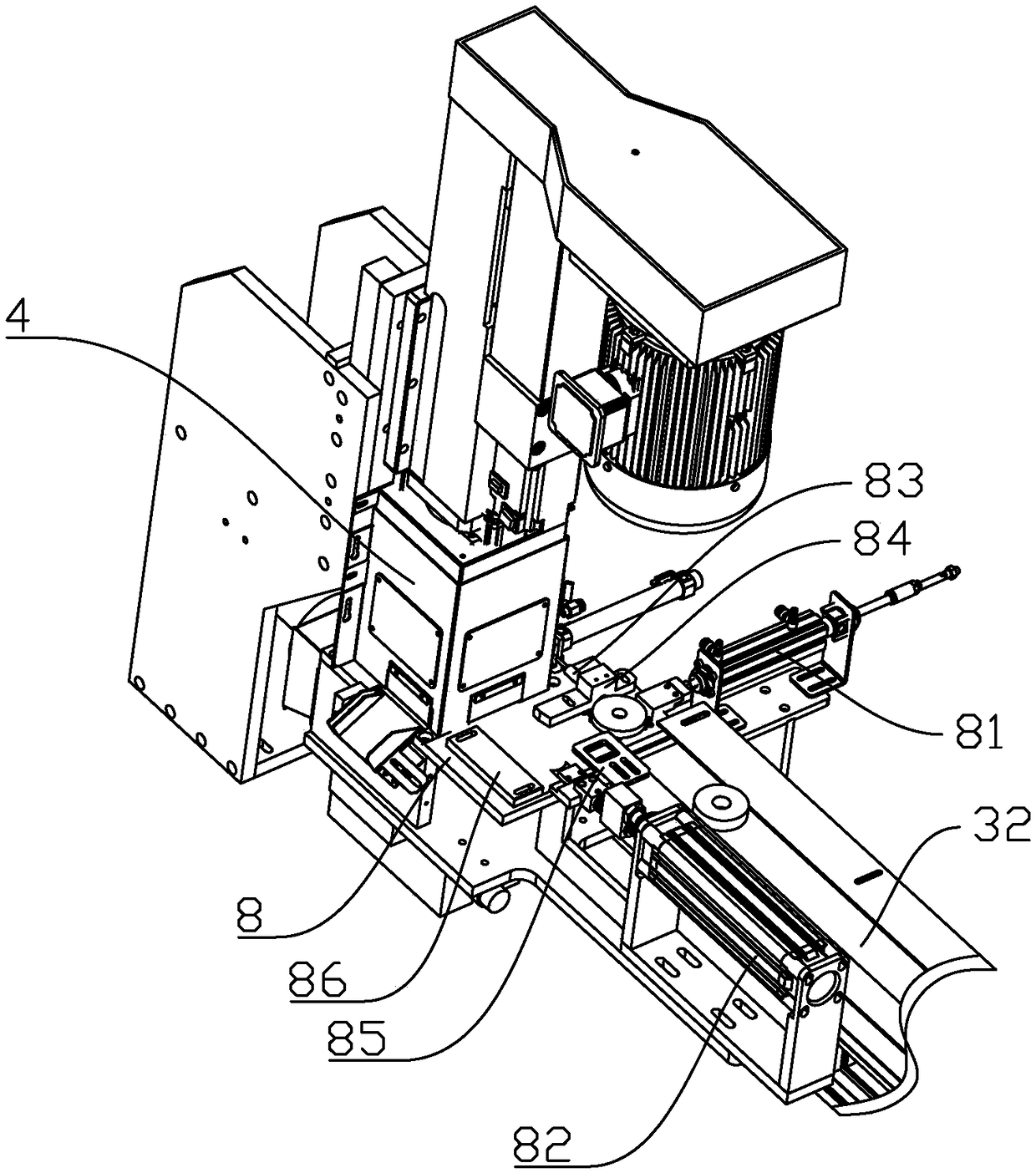

ActiveCN109396555AAchieve finishingImprove consistencyEngineeringElectrical and Electronics engineering

The invention discloses full-automatic magnetic ring chamfering grinding equipment for continuously conveying the magnetic rings. The full-automatic magnetic ring chamfering grinding equipment comprises a base, a feeding mechanism, a first grinding mechanism, an overturning mechanism, a second grinding mechanism and a discharging mechanism, wherein the first grinding mechanism and the second grinding mechanism both comprise a chamfering head assembly and a pushing-out assembly, the chamfering head assembly comprises a main shaft motor, a main shaft support, a power head and a chamfering disc,the main shaft motor is connected with the chamfering disc through the power head, the chamfering disc is provided with two chamfering tool mounting blocks, through holes are formed in the two chamfering tool mounting blocks, a transverse hole is formed in the chamfering disc, the two chamfering tool mounting blocks are connected the positions of the inner ring and the outer ring of the magnetic ring correspond to each other respectively and are fixed by screws; a limiting block is arranged below the chamfering head assembly, the height of the cross section of the limiting block is lower thanthat of the magnetic ring; and the pushing-out assembly comprises a pushing-out air cylinder and a pushing-out block. The full-automatic magnetic ring chamfering grinding equipment has the following advantages and effects that the inner ring and the outer ring of the two end surfaces of the magnetic ring can be subjected to chamfering and grinding, labor is saved, and production efficiency is improved.

Owner:WENZHOU POLYTECHNIC

Full-automatic magnetic chamfering grinding device

ActiveCN109396556AAchieve finishingImprove consistencyElectrical and Electronics engineeringPush out

The invention discloses a full-automatic magnetic ring chamfering grinding device. The grinding device comprises a base, a feeding mechanism, a first grinding mechanism, a turnover mechanism, a secondgrinding mechanism and a discharging mechanism, wherein both the first grinding mechanism and the second grinding mechanism comprise chamfering head assemblies and pushing-out assemblies, each chamfering head assembly comprises a main shaft motor, a main shaft support, a power head and a chamfering disc, the main shaft motor is connected with the chamfering disc through the power head, the chamfering disc is provided with two chamfering tool mounting blocks, through holes are formed in the two chamfering tool mounting blocks, a transverse hole is formed in the chamfering disc, the two chamfering tool mounting blocks are matched with the positions of the inner ring and the outer ring of the magnetic ring respectively and are fixed by screws, a limiting block is arranged below the chamfering head assembly, and the cross section height of the limiting block is lower than the magnetic ring; the push-out assembly comprises a push-out air cylinder and a push-out block which are used to pushout the magnetic ring. The device has the advantages and effects that the inner rings and the outer rings of the two end surfaces of the magnetic ring can be chamfering ground, the labor is saved, and the production efficiency is improved.

Owner:WENZHOU POLYTECHNIC

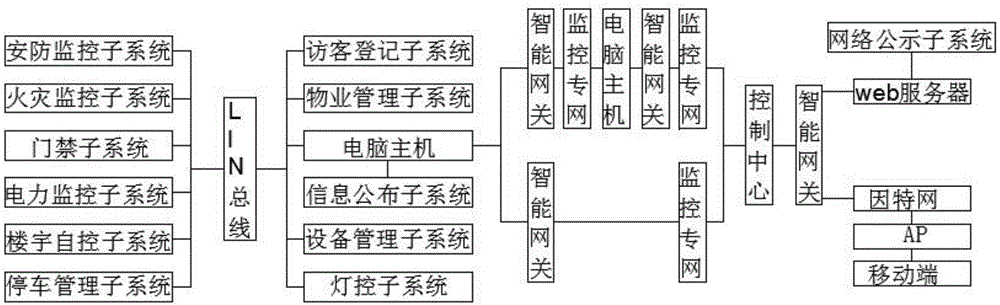

Remote control building intelligent monitoring system

InactiveCN106774189ALow costEasy to operateClosed circuit television systemsTransmissionIntelligent lightingPrivate network

The invention relates to the technical field of intelligent building equipment, and particularly relates to a remote control building intelligent monitoring system which comprises a photovoltaic power supply subsystem, a power monitoring subsystem, a building autonomous control subsystem, a parking management subsystem, a property management subsystem, a visitor registration subsystem, a light control subsystem, a device management subsystem, a network public announcement subsystem, an information publishing subsystem, a web server, an LIN bus, a computer host, a control center, a monitoring private network, AP, an intelligent gateway, Internet and a mobile terminal. According to the invention, photovoltaic power supply is used as energy, which saves cost; power monitoring, building autonomous control, parking management, property management, visitor registration, equipment management and other building residential district modules are under centralized control; the system can be remotely connected with the mobile terminal; the web server is used to publicize data online, which is convenient; and the system has the advantages of remote intelligent control, high security performance, complete function, convenient operation and great creativity.

Owner:NORTH CHINA INST OF SCI & TECH

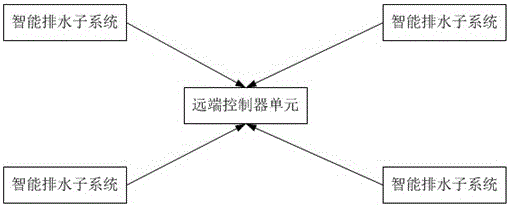

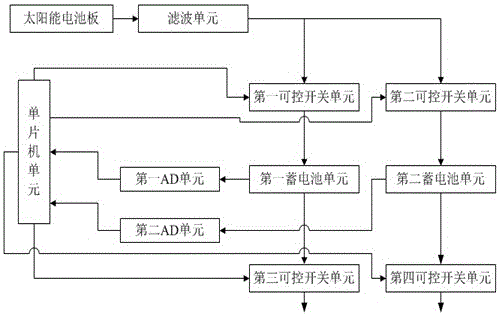

IoT based urban road drainage system

InactiveCN105908821AHigh strengthGuaranteed flexibilityBatteries circuit arrangementsElectric powerCommunication unitWater flow

The invention discloses an IoT based urban road drainage system. The system includes a plurality of intelligent drainage sub systems and a remote controller unit. The intelligent drainage sub systems are in communication with the remote controller unit through a wireless communication unit. The intelligent drainage sub systems include road faces, sewer wells and drainage well covers, wherein the drainage well covers are arranged on the upper ends of the sewer wells and the sewer wells are arranged below the road faces. The intelligent drainage sub systems also include motors, pressure sensor units, controller units, wireless communication units and GPS positioning modules. The invention can increase water flow volume of the sewer well covers substantially.

Owner:LAIAN COUNTY XINYUAN MECHANICAL & ELECTRICAL EQUIP

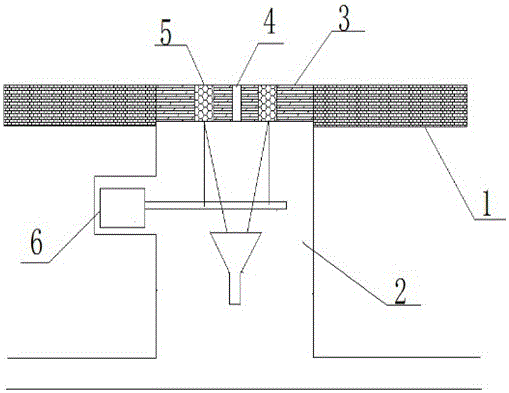

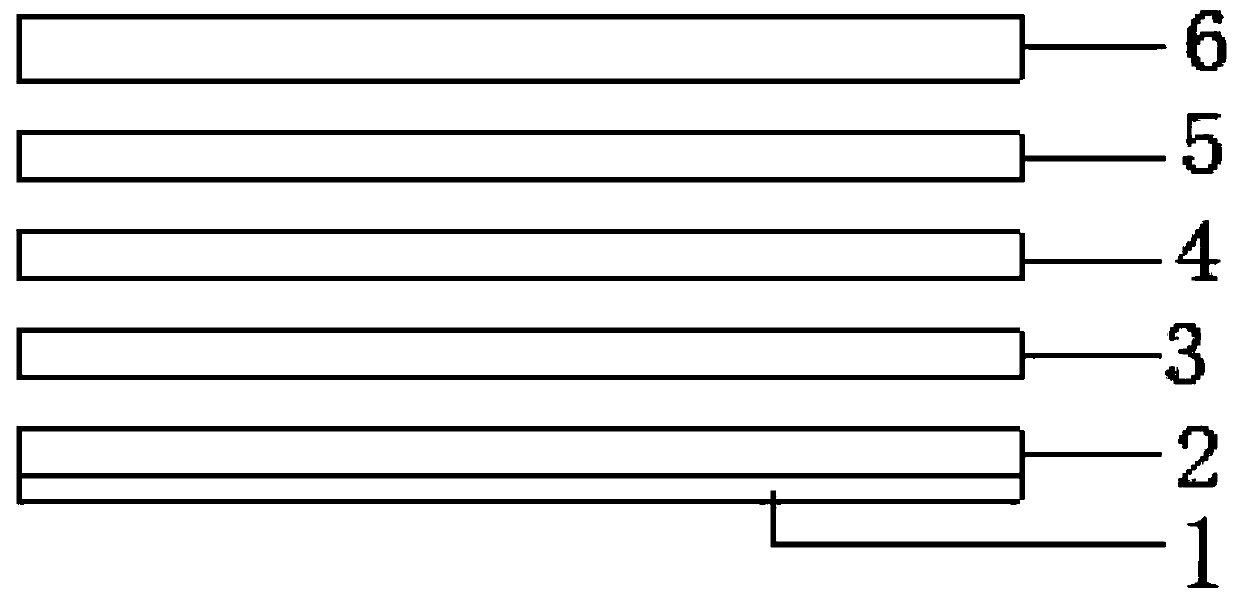

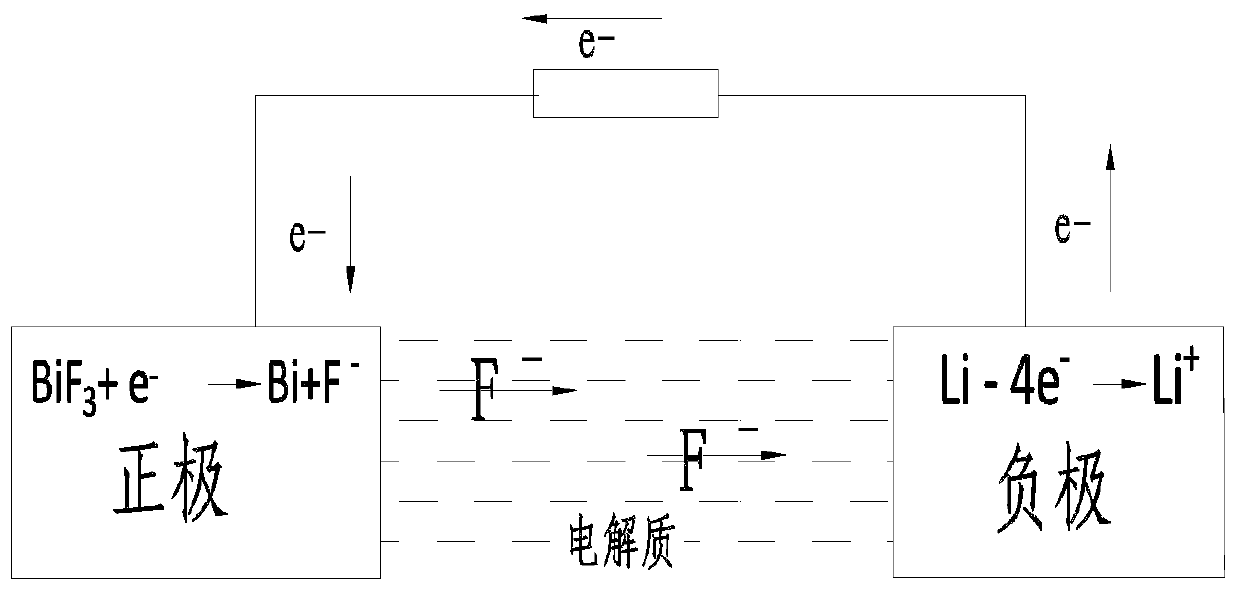

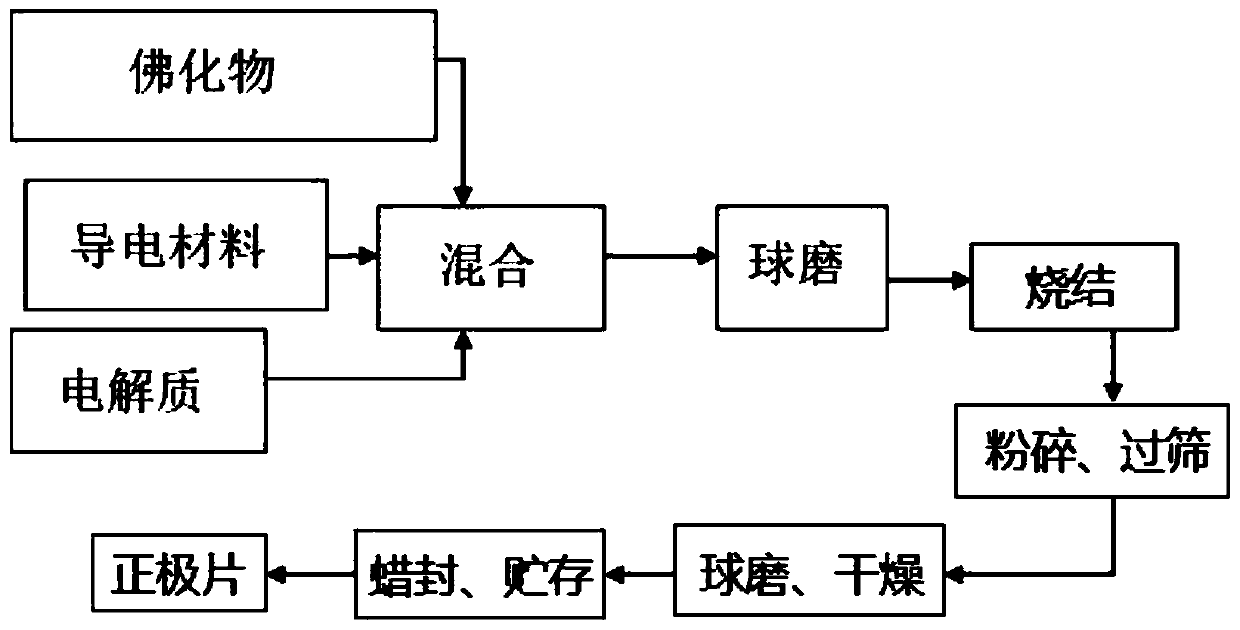

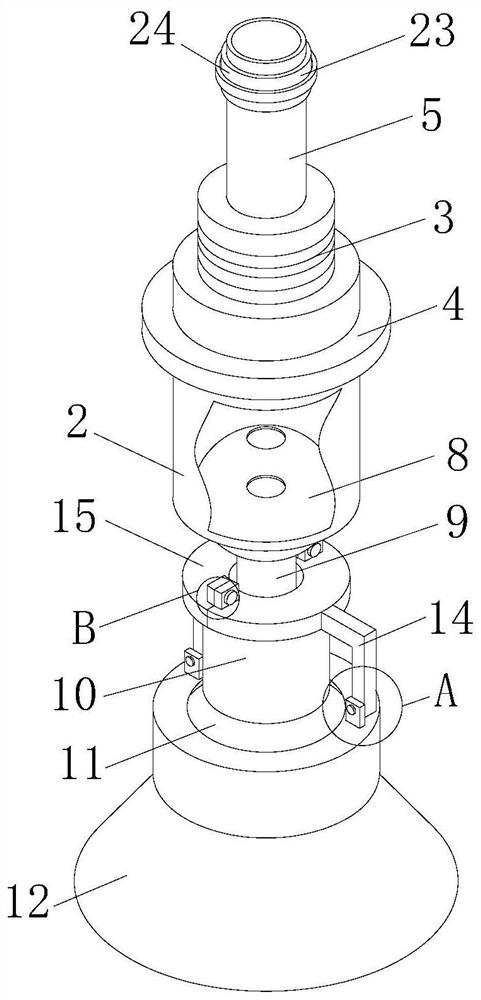

Novel fluorine ion thermal battery and preparation method thereof

InactiveCN111354954AHigh decomposition temperatureGood chemical and thermal stabilityPrimary cell manufactureDeferred-action cellsCapacity lossElectrical battery

The invention discloses a novel fluorine ion thermal battery, which is composed of a substrate (1), a positive electrode sheet (2), a diaphragm sheet (3), a negative electrode sheet (4), a current collecting sheet (5) and a heating sheet (6); the diaphragm sheet (3) is a ternary perfluorinated diaphragm sheet and is formed by mixing and sintering an electrolyte and magnesium oxide modified asbestos fibers, and the positive electrode sheet (2) is prepared from fluoride, a conductive material, and electrolyte. The novel fluorine ion thermal battery is good in chemical stability, and capacity loss does not exist in the high-temperature working process; the specific energy is high, and the specific energy of the thermal battery can be improved; the fluorine ion discharge capacity can be improved, and other metals except lithium alloy can be selected as the negative electrode, so that the cost of the thermal battery is reduced; and the open-circuit voltage of the thermal battery monomer isgreater than 2.8 V, so that the battery space height can be reduced.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

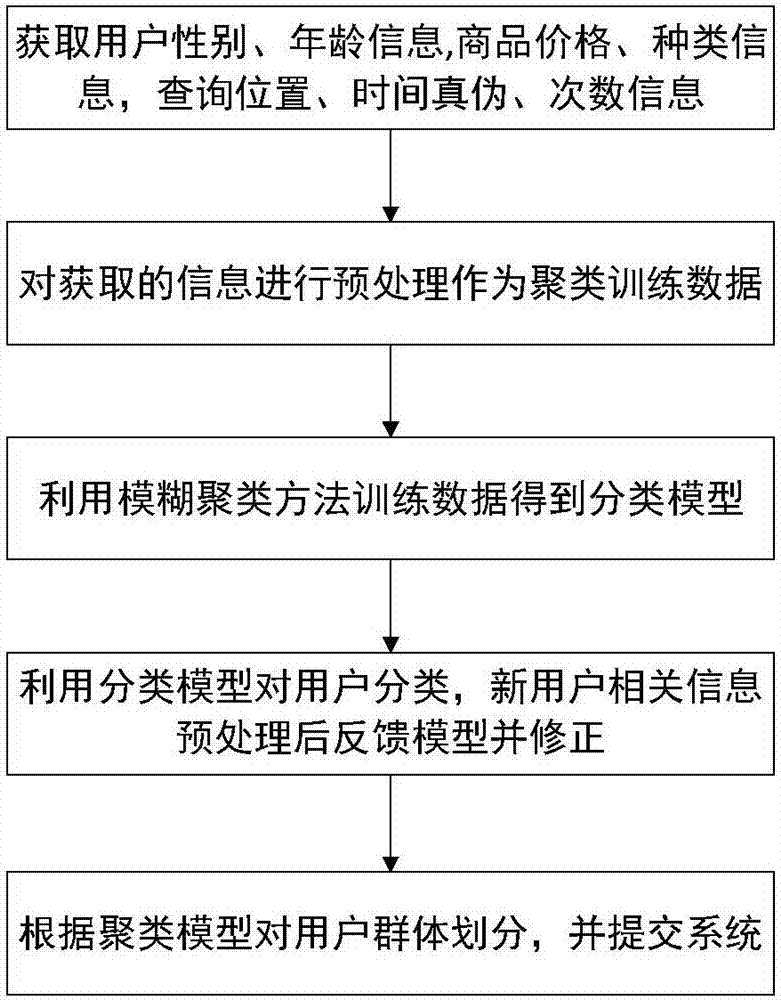

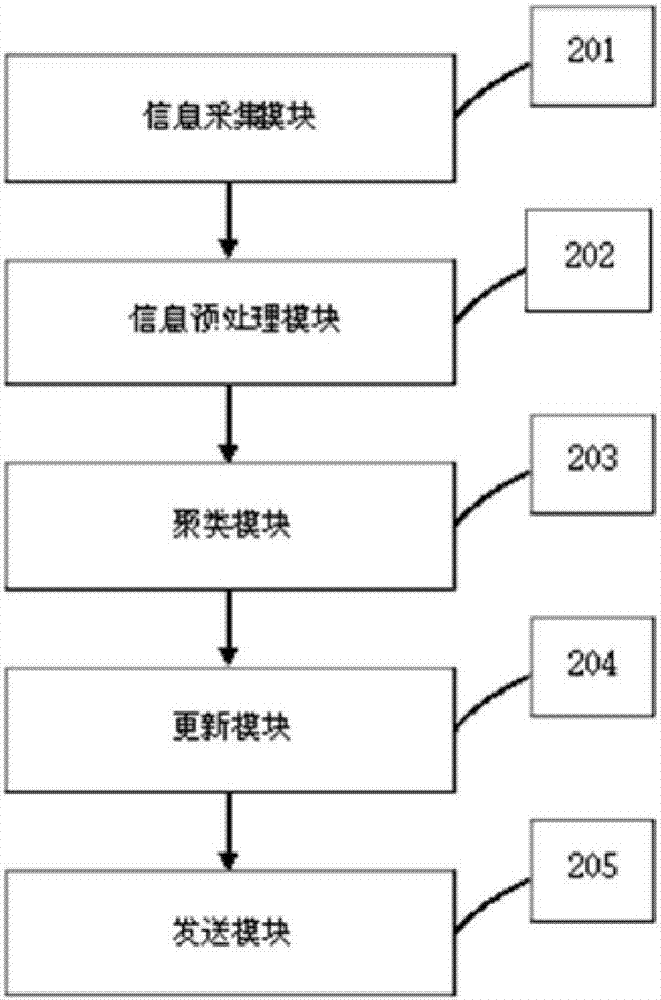

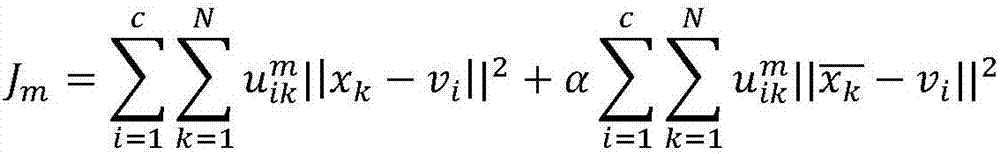

User group division method based on anti-fake traceability system and system thereof

InactiveCN107220831AFully excavatedTargetedCharacter and pattern recognitionMarket data gatheringLibrary scienceUser group

The invention provides a user group division method based on an anti-fake traceability system and a system thereof. A user inquires commodity authenticity through the anti-fake traceability system. Through combining characteristic information of the user, characteristic information of a commodity, and query information, a user group is divided so that later marketing of a merchant and manufacturer production possess pertinence. Information acquired by the anti-fake traceability system is fully excavated and system creativity is increased.

Owner:SYSU CMU SHUNDE INT JOINT RES INST +1

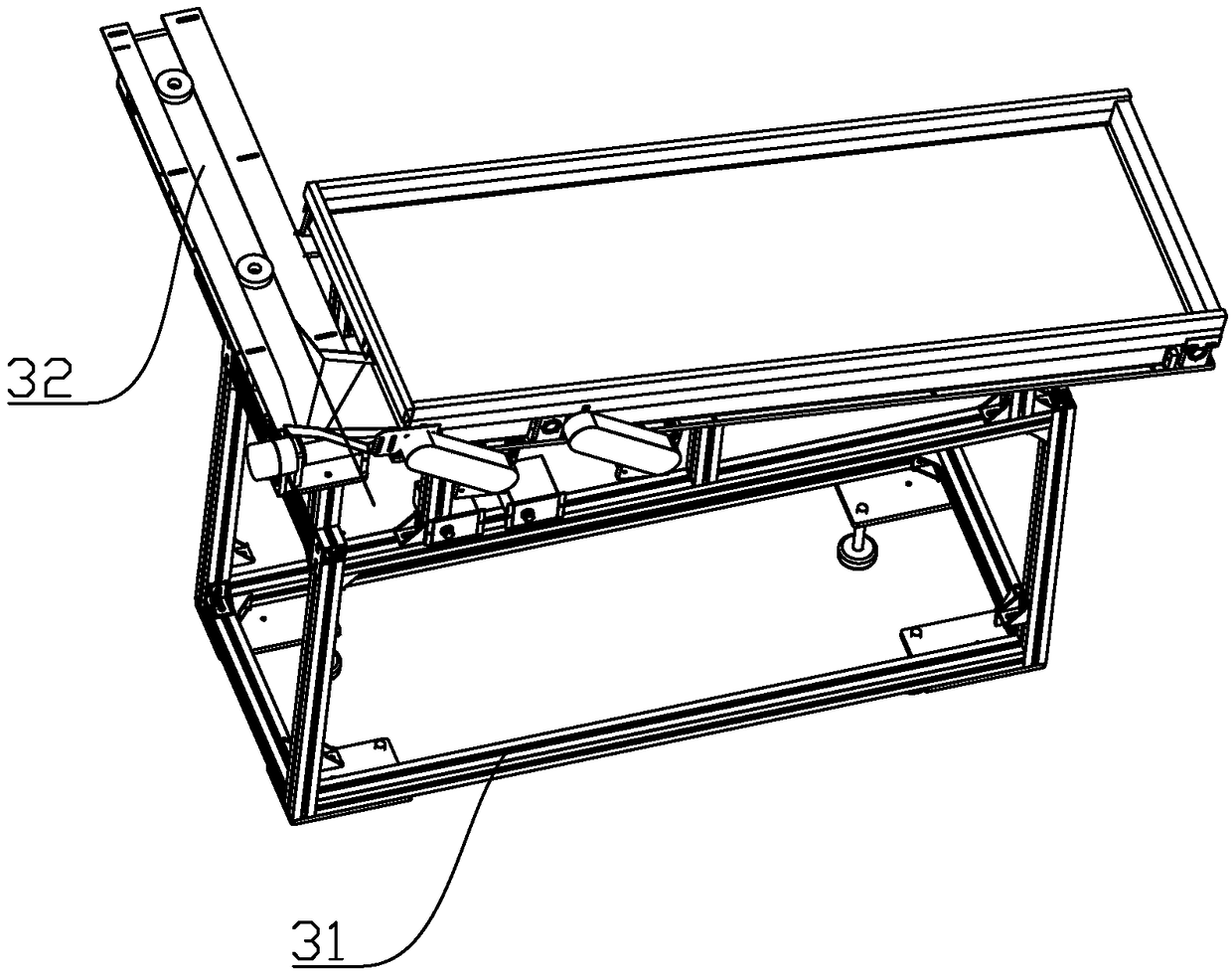

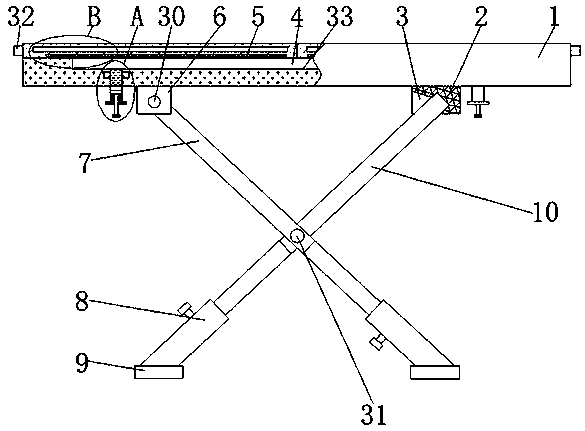

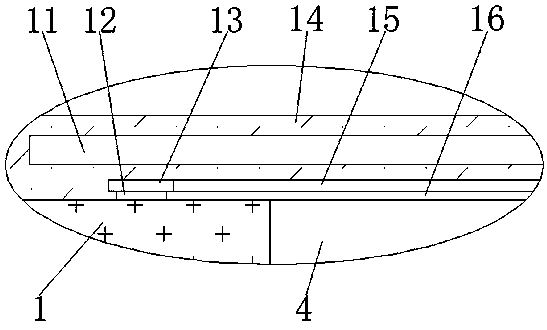

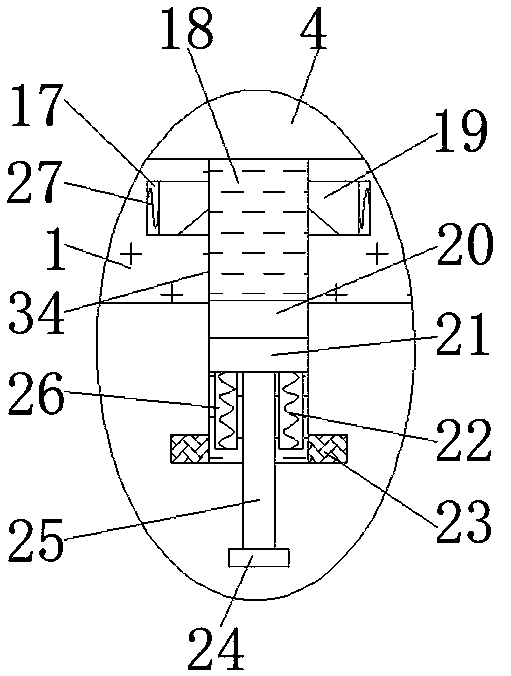

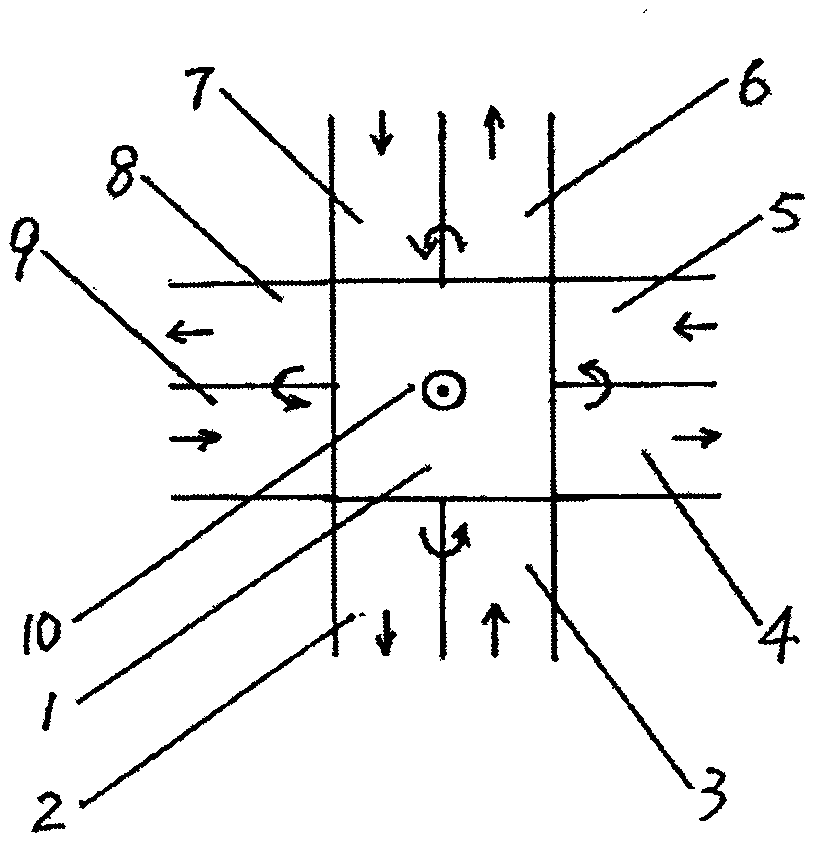

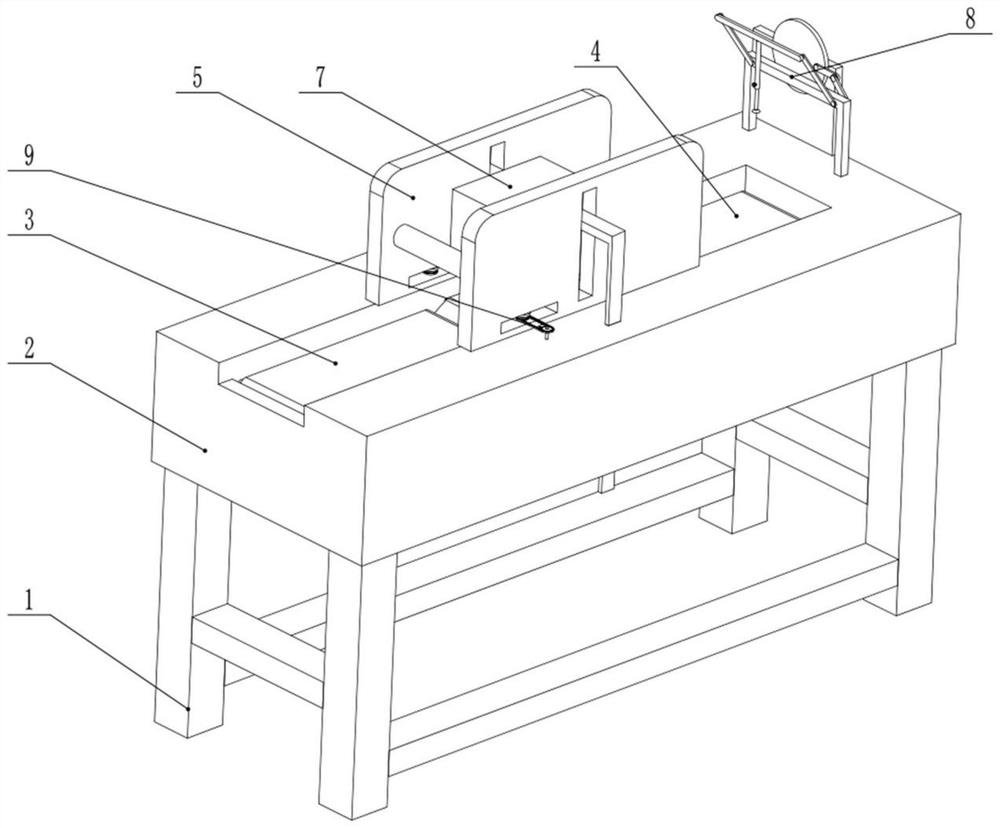

Portable clothing cutting platform for clothing design

PendingCN109079726ASolve the problem of simple structure and inconvenient useHigh creativityWork benchesFixed frameSlide plate

The invention discloses a portable clothing cutting platform for clothing design. The portable clothing cutting platform for clothing design comprises a fixed frame; a sliding groove is formed at thetop of the fixed frame; the two sides of the bottom of an inner cavity of the sliding groove are fixedly connected with connecting blocks; a limiting block is arranged at the top of each connecting block; the two sides of the inner cavity of the sliding groove are movably connected with sliding plates; and the two sides of the sliding plates are fixedly connected with sliding blocks. Through cooperative use of the fixed frame, a movable plate, the sliding groove, the sliding blocks, the sliding plate, a first spring groove, a push rod, a clamping block, a clamping groove, a push block, a firstspring, a pressing rod, a second spring groove, a second spring, a rotating groove and a push groove, the portable clothing cutting platform for clothing design is convenient to use and solves the problems that the existing clothing cutting platform is simple in structure and is not convenient to use, so that the portable clothing cutting platform for clothing design is convenient for users to use, greatly improves the convenience of the users during clothing cutting, improves the creativity of the cutting platform and is suitable for popularization and use.

Owner:IANGSU COLLEGE OF ENG & TECH

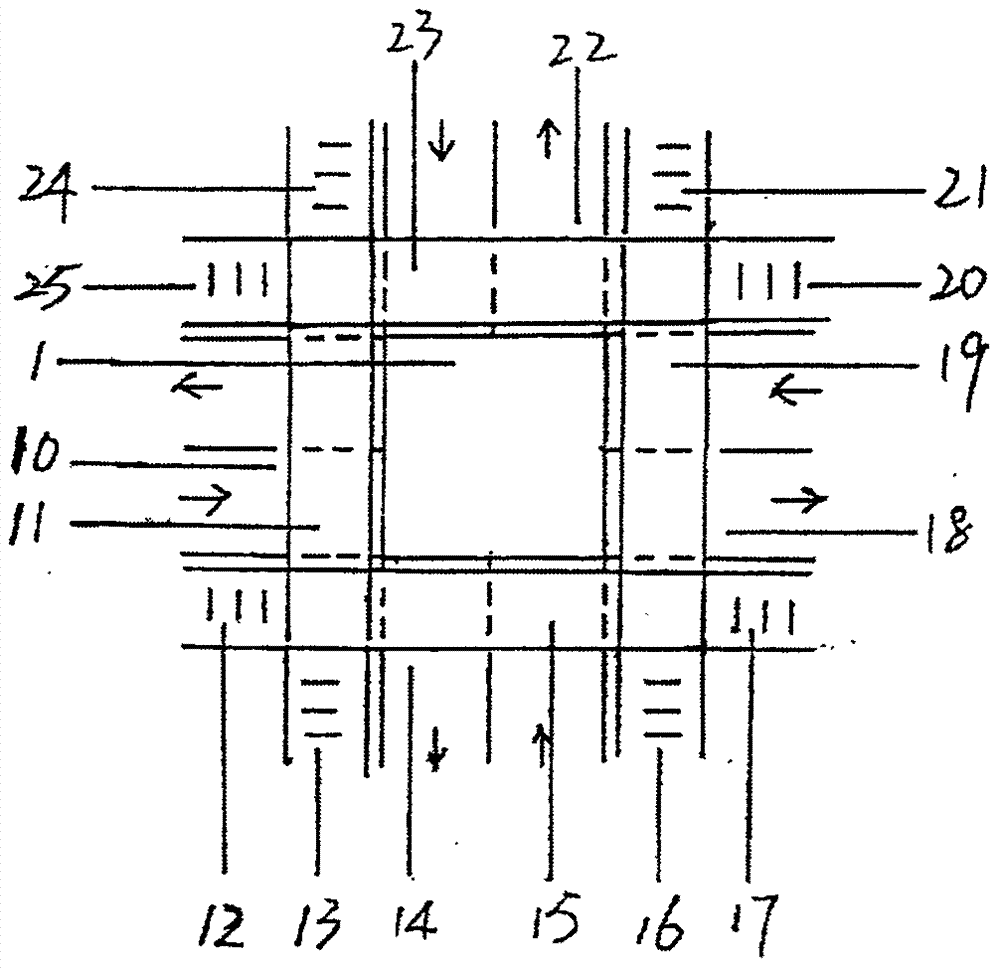

Method for travelling of motor vehicles at intersection in mode of going straight or turning right firstly and then turning left and specific lane

PendingCN107419627ASolve persistent problemsSolve congestionControlling traffic signalsRoadwaysControl theoryMechanical engineering

Owner:褚万青

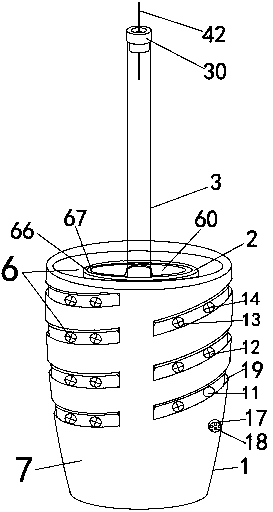

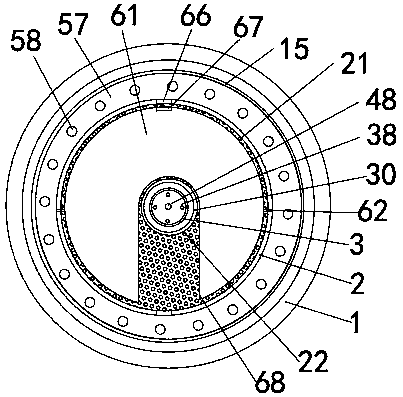

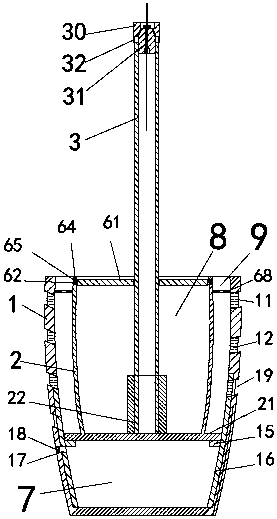

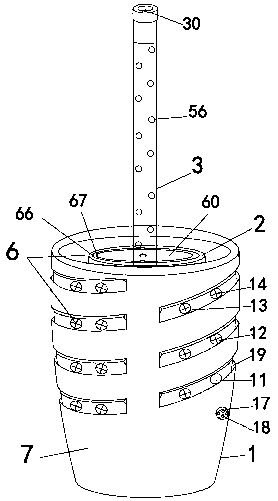

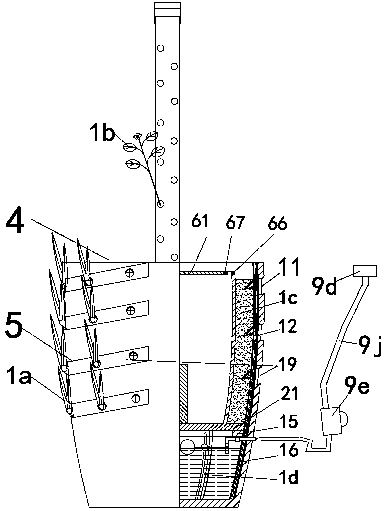

Mousing fish tank flower-arranging pot

InactiveCN108834652AGood for watchingAdd modification functionGeneral water supply conservationSelf-acting watering devicesWater balanceBalance water

The invention discloses a mousing fish tank flower-arranging pot. An inner pot body divides an outer pot body into three longitudinal and transverse spaces of a water storage area, an inner functionalarea and an annular planting area; a capillary pore water retention layer and a spiral shallow groove are formed outside the outer pot body, and multiple knock-off holes which are inward aslant formed are formed in the spiral shallow groove; a rotation plate type mousing trap and a transparent column-shaped fish tank are arranged in the inner pot body, and an invisible fountain assembly which promotes water recycle and improves the ornamental value is arranged on the upper portion of the transparent column-shaped fish tank. The mousing fish tank flower-arranging pot has the advantages that the structure is scientific, compact and novel, the design is ingenious, the space is sufficiently utilized, and the function is diversified; functions of the mousing trap, flower arranging, a vegetablegarden, a fish tank and a fountain are integrated; the water storage area can collect watering balance water, and earth is kept wet; the foam flower arranging earth can be remodeled and reused; the environmentally friendliness is prominent, limited plane space is expanded in the three-dimensional direction, the planting area is greatly increased, the garlic shoot planting area is ingeniously adopted to plant garlic shoots which easily grow, and great convenience is brought to daily life; the mousing fish tank flower-arranging pot is suitable for household usage.

Owner:FOSHAN MIAOTU TECH CO LTD

Aluminum plate part blanking die

PendingCN110695238AReduce workloadHigh creativityShaping safety devicesStripping-off devicesPunchingStructural engineering

The invention discloses an aluminum plate part blanking die comprising a punching machine body and a bottom plate. A lower die block is arranged at the top of the punching machine body. The bottom ofthe lower die block makes contact with the punching machine body. Inclined plates are arranged on one side of the lower die block. Connection rods are fixedly connected to the bottoms of the inclinedplates. The positions, close to the two sides, of the front and rear surfaces of the punching machine body are each fixedly connected with a clamping sleeve. Clamping rods are fixedly connected to thebottoms of the connection rods. Nuts are arranged at the bottoms of the clamping grooves. Threaded rods are arranged at the tops of the clamping sleeves. A fixed plate is fixedly connected to the positions, close to one side, of the opposite sides of the two inclined plates. According to the aluminum plate part blanking die, through the design of the inclined plates, the fixed plate, the clampingrods, the clamping sleeves and a movable plate, an aluminum plate part and waste materials can be separated and collected separately and are not mixed together, the workload of operators is reduced greatly, convenience is provided for the operation workers, and creativity of the aluminum plate part blanking die is improved.

Owner:JIANGSU HERUN AUTOMOTIVE BODY MOLD

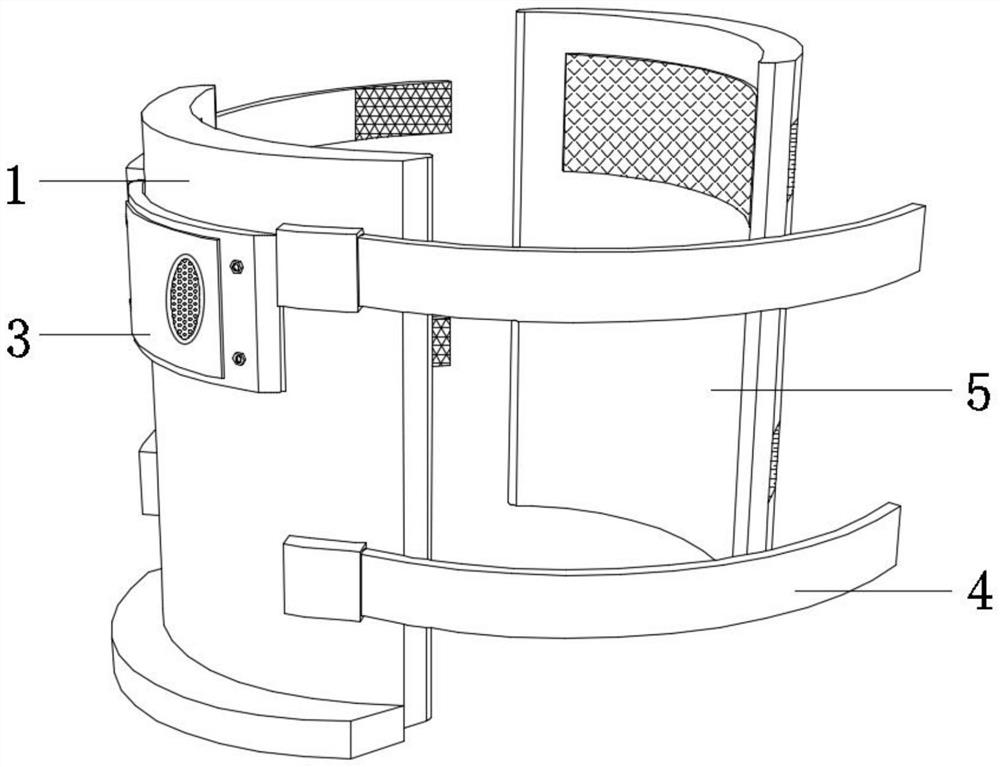

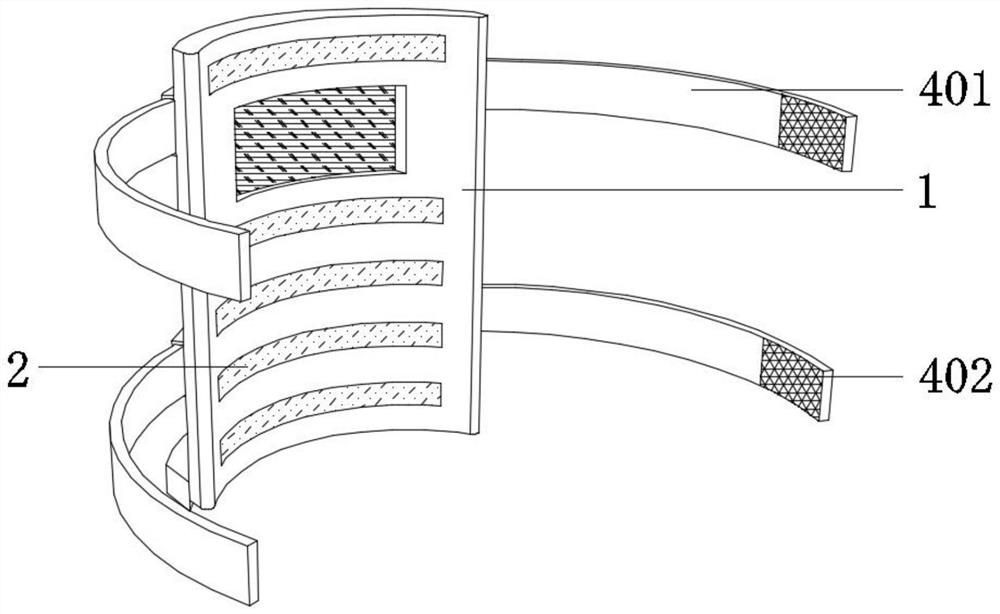

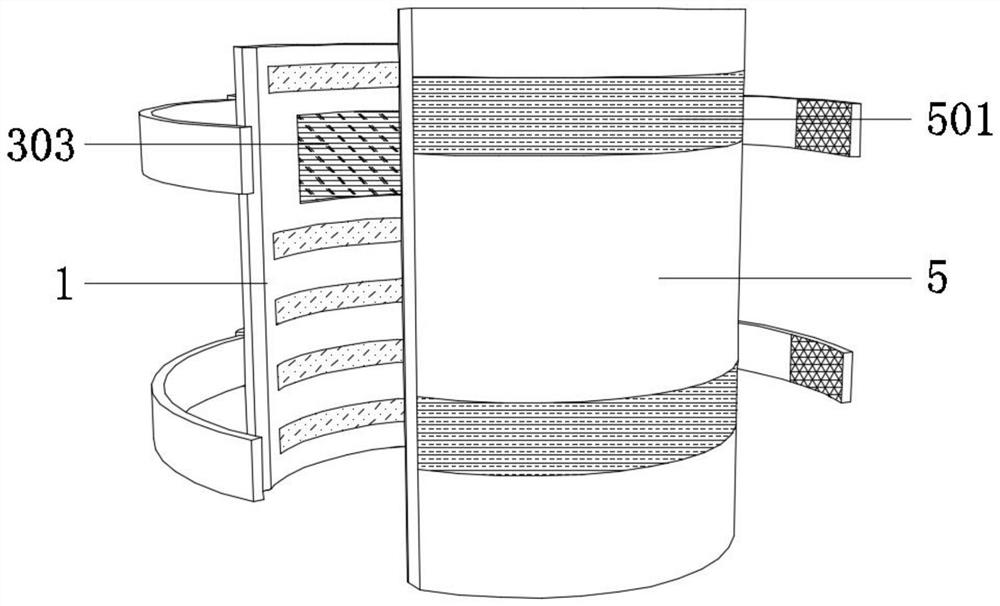

Medical thyroid postoperative protective device

PendingCN114191158AHighly creativePromote wound healingHead bandagesNon-adhesive dressingsEngineeringMassage

The invention discloses a medical thyroid postoperative protection device which comprises a front protection shell, heating strips, a filtering device, a fixing device, a rear protection shell and massage strips, five sets of heating strips distributed side by side are installed on the inner wall of the front protection shell, the filtering device is installed on the outer surface of the front protection shell, and a control device is installed on the filtering device. The left side and the right side of the filtering device are each provided with two fixing devices which are distributed side by side, a rear protection shell is arranged on one side of each fixing device, massage strips are arranged on the inner wall of a front protection shell, the front protection shell comprises a first pure cotton layer, an antibacterial layer, a breathable layer and a first outer surface layer, the antibacterial layer is arranged at the bottom of the first pure cotton layer, and the breathable layer is arranged at the bottom of the first outer surface layer. A breathable layer is arranged at the bottom of the antibacterial layer, and evenly-distributed breathable holes are formed in the breathable layer. The medical thyroid postoperative protection device can ventilate the neck of a patient, is antibacterial, is soft in hand feeling, comfortable to wear and free of oppression, and greatly improves the wearing comfort of the patient.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

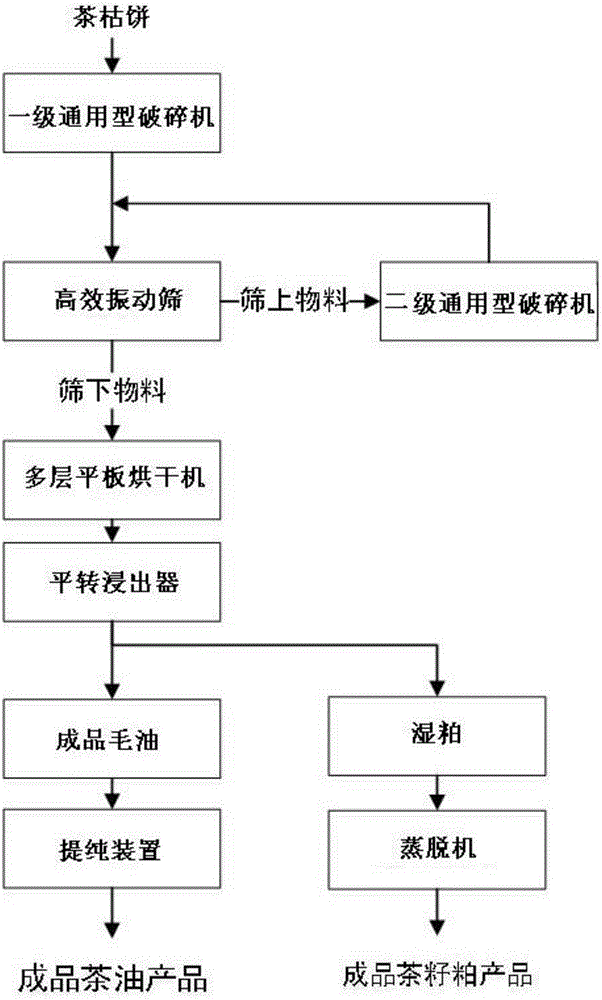

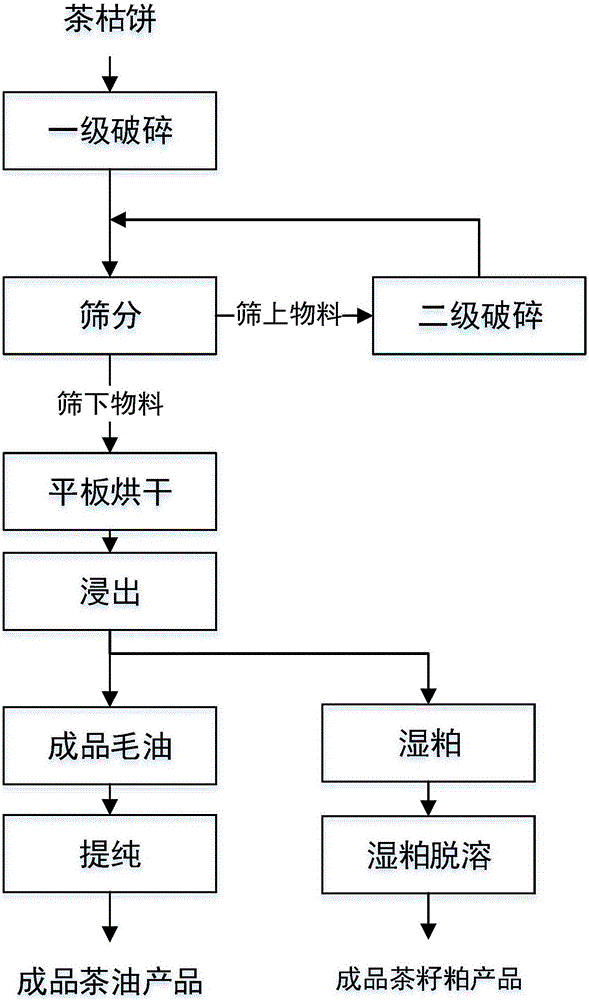

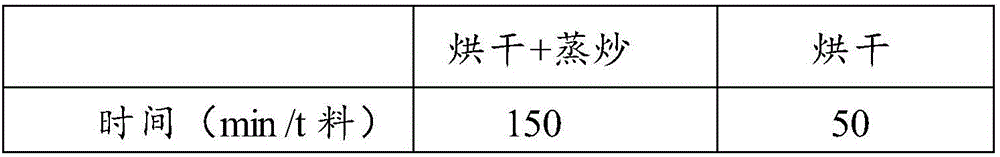

Comprehensive recycling production technology and comprehensive recycling system for defatted camellia cakes

PendingCN106675768AReduce residual oil contentReduce labor costsFatty-oils/fats refiningFatty-oils/fats productionGranularityMaterials science

The invention provides a comprehensive recycling production technology for defatted camellia cakes. The comprehensive recycling production technology includes the steps of firstly, subjecting defatted camellia cake materials to two-stage crushing so as to obtain fine particles of the defatted camellia cakes; secondly, drying the fine particles of the defatted camellia cakes obtained in the first step, and leaching so as to obtain crude oil and wet meal; thirdly, subjecting the crude oil obtained in the second step to refining and purification so as to obtain a camellia oil finished product; finally, subjecting the wet meal to exsolution so as to obtain a camellia seed cake finished product. The comprehensive recycling production technology has the advantages that starting on the whole, the technology involves analysis of every process and optimization and integration sequentially, raw material granularity uniformity is selected as a basis for improving a subsequent technology, and the technical prejudice that cooking is required in an existing technology is overcome; through adoption of two-stage crushing, raw material granularity uniformity is improved, the whole technological process is improved, leaching effects are improved effectively, a necessary cooking step is omitted, and accordingly automation degree and energy utilization rate of the whole technology are increased.

Owner:湖南淳湘农林科技有限公司

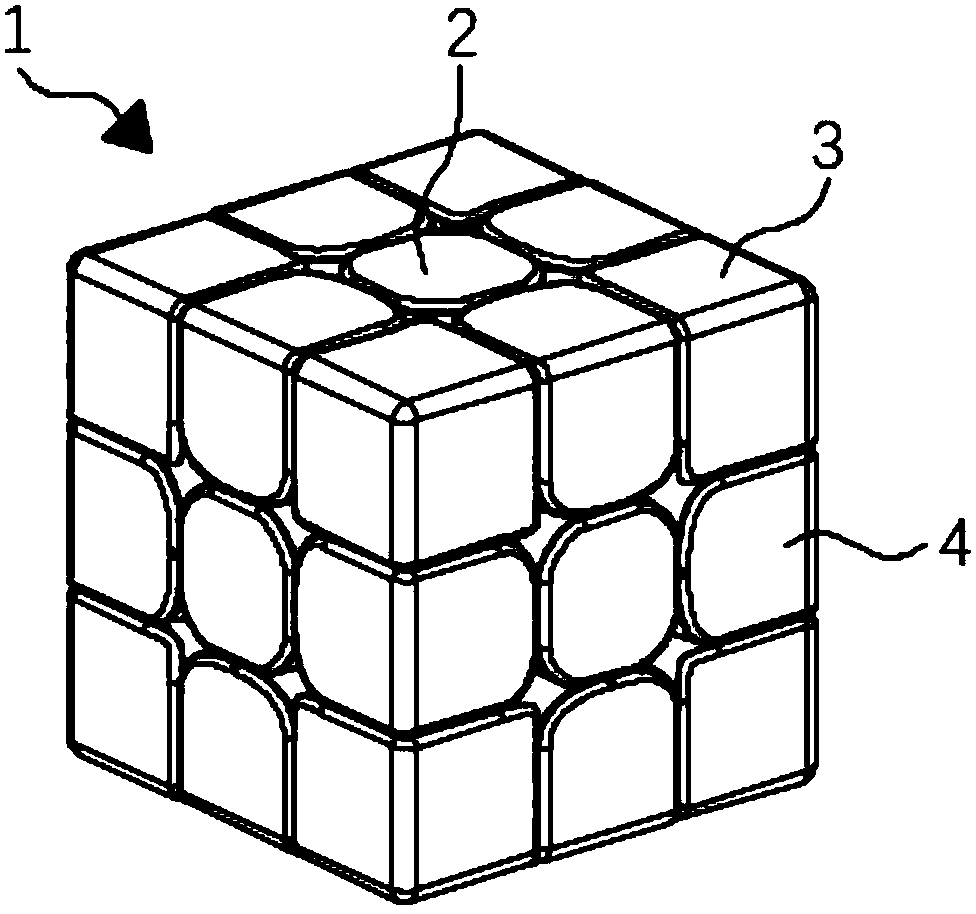

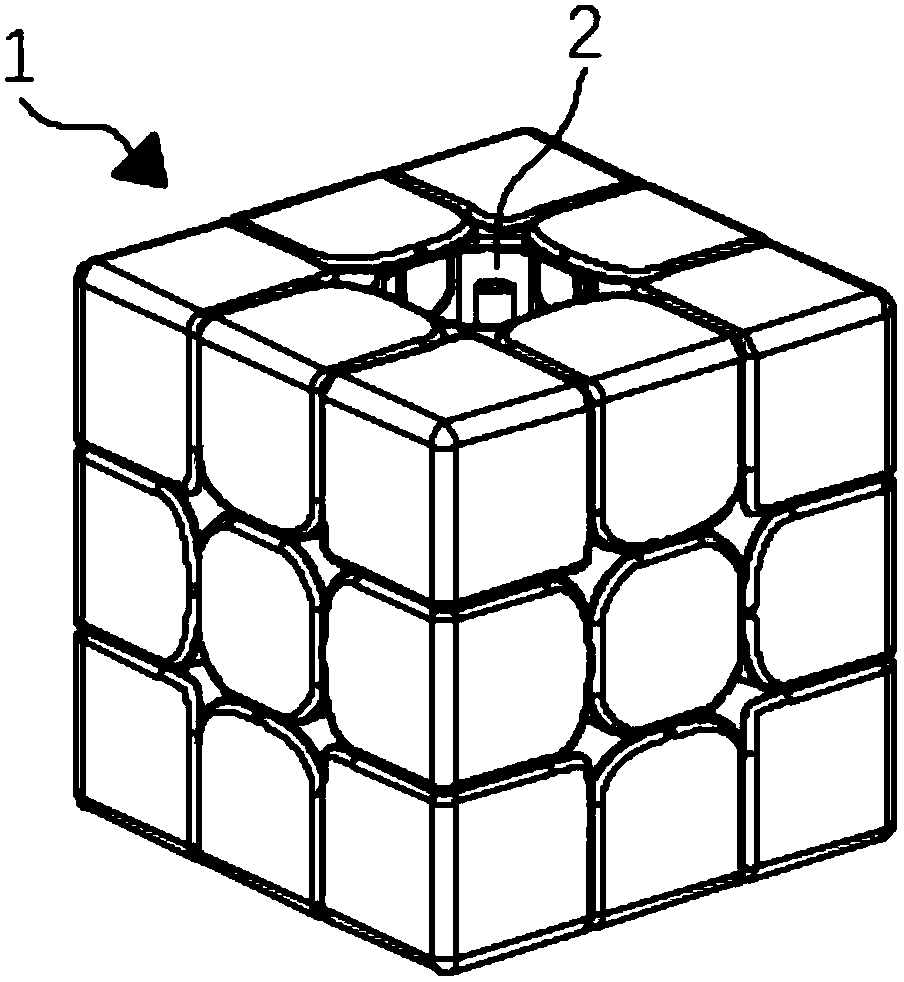

Center block magnetic auxiliary positioning magic cube

PendingCN111481917AAvoid CatonSmooth rotationIndoor gamesStructural engineeringMagnetic tension force

The invention discloses a center block magnetic force auxiliary positioning magic cube which comprises a magic cube body, and the magic cube body is composed of two magic cube outer layers and a magiccube inner layer; the magic cube outer layers and the magic cube inner layer are each composed of a center block assembly, corner block assemblies and edge block assemblies. Magnetic pieces are arranged in the center block assemblies, the corner block assemblies and the edge block assemblies. The magnetic pole directions of the magnetic pieces in the angle block assemblies are the same as the magnetic pole direction of the center block assemblies; the edge block assemblies located in the same face of the magic cube body can be attracted by the center block assemblies making contact with the edge block assemblies through the magnetic pieces. According to the invention, each center block assembly and the four peripheral edge block assemblies attract each other through magnets to generate amagnetic positioning sense, the magic cube can rotate more accurately and is prevented from being stuck, on the basis of a positioning mode formed by mutual attraction, mutual repulsion auxiliary positioning design is creatively added, the magic cube can rotate more easily and smoothly, and positioning is more accurate.

Owner:杜建华 +1

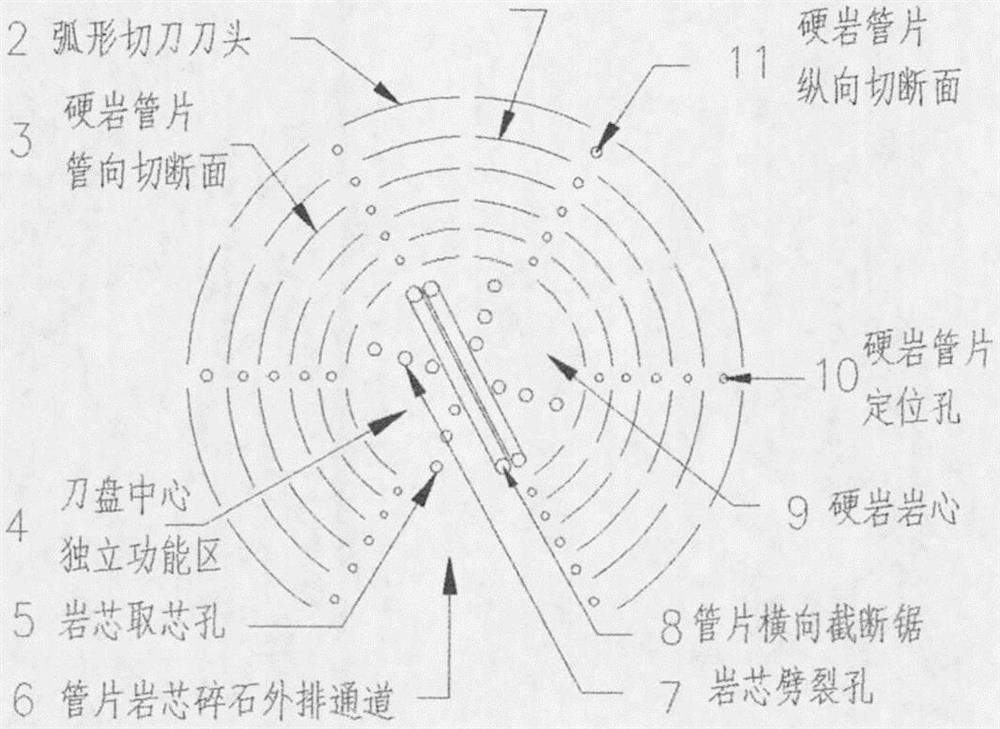

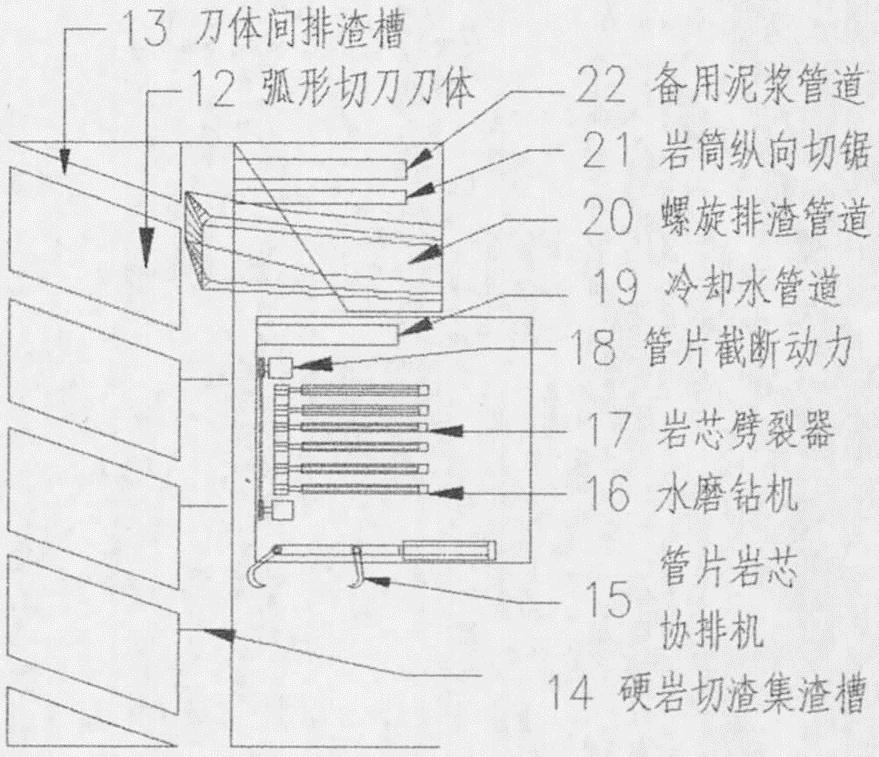

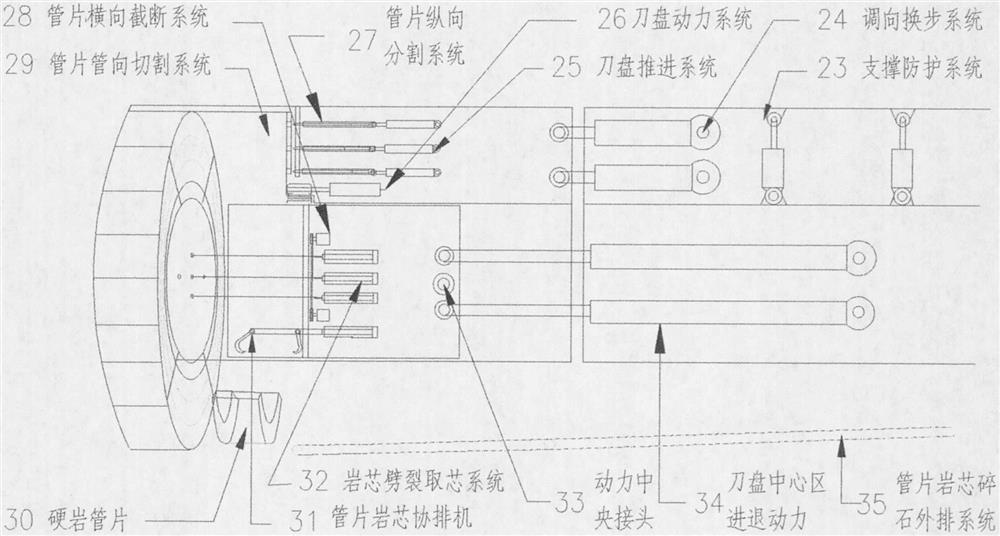

Split type hard rock heading machine

PendingCN112211643AImprove securityImprove reliabilityUnderground chambersTunnel liningRock coreMining engineering

The invention provides a split type hard rock heading machine, and belongs to the field of engineering machinery. The heading technology comprises the steps that a cutter head arc-shaped cutter annularly cuts rock cylinders; a cutter head center water grinding drill and a splitter take out rock cores, wherein pipe pieces are longitudinally cut between the rock cylinders through cutting saws; the pipe pieces are transversely separated through a cutter head center cutting saw; and a middle cutter head front support positions a cutter head completed hard rock wall, a rear support pushes a middlecutter head to rotationally cut and separate the pipe pieces, a large cutter head front support positions the middle cutter head completed rock wall, the rear support pushes the middle cutter head torotationally cut and separate the pipe pieces, and an external discharging system discharges all the pipe pieces. According to the split type hard rock heading machine, the heading space hard rock isused for manufacturing pipe piece lining heading rock walls, the investment is saved due to the selling income of the remaining pipe pieces, the hard rock cutting amount is small, the resource utilization rate is high, the heading speed is high, the heading cost is low, the engineering investment is small, and the service life of a building is 1000 years. The problems that in the prior art, the hard rock cutting amount is large, resources are wasted, the heading speed is low, the heading cost is high, concrete pipe pieces are purchased, and the service life of the building is short are solved.

Owner:CORNELIUS

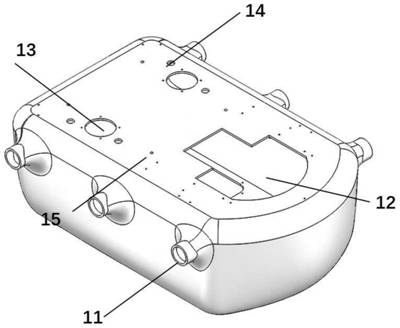

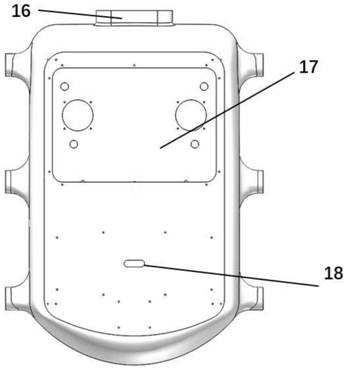

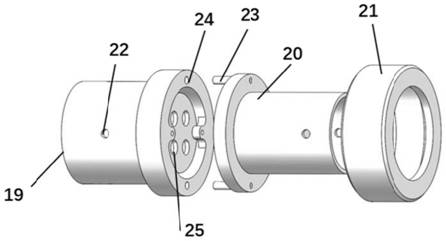

Oil-electricity hybrid water-air dual-purpose multi-rotor unmanned aerial vehicle

PendingCN112793374AImprove battery lifeAchieve strong wind resistanceRemote controlled aircraftPower plant typeUncrewed vehicleDual purpose

The invention discloses an oil-electricity hybrid water-air dual-purpose multi-rotor unmanned aerial vehicle which comprises a multi-rotor unmanned aerial vehicle body, a flight control system, an energy system, a power driving system and a ground control station, the flight control system, the energy system and the power driving system are all installed on the multi-rotor unmanned aerial vehicle body, the flight control system is connected with the energy system, the energy system provides power for the power driving system, and the flight control system is in communication connection with the ground control station. Compared with the prior art, the unmanned aerial vehicle has the beneficial effects that the cruising ability of the unmanned aerial vehicle is greatly improved; the possibility of large load is provided by the larger power margin of the oil-electricity hybrid power system; meanwhile, the strong wind resistance of the unmanned aerial vehicle is realized; in addition, a water unmanned ship function is added, the water take-off and landing and water sailing functions of the multi-rotor unmanned aerial vehicle are achieved, possibility is provided for use of the unmanned aerial vehicle on water, and a new technical means is provided for polling and monitoring of the water environment.

Owner:NANJING KAITIANYAN UAV TECH CO LTD

Wear-resistant and corrosion-resistant frying pan and manufacturing method thereof

InactiveCN114098442AImprove wear resistanceAccelerated corrosionCooking-vessel materialsLiquid surface applicatorsBoridingSilicon

The invention relates to the technical field of frying pans, and discloses a wear-resistant and corrosion-resistant frying pan and a manufacturing method thereof.The wear-resistant and corrosion-resistant frying pan comprises a marmite, the marmite is provided with a marmite coating, the marmite coating comprises a bottom layer material and a surface layer material, the surface layer material is of a wave-shaped structure connected end to end, the surface layer material is attached to the surface of the bottom layer material, and the surface layer material is of a wave-shaped structure. Wherein the bottom layer material comprises the following components in parts by mass: 18-25 parts of nickel-aluminum alloy powder, 4-6 parts of boron carbide, 5-7 parts of titanium boride and the like. According to the wear-resistant and corrosion-resistant frying pan and the manufacturing method thereof, the coating of the marmite comprises the bottom layer material and the surface layer material, the bottom layer material comprises nickel-aluminum alloy powder and the like, and the surface layer material comprises organic silicon resin and the like, so that wear-resistant and corrosion-resistant materials are adopted on the bottom layer material and the surface layer material; the nickel-aluminum alloy powder, the boron carbide, the titanium boride and the like can also improve the use strength and the hardness of the wok disclosed by the invention.

Owner:湖州运酬信息科技股份有限公司

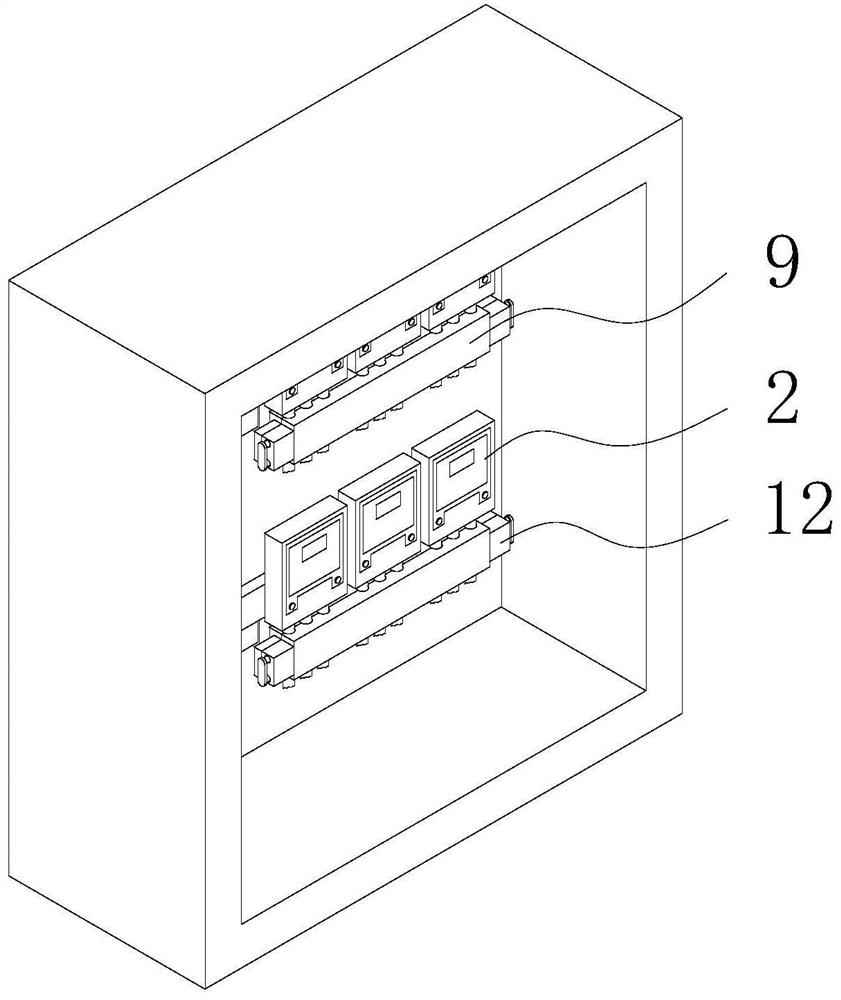

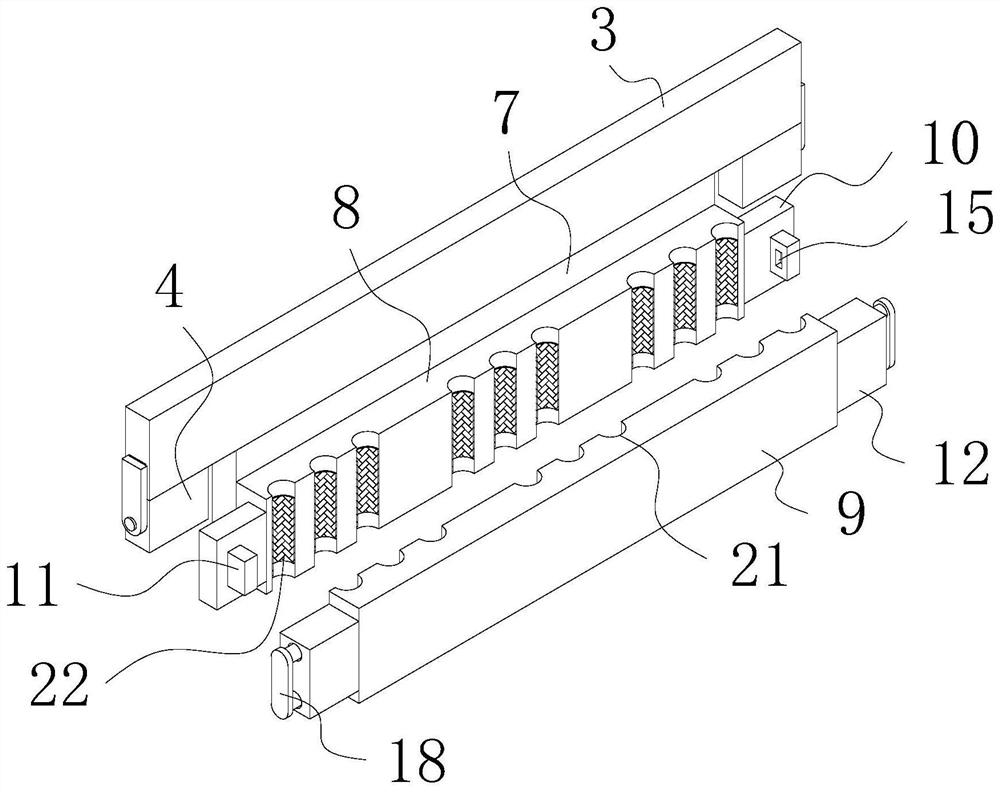

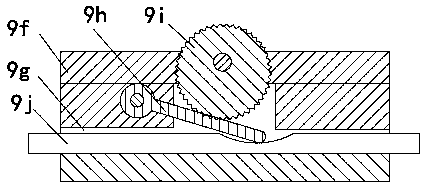

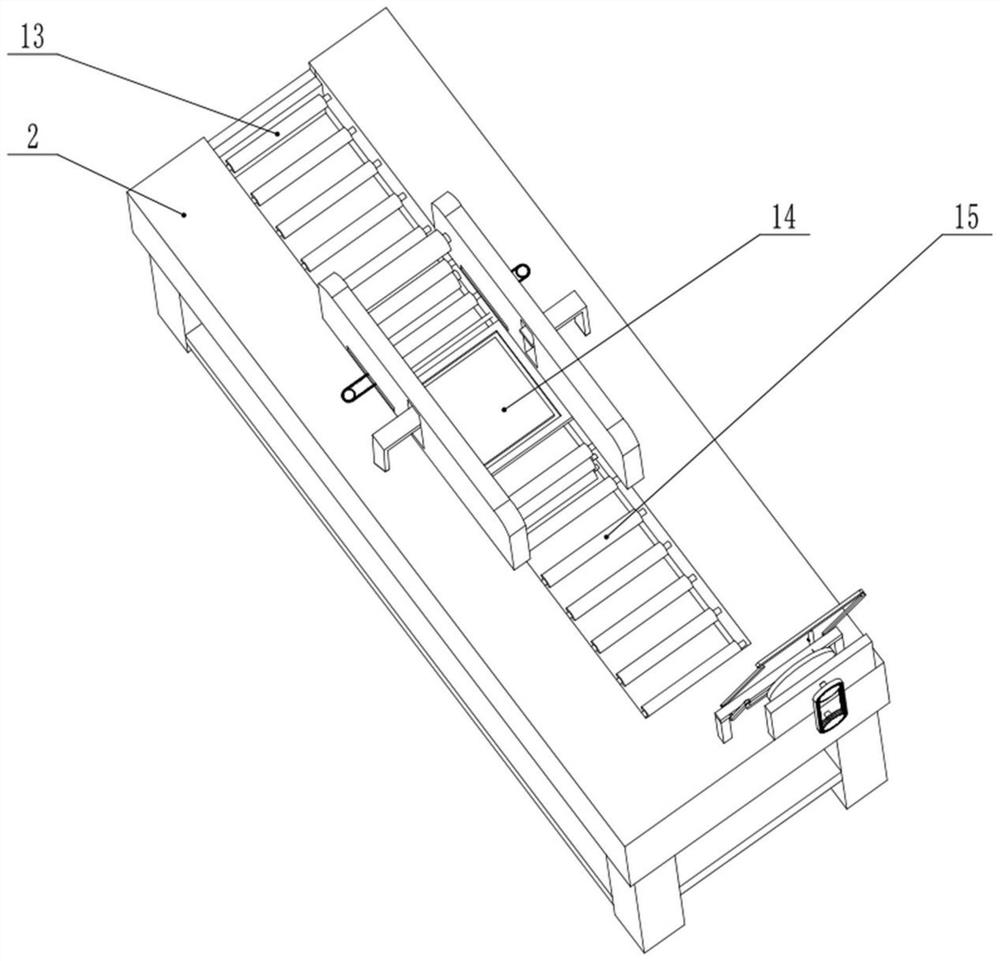

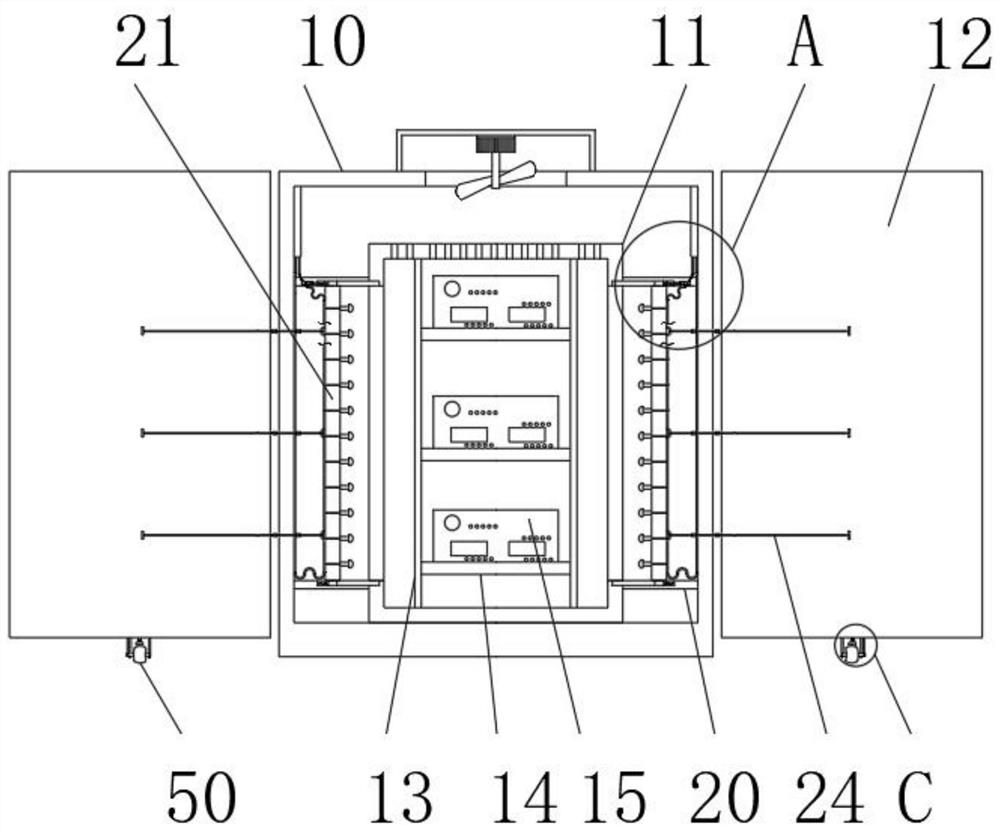

Bunching equipment of power distribution cabinet and power distribution cabinet

PendingCN112636187AEasy to fix componentsEasy to install and fixBus-bar/wiring layoutsSubstation/switching arrangement casingsStructural engineeringPush-button

The invention discloses bunching equipment of a power distribution cabinet and a power distribution cabinet. The bunching equipment comprises a cabinet body, an inner cavity of the cabinet body is movably connected with an element body, and the rear side of the element body is fixedly connected with a fixing plate. Through cooperative use of the cabinet body, the element body, the fixing plate, a fixing block, a connecting mechanism, a groove body, a connecting plate, a wire bunching plate, a limiting plate, a transverse plate, a positioning plate, a fixing shell, a positioning groove, a limiting mechanism, a limiting groove, a baffle, a transmission rod, a button, a clamping rod, a clamping groove, a wire bunching groove and a protection pad, problems of tedious installation operation, labor wasting, shortage of the wire bunching function in the distribution cabinet, and the short circuit caused by frequent winding of connecting wires are solved; the wire bunching equipment of the internal component mounting structure of the power distribution cabinet has the advantages of facilitating fixation of the components and tightening the connecting wires, and is worth popularizing.

Owner:薛强

Mouse catching and flower arranging garlic pot with automatic moisture preservation function

InactiveCN109089616AReduce total usageAvoid wastingSelf-acting watering devicesReceptacle cultivationWater storageEngineering

The invention discloses a mouse catching and flower arranging garlic pot with an automatic moisture preservation function. The mouse catching and flower arranging garlic pot is characterized in that an outer pot is divided into three longitudinal and transverse spaces by an inner pot, and the three longitudinal and transverse spaces include a water storage region, an inner functional region and aring planting region; a water feed device with an automatic water adding function is arranged in the water storage region; a capillary pore water preservation layer for carrying out capillary enhancement penetration on water in the water storage region towards the ring planting region is arranged on the inner wall of the outer pot; the capillary pore water preservation layer is arranged outside the outer pot, spiral shallow grooves are formed in positions outside the outer pot, and a plurality of knocking-off holes are formed in the spiral shallow groove; the inner pot is provided with a rotary plate type mouse catching trap and a flower arranging hollow cylinder. The mouse catching and flower arranging garlic pot has the advantages that the mouse catching and flower arranging garlic pot is scientific, compact and novel in structure and ingenious in conception and has multiple functions, and spaces can be sufficiently utilized; mouse catching mechanism, flower arranging, vegetable garden and fountain functions are integrated with one another; water can be automatically supplemented for the water storage region by the water feed device, and accordingly soil can keep moist; limited plane spaces can be expanded towards the stereoscopic directions, and accordingly the planting areas can be greatly increased; the garlic sprout planting region can be ingeniously utilized for plantinggarlic sprouts which are easy to grow, and accordingly the mouse catching and flower arranging garlic pot can bring great convenience for daily life; the mouse catching and flower arranging garlic pot is applicable to home living use.

Owner:FOSHAN MIAOTU TECH CO LTD

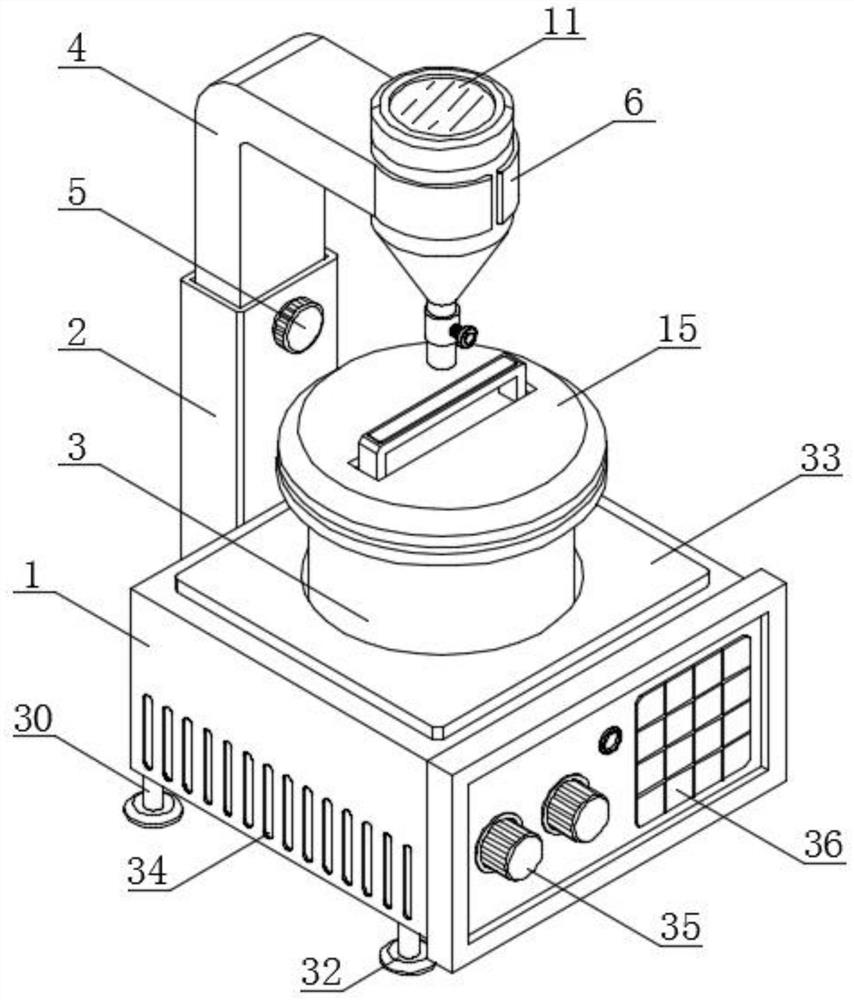

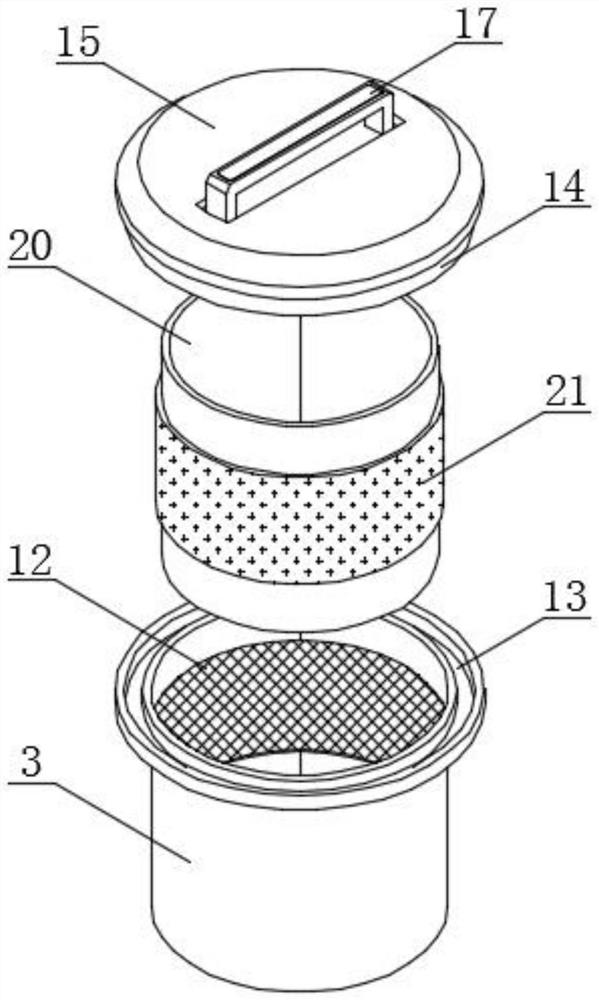

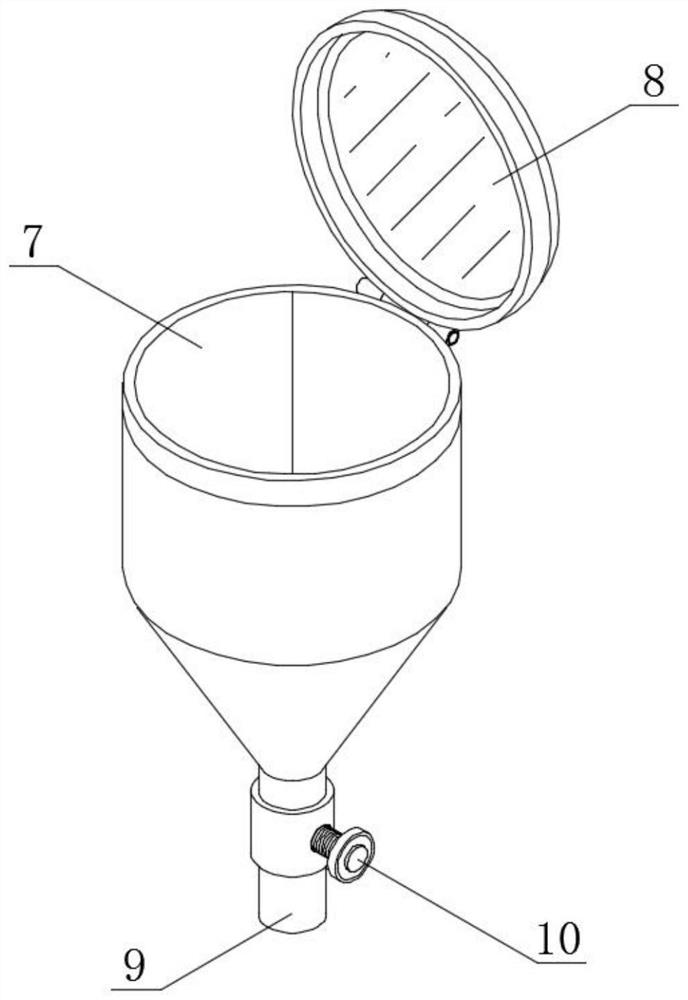

Magnetic powder stirring device with feeding structure and processing method

PendingCN114272815AAvoid pollutionEasy to observeRotating receptacle mixersTransportation and packagingStructural engineeringControl valves

The invention discloses a magnetic powder stirring device with a feeding structure and a processing method.The magnetic powder stirring device comprises a working box, a supporting sleeve and an outer barrel, the supporting sleeve is installed in the middle of the back of the working box, and the outer barrel is arranged in the middle of the top of the working box; an adjusting frame is slidably connected to the interior of the supporting sleeve, and a fastening knob is in threaded connection to the intersection of the adjusting frame and the supporting sleeve; a fixing clamp is installed at the top end of the adjusting frame, and a feeding cylinder is arranged in the fixing clamp. Through the arrangement of the feeding cylinder, a worker can add proper magnetic powder into the feeding cylinder, the control valve can adjust the output amount of the magnetic powder, so that the worker can perform selective discharging according to the amount of the required magnetic powder, and through the arrangement of the switch cover, external dust can be prevented from falling into the device to cause magnetic powder pollution; and through arrangement of an observation window, a worker can conveniently observe the interior of the feeding cylinder, so that the novelty of the device is improved.

Owner:HAIAN JULI MAGNETIC MATERIAL CO LTD

E-commerce logistics article packaging device

ActiveCN112389764ARealize reciprocating liftingIngenious structureWrapper twisting/gatheringLogistics managementElectric machinery

Owner:DEZHOU VOCATIONAL & TECHN COLLEGE

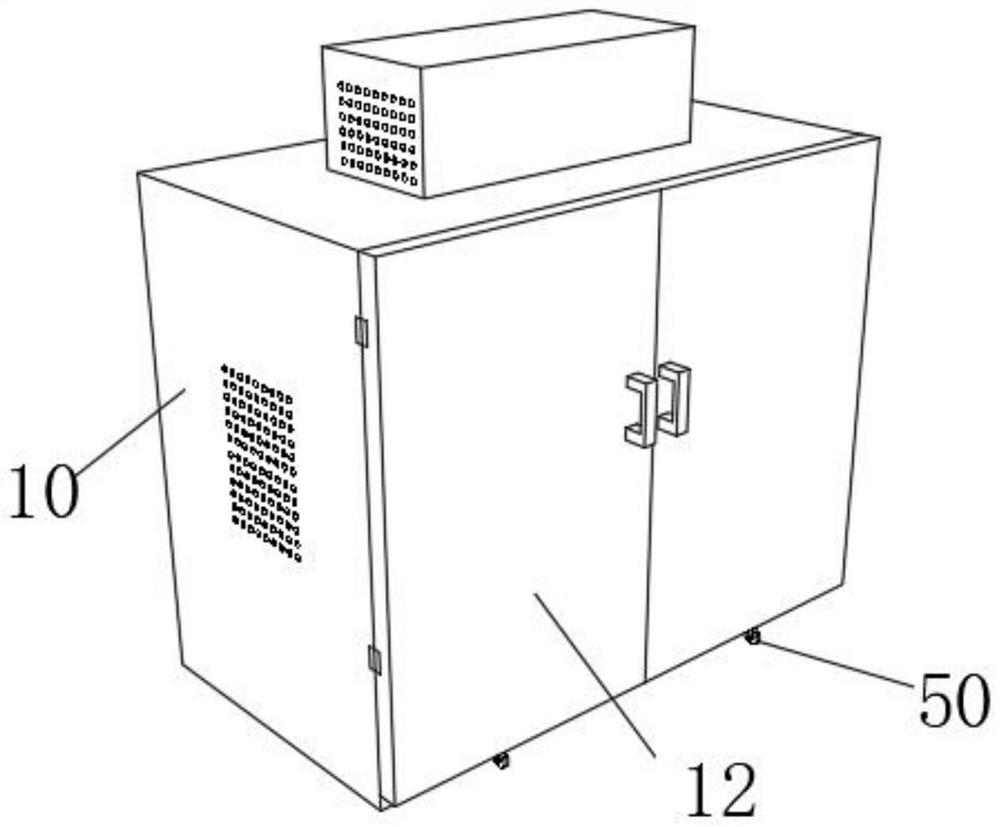

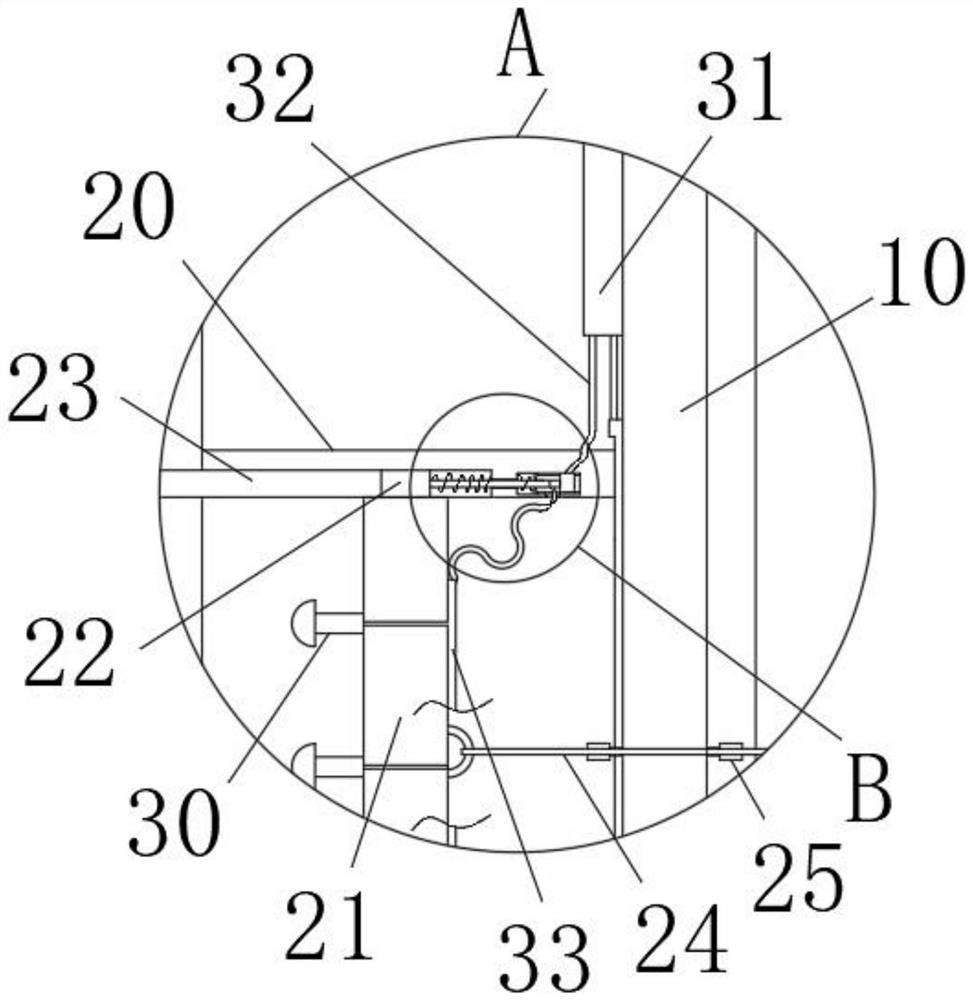

Automatic inspection control equipment for fire pump

PendingCN114733129AEasy to observeEasy to controlLighting elementsFire rescuePull forceIndustrial engineering

The invention relates to the technical field of fire fighting, and discloses a fire pump automatic inspection control device which comprises an outer cabinet and an inner cabinet, the inner cabinet is fixedly installed in an outer cabinet cavity, a fan is installed at the top of the outer cabinet, cabinet doors are movably installed on the front outer walls of the left side and the right side of the outer cabinet through hinges, and a control body is arranged in a cavity of the inner cabinet. According to the automatic inspection control equipment for the fire pump, the cabinet doors and the unfolding plate are arranged, after the cabinet doors are opened, the steel wire rope can pull the unfolding plate to horizontally move through the pulling force effect of the steel wire rope, and therefore the unfolding plate slides towards the side, away from the corresponding inner cabinet, of the unfolding plate; the two unfolding plates can move to the two sides in the outer cabinet cavity, so that a worker can conveniently observe the state of the control body in the inner cabinet and conveniently carry out work such as repair and maintenance on the control body, and the problem that the control body is installed in the inner cabinet, and work is not easy to carry out due to narrow space is solved.

Owner:武汉继仁科技有限公司

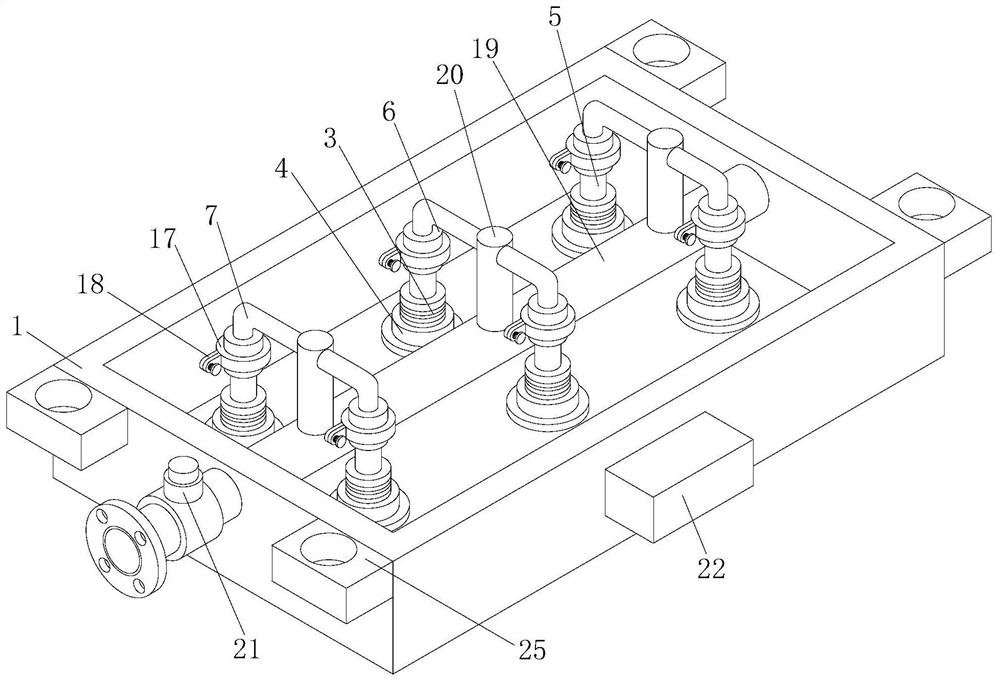

Horizontally-installed water mist nozzle structure

InactiveCN113440781AImprove efficiencyReduce property damageFire rescueEnvironmental geologyStructural engineering

The invention discloses a horizontally-installed water mist nozzle structure. The horizontally-installed water mist nozzle structure comprises an installation frame, the front side and the rear side of the bottom of the installation frame are sequentially and movably connected with first connecting pipes from left to right, the tops of the first connecting pipes communicate with drainage pipes, and threads are arranged on the surfaces of the drainage pipes. The tops of the drainage pipes penetrate into an inner cavity of the installation frame and communicate with water inlet pipes, the surfaces of the drainage pipes are in threaded connection with threaded sleeves, the upper ends of the surfaces of the water inlet pipes are sleeved with connecting clamping sleeves, and the tops of the connecting clamping sleeves communicate with water outlet pipes. According to the horizontally-installed water mist nozzle structure, through cooperation of the drainage pipes and the threaded sleeves, the first connecting pipes are fixed, so that the first connecting pipes kept stable, the problem that the first connecting pipes are wobbled during water supply, and the service life of the first connecting pipes is shortened due to abrasion of the first connecting pipes and the installation frame is solved, the beneficial effect that the first connecting pipes are conveniently fixed is achieved, and therefore the mounting efficiency of the first connecting pipes is improved.

Owner:南京天海水雾安全设备研发有限公司

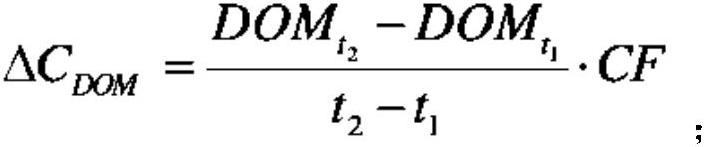

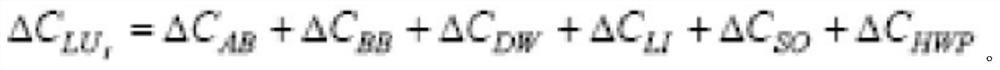

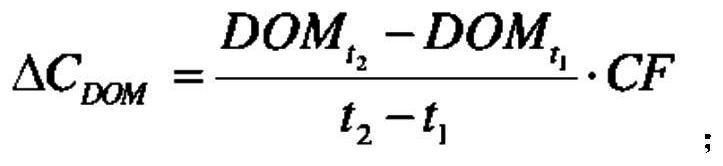

Forestry carbon sequestration algorithm for forest land environment data

PendingCN113742647AGuaranteed accuracyEnsure the efficiency of settlementData processing applicationsEnergy industryCarbon sequestrationCarbon stock

The invention relates to the technical field of forestry carbon sequestration algorithms, and discloses a forestry carbon sequestration algorithm for forest land environment data. The algorithm comprises the following working steps: 1 acquiring a carbon library of a forest land, the carbon library being composed of overground biomass, underground biomass, litter, dead wood and soil organic carbon and wood generation. The forestry carbon sequestration algorithm for the forest land environment data comprises the following steps: firstly, acquiring the carbon library of the forest land; secondly, determining an assumed value; thirdly, determining a carbon reserve change value and a non-carbon dioxide emission value; fourthly, determining the biomass value and dead organic matter value; and fifthly, determining the soil organic matter value. According to the method, the forestry carbon sequestration process of the forest land environment data is linked with one another, the forestry carbon sequestration amount of the forest land environment data is calculated on the premise of scientificity, and therefore, the forestry carbon sequestration efficiency and accuracy of the forest environment data are ensured.

Owner:知晓(北京)通信科技有限公司

Activity observation device for food microorganism culture experiment and operation method of activity observation device

PendingCN114574352AEasy to observeSuitable for growthBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMicroorganism

The invention discloses an activity observation device for a food microorganism culture experiment and an operation method thereof, the activity observation device comprises a base, the top of the base is provided with an incubator, and the interior of the incubator is provided with a cross partition plate; according to the invention, the interior of the incubator can be divided into different spaces by mounting the cross-shaped partition plate in the incubator and using the sealing gasket and the sealing groove, and the interiors of the different spaces can be in different mimicry environments by matching with the heater and the refrigerator, so that a worker can conveniently observe the microbe culture, and the working efficiency is improved. The mimicry environment is more suitable for growth of microorganisms, an annular groove is formed in the top of the incubator, an annular base is installed in the annular groove, and a single-tube electron microscope is installed in the annular base, so that workers do not need to take out the microorganisms from the interior of the incubator; the activity of microorganisms in different mimicry environments can be observed, and the creativity of the device is improved.

Owner:SHANDONG INST FOR FOOD & DRUG CONTROL

Repeated cylinder sleeve pressing technology of cylinder block

InactiveCN102310317ASolve problems such as overheatingEliminate gapsMetal working apparatusGasolineEngineering

The invention relates to a repeated cylinder sleeve pressing technology of a cylinder block, which comprises the steps of cylinder sleeve pressing, cylinder hole boring, repeated cylinder sleeve pressing, cylinder hole honing, top surface milling, cylinder sleeve pressing, cylinder hole boring, repeated cylinder sleeve pressing, top surface milling and cylinder hole honing. By adopting the repeated cylinder sleeve pressing technology of the cylinder block, clearances generated between faying surfaces of the cylinder sleeve and the cylinder block during processing a cylinder hole are eliminated, and faults such as engine overheat, and the like, which occur in outer fields and are caused by the sinking of the cylinder sleeve of the cylinder block of a gasoline engine, are thoroughly solved.

Owner:HARBIN DONGAN AUTO ENGINE

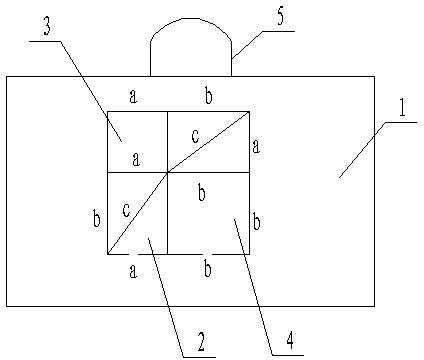

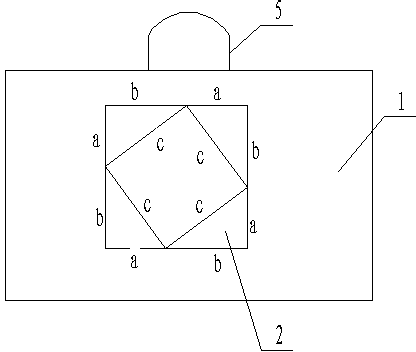

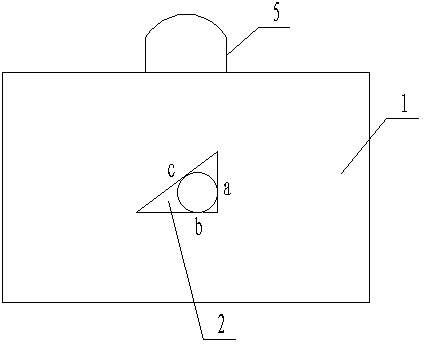

Pythagorean theorem teaching aid

InactiveCN103514787AIncrease motivationDivergent thinkingEducational modelsRight triangleComputer science

The invention discloses a teaching aid, and particularly discloses a Pythagorean theorem teaching aid which comprises a bottom plate, four congruent right triangle templates, a first square template and a second square template. An iron sheet is arranged in the bottom plate. The length of one leg of each right triangle template is a, the length of the other leg of each right triangle template is b, and the length of the hypotenuse is c. The length of each side of the first square template is a. The length of each side of the second square template is b. Magnets are arranged in the right triangle templates, the first square template and the second square template. According to the Pythagorean theorem teaching aid, the right triangle templates, the first square template and the second square template are demonstrated on the bottom plate so that students can know about and understand the Pythagorean theorem visually, the students can also splice the templates by themselves, so that the enthusiasm for learning of the students is stimulated, the creativeness of learning is improved, and meanwhile by demonstrating different proving processes, divergent thinking of the students can be improved, imagination of the students can be improved, and meanwhile the teaching aid is simple in structure and convenient to operate.

Owner:陈燕奇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com