Comprehensive recycling production technology and comprehensive recycling system for defatted camellia cakes

A production process and technology of tea gluten, which is applied in the production of fat oil/fat, production of fat, and refining of fat oil/fat, etc., can solve the problems of low degree of automation, high labor cost and cumbersome process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

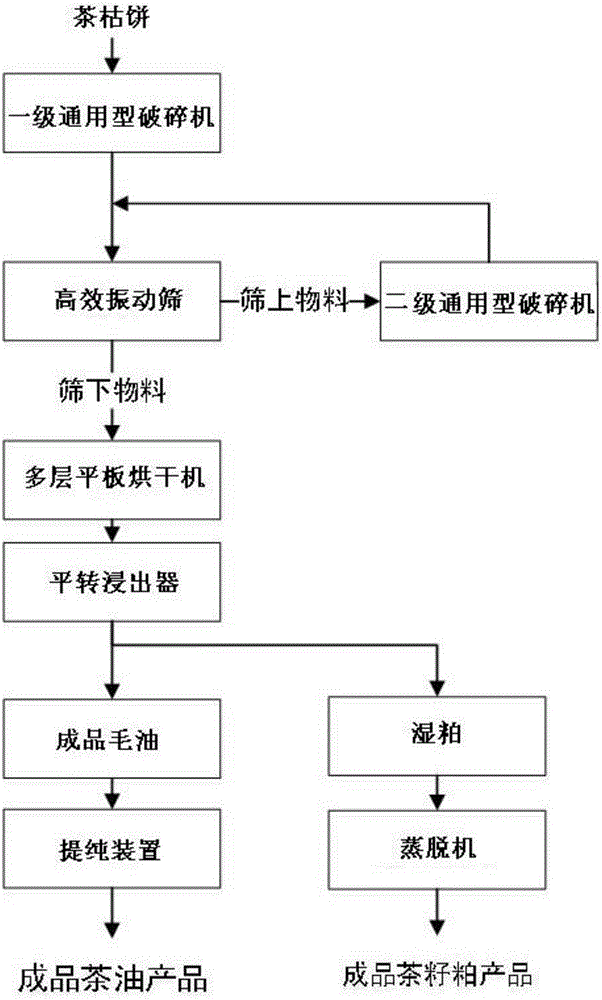

[0116] Comprehensive recycling system

[0117] The outlet of the primary general-purpose crusher is connected to the inlet of the high-efficiency vibrating screen, and the outlet of the unscreened material (coarse particles on the screen) of the high-efficiency vibrating screen is connected to the inlet of the secondary general-purpose crusher. The outlet of the machine is also connected with the inlet of the high-efficiency vibrating screen to form a two-stage crushing and screening closed loop system. The screen aperture of the high-efficiency vibrating screen is 2.8mm.

[0118] The outlet of the sieved material (fine particles after sieving) of the high-efficiency vibrating screen is connected to the inlet of the multi-layer flat dryer, and the outlet of the multi-layer flat dryer is connected to the inlet of the rotary extractor. , the discharge port of the horizontal extractor is connected with the inlet of the evaporation machine.

[0119] The tea dry cake is sent to t...

Embodiment 2

[0130] Comprehensive recycling system

[0131] The outlet of the primary general-purpose crusher is connected to the inlet of the high-efficiency vibrating screen, and the outlet of the unscreened material (coarse particles on the screen) of the high-efficiency vibrating screen is connected to the inlet of the secondary general-purpose crusher. The outlet of the machine is also connected with the inlet of the high-efficiency vibrating screen to form a two-stage crushing and screening closed loop system. The mesh aperture of the high-efficiency vibrating screen is 2.5mm.

[0132] The outlet of the sieved material (fine particles after sieving) of the high-efficiency vibrating screen is connected to the inlet of the multi-layer flat dryer, and the outlet of the multi-layer flat dryer is connected to the inlet of the rotary extractor. , the discharge port of the horizontal extractor is connected with the inlet of the evaporation machine.

[0133] see figure 1 , figure 1 It is...

Embodiment 3

[0147] Comprehensive recycling system

[0148] The outlet of the primary general-purpose crusher is connected to the inlet of the high-efficiency vibrating screen, and the outlet of the unscreened material (coarse particles on the screen) of the high-efficiency vibrating screen is connected to the inlet of the secondary general-purpose crusher. The outlet of the machine is also connected with the inlet of the high-efficiency vibrating screen to form a two-stage crushing and screening closed loop system. The screen aperture of the high-efficiency vibrating screen is 2mm.

[0149] The outlet of the sieved material (fine particles after sieving) of the high-efficiency vibrating screen is connected to the inlet of the multi-layer flat dryer, and the outlet of the multi-layer flat dryer is connected to the inlet of the rotary extractor. , the discharge port of the horizontal extractor is connected with the inlet of the evaporation machine.

[0150] The tea dry cake is sent to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com