A kind of preparation method and selected equipment of high-protein cotton meal

A technology of high-protein cottonseed meal and cottonseed is applied in the field of preparation of high-protein cottonseed meal, which can solve the problems of poor quality of cottonseed meal and low oil yield, and achieve the effect of improving the whole kernel rate of cottonseed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment one: the preparation of high-protein cotton meal

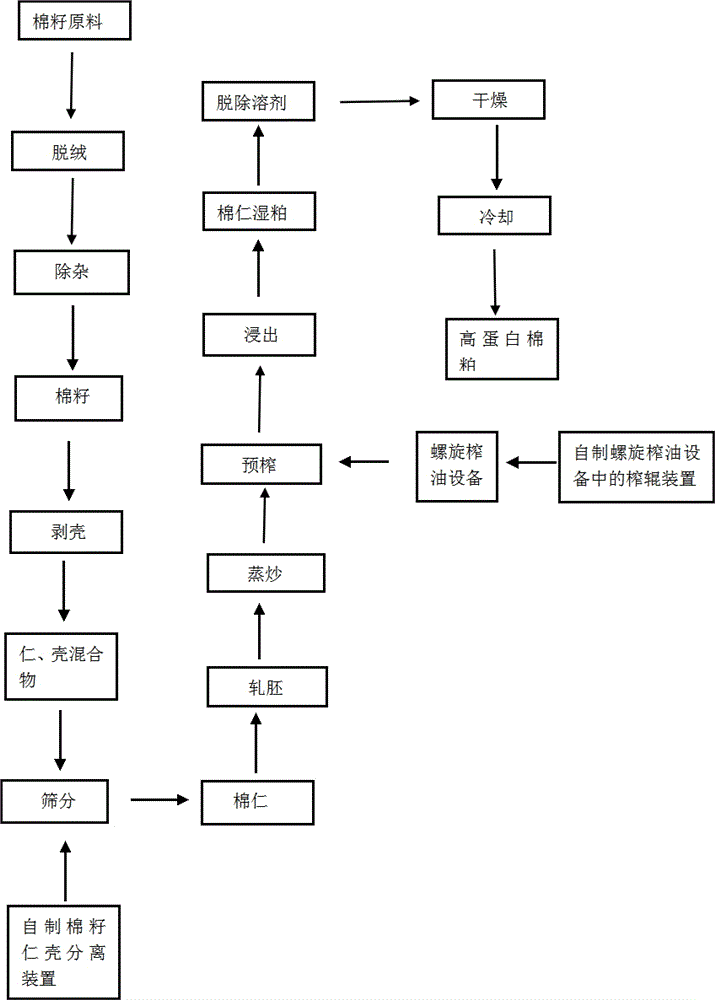

[0064] See attached figure 1 , the present invention provides a kind of preparation method of high-protein cotton meal, % is calculated by weight ratio w / w (kg / kg), and specific preparation method is as follows:

[0065] (1) Cottonseed delint and impurity removal: After the cottonseed has been processed to remove impurities and delint, the impurity content is less than 0.5%, and the cashmere content is less than 4%.

[0066] (2) Cottonseed peeling: The cleaned and removed cottonseed is evenly fed into the shelling roller through the frequency conversion feeding device, and the tooth angle of the first set of toothed rollers of the shelling roller is 40°-85°. The angle is the angle between the horizontal line and the inclined line, and the adjustment gap is 2.4-2.8mm; the tooth angle of the second set of toothed rollers is 35°-70°, the tooth angle is the angle between the horizontal line and the inclined lin...

Embodiment 2

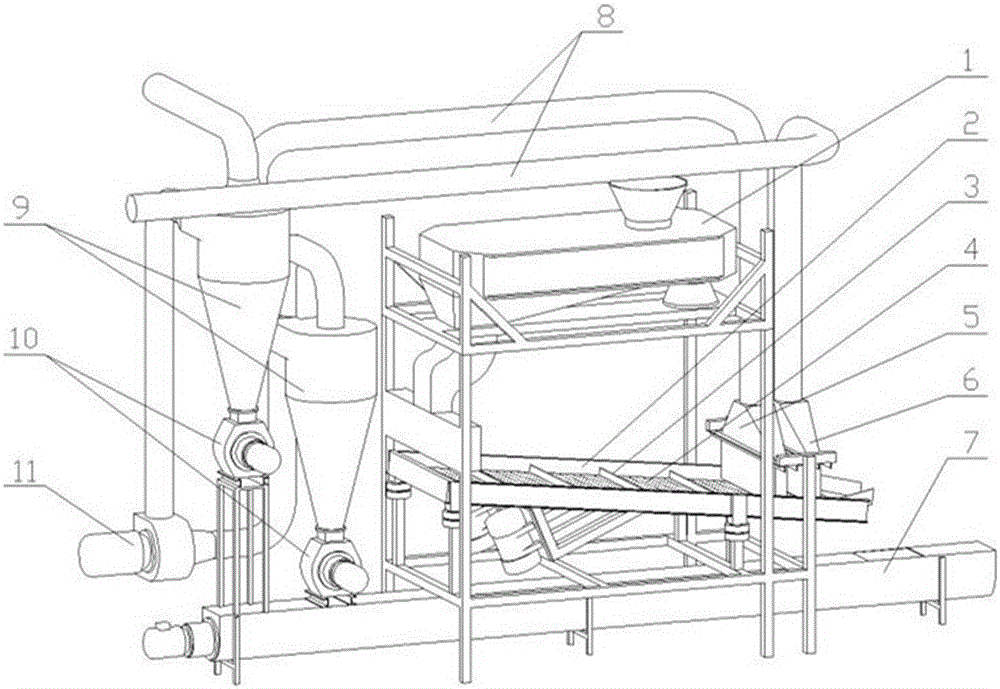

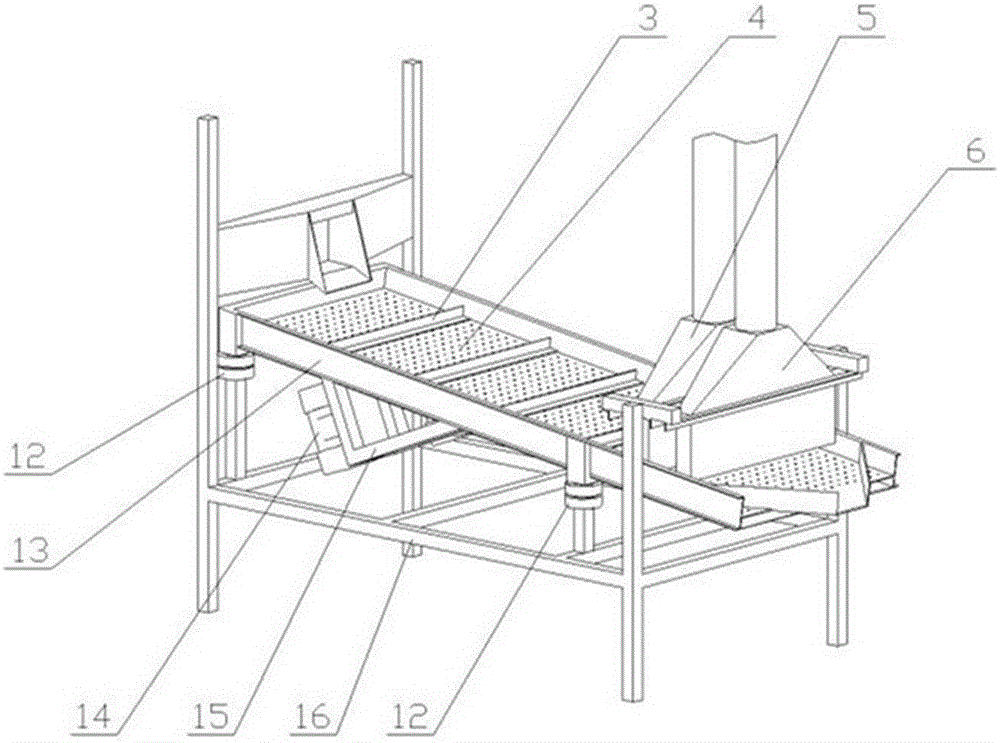

[0076] Embodiment two: Cottonseed shell separation device

[0077] See attached Figure 2-3 , a kind of cottonseed shell separation device provided by the invention is specifically described as follows:

[0078] A cottonseed kernel shell separation device, the cottonseed shell separation device consists of a primary screen assembly, a selection screen assembly, a fan kernel shell separation assembly, a frame (16), and a screw conveying assembly (7). The primary screen assembly, selection screen assembly, blower kernel shell sorting assembly and screw conveying assembly (7) are fixedly connected through the frame (16), and the primary screen (1) is placed on the upper part of the frame (16); the selection screen The assembly consists of a grate screen (2), a vibrating motor (14), a motor base (15) and a damping spring (12); the fan shell sorting assembly consists of the first air inlet (5), the second air inlet ( 6), ventilation pipe (8), Shacron (9), air locker (10) and blow...

Embodiment 3

[0097] Embodiment 3: A screw squeezing device suitable for screw oil pressing equipment

[0098] See attached Figure 5-6 , the present invention adopts a kind of screw squeezing device suitable for screw oil pressing equipment to be specifically described as follows:

[0099] A snail squeezing device suitable for screw oil pressing equipment is mainly composed of a snail (17), a resistance ring (18), and a squeezing shaft (19). It is composed of 8 sets of snail squeezing units with an even number of segments. The first snail The unit to the sixth snail squeezer unit are respectively provided with lining rings and squeeze snails, and two resistance rings (18) are respectively welded on the last two snail squeezer units near the left, that is, the seventh to eighth snail squeezer units.

[0100] In the present invention, the compression ratio is adjusted to: the first snail pressing unit 0.9-1.1, the second snail pressing unit 1.64-1.66, the third snail pressing unit 2.77-2.79...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com