A kind of oil sludge demulsifier and its preparation method and application

A demulsifier and oil sludge technology, which is applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of various raw materials, unsatisfactory treatment effect of oily sludge, and complicated preparation process. Achieve the effect of good demulsification effect, low production cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

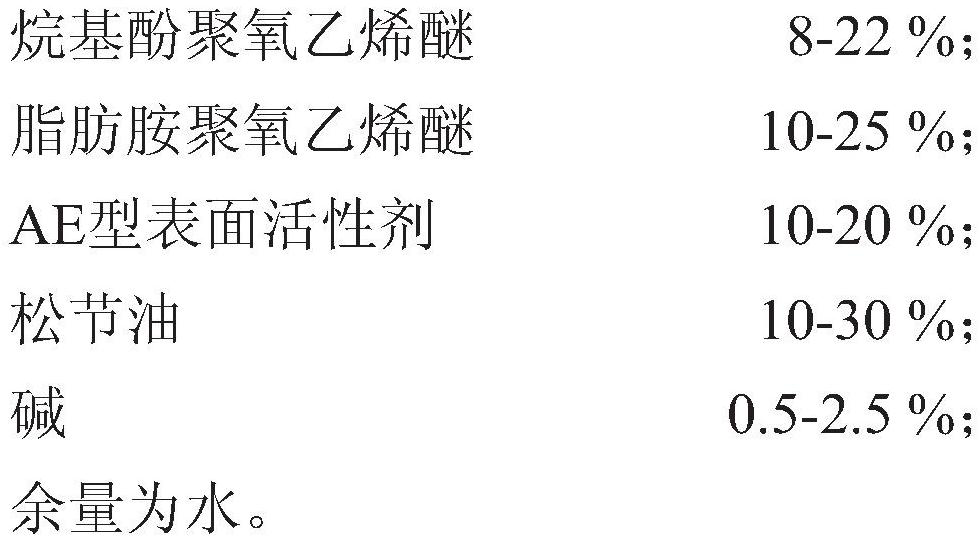

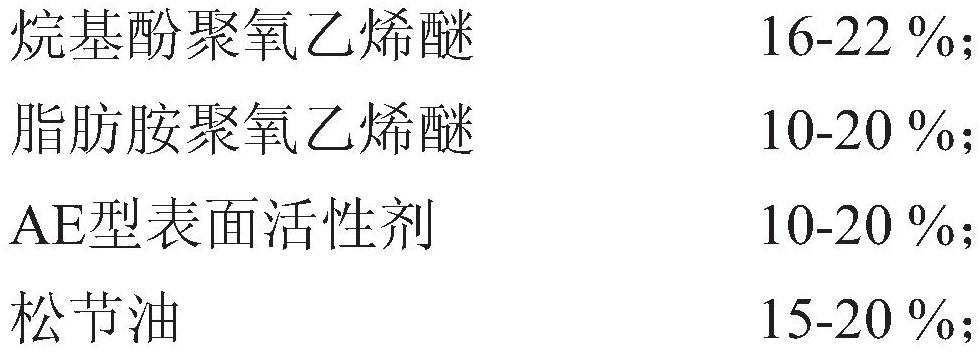

[0054] An oil sludge demulsifier, consisting of the following raw materials in parts by weight:

[0055] Octylphenol polyoxyethylene ether 16%, octadecylamine polyoxyethylene ether 19%, polyethylene polyamine polyoxyethylene polyoxypropylene polyether 15%, turpentine (boiling range 120-170°C) 20%, sodium silicate 1.5%, water 28.5%.

[0056] The preparation method of this oil sludge demulsifier is:

[0057]First add 1 / 2 of the formula amount of water into the reaction kettle, start the agitator, add 1.5% sodium silicate, stir for 20 minutes until the sodium silicate is completely dissolved, then add 16% octylphenol polyoxyethylene ether, octadecylamine Polyoxyethylene ether 19%, polyethylene polyamine polyoxyethylene polyoxypropylene polyether 15%, heat preservation reaction for 30 minutes, finally add 20% turpentine (boiling range 120-170°C), disperse evenly, add remaining water, heat up to 40°C, continue to stir for 30 minutes, then stop stirring, cool down to room temperat...

Embodiment 2

[0060] An oil sludge demulsifier, consisting of the following raw materials in parts by weight:

[0061] Octylphenol polyoxyethylene ether 8%, octadecylamine polyoxyethylene ether 10%, polyethylene polyamine polyoxyethylene polyoxypropylene polyether 10%, turpentine (boiling range 120-170°C) 15%, sodium silicate 0.5%, water 56.5%.

[0062] The preparation method of this oil sludge demulsifier is:

[0063] First add 1 / 2 of the formula amount of water into the reaction kettle, start the agitator, add 0.5% sodium silicate, stir for 20 minutes until the sodium silicate is completely dissolved, then add 8% octylphenol polyoxyethylene ether, octadecylamine 10% polyoxyethylene ether, 10% polyethylene polyamine polyoxyethylene polyoxypropylene polyether, keep warm for 30 minutes, and finally add 15% turpentine (boiling range 120-170°C), disperse evenly, add the remaining water, and heat up to 40°C, continue to stir for 30 minutes, then stop stirring, cool down to room temperature, a...

Embodiment 3

[0066] An oil sludge demulsifier, consisting of the following raw materials in parts by weight:

[0067] Octylphenol polyoxyethylene ether 20%, octadecylamine polyoxyethylene ether 18%, polyethylene polyamine polyoxyethylene polyoxypropylene polyether 20%, turpentine (boiling range 120-170°C) 15%, sodium silicate 1.0%, water 26%.

[0068] The preparation method of this oil sludge demulsifier is:

[0069] First add 1 / 2 of the formula amount of water into the reaction kettle, start the agitator, add 1.0% sodium silicate, stir for 20 minutes until the sodium silicate is completely dissolved, then add 20% octylphenol polyoxyethylene ether, octadecylamine Polyoxyethylene ether 18%, polyethylene polyamine polyoxyethylene polyoxypropylene polyether 20%, heat preservation reaction for 30 minutes, finally add 15% turpentine (boiling range 120-170°C), disperse evenly, add remaining water, heat up to 40°C, continue to stir for 30 minutes, then stop stirring, cool down to room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com